Patents

Literature

50results about How to "High iron recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral benefication method for specularite

ActiveCN101716551AAchieve economyRealize environmental protection utilizationFlotationMagnetic separationHigh intensityEngineering

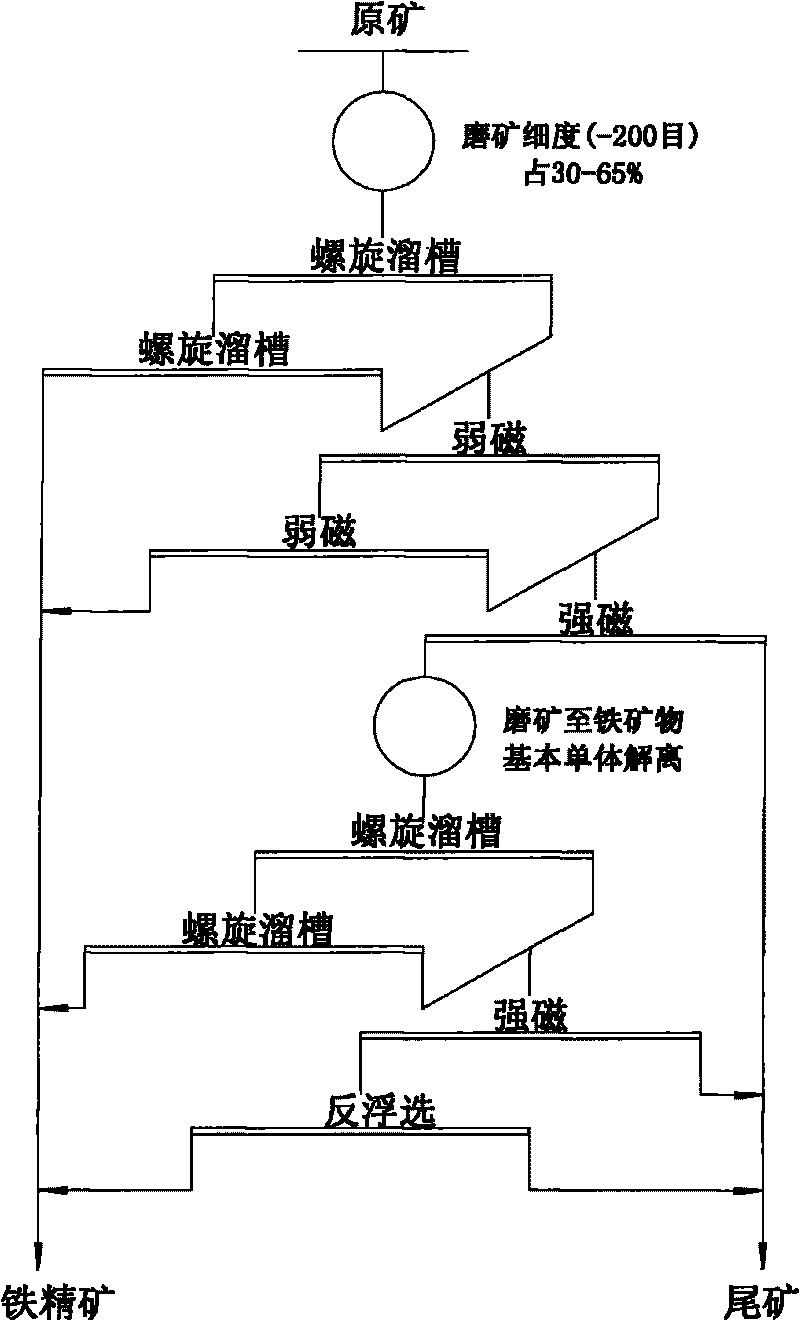

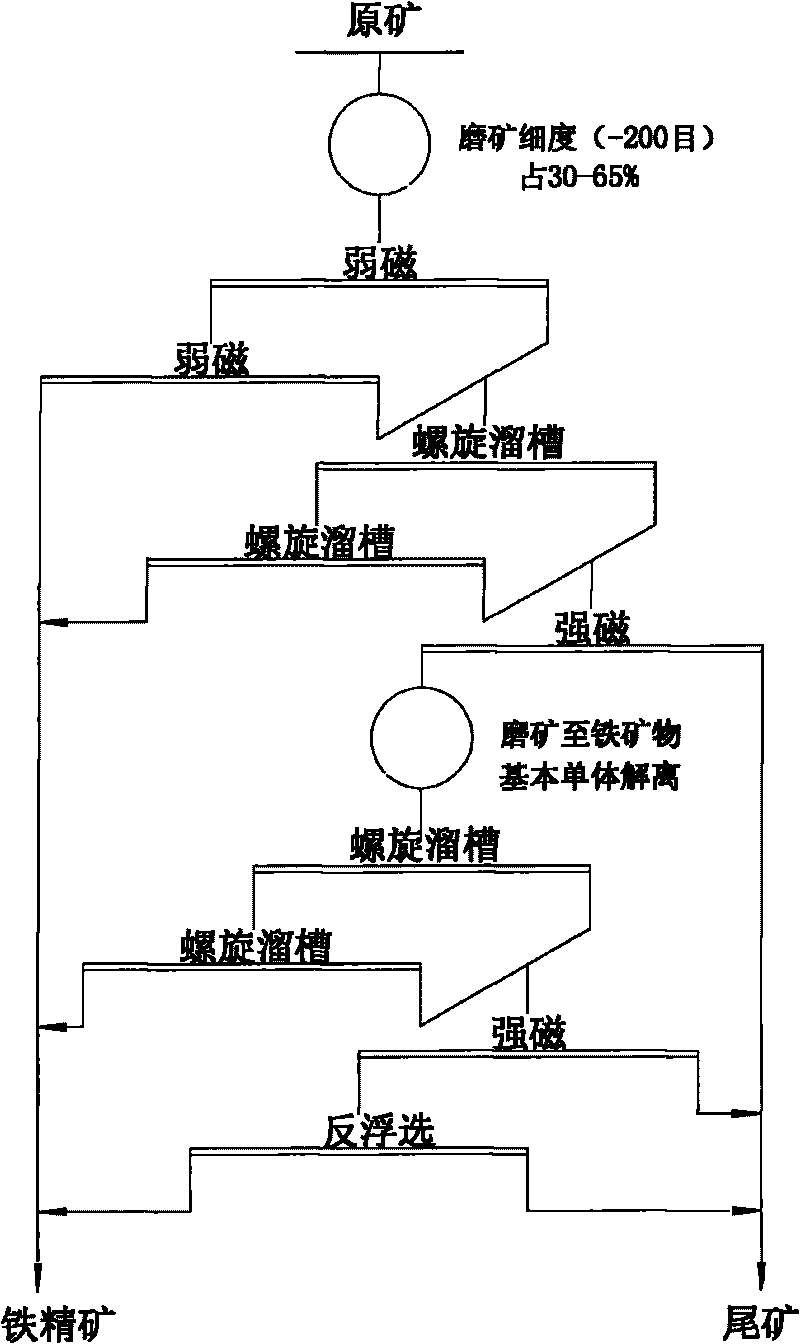

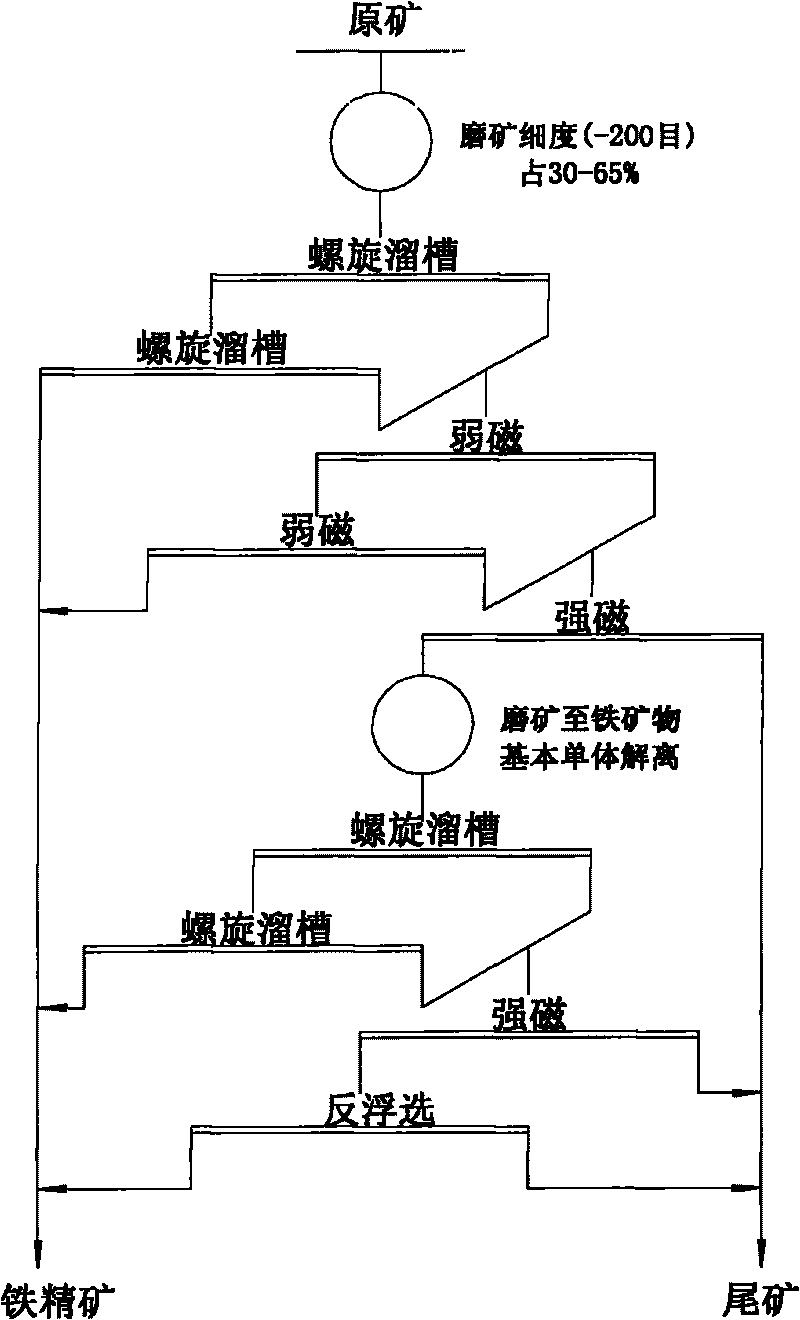

The invention relates to a mineral benefication method for specularite, comprising recycling the iron ore concentrate in the specularite by first-stage coarse grinding, spiral chute sorting, low-intensity magnetic separating, high-intensity magnetic separating, second-stage ore-grinding, spiral chute sorting, high-intensity magnetic separating and reverse flotation separating process, or first-stage coarse grinding, low-intensity magnetic separating, spiral chute sorting, high-intensity magnetic separating, second-stage ore-grinding, spiral chute sorting, high-intensity magnetic separating and reverse flotation separating process. The method has the characteristics of simple process and structure, low investment cost, low production cost, economy and environment protection, and strong flexibility; when the mineral property changes, the iron minerals are sorted and recycled by properly regulating the method.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Beneficiation method for micro-fine iron ore

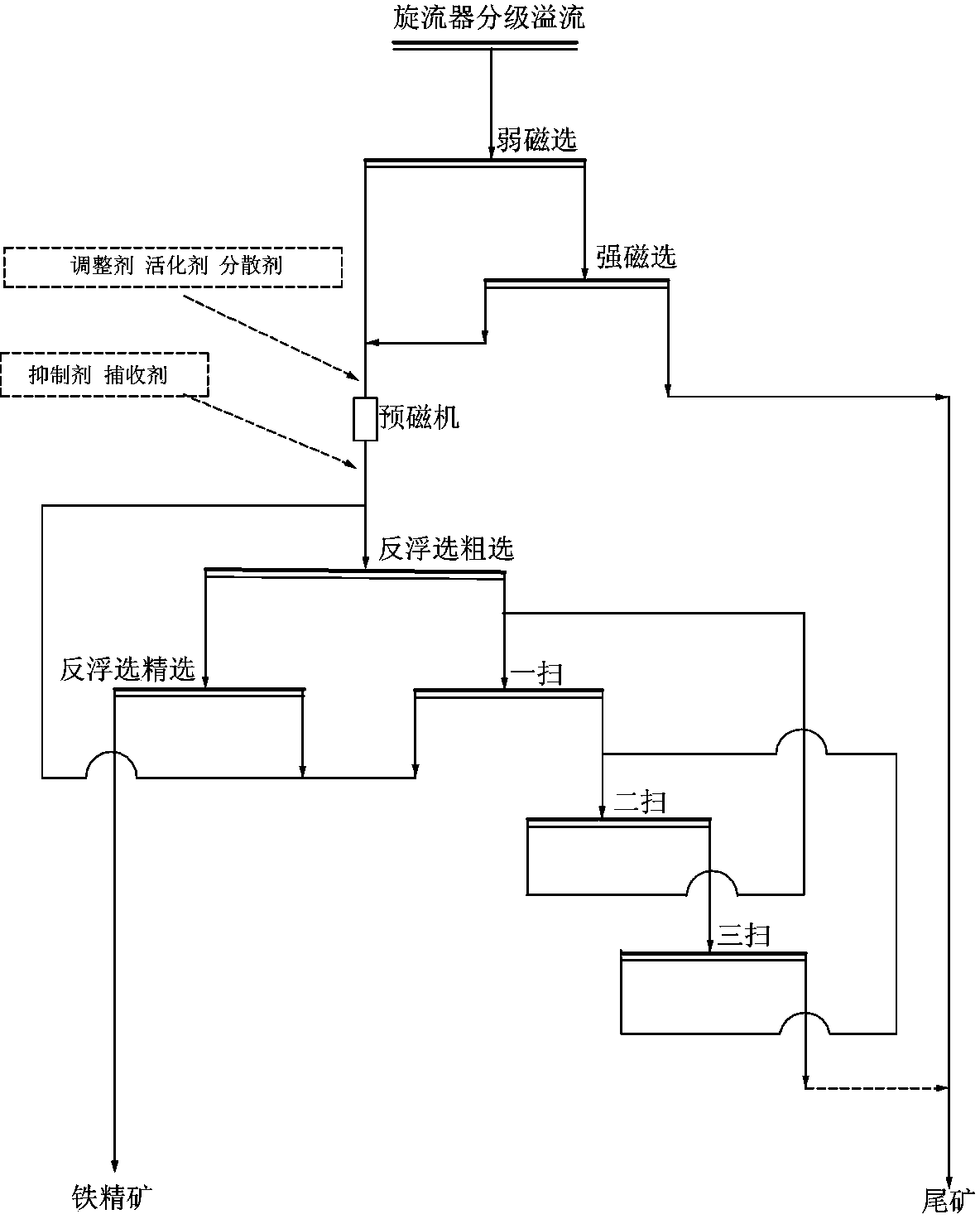

The invention relates to a beneficiation method for micro-fine iron ore. The beneficiation method for the micro-fine iron ore comprises the steps of ore grinding, classification with a hydrocyclone, pre-separation through low-intensity magnetic separation and high-intensity magnetic separation, and hybrid-magnetic-separated iron ore concentrate obtaining. The beneficiation method for the micro-fine iron ore is characterized by further comprising the steps that (1) mixing depression is conducted, wherein the magnetic-separated iron ore concentrate is placed into a stirring groove, a regulator, an activating agent and a dispersing agent are added into the stirring groove, and then mixing depression is conducted; (2) magnetic carrier-pre-magnetization is conducted, wherein a magnetic carrier with the weight being 10%-30% that of fed ore to be separated in a magnetic mode is added into the ore pulp, and then pre-magnetization is conducted through a pre-magnetizing machine; (3) coagulation and reverse flotation are conducted, wherein after an inhibitor and a collecting agent are added into the pre-magnetized ore pulp, reverse flotation which comprises the step of conducting rough concentration once, conducting fine concentration once and conducting scavenging concentration three times is conducted, tailings obtained after scavenging concentration is conducted for the last time serve as final tailings, and concentrate obtained through fine concentration serves as final concentrate. The beneficiation method for the micro-fine iron ore has the advantages that the yield of the finally obtained iron ore concentrate can be increased by 1.5% -3%, the recovery rate of iron can be increased by 5%-10%, energy can be saved greatly, consumption can be reduced greatly, and the grading index can be increased greatly.

Owner:ANSTEEL GRP MINING CO LTD

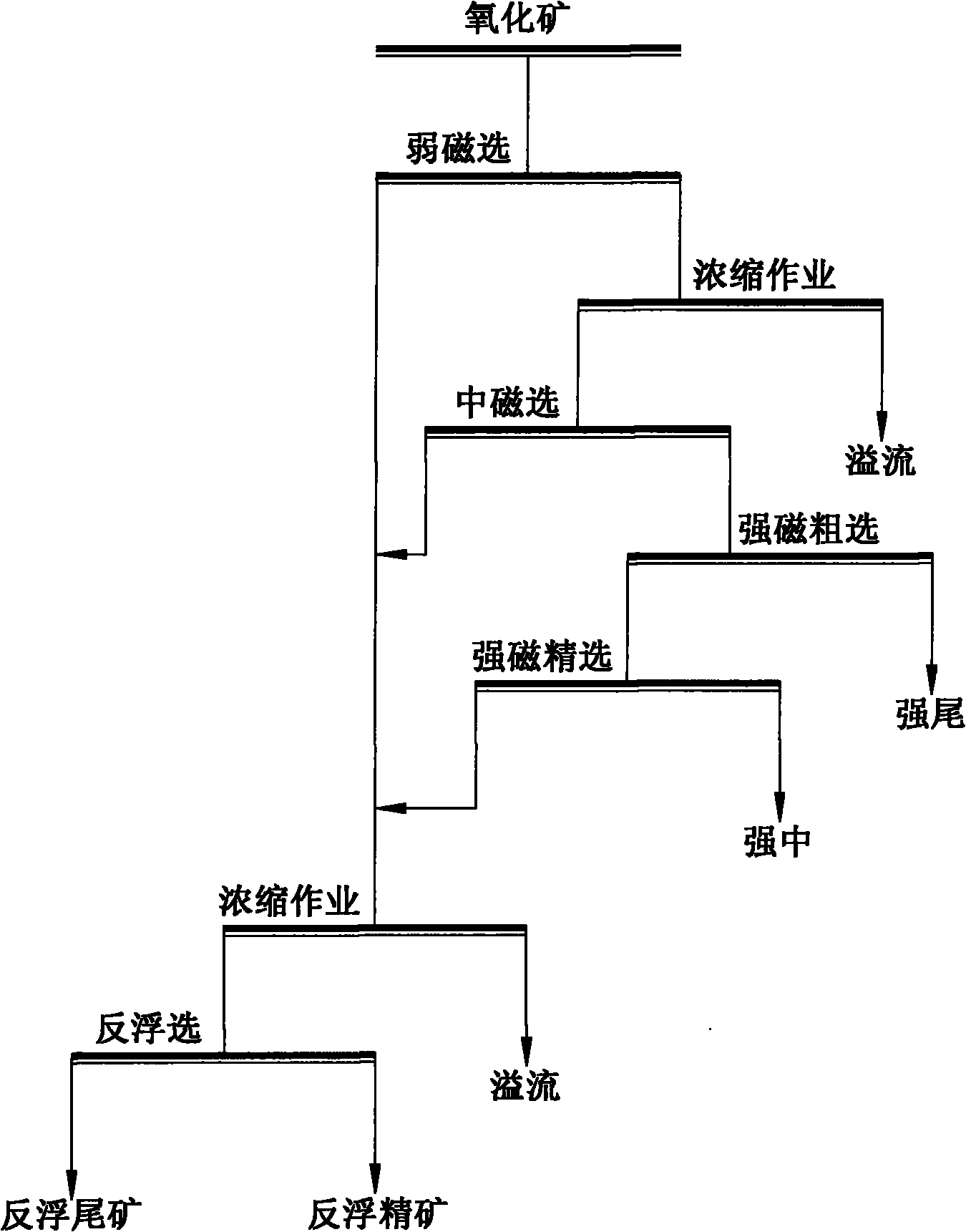

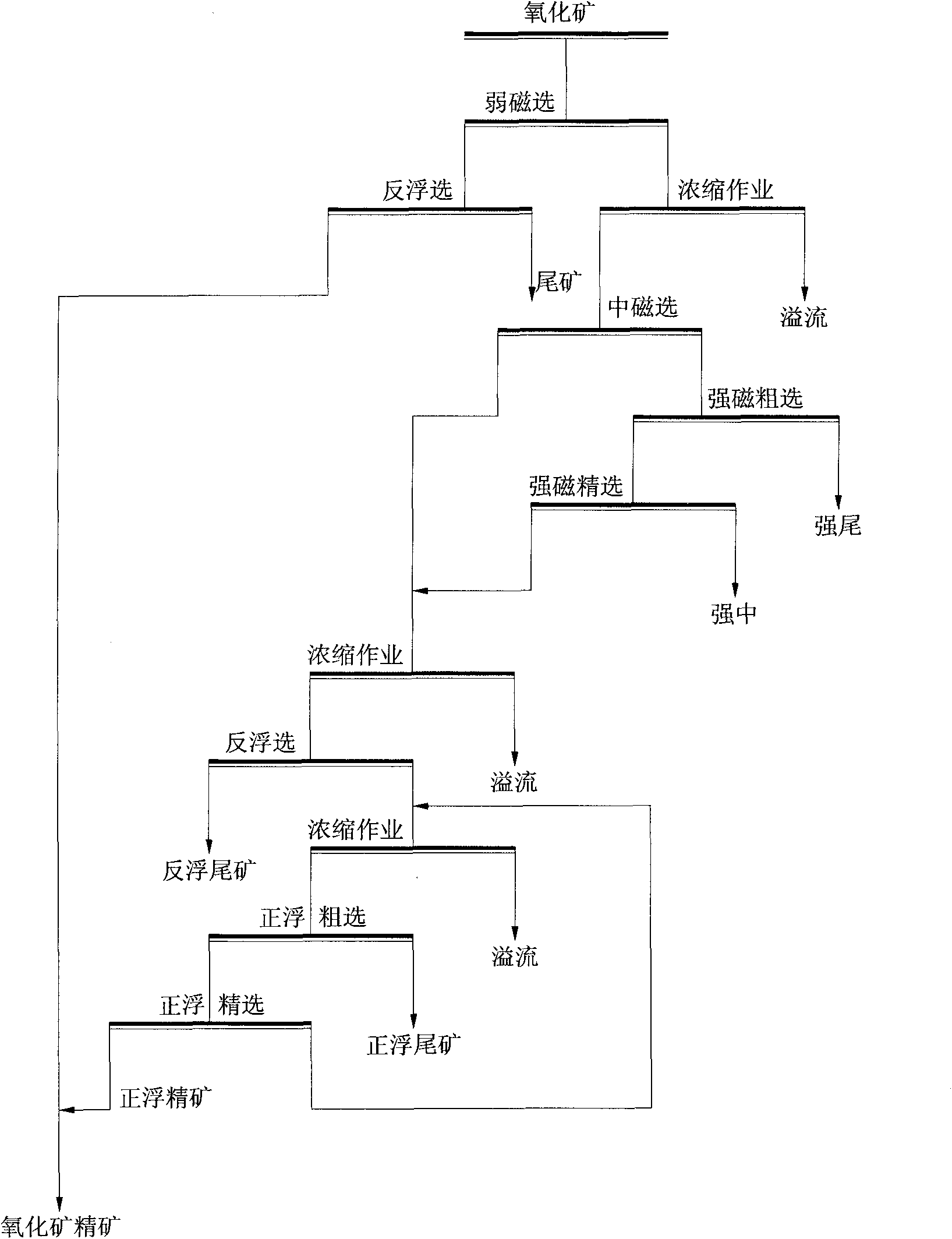

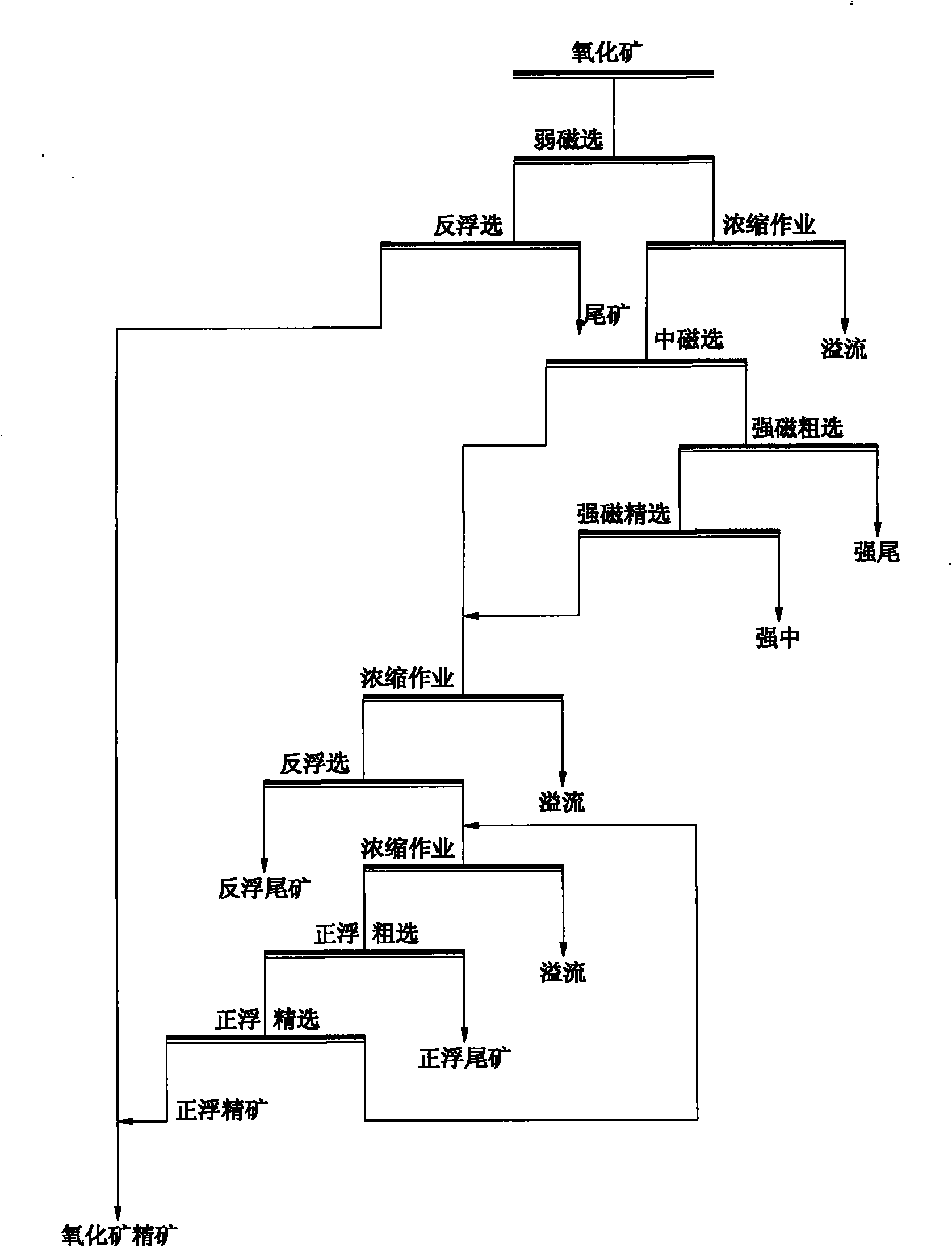

Mine-processing process for extracting iron, reducing fluorine and reducing potassium and sodium of oxide iron ore with high fluorine and high potassium and sodium

InactiveCN101791587ARaise the gradeHigh iron recoveryFlotationMagnetic separationPotassiumMagnetic separation

The invention discloses a mine-processing process for extracting iron, reducing fluorine and reducing potassium and sodium of oxide iron ore with high fluorine and high potassium and sodium, which comprises the following steps of: breaking, grinding and grading oxide iron ore and feeding to low-intensity magnetic separation operation to obtain low-intensity magnetic separation concentrates; extracting iron and reducing fluorine of the low-intensity magnetic separation ore concentrates by reverse flotation to obtain low-concentration reverse flotation concentrates; carrying out medium-intensity magnetic separation operation and high-intensity magnetic separation operation of low-intensity magnetic separation tailings to obtain medium-intensity magnetic concentrates and high-intensity magnetic concentrates; merging the medium-intensity magnetic concentrates and the high-intensity magnetic concentrates and feeding to reverse flotation operation to obtain reverse flotation concentrates; carrying out forward crude flotation and forward fine flotation operation of the reverse flotation concentrates to obtain forward flotation concentrates; and merging the low-concentration reverse flotation concentrates and the forward flotation concentrates to obtain finial oxide ore concentrates. According to the difference between the floatability and the floating speed of an iron mineral and a gangue mineral, the invention adopts a staged floatation combined new process of reducing fluorine by reverse flotation in a weak alkaline medium and reducing potassium and sodium by forward flotation in a weak acidic medium and has high iron concentrate grade, high iron recovery rate and low F, K2O and Na2O contents in the iron concentrates.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

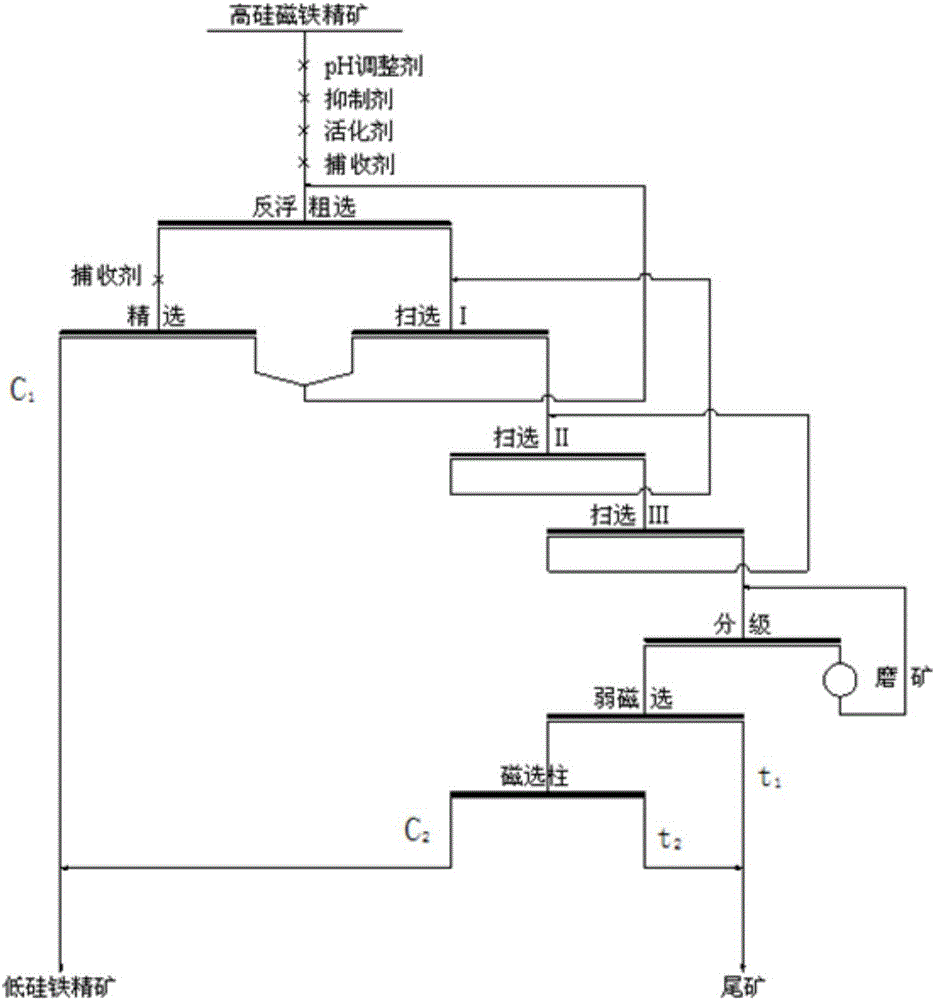

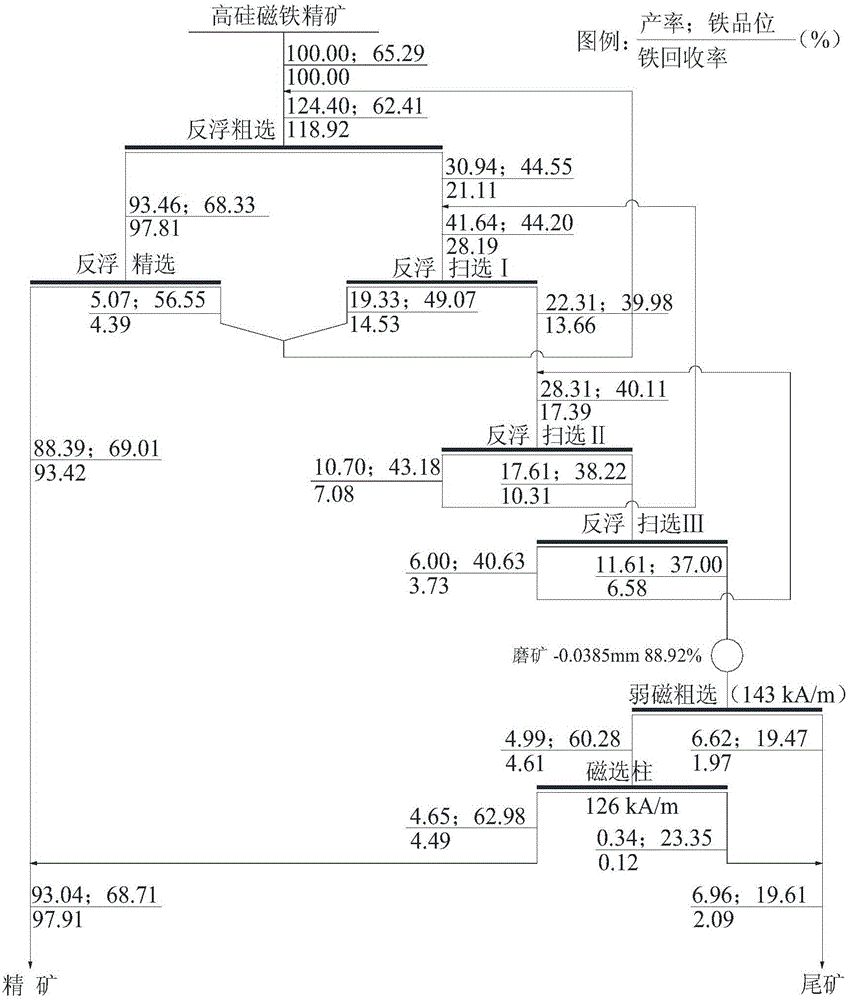

Beneficiation method for reducing content of SiO2 in magnetite concentrate

InactiveCN105728176AReduce SiO <sub>2</sub> contentSiO <sub>2</sub> Low contentDifferential sedimentationFlotationMagnetiteReverse flotation

The invention discloses a method for reducing SiO in magnetite concentrate 2 The beneficiation method adopts the following process: 1) Anion reverse flotation of high-silicon magnetite concentrate to obtain TFe≥68.75%, SiO 2 High-quality low-silicon ferrosilicon concentrate C with content <3.0% 1 , and discharge anion reverse flotation tailings; 2) anion reverse flotation tailings pre-classification-regrinding-weak magnetic separation to obtain weak magnetic separation concentrates; 3) weak magnetic separation magnetic re-separation concentrates to further obtain TFe≥ 62.5%% Magnetic Gravity Separation Iron Concentrate C 2 . The invention has the advantages of high grade iron concentrate, SiO 2 It has the advantages of low content, high iron recovery rate, small loss of fine-grained iron minerals, low energy consumption for beneficiation, stable indicators, and easy operation and management on site.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

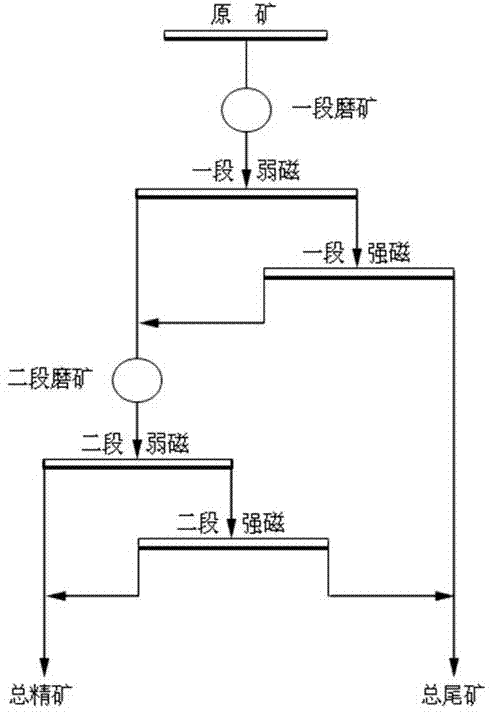

Beneficiation method of efficiently recovering fine-grain low-grade magnetite

The invention discloses a mineral processing method for efficiently recovering fine-grained low-grade magnetite. Iron concentrate I and tailings I can be obtained by weak magnetic separation with a magnetic induction intensity of 1100-1300Oe; iron concentrate II and tailings II can be obtained from tailings I by strong magnetic separation with a magnetic induction intensity of 0.9-1T; iron concentrate I and iron Concentrate II is combined and ground to -0.045mm, accounting for 75-85% to obtain fine-grained ore II; fine-grained ore II is subjected to weak magnetic separation with a magnetic induction intensity of 1000-1200Oe to obtain iron concentrate III and tailings III; Iron concentrate IV and tailings IV are obtained by strong magnetic separation with a magnetic induction intensity of 0.560-0.783T, and iron concentrate III and iron concentrate IV are combined to obtain a total concentrate, and tailings II and tailings IV are combined to throw tailings. The invention has the characteristics of short process flow, less grinding amount, high beneficiation efficiency, iron recovery rate and high concentrate grade.

Owner:YUXI DAHONGSHAN MINING

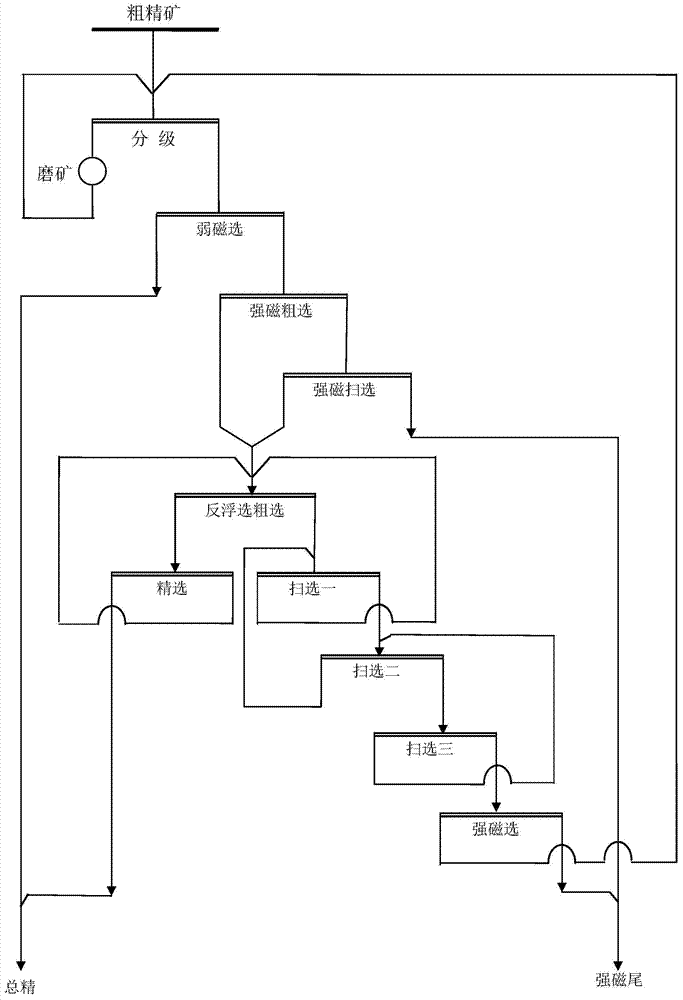

Beneficiation method for improving micro-fine particle refractory iron ore flotation ore-concentrate production rate and recovery rate

The invention discloses a beneficiation method for improving the micro-fine particle refractory iron ore flotation ore-concentrate production rate and the recovery rate. The method includes the following steps that pre-treated micro-fine particle rough concentrate is sent to a closed circuit grinding grading system, so that most of the rough concentrate undergoes monomer separation; obtained ground ore products which undergo monomer separation sequentially undergo low-intensity magnetic separation, high-intensity magnetic rough flotation and high-intensity magnetic scavenging carried out at least once, and ultimately, low-intensity magnetic ore-concentrate and high-intensity magnetic rough ore-concentrate are obtained, the obtained high-intensity magnetic rough ore-concentrate is concentrated, concentration bottom currents are involved in a reverse flotation operation, and accordingly reverse flotation ore-concentrate is obtained; the low-intensity ore-concentrate and the reverse flotation ore-concentrate are combined to form a finished ore-concentrate product, foam after reverse flotation enters a high-intensity magnetic floatation procedure for re-flotation, the ore-concentrate after high-intensity magnetic flotation treatment returns to the closed circuit grinding grading system, and the preceding steps are repeated. The method has the advantages that procedure operations are easy and controllable, the iron grade of flotation tailings is low, and the recovery rate of the ore-concentrate is high.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method of producing iron oxide red using ferrous sulphate

ActiveCN1903735ANo pollution in the processShort reaction timePigmenting treatmentFerric oxidesSulfateFerrous sulphate

The present invention provides a method for producing iron oxide red by using ferrous sulfate. Said method includes the following steps: (1), placing ferrous sulfate and ammonia water into a reactor; (2), introducing oxygen gas to make oxidation reaction; (3), discharging material, filtering, washing, drying and pulverizing so as to obtain the iron oxide red.

Owner:PANZHIHUA LIYU MINING

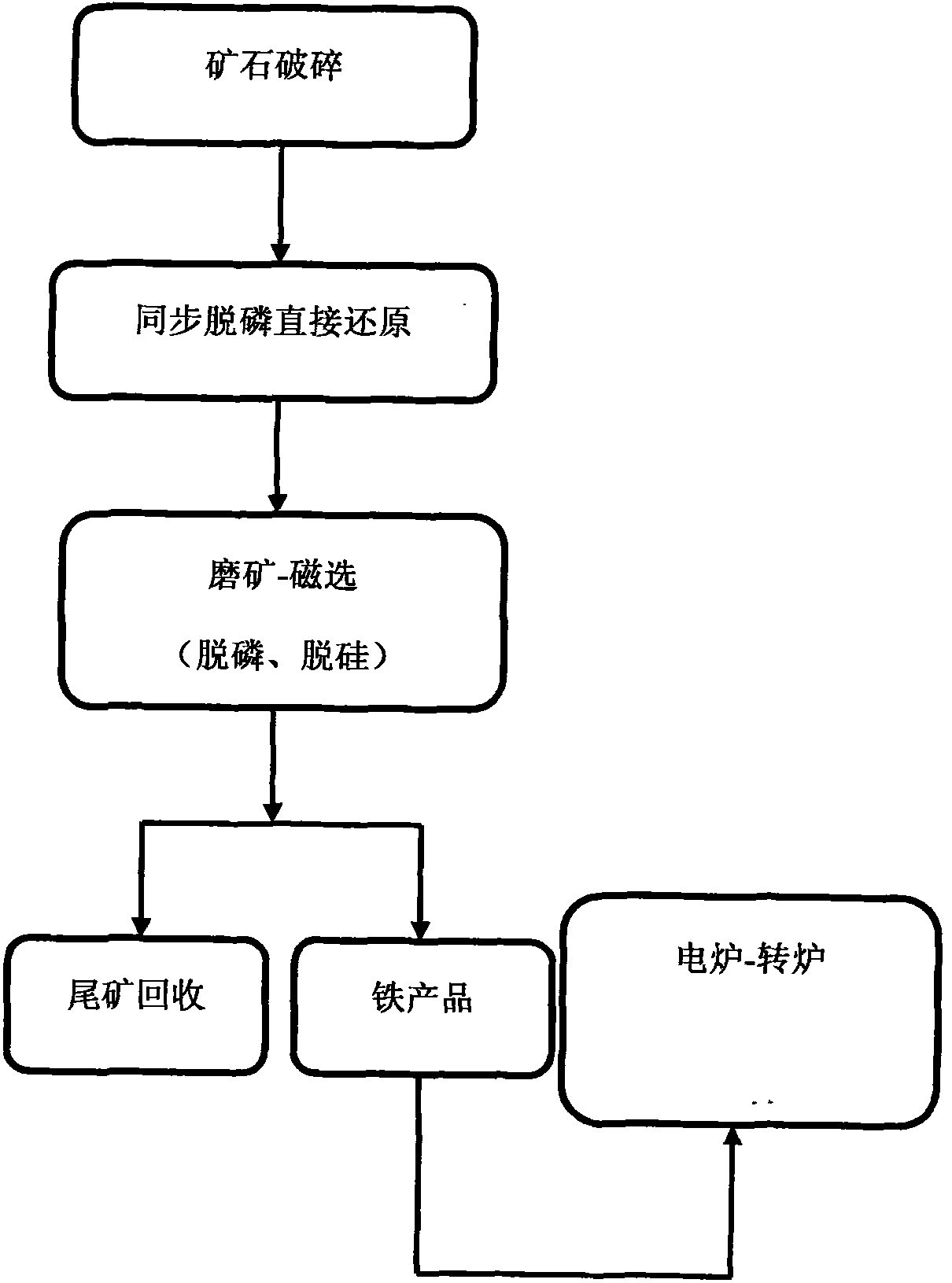

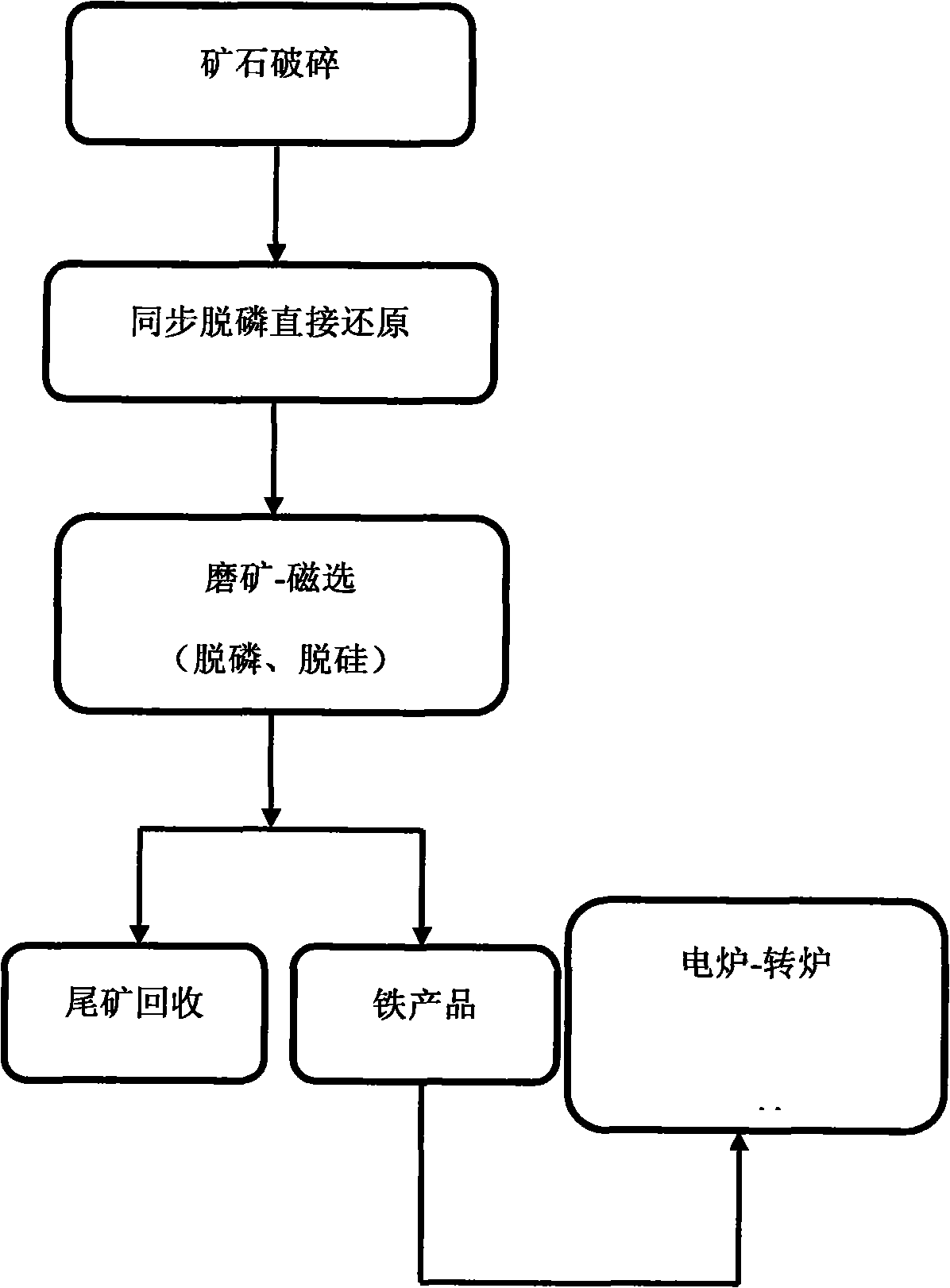

Method for preparing direct reduced iron from low-grade high-phosphorus high-silicon iron ore

InactiveCN101864506AHigh iron recoverySolve the problem of contradiction between supply and demand of resourcesFluidised-bed furnacesHigh energyMass ratio

The invention provides a method for preparing direct reduced iron from low-grade high-phosphorus high-silicon iron ore. The method comprises the following steps of: uniformly mixing the low-grade high-phosphorus high-silicon refractory iron ore serving as a raw material, a reducing agent and a dephosphorizing agent in a mass ratio of 100:30-45:25-50, reducing and roasting the mixture for 18 to 24 hours; separating impurities such as phosphorus, SiO2 and the like from the ore by conventional grinding and magnetic separation; briquetting direct reduced iron powder obtained by magnetic separation, and feeding briquette serving as a steel-making raw material instead of steel scrap into a steel-making furnace, so that the low-grade high-phosphorus high-silicon iron ore with complex mineral composition, various tightly symbiotic minerals and low disseminated grain size is comprehensively utilized. The method has the advantages of small investment and simple process by saving equipment and processes with high energy consumption and heavy pollution such as ore dressing, sintering, palletizing, coking and the like, no waste discharge, no environmental pollution, high recovery rate of the iron from the ore, and remarkable phosphorus and silicon removing effect by comprehensively utilizing phosphorus-containing and silicon-containing gangue and recovering valuable elements therein.

Owner:KUNMING IRON & STEEL HLDG CO LTD

Recycling and treating method for pickling waste water of iron and steel

ActiveCN106222681AIncrease the hydrogen evolution overpotentialHigh iron recoveryPhotography auxillary processesProcess efficiency improvementIron powderWastewater

The invention discloses a recycling and treating method for pickling waste water of iron and steel. The recycling and treating method comprises the following steps of adding a cationic surfactant in the pickling waste water of the iron and the steel to obtain an electrolyzed mixed solution; electrolyzing the electrolyzed mixed solution in a diaphragm electrolytic cell, separating out high-purity iron at a cathode, and regenerating waste acid at an anode; breaking, annealing and reducing the separated high-purity iron to obtain high-purity iron powder; and enabling the waste acid regenerated at the anode to return to a pickling step of the iron and the steel for recycling. The recycling and treating method for the pickling waste water of the iron and the steel is simple in technique and high in iron recovery rate; the high-purity iron can be obtained and no secondary pollution is caused; after recycling and treatment, the acidity of the waste water is not reduced, and the pickling waste water can be regenerated for recycling; and in addition, the recycling and treating method is suitable for treating the pickling waste water of which the pH value is smaller than 2 of the iron and the steel.

Owner:ZHUZHOU SMELTER GRP

Method for extracting iron ore concentrate from flyash

The invention relates to a method for extracting iron ore concentrate from flyash. According to the technical scheme, flyash undergoes dry magnetic separation in a spiral dry magnetic separator with its magnetic field intensity being 0.3-0.5 T so as to obtain rough concentrate and dry tailings; after addition of water, the rough concentrate is put into a wet magnetic separator with its magnetic field intensity being 0.16-0.2 T to undergo wet magnetic separation so as to obtain wet magnetic concentrate; the wet magnetic concentrate or a mixture of the wet magnetic concentrate and second-stage tailings obtained in a subsequent process is put into a ball mill, water is added and then ball-milling is carried out until granularity of 70-90 wt% of the ball-milling product is less than 0.045 mm so as to obtain fine-ground ore slurry; the fine-ground ore slurry is added into a wet magnetic separator with its magnetic field intensity being 0.06-0.1 T so as to obtain first-stage concentrate; the first-stage concentrate is added into a wet magnetic separator with its magnetic field intensity being 0.04-0.08 T to undergo second-stage weak magnetic separation so as to obtain iron ore concentrate and second-stage tailings; and the second-stage tailings return to the step 3. The method of the invention has characteristics of simple process, low energy consumption, high iron grade of iron concentrate powder and high iron recovery rate.

Owner:WUHAN UNIV OF SCI & TECH

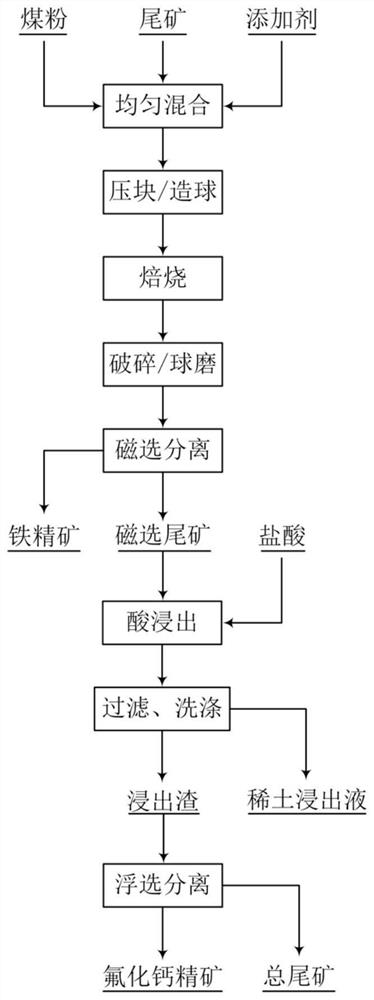

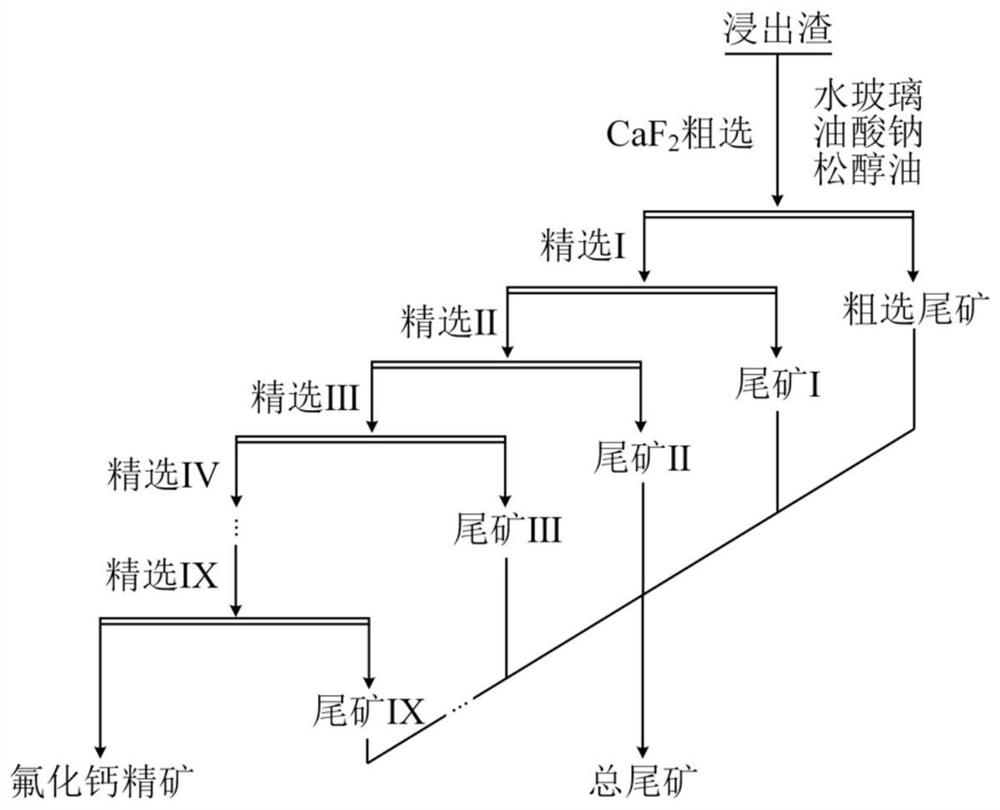

Method for separating and recovering iron, rare earth and fluorine from rare-earth-contained tailings after beneficiating iron

ActiveCN112791847AHigh recovery rateReduce manufacturing costCalcium/strontium/barium fluoridesSolid separationHydrometallurgyCoal

The invention relates to a method for separating and recovering iron, rare earth and fluorine from rare-earth-contained tailings after beneficiating iron. The method comprises the steps that the rare-earth-contained tailings after beneficiating iron, an additive and pulverized coal are subjected to roasting, ball-milling and magnetically separating after being mixed, briquetted or pelletized to obtain magnetic iron ore concentrate and magnetic tailings; hydrochloric acid is added into the magnetic tailings for leaching, and rare earth chloride leaching liquid and leaching residues rich in calcium fluoride are obtained after filtering; and water is added into the leaching residues to be stirred to form ore pulp, water glass, sodium oleate and terpenic oil are added to obtain rougher concentrate and rougher tailings, and after concentration, calcium fluoride concentrate and total tailings containing a mixture of silicate and a small amount of calcium fluoride are obtained. The method disclosed by the invention has the characteristics of good separation effect, high recovery rate of iron and rare earth, low production cost, large treatment capacity, environmental friendliness and the like, and is a process method relating to the fields of non-blast furnace ironmaking, hydrometallurgy, mineral processing technologies and comprehensive utilization of resources.

Owner:NORTHEASTERN UNIV

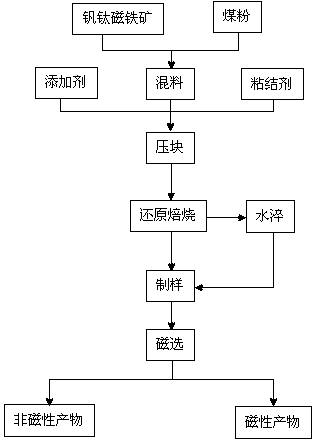

Solid phase reinforcement reduction-magnetic separation method of vanadium titano-magnetite

The invention belongs to the non-blast furnace smelting field of vanadium titano-magnetite, and specifically relates to a solid phase reinforcement reduction-magnetic separation method of the vanadium titano-magnetite. The method comprises the steps of mixing the vanadium titano-magnetite and anthracite duff, adding additives of CsF2, Na2CO3 or Fe2O3, mixing the above materials uniformly, adding a binding agent, mold pressing into a cylindrical sample, reducing the cylindrical sample for 30-120 min at a temperature of 1,100-1,400 DEG C to obtain reduced iron powder, cooling the reduced iron powder by water quenching or naturally cooling to a room temperature, grinding fine, and magnetic separating to obtain iron powder with a recovery rate of 94-97%. The method is simple in operation, reduces energy consumption and saves cost by replacing coke by the anthracite, and promotes growth of iron crystals after adding CsF2, Fe2O3 and Na2CO3, thereby increasing metallization ratio. At the same time, the method facilitates slag-iron separation. Water quenching after reduction can prevent the reduced metal iron and iron suboxide from being re-oxidized into iron oxide, enabling the metallization ratio to be between 86%-98% and the iron recovery rate to reach 94-97%.

Owner:NORTHEASTERN UNIV

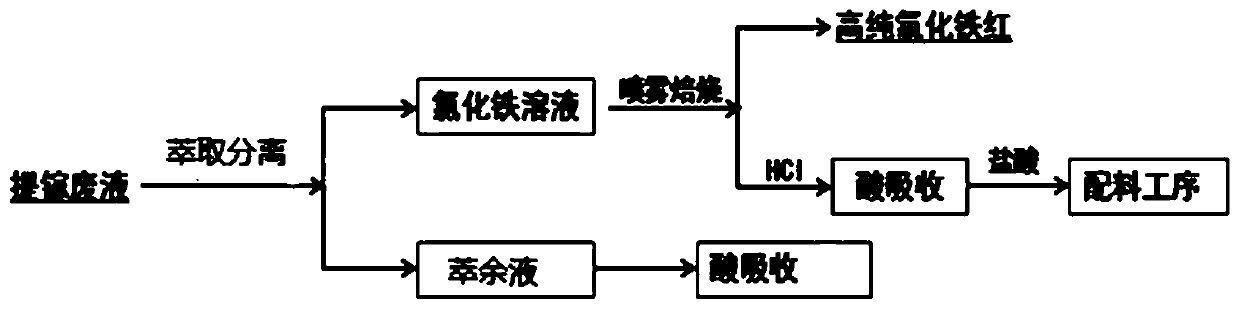

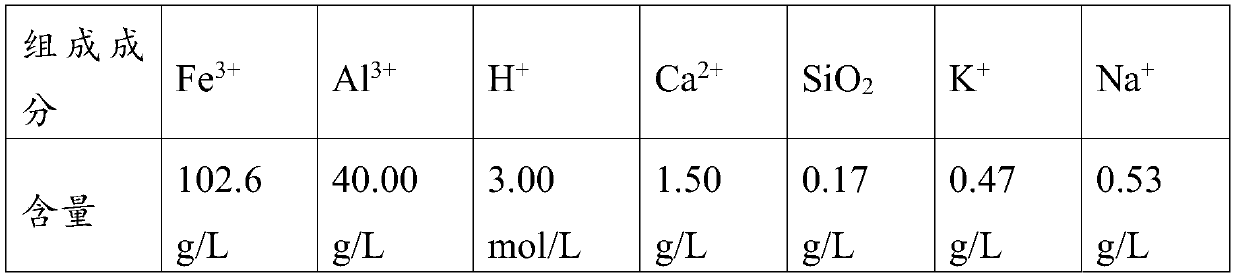

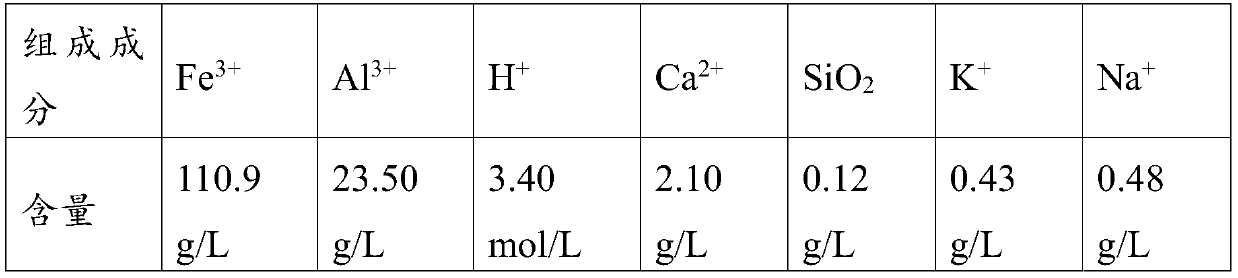

Gallium extracted waste liquor resource utilization technology in process of one-step acid solution method technology

InactiveCN110885931ARealize recycling of resourcesExtract ironChlorine/hydrogen-chlorideProcess efficiency improvementPhysical chemistryIron chloride

The invention discloses a gallium extracted waste liquor resource utilization technology in the process of the one-step acid solution method technology. The technology comprises the following steps that firstly, iron in gallium extracted waste liquor is extracted, and low-iron raffinate and an iron-contained load organic phase are obtained; secondly, a stripping agent is used for carrying out reverse extraction on the load organic phase, and a reverse extraction liquid ferric chloride solution is obtained; and thirdly, the ferric chloride solution is subjected to mist spraying and roasting, thus ferric chloride is decomposed to obtain ferric oxide red and chlorine hydride gas, the low-iron raffinate is utilized for absorbing and dissolving the chlorine hydride gas in the acid absorbing working procedure, and an obtained acid solution serves as acid for coal ash acid solution in the one-step acid solution method. According to the technology, resource recycling of iron ions, aluminum ions and hydrochloric acid in the waste liquor can be achieved with the low cost, and the technology is environmentally friendly and saves energy.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

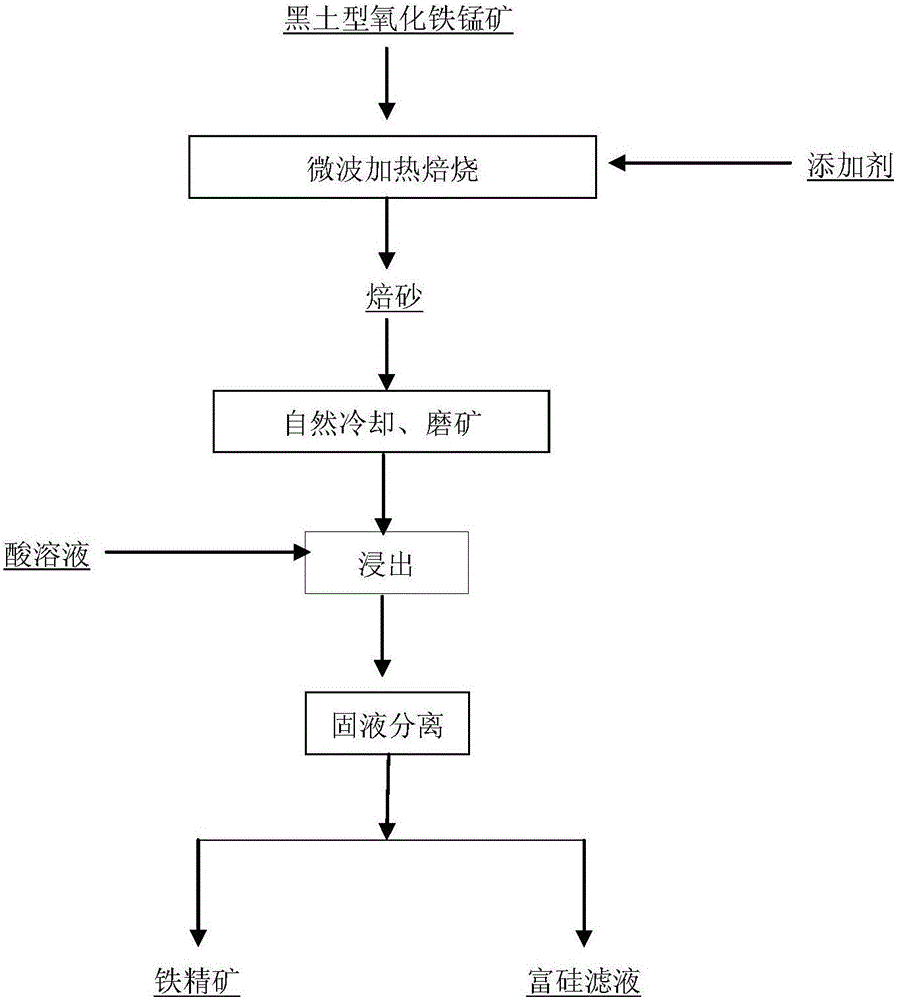

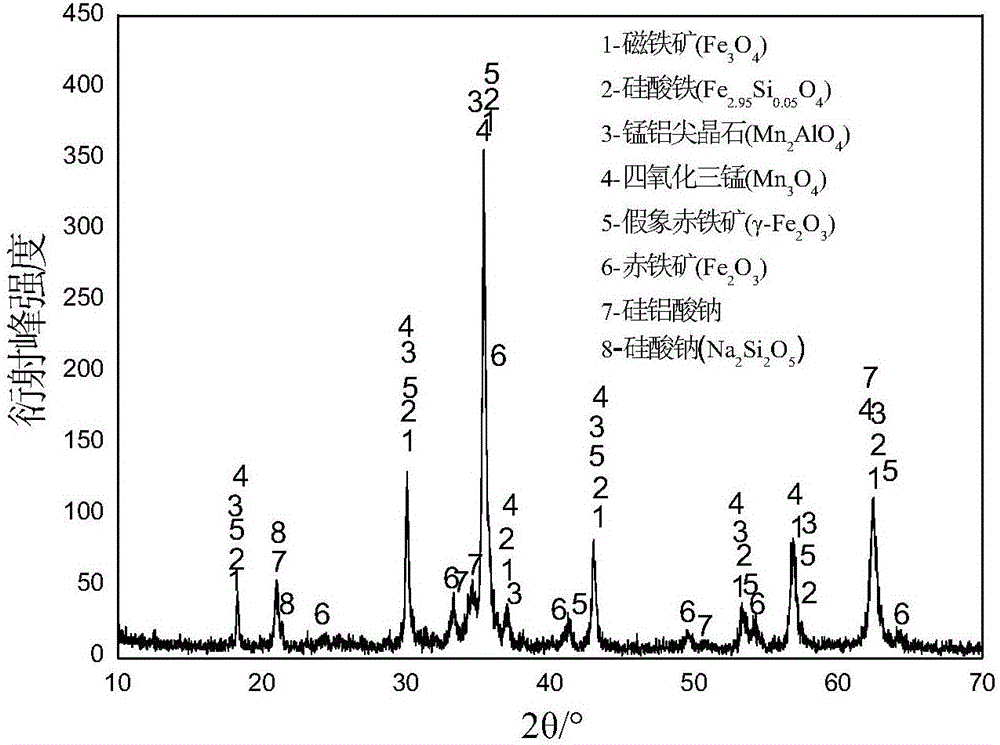

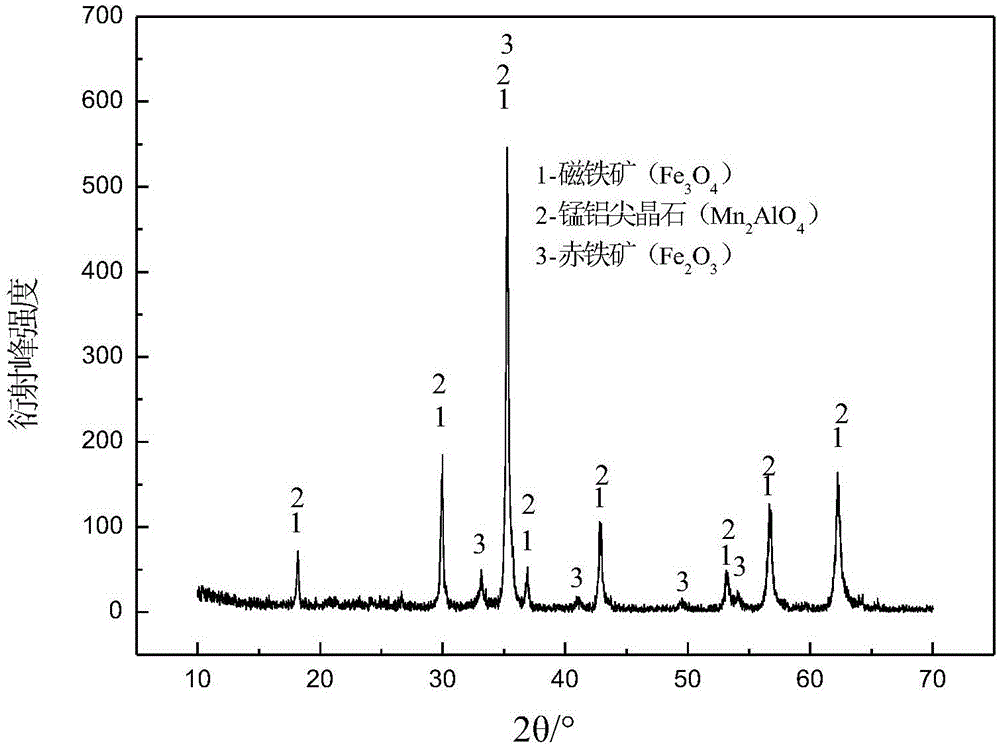

Chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation

ActiveCN106544502ARealize resource utilizationLow preprocessing requirementsSilicate mineralsPollution

The invention discloses a chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation. The chemical desiliconization method adopts microwaves to serve as a heating source so that silicon in silicate mineral can be quickly activated at the low temperature and then can react with alkali (soil) metallic oxide (salt) additives to generate acid-soluble salt, and the desiliconization purpose is achieved through an acid pickling process. The application of the chemical desiliconization method in black soil type iron oxide manganese ore beneficiation comprises the following steps that black soil type iron oxide manganese ore is crushed and ground to be 0.9 mm or less, then uniformly mixed with lignin additives and the alkali (soil) metallic oxide (salt) additives and put into a microwave reaction device for reducing roasting, and roasted ore is obtained; the roasted ore is cooled naturally and added into an acid solution to be subjected to stirring, leaching and desiliconization at the low temperature; and solid-liquid separation is conducted, and the obtained solid phase is iron ore concentrate. The chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation have the advantages of being low in pretreatment requirement, mild in reaction condition, high in desiliconization efficiency, small in acid consumption, high in iron recovery rate, free of pollution, controllable and the like and have wide application prospects.

Owner:CENT SOUTH UNIV

Method for reducing vanadium-titanium magnetite concentrate in tunnel kiln to obtain ferrite

The invention relates to a method for reducing the vanadium-titanium magnetite concentrate in the tunnel kiln to obtain the ferrite, comprising the following steps: adding a desiccating agent into the vanadium-titanium magnetite concentrate, stirring and mixing uniformly, dehydrating and drying the vanadium-titanium magnetite concentrate, adding a reducing agent and a ferrite aggregating agent into the mixture, mixing uniformly, loading the mixture on a trolley in the tunnel kiln, covering a layer of coke powder o reduce and roast, quenching by water to cool, grinding, ball milling and dressing by magnetic separation to obtain the high-grade ferrite alloy. According to the method, the traditional reducing tank is not used. The method has the advantages of simple production, short reduction time, high yield, convenience of operation, energy consumption saving, low cost and high recovery of iron. The produced ferrite alloy can be directly used as the excellent raw materials for electrosmelting of steel.

Owner:毛耐文

Modified additive for recycling copper and iron in depleted slag of electric copper smelting furnace and application thereof

ActiveCN106929684ARecoveries remain unchanged or slightly improvedHigh recovery rateProcess efficiency improvementManganese oxideMolten slag

The invention relates to a modified additive for recycling copper and iron in depleted slag of an electric copper smelting furnace and an application thereof. The modified additive comprises, by mass, 40-50% of quick lime, 10-15% of manganese monoxide, 10-15% of pyrite, 5-15% of copper pyrite and 10-20% of iron oxides. According to the application of the modified additive for recycling copper and iron in depleted slag of the electric copper smelting furnace, the amount of the added modified additive is 8-20% of the mass of the copper slag. By means of the modified additive, mineral phase reconstruction of iron and copper target minerals is realized by making full use of high-temperature latent heat of depleted slag of the electric copper smelting furnace. The modified additive has the functions of fayalite modification, induced crystallization of initial crystal seeds and stabilization of copper matte minerals. Copper concentrates for copper smelting and magnetite concentrates for iron smelting can be produced by using modified slag through a floatation-magnetic separation process. Accordingly, efficient separation and recycling of iron and copper in depleted slag of the electric copper smelting furnace are realized, resources are saved, and energy consumption is reduced.

Owner:CENT SOUTH UNIV

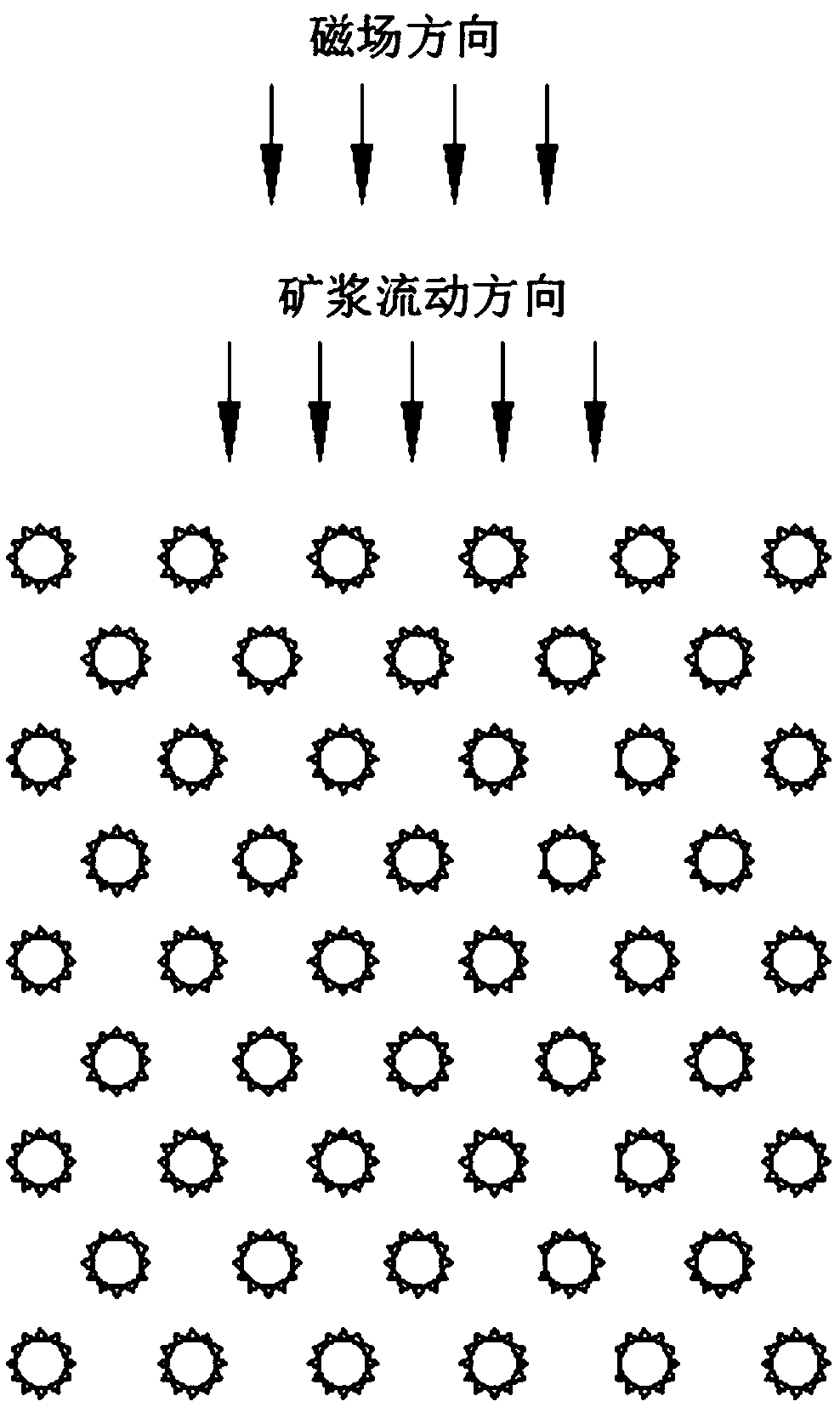

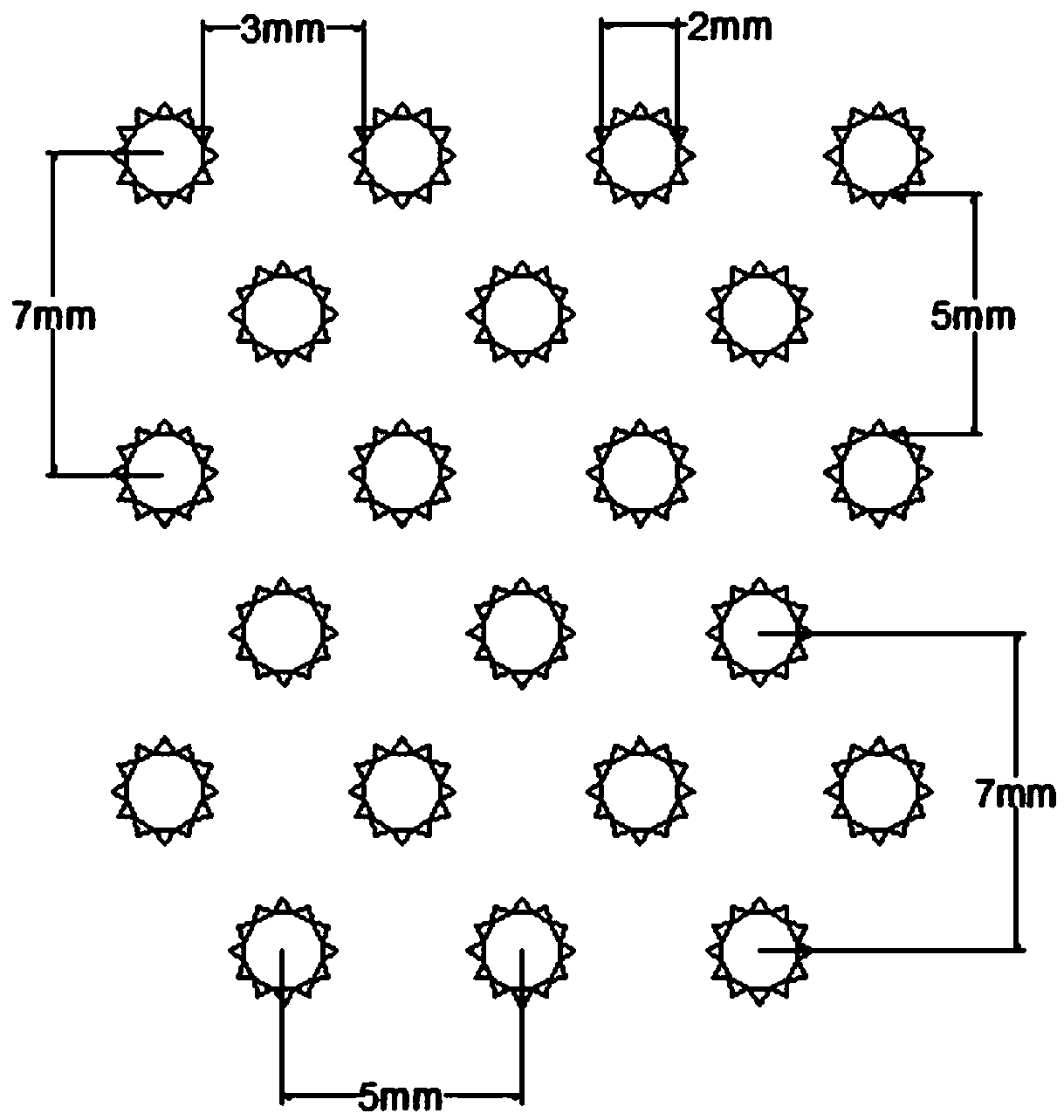

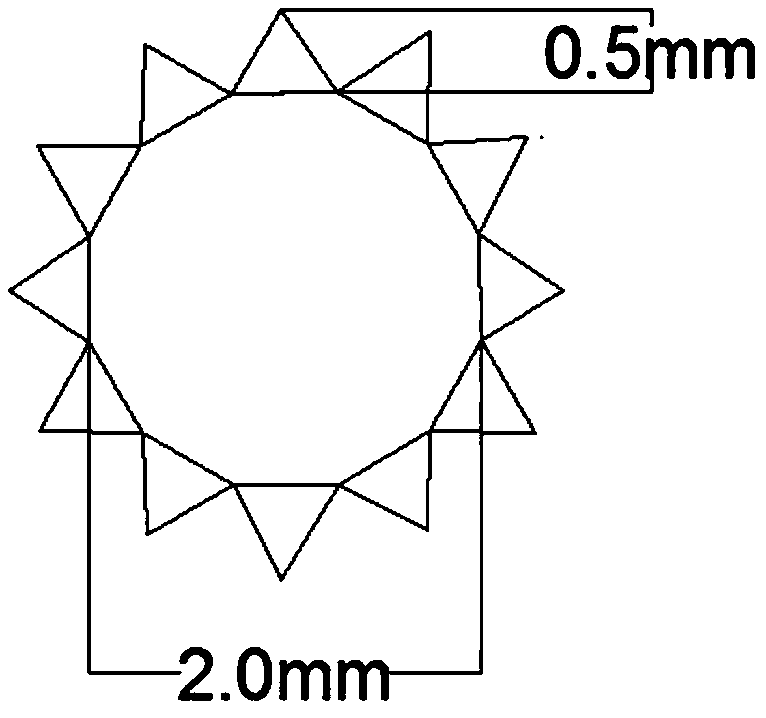

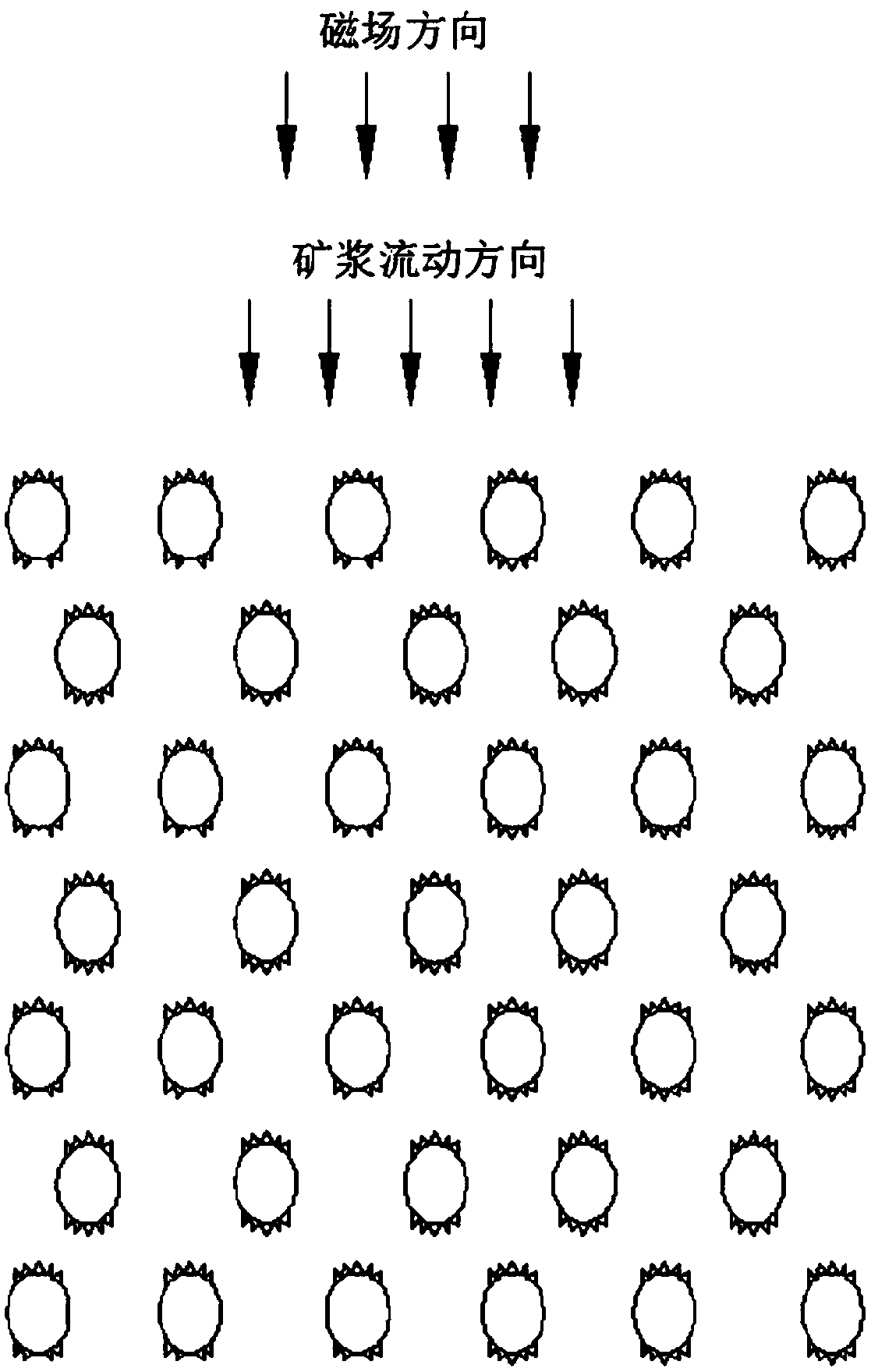

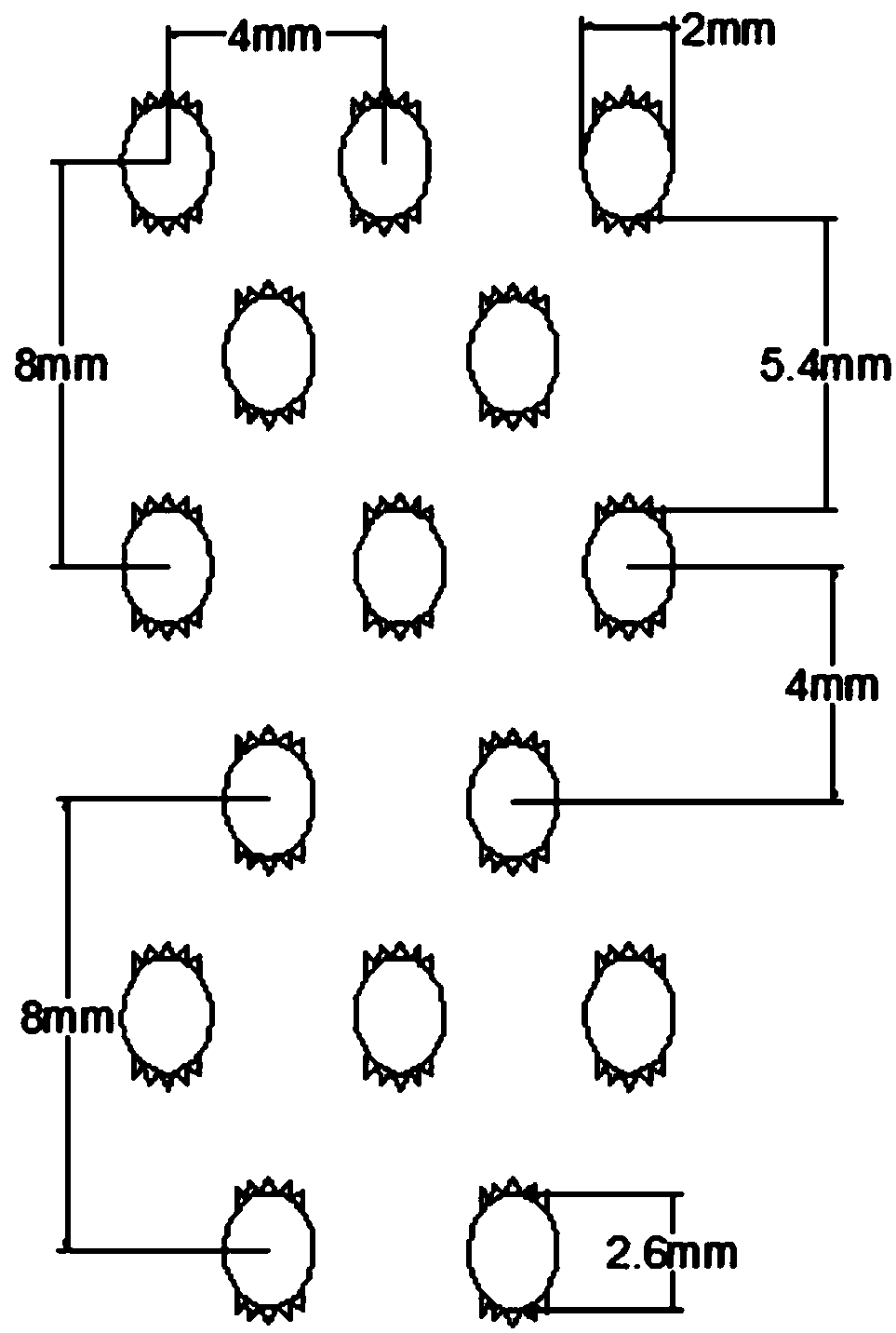

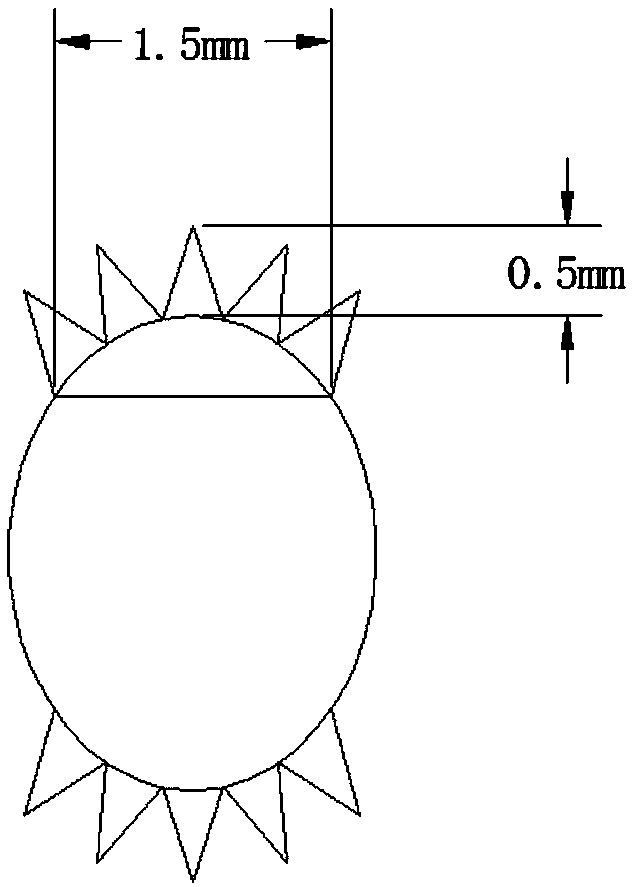

Cassava starch pretreatment-special-shaped medium magnetic separation process

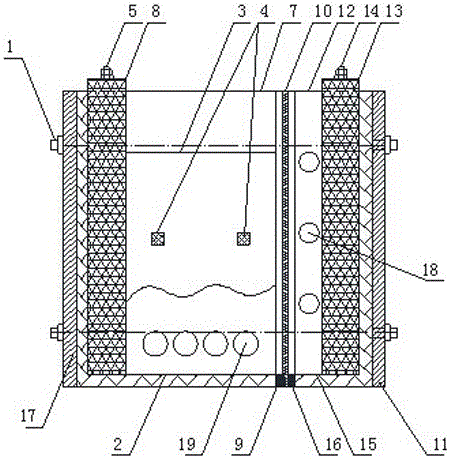

InactiveCN108672083AIncrease catch rateEasy to recycleHigh gradient magnetic separatorsFlocculationMagnetic media

The invention relates to a cassava starch pretreatment-special-shaped medium magnetic separation process, and belongs to the technical field of mineral machining. The cassava starch pretreatment-special-shaped medium magnetic separation process comprises the steps of pulping, weak-magnetism iron ore flocculation pretreatment, magnetic separation and scavenging, wherein the magnetic separation comprises the following steps: the high magnetic separation is performed on pulp, obtained by treatment, by adopting a vertical ring pulsation high-gradient magnetic separator with a special-shaped magnetic medium box with a circular section with sawteeth under the conditions of the background field strength of 5000-10000 Oersted, the pulsation stroke of 0-20 mm and the pulsation jig frequency of 0-250 t / min to obtain high magnetic separation magnetic products. Compared with a traditional reinforced fine particle weak-magnetism iron ore recovery process, the method has the advantages of high ironrecovery rate, low comprehensive cost, simple flow structure and the like.

Owner:NORTHEASTERN UNIV

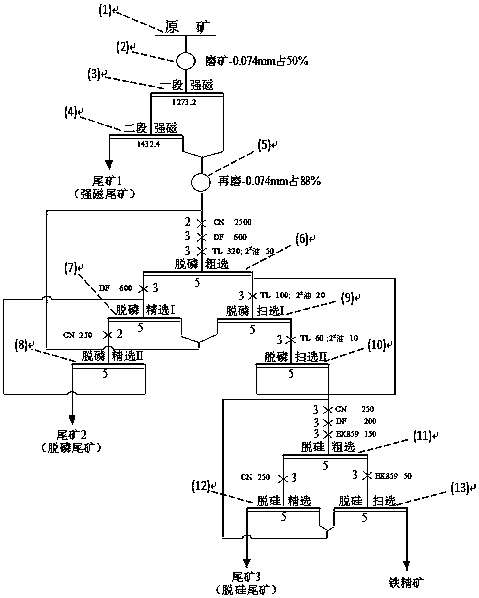

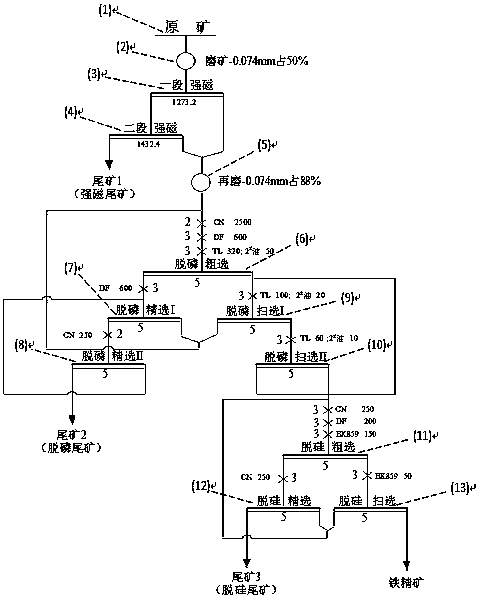

High-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology

The invention relates to a high-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology used in the field of mineral processing. The technological processes include (1) mineral feeding, (2) mineral grinding, (3) first-stage high magnetic separation, (4) second-stage high magnetic separation, (5) regrinding, (6) dephosphorization roughing, (7) dephosphorization selection, (8) dephosphorization selection, (9) dephosphorization scavenging, dephosphorization scavenging, desilicication roughing, desilicication selection and selection scavenging. According to the technology, the high-magnetic tailing discarding-reverse flotation dephosphorization-reverse flotation desilicication double reverse flotation beneficiation combined method technology is adopted, dephosphorization and desilicication efficient composite collecting agents TL and BK-859 are adopted, the separation efficiency of high-phosphorus oolitic hematite is obviously improved, the problems of iron increase and phosphorous reduction of this kind of iron mine are successfully solved, and exploitation of the kind of resource becomes possible. By means of the high-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology, high-phosphorus oolitic hematite beneficiation technical indexes reach the conditions that the iron ore concentrate grade is higher than 55.74%, contained phosphorus is lower than 0.12%, the iron recovery rate is higher than 62%, and the phosphorus removal rate is higher than 94%.

Owner:北京中矿东方矿业有限公司

A kind of steel pickling wastewater recovery and treatment method

ActiveCN106222681BIncrease the hydrogen evolution overpotentialHigh iron recoveryPhotography auxillary processesProcess efficiency improvementIron powderActive agent

The invention discloses a recycling and treating method for pickling waste water of iron and steel. The recycling and treating method comprises the following steps of adding a cationic surfactant in the pickling waste water of the iron and the steel to obtain an electrolyzed mixed solution; electrolyzing the electrolyzed mixed solution in a diaphragm electrolytic cell, separating out high-purity iron at a cathode, and regenerating waste acid at an anode; breaking, annealing and reducing the separated high-purity iron to obtain high-purity iron powder; and enabling the waste acid regenerated at the anode to return to a pickling step of the iron and the steel for recycling. The recycling and treating method for the pickling waste water of the iron and the steel is simple in technique and high in iron recovery rate; the high-purity iron can be obtained and no secondary pollution is caused; after recycling and treatment, the acidity of the waste water is not reduced, and the pickling waste water can be regenerated for recycling; and in addition, the recycling and treating method is suitable for treating the pickling waste water of which the pH value is smaller than 2 of the iron and the steel.

Owner:ZHUZHOU SMELTER GRP

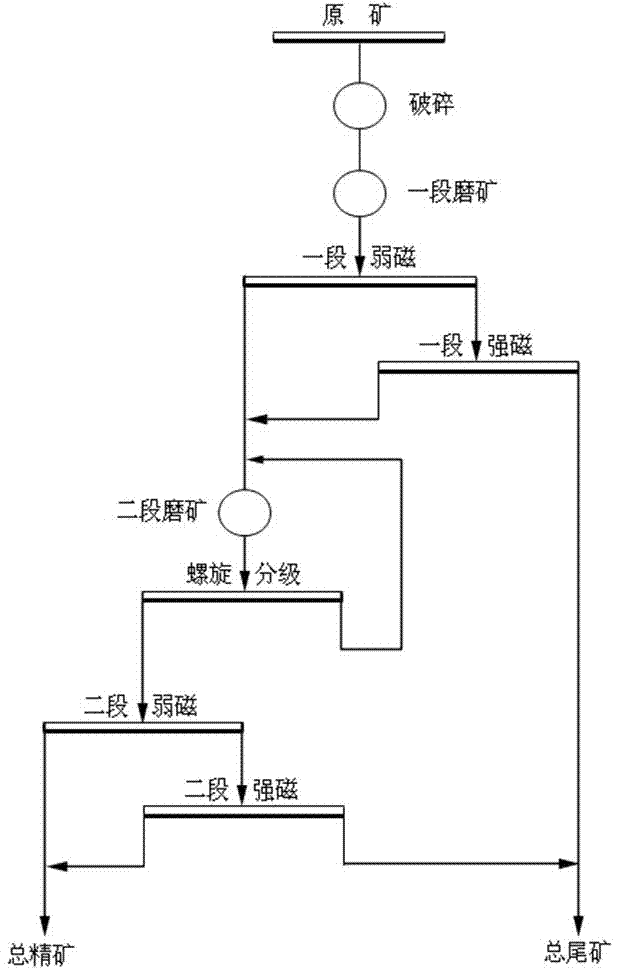

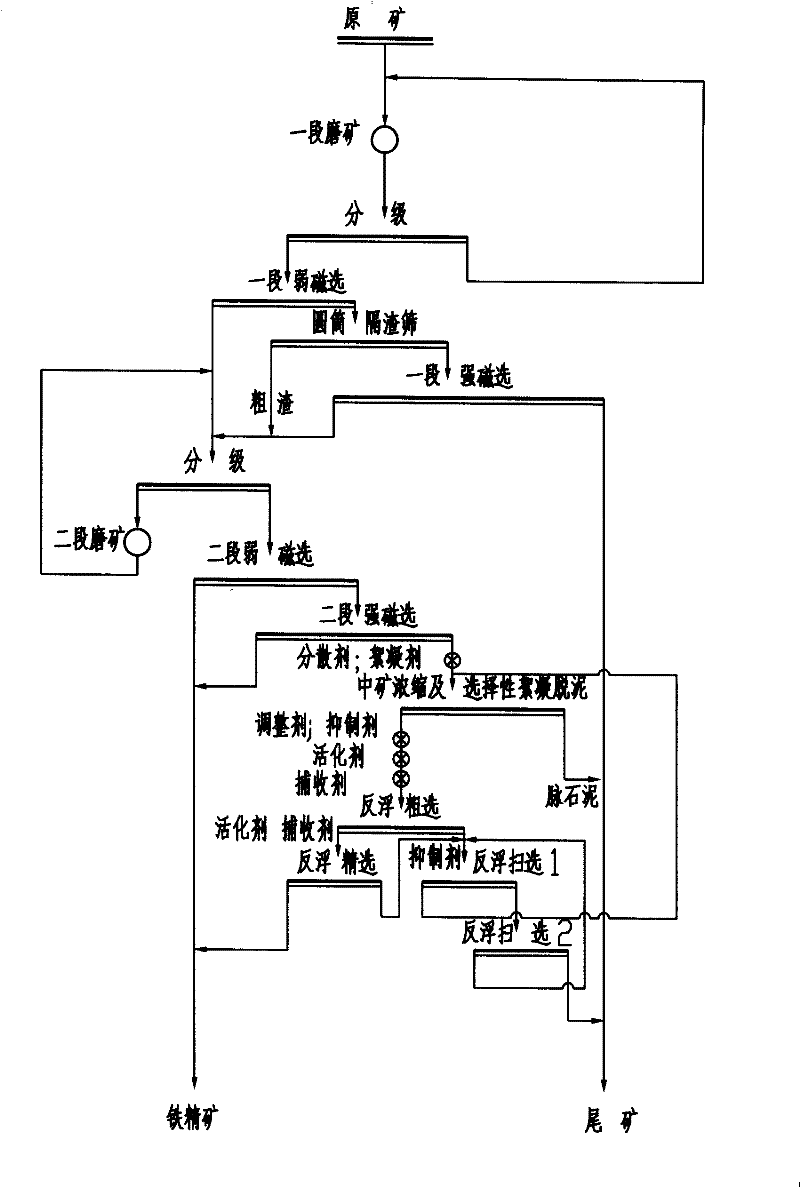

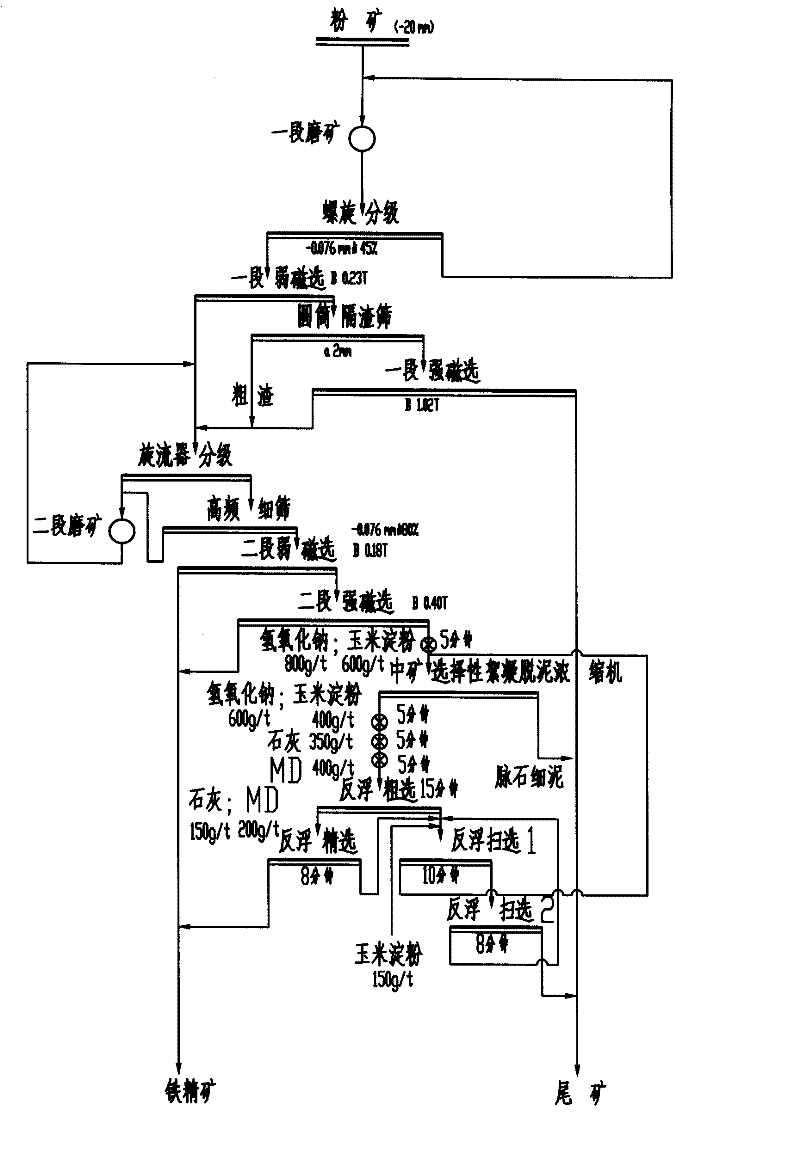

Beneficiation method for recycling specularite

InactiveCN101428248BReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

The invention discloses a benefication method for recovering specularite. The method comprises the processes of primary grinding, grading, primary low intensity magnetic separation, and tailings discarding by primary high intensity magnetic separation; rough concentrate pre-classification by the primary low intensity magnetic separation and the primary high intensity magnetic separation, secondary grinding, secondary low intensity magnetic separation to obtain concentrates, secondary high intensity magnetic separation to obtain concentrates; and selective flocculation desliming secondary conducted on high intensity magnetic separation tailings (middlings), and anionic reverse flotation. The method further comprises the step of arranging a cylindrical slag separating sieve before the primary high intensity magnetic separation. With the advantages that the iron concentrate grade and the iron recovery are high, the loss of granular iron minerals is low, the mineral process flow is short,concentrates and tailings can be obtained in advance and the energy consumption of the benefication is low, the invention can be used not only for selecting specularite ores, but also for selecting weakly magnetic iron minerals, such as hematite, goethite, siderite, limonite, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

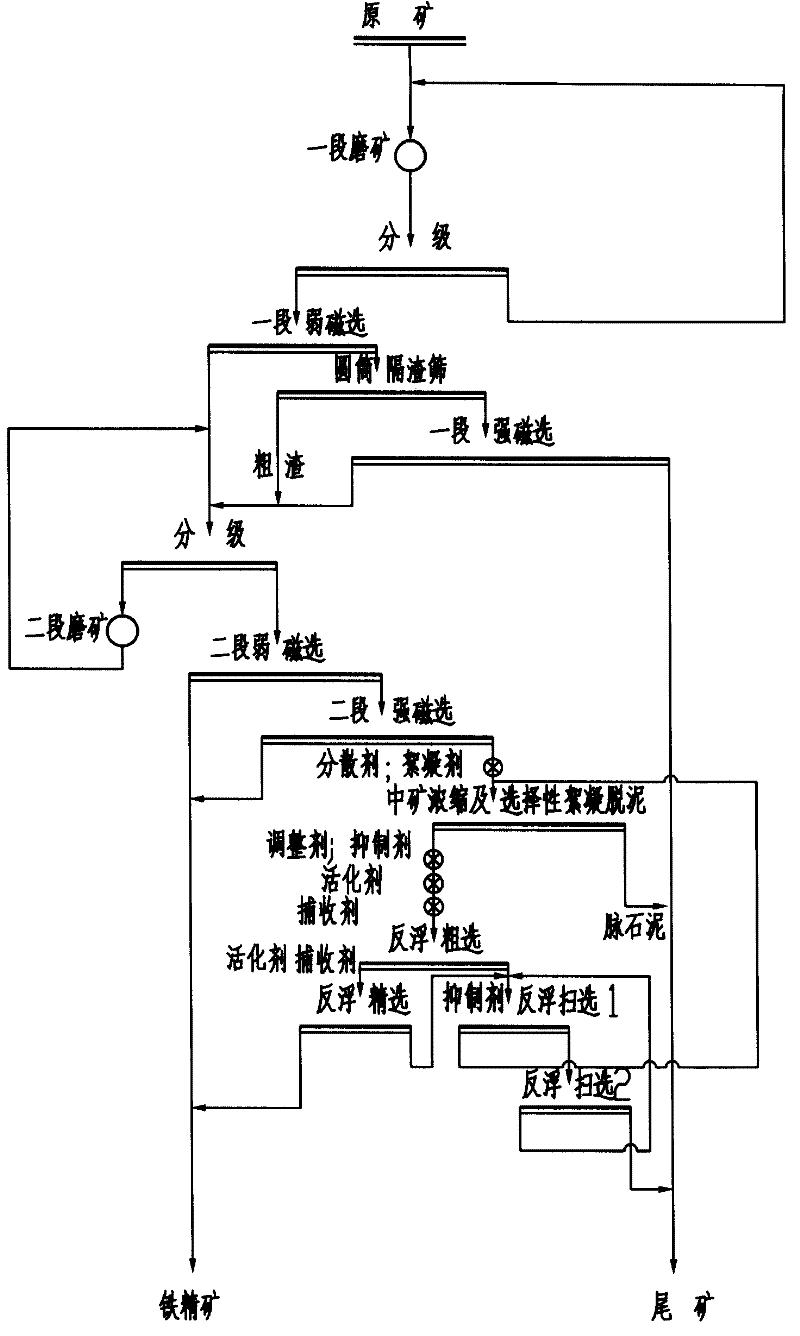

Separation method for strengthening recycling of fine-grain low-intensity-magnetic iron ore through magnetic levitation stage agent addition

InactiveCN106824507AReduce pollutionHigh iron recoveryFlotationWet separationSlurryMaterials science

The invention relates to a separation method for strengthening recycling of fine-grain low-intensity-magnetic iron ore through combination of magnetic levitation stage agent addition in the field of ore machining. The separation method includes the steps that firstly, ore pulp containing the fine-grain low-intensity-magnetic iron ore is subjected to low-intensity-magnetic separation work; secondly, after slurry mixing of low-intensity-magnetic separation tailings is conducted, a pH modifier is added, and an organic inhibitor serves as a first-stage agent to be added into the ore pulp; thirdly, one time of high-intensity-magnetic separation is conducted on the ore pulp; fourthly, a pH modifier is added into a mixed magnetic product of low-intensity-magnetic separation and high-intensity magnetic separation, a second-stage agent, a quartz activating agent and a negative ion reverse flotation collecting agent are added into the ore pulp, and reverse flotation feed ore is obtained; and fifthly, the reverse flotation feed ore is subjected to one time of roughing and one time of concentrating, final concentrates are obtained, reverse flotation rougher tailings are subjected to two times or three times of scavenging, and final reverse flotation scavenged tailings are obtained.

Owner:NORTHEASTERN UNIV

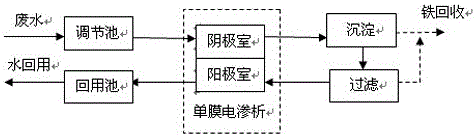

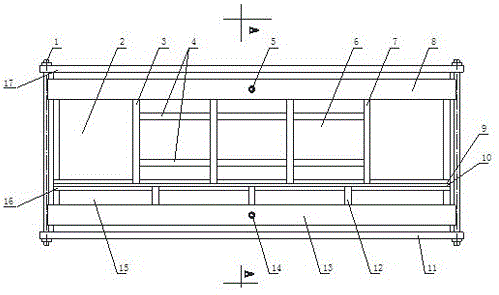

Resourceful treatment process for silicon carbide pickling wastewater

InactiveCN105731696AAchieve separationLower iron levelsCellsPhotography auxillary processesFiltrationWastewater

The invention discloses a resourceful treatment process for silicon carbide pickling wastewater, and the resourceful treatment process mainly adopts a process route of taking single membrane electroosmosis+ precipitation+ filtration as a pickling wastewater resourceful treatment technology. On the premise of not introducing extra chemical agent, separation of acid and metal ions in sulfuric acid pickling wastewater can be effectively realized, so that the iron content in the sulfuric acid pickling wastewater is guaranteed to be reduced to be lower than 10mg / L from 500mg / L, the iron recovery rate is 90% or higher, and the acid recovery rate is 99% or higher. According to the resourceful treatment process, no other impurities are newly introduced, and 3g of concentrated sulfuric acid with concentration being 98% only needs to be added into every liter of the recycled sulfuric acid pickling wastewater, so that the acidity of the recycled sulfuric acid pickling wastewater is supplemented to be 3%, and therefore, wastewater recycling can be realized. Meanwhile, simple substances and / or compounds are generated by the treatment process, so that zero release can be realized, clean production is guaranteed, and resource recycling of wastewater and iron is realized, and therefore, very good economic and environmental benefits are generated.

Owner:HENAN UNIVERSITY

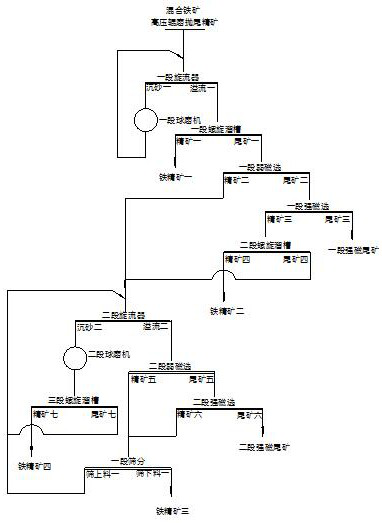

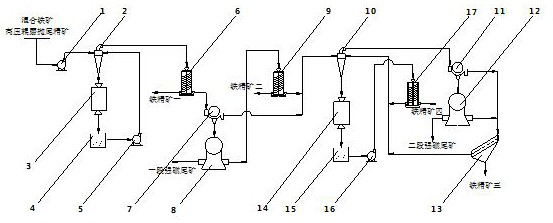

Flotation-free dressing recovery process for mixed iron ore

ActiveCN113333158AHigh recovery rateReduce cycle loadMechanical material recoveryWet separationOre concentrateMineralogy

The invention discloses a flotation-free dressing recovery process for mixed iron ore, and relates to the technical field of ore dressing. Mixed iron ore high-pressure roller milling-wet pre-selected concentrate enters a follow-up grinding and selecting first-section hydrocyclone to be classified, sand settled by the hydrocyclone enters a first-section ball mill to be ground, and ball-milling discharged ore returns to the first-section hydrocyclone to be classified; overflow of the first-section hydrocyclone enters a spiral chute for grading to obtain iron ore concentrate; tailings in the spiral chute are subjected to weak magnetic separation and strong magnetic separation tailings discarding, strong magnetic concentrate passes through the spiral chute to obtain iron ore concentrate, the tailings in the spiral chute and the weak magnetic concentrate are combined and enter a second-stage hydrocyclone to be classified, classified settled sand enters a second-stage ball mill to be ground, second-stage ball mill discharged ore passes through the spiral chute to obtain an iron ore concentrate product III, and second-stage ground ore overflow is subjected to weak magnetic separation and strong magnetic separation tailings discarding; and the weak magnetic concentrate and the strong magnetic concentrate are combined and classified through screening, the undersize product is an iron ore concentrate product IV, and the screened product returns to the second-stage cyclone to be classified, so that a closed cycle is formed. The method has the advantages of low production cost, high recovery rate, high concentrate dewatering and filtering performance, economical, environmental protection and the like.

Owner:ANHUI JINRISHENG MINING

Method for producing iron oxide red with green copperas

ActiveCN101172663BHigh chemical levelGood physical propertiesFerric oxidesIron powderResource utilization

Owner:PANZHIHUA LIYU MINING

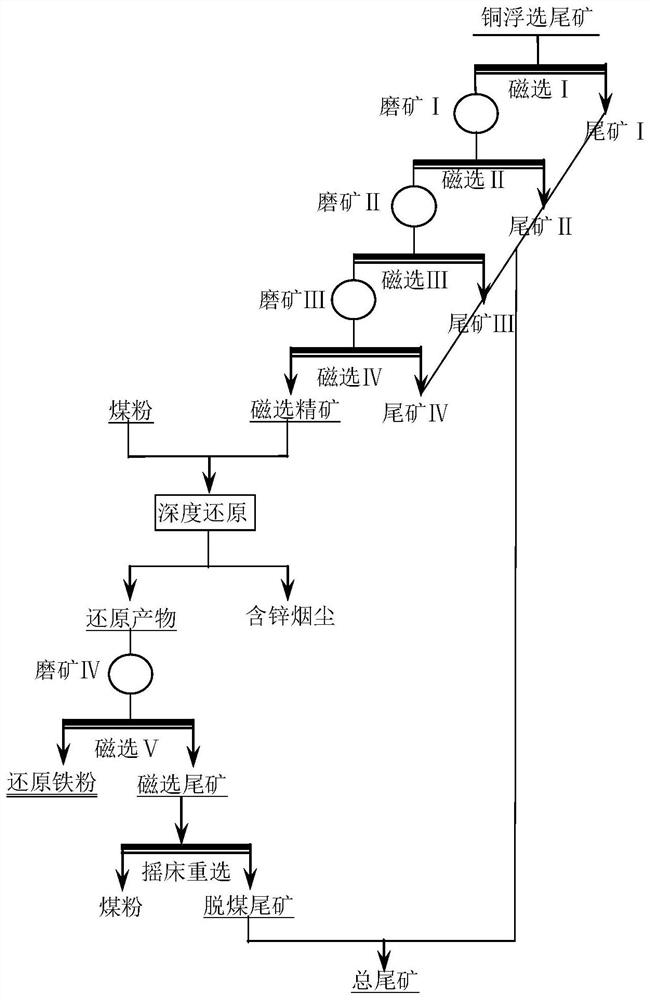

Dressing-smelting combined process for recovering iron from copper slag flotation tailings

PendingCN113578521AReduce energy consumptionSimple processProcess efficiency improvementWet separationIron powderZinc smelting

The invention discloses a dressing-smelting combined process for recovering iron from copper slag flotation tailings. The dressing-smelting combined process comprises the following steps: obtaining magnetic concentrate through an ore grinding and magnetic separation method, mixing the magnetic concentrate with pulverized coal, carrying out deep reduction roasting, controlling the reduction temperature and time, carrying out ore grinding and magnetic separation on the roasted product to obtain reduced iron powder, and selling the reduced iron powder as scrap steel. The magnetic separation tailings are subjected to decarburization treatment, removed carbon can serve as pulverized coal, the tailings after decarburization and the magnetic separation tailings before roasting are mixed to serve as final tailings which can be used for cement production, and dust collected through deep reduction roasting can serve as zinc smelting raw materials. The whole process has the advantages of being simple, short in flow, low in energy consumption, economical, environmentally friendly, good in iron recovery effect, higher in economic benefit and the like.

Owner:WESTERN MINING CO LTD +1

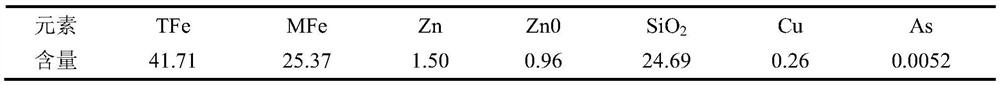

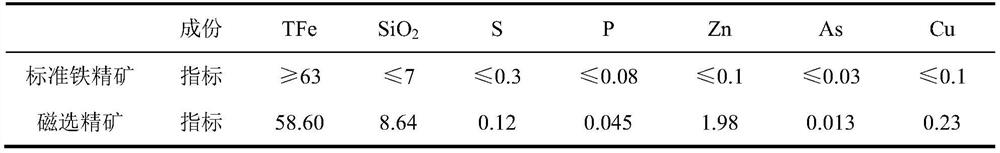

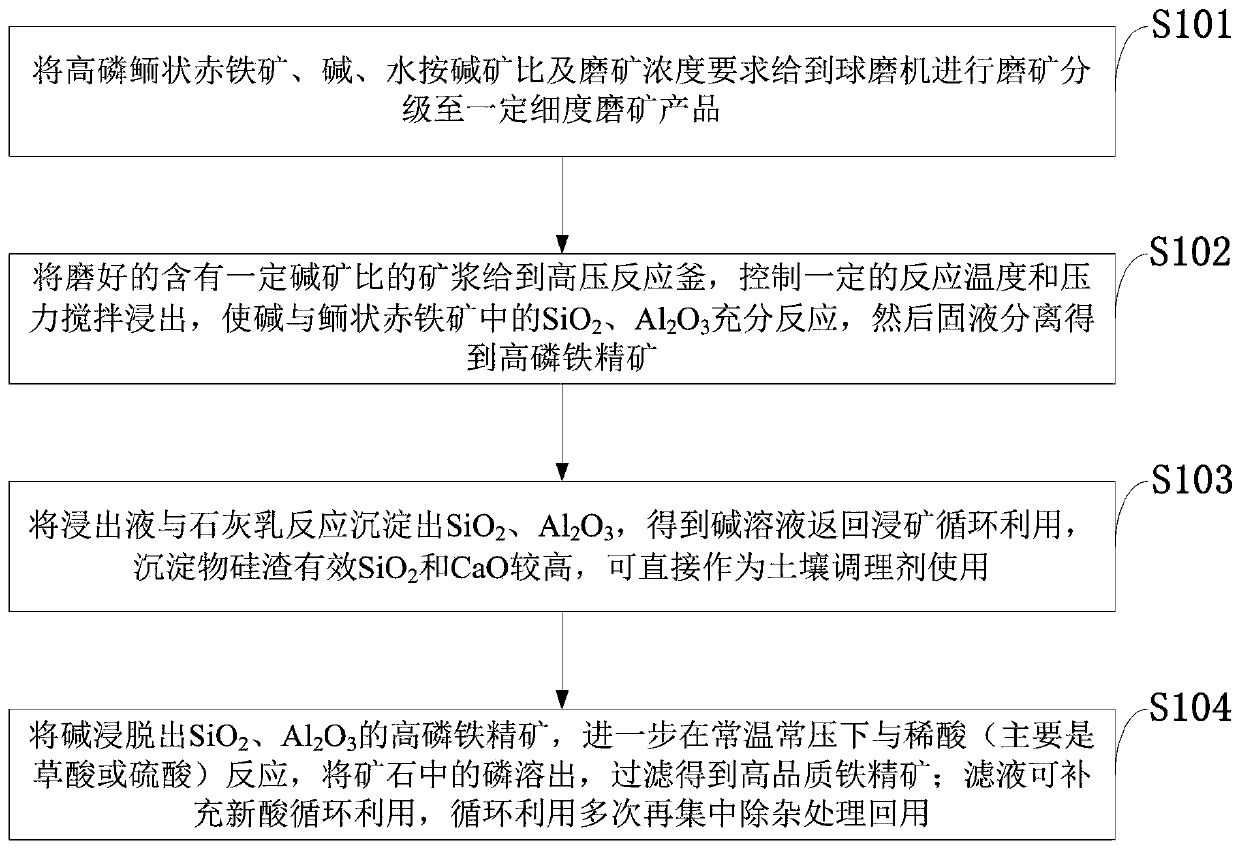

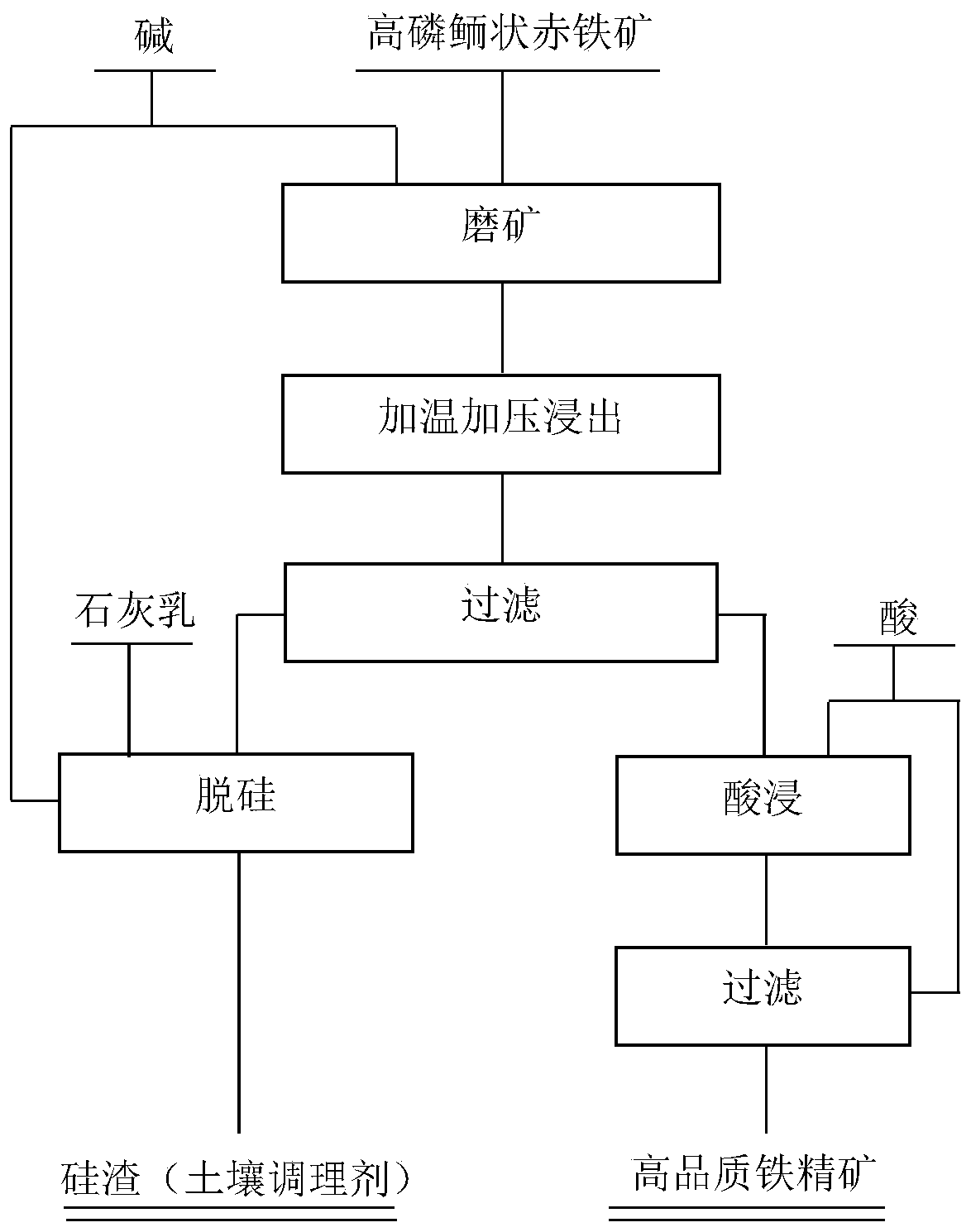

Method for preparing high-quality iron mineral concentrates from high phosphorus oolitic hematite through chemical impurity reduction

InactiveCN109943716AImprove qualityHigh iron recoveryProcess efficiency improvementSlagSoil conditioner

The invention belongs to the technical field of mineral processing engineering and discloses a method for preparing high-quality iron mineral concentrates from high phosphorus oolitic hematite throughchemical impurity reduction. The method for preparing the high-quality iron mineral concentrates from the high phosphorus oolitic hematite through chemical impurity reduction comprises the steps of dissolving out SiO2 and Al2O3 from the oolitic hematite through alkali under the heating and pressurizing conditions; dissolving out phosphorus from the oolitic hematite through dilute acid under the normal-temperature and normal-pressure conditions to obtain the high-quality iron mineral concentrates; and depositing SiO2 and Al2O3 from an alkali leaching solution through lime milk to serve as a leaching agent for cyclic utilization. According to the method, SiO2 and Al2O3 are deposited from the alkali leaching solution through the lime milk and serves as the leaching agent for cyclic utilization; the effective SiO2 and capable of content of deposited silica slag is high, the deposited silica slag can be directly used as a soil conditioner. The method has the characteristics of high iron recovery rate, alkaline cyclic utilization, comprehensive utilization of silicon and the like.

Owner:KUNMING UNIV OF SCI & TECH

Amine-containing formulations for reverse froth flotation of silicates from iron ore

The present invention relates to a process for enriching an iron mineral from a silicate-containing iron ore by reverse froth flotation of the ore using a collecting composition comprising: a) a compound of formula R1O-A-NH(CH2)nNH2 (I), wherein R1 is a straight or branched hydrocarbyl group with 12-15 carbon atoms, A is a group —CH2CHXCH2—, wherein X is hydrogen or a hydroxyl group, and n is a number 2-6; b) a compound of formula R2NH2 (II), where R2 is a hydrocarbyl group having 12-14 carbon atoms; c) a compound of formula R3NH2 (III), wherein R3 is a straight or branched, saturated or unsaturated hydrocarbyl group having 16-22 carbon atoms; and d) optionally a depressing agent for the iron mineral, wherein the amount of a) is at least 65% by weight, based on the total weight of a), b) and c), and at most 90% by weight, based on the total weight of a), b) and c), and wherein the weight ratio between c) and b) is 4:1 to 1:1.

Owner:AKZO NOBEL CHEM INT BV

Corn starch pretreatment-unusual medium magnetic separation process

InactiveCN108654834AIncrease catch rateEasy to recycleHigh gradient magnetic separatorsFlocculationMagnetic media

The invention relates to a corn starch pretreatment-unusual medium magnetic separation process and belongs to the technical field of mineral processing. The corn starch pretreatment-unusual medium magnetic separation process comprises the steps of pulp mixing, weak magnetic iron mineral flocculation pretreatment, magnetic separation and scavenging, wherein the magnetic separation step is that strong magnetic separation work is carried out on obtained pretreated ore pulp through a vertical ring pulsating high gradient magnetic separator with an elliptic unusual magnetic medium box under the condition that the background field intensity is 5,000 oersted-10,000 oersted, the pulsation stroke is 0 mm-20 mm and the pulsation frequency of stroke is 0-250 per minute, a strong magnetic separation magnetic product is obtained, and the cross section of the unusual magnetic medium box is provided with saw teeth. Compared with an existing intensifying micro-fine particle weak magnetic iron mineralrecovering process, the method has the advantages of being high in iron recovering rate, low in composite cost, simple in flowage structure and the like.

Owner:NORTHEASTERN UNIV

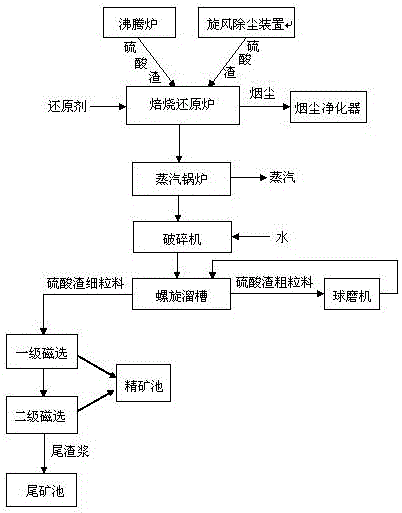

Method for producing ferric oxide fine powder through high-temperature sulfuric-acid residues in fluidized bed combustion boiler

InactiveCN105883931AImprove qualityHigh quality iron oxide fine powder with iron recovery rateFerroso-ferric oxidesFerric oxidesSlurryBall mill

The invention discloses a method for producing ferric oxide fine powder through high-temperature sulfuric-acid residues in a fluidized bed combustion boiler, and relates to the technical field of metallurgy. The technical problems of increasing the iron recovery rate, the compactness and the compression resistance index of products are solved. By means of the method, sulfuric-acid residues are heated to 250 DEG C or above through a roasting reduction furnace, and a reduction agent is added to sulfuric-acid residues; heat energy of sulfuric-acid residues is recovered through a steam boiler; sulfuric-acid residues are smashed with water, ball-milled and decomposed in sequence through a smashing machine and a ball mill and then sent into a primary magnetic separator for primary magnetic separation, tailing slurry subjected to primary magnetic separation is subjected to secondary magnetic separation through a secondary magnetic separator, and ferric oxide fine powder is selected through primary magnetic separation and secondary magnetic separation. By means of the method, high-quality ferric oxide fine powder can be produced.

Owner:四川省摘塬勇鑫矿业科技有限公司

Method for producing molten iron through multistage restoring complex difficultly-separated iron mine powder

The invention relates to a method for producing molten iron through multistage restoring complex difficultly-separated iron mine powder, and belongs to the technical field of steel metallurgy. The method is characterized in that the iron mine powder and pulverized coal are mixed according to proportion through coal blending calculation, a mixture is fed into a fluidized bed reactor to be heated to700 DEG C-1100 DEG C, the motion lasts for 0.2 h-1.0 h, and first-stage restoring is carried out; a first-stage restored material is fed into a second-stage reaction tank at the temperature ranging from 800 DEG C-1300 DEG C, the motion lasts for 1.0 h-5.0 h, the second-stage restoring process is carried out, a second-stage restored material is fed into a deep reduction furnace at the temperatureranging from 1200 DEG C-1500 DEG C, motion lasts for 2.0 h-5.0 h, third-stage restoring is carried out, and separation of the molten iron and slag is achieved; and the iron metallization ratio of third-stage reduction molten iron discharged from the deep reduction furnace can reach 95% or above.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com