Dressing-smelting combined process for recovering iron from copper slag flotation tailings

A combined technology of flotation tailings and dressing and smelting, which is applied to the improvement of process efficiency, wet separation, solid separation, etc., can solve the problems of complex process, long process, high energy consumption, etc., and achieve simple process and high iron recovery rate , high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

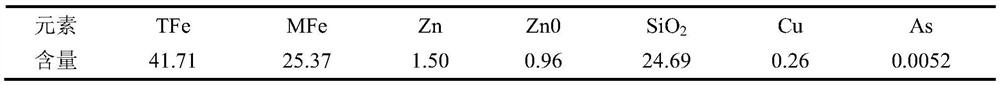

[0019] In this embodiment: the chemical multi-element analysis results of the copper slag flotation tailings of a certain copper smelter are shown in Table 1 below:

[0020] Table 1 Chemical multi-element analysis results of copper slag flotation tailings in a copper smelter (unit / %)

[0021]

[0022] The recovery process proceeds in the following steps:

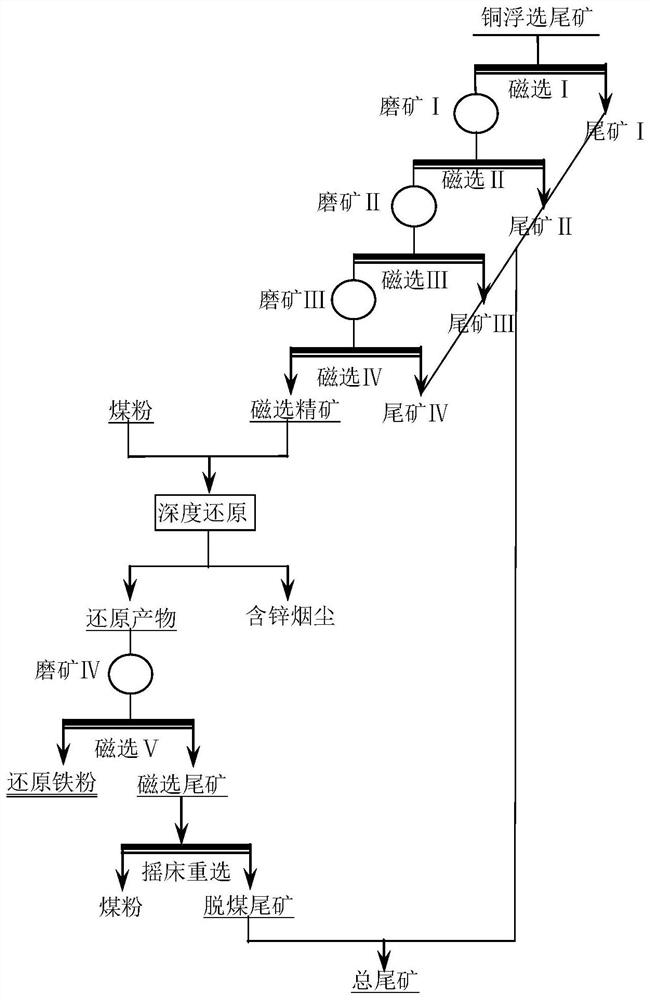

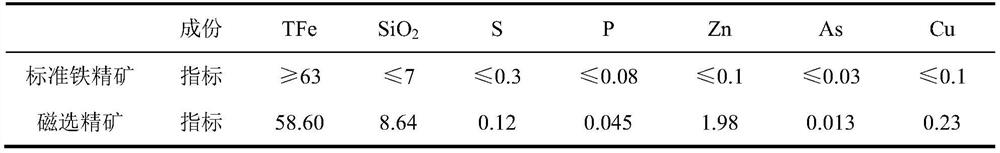

[0023] 1) Take 1 kg of copper slag flotation tailings from a copper smelter, and process them according to the process of magnetic separation Ⅰ → ore grinding Ⅰ → magnetic separation Ⅱ → grinding Ⅱ → magnetic separation Ⅲ → grinding Ⅲ → magnetic separation Ⅳ. The magnetic field strength of the process is 1900Oe, 1900Oe, 1700Oe, 1400Oe respectively, and the grinding fineness of the grinding process is -400 mesh accounting for 90%, -500 mesh accounting for 90%, -600 mesh accounting for 90%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com