Gallium extracted waste liquor resource utilization technology in process of one-step acid solution method technology

A process and resource utilization technology, which is applied in the technical field of resource utilization of gallium waste liquid in the one-step acid solution process, can solve the problems of high solution viscosity, secondary pollution, waste of resources, etc., and achieve large saturation capacity, iron High recovery rate and good stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

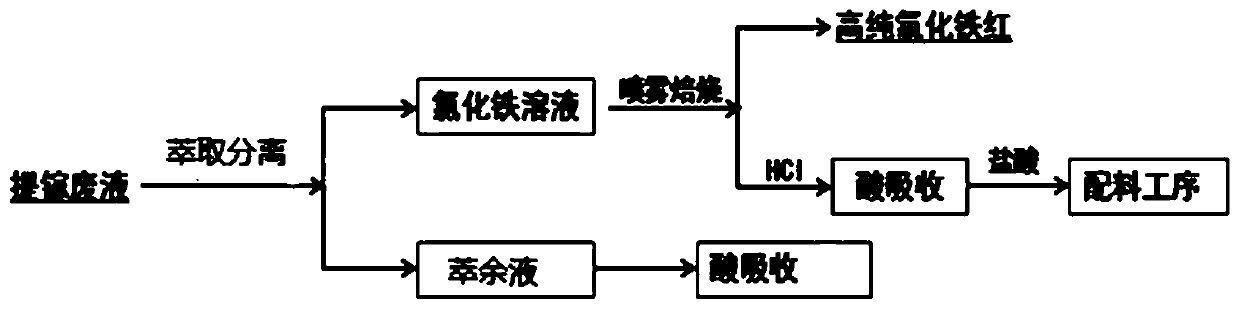

Method used

Image

Examples

Embodiment 1

[0057] 1. Separation and purification of iron and aluminum in gallium extraction waste liquid

[0058] Extraction system (also known as organic phase): using composite extractant N, N-bis(1-methylheptyl) caproamide and tributyl phosphate, compound ratio 3:1, accounting for 40% of the volume of the organic phase; dilute 260 # Kerosene occupies 40% by volume of the organic phase; the phase regulator adopts 2-octanol, which occupies 20% by volume of the organic phase.

[0059] Extraction process conditions: extraction: comparison O / A=2.5:1, countercurrent extraction 6 stages; washing: comparison O / A=8:1, stage 2, detergent is 4N hydrochloric acid; back extraction: comparison O / A=3.5:1, 8 stages of countercurrent back extraction, the back extraction agent is dilute hydrochloric acid solution with pH=2.

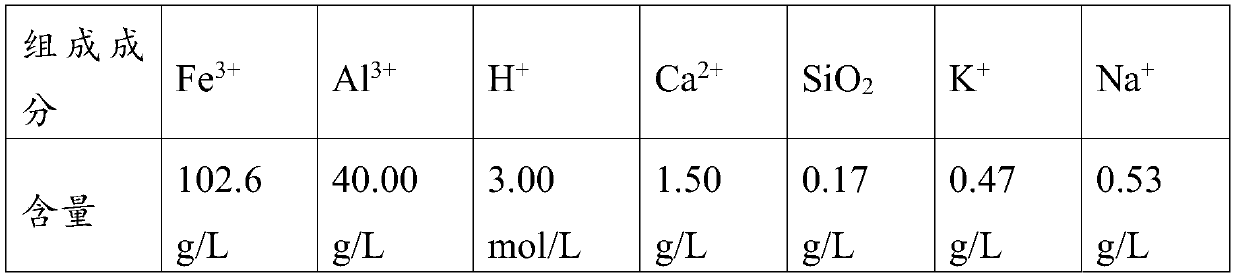

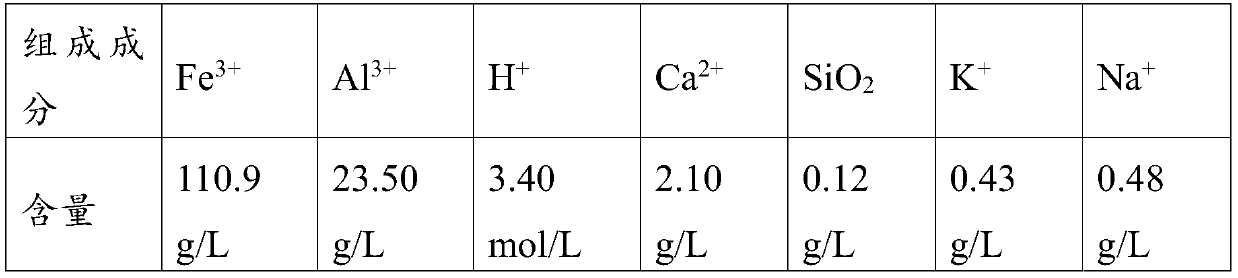

[0060] In the laboratory, containing Fe 3+ Concentration is 102.6g / L gallium extraction waste liquid (see table 1), through above-mentioned extraction process condition treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com