High-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology

A hematite and reverse flotation technology, applied in the field of mineral processing, can solve the problems of high iron distribution rate, serious muddy degree, and reduced separation efficiency, and achieve good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

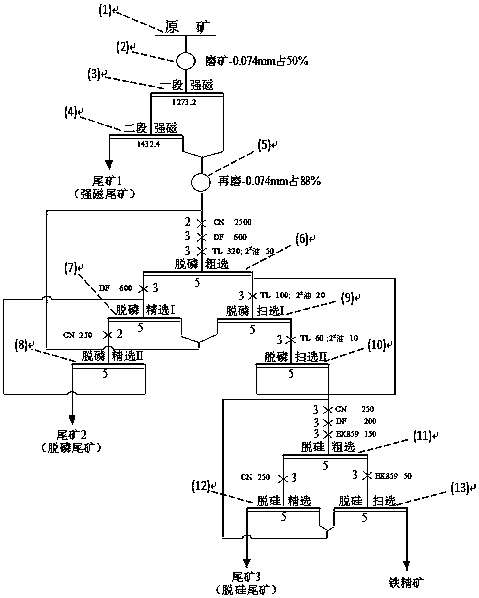

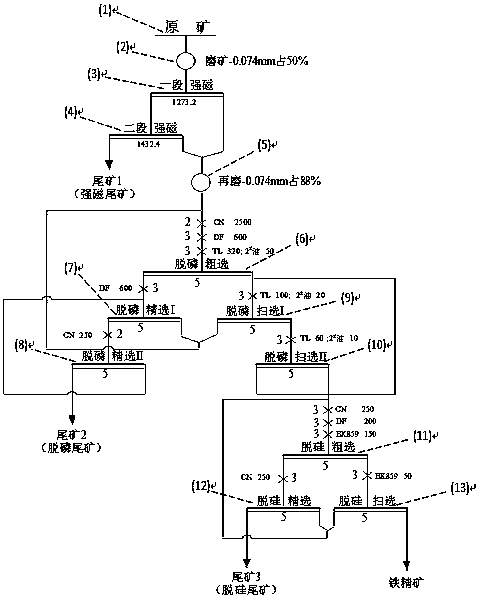

[0017] An embodiment of the high-phosphorus oolitic hematite strong magnetic reverse flotation dephosphorization and desiliconization process of the present invention. Huoshaoping Iron Mine in Yichang, Hubei belongs to high-phosphorus oolitic hematite, the raw ore grade is 35.82%, and the phosphorus content is 0.912%. Grinding ⑸, Dephosphorization Rough Selection ⑹, Dephosphorization Selection ⑺, Dephosphorization selection ⑻, dephosphorization scanning ⑼, dephosphorization scanning , Desiliconization , desiliconization selection and desiliconization composition, see figure 1 .

[0018] 1. First, restore the geological grade through a stage of grinding-strong magnetic separation. Occurrence state of this kind of resource ore body is thin plate, gently inclined, and deeply buried. There are local ore body outcrops, and cave mining must be carried out, and the amount of ore that can be mined is relatively small compared with the entire ore body. In addition, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com