Mineral benefication method for specularite

A beneficiation method, specularite technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of high equipment investment, large ore volume, large investment, etc., and achieve simple process structure and low production cost , the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

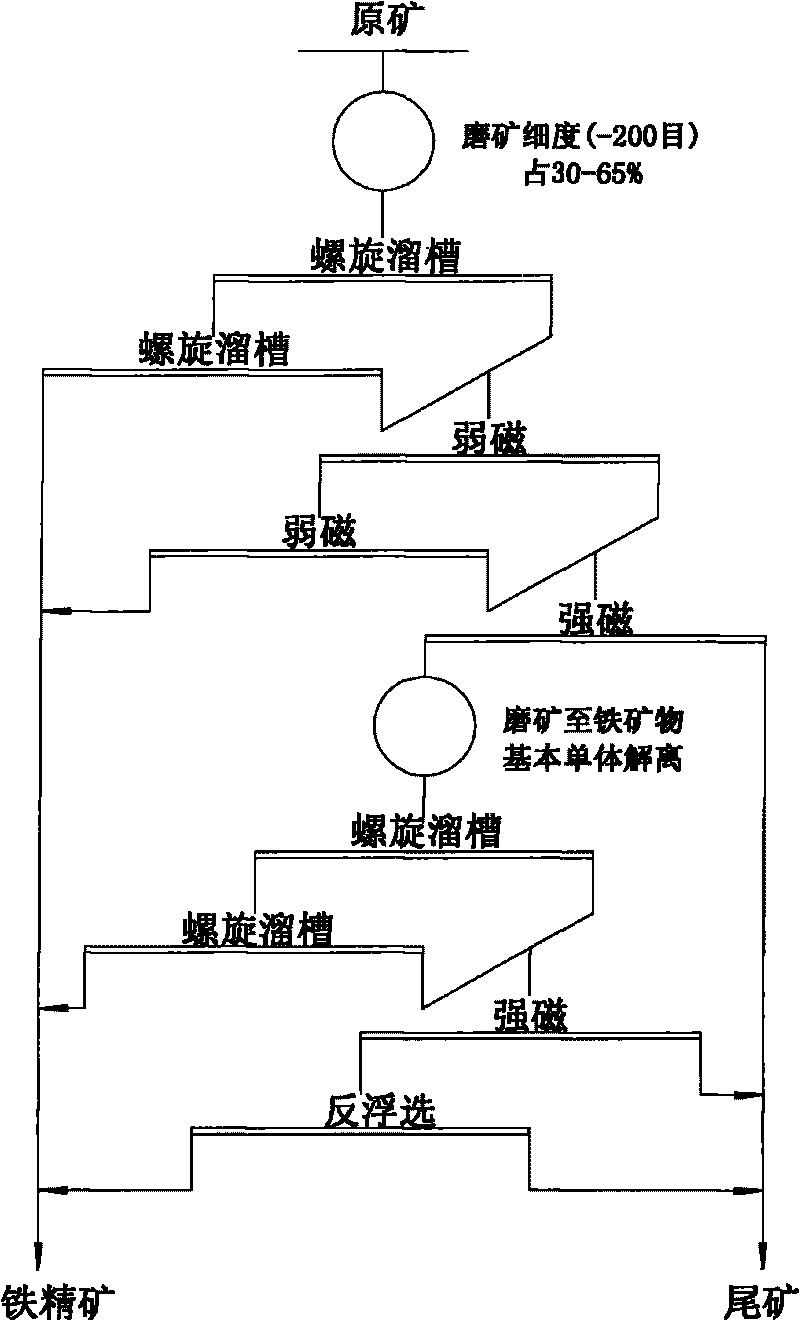

[0022] Embodiment 1 is the result of industrial production in a certain mine. The iron minerals in the ore extracted from this mine are mainly specularite and pseudohematite, and a small amount of limonite is occasionally seen; the gangue minerals are mainly quartz, followed by chlorite, sericite, muscovite and calcite, and other trace amounts Minerals include zircon, apatite, titanite and pyrite, etc. The raw ore grade is 31.17%, the iron silicate content is about 5%, and the magnetite accounts for about 1% of the total iron. figure 1 The principle process, the steps are as follows:

[0023] (1) After the raw ore is subjected to the first section of coarse grinding (grinding fineness -200 mesh accounts for 55%), the first section of 2-stage spiral chute sorting is directly carried out to obtain iron concentrate with a yield of 20.60 and a grade of 66.52%. The recovery rate of iron is 46.18%;

[0024] (2) After the tailings in the first section of the spiral chute are subjec...

Embodiment 2

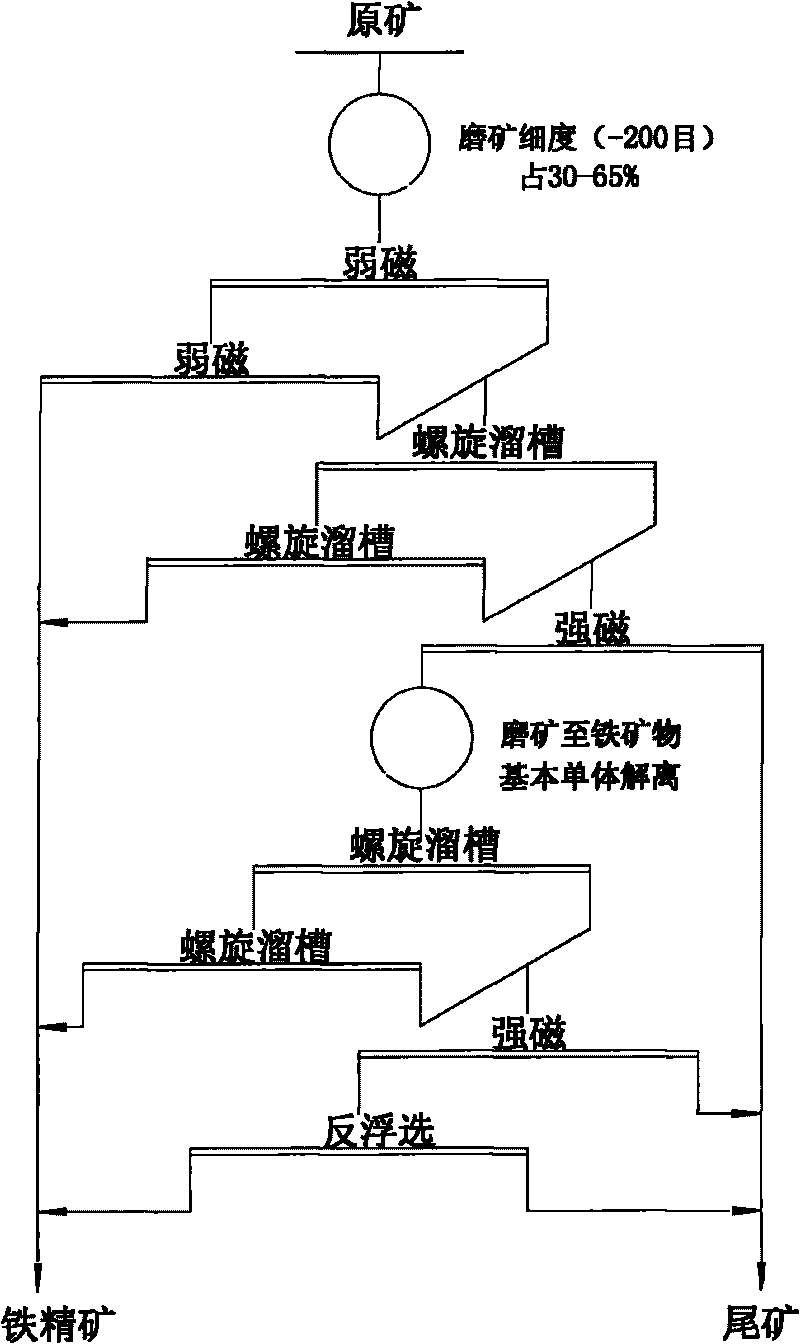

[0031] The iron minerals in a mine are mainly magnetite and specularite and a small amount of semi-pseudo-false hematite and limonite; the gangue minerals are mainly quartz, followed by biotite, muscovite, actinolite, and tremolite Other trace minerals are zircon, apatite and sphene, among which the iron silicate content is 10.59%. The raw ore grade is 29.47%, and the magnetite content accounts for about 40% of the total iron. figure 2 The principle process (but the second section of spiral chute sorting is not carried out), the specific sorting steps are as follows:

[0032] (1) After the raw ore is subjected to the first stage of coarse grinding (grinding fineness -200 mesh accounts for 51.6%), it is firstly subjected to two weak magnetic separations, one coarse and one fine, to obtain a weak magnet with a yield of 18.58% and a grade of 67.54% Concentrate, iron recovery rate 42.58%;

[0033] (2) the weak magnetic tailings of (1) step gained enters two-stage spiral chute s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com