Beneficiation method for micro-fine iron ore

A beneficiation method and fine-grained technology, which is applied in the beneficiation field of fine-grained iron ore, to achieve the effect of improving flotation behavior, reducing adverse effects, and improving the separation index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

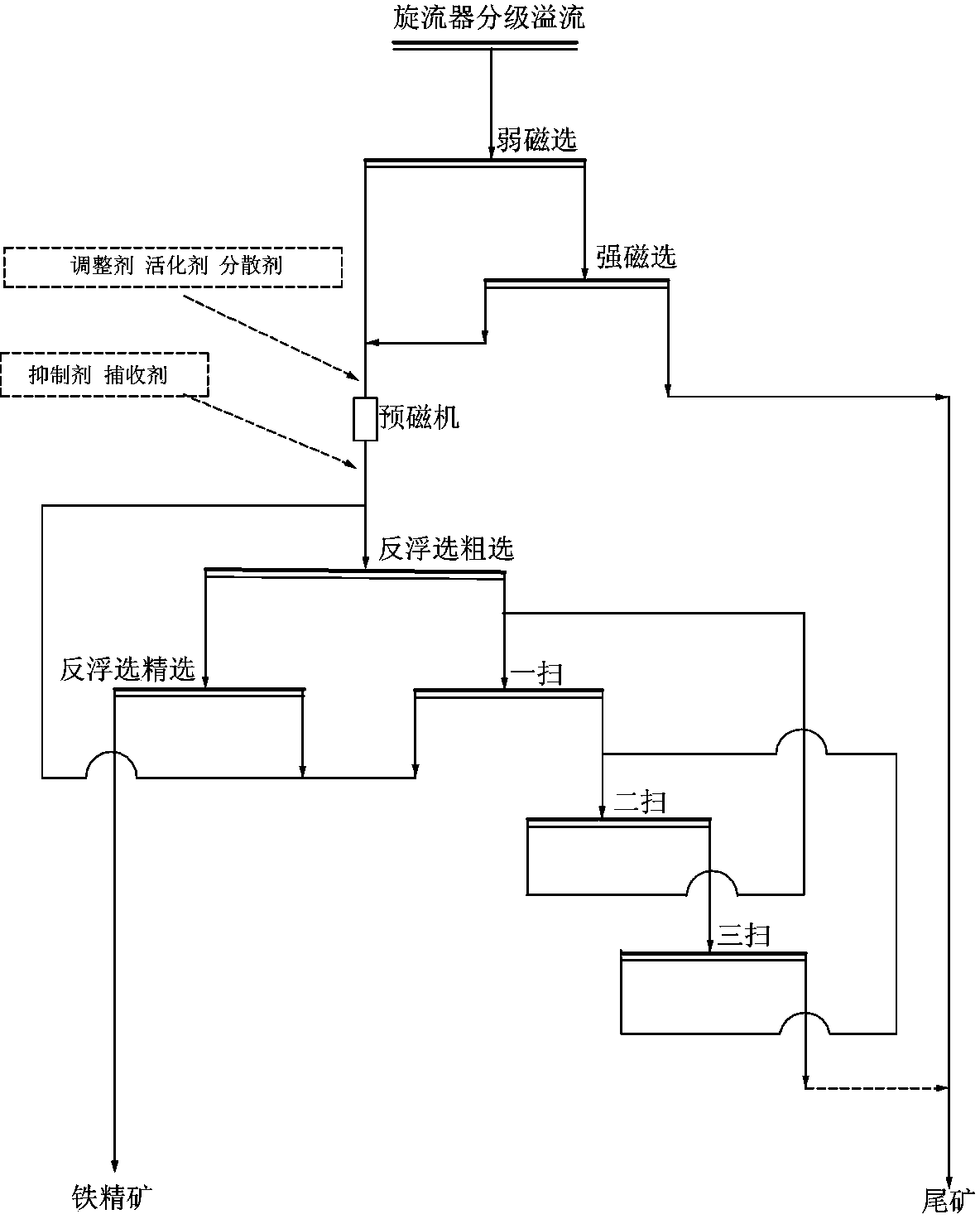

[0029] like figure 1 As shown, the above-mentioned fine-grained iron ore in the dressing plant is ground through two stages of grinding until -0.075mm accounts for more than 90%, of which -0.019mm accounts for more than 40%~50%, and then it is sent to the cyclone for classification. Weak magnetic separation and strong magnetic separation are used for pre-separation. The weak magnetic separation uses weak magnetic tailings to enter the vertical ring pulsating strong magnetic separator to obtain strong magnetic coarse concentrate and strong magnetic tailings. The strong magnetic tailings enter The total tailings are discarded directly, and the strong magnetic coarse concentrate and weak magnetic coarse concentrate are combined into mixed magnetic separation iron concentrate and fed into reverse flotation operation; the obtained concentration is 30% mixed magnetic separation iron concentrate, and the concentrate grade is 44% ~46%,

[0030] Include the following steps

[0031] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com