Beneficiation method for reducing content of SiO2 in magnetite concentrate

A technology for magnetite concentrates and beneficiation methods, applied in selective deposition methods, chemical instruments and methods, flotation, etc. Small and other problems, to achieve the effect of reducing tailings grade, low energy consumption in beneficiation, and small loss of fine-grained iron minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

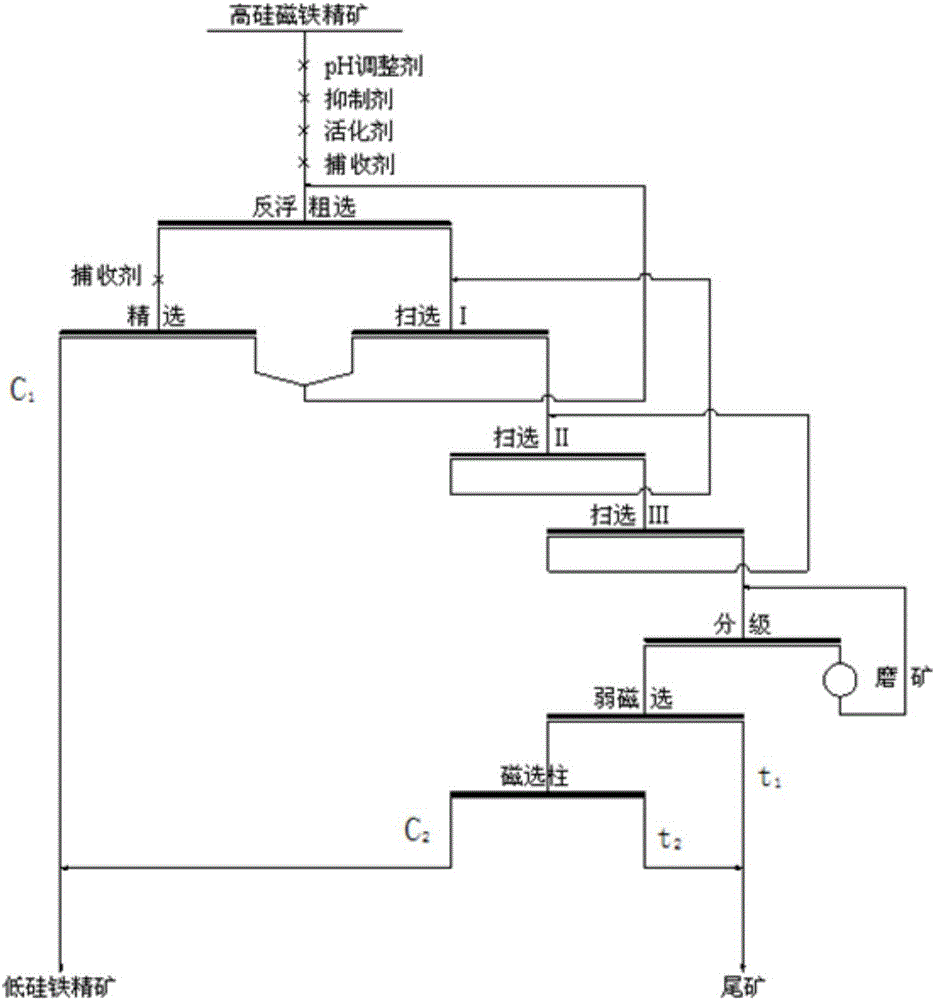

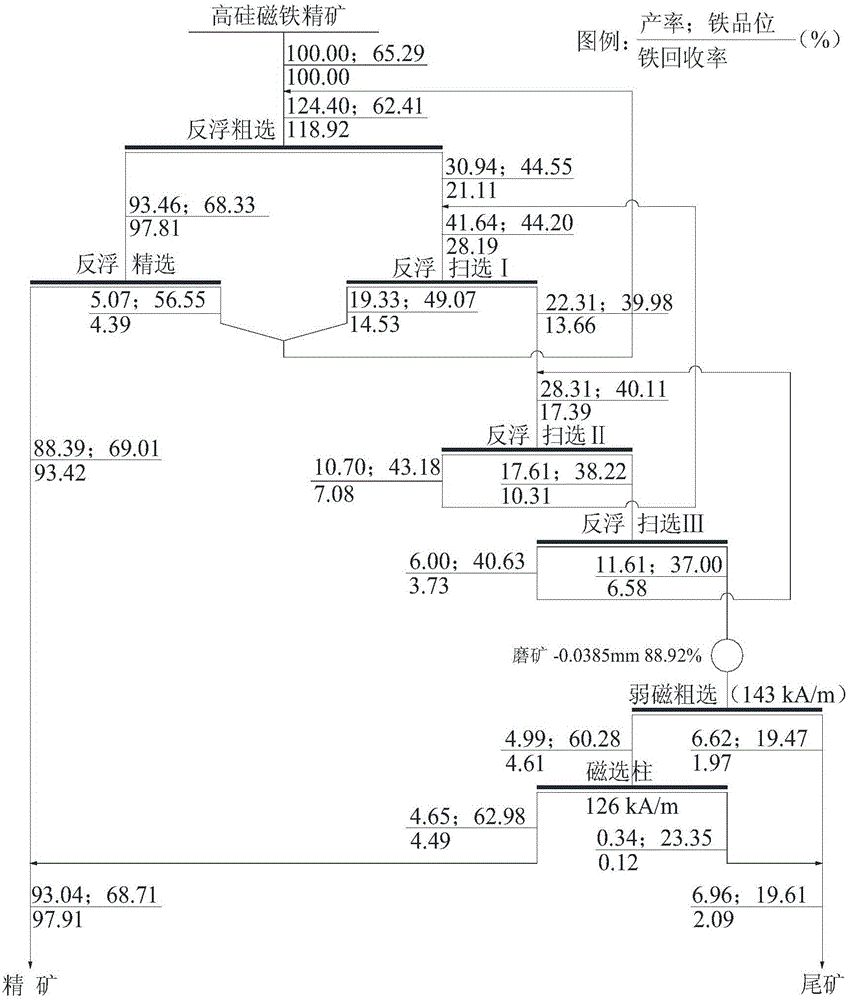

[0032] For describing the present invention, below in conjunction with accompanying drawing and embodiment to the present invention a kind of reducing SiO in magnetite concentrate 2 The beneficiation method of content will be further explained in detail.

[0033] Depend on figure 1 A kind of shown present invention reduces SiO in the magnetite concentrate 2 The principle process flow diagram of the ore dressing method of content finds out, a kind of present invention reduces SiO in the magnetite concentrate 2 The beneficiation method of content comprises following process, step:

[0034] (1) High silicon magnetite concentrate anion reverse flotation.

[0035] Fe grade 65.0-66.5% (SiO 2 content of 6-8%), the high-silicon magnetite concentrate is pumped into the anion reverse flotation stirring tank, and the regulator sodium hydroxide 600-800g / t, the inhibitor corn starch 1200-1500g / t, the activator lime 300g -500g / t, anion collector MH (a modified fatty acid salt, purchase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com