Resourceful treatment process for silicon carbide pickling wastewater

A treatment process, carbonized silicic acid technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as waste of land resources, failure to realize reuse, high salt content in wastewater, and achieve guaranteed The effect of cleaner production, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

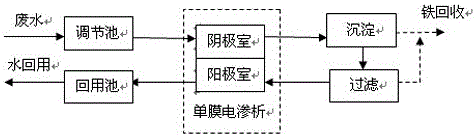

[0025] The treatment process of the present invention, after countless experiments, selects "single-membrane electrodialysis + precipitation + filtration" as the final process route of pickling wastewater recycling technology, and adopts single-membrane electrodialysis equipment as silicon carbide pickling wastewater recycling treatment process core technical equipment.

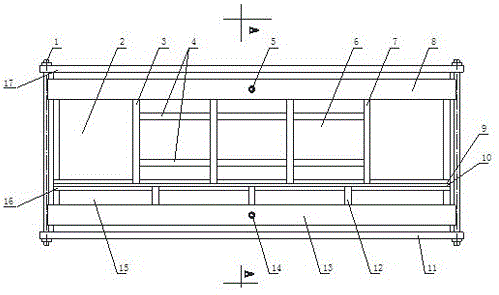

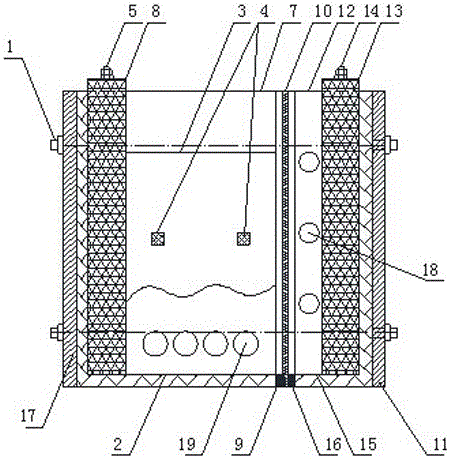

[0026] refer to figure 1 , figure 2 , image 3 , the single-membrane electrodialysis equipment is mainly that a single anion exchange membrane 10 is arranged between the cathode chamber 2 and the anode chamber 15, and a left U-shaped rubber gasket 9 and a right U-shaped rubber gasket are arranged on both sides of the single anion-exchange membrane 10 16. Make the cathode chamber 2, the anode chamber 15 and the single anion exchange membrane 10 sealed. A graphite cathode plate 8 is set in the cathode chamber 2 as a cathode electrode, and a netted electrode fixing plate (not shown in the figure) with high a...

Embodiment 2

[0035] In step (b), the operating voltage is set to 40V, and the water flow in the cathode chamber 2 is adjusted to 10.6L / h, 9.0L / h, 7.9L / h, 7.0L / h and 6.3L / h respectively, so that the pickling The effective residence times of the wastewater in the cathode chamber 2 are 1.5h, 1.75h, 2h, 2.25h and 2.5h respectively. Electrolysis of sulfuric acid waste liquid with iron ion concentration of 100mg / L.

[0036] After the test, the highest iron recovery rate was 93.18%, the sulfuric acid recovery rate was above 99%, the lowest pH of the system effluent was 2.08, and the iron content was around 10mg / L. Others are the same as in Example 1.

Embodiment 3

[0038] In step (b), set the operating voltage to 40V, adjust the influent flow rate to 6.3L / h, and electrolyze sulfuric acid waste liquids with iron ion concentrations of 100mg / L, 300mg / L, 500mg / L and 700mg / L respectively.

[0039] After the test, the highest iron recovery rate was 91.78%, the sulfuric acid recovery rate was above 99%, the lowest pH of the system effluent was 1.97, and the iron content was around 10mg / L. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com