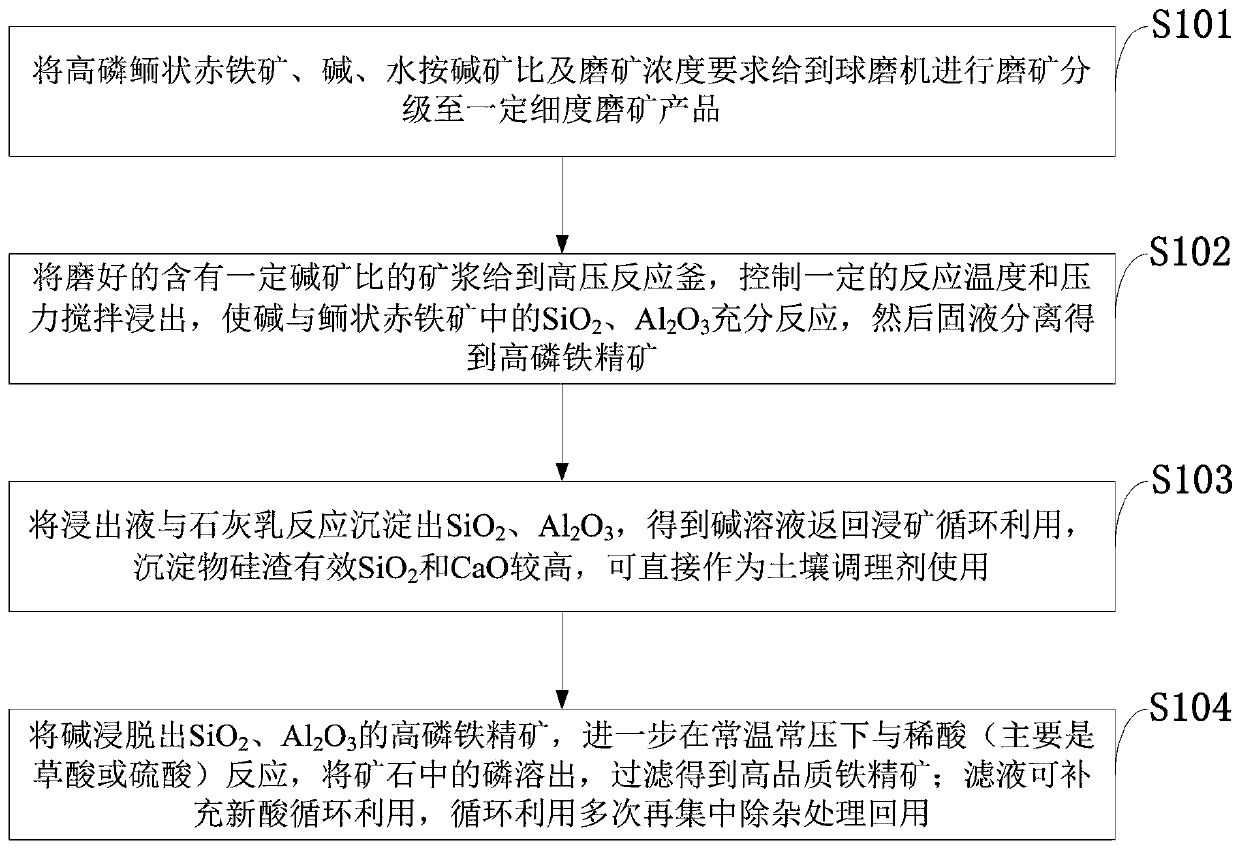

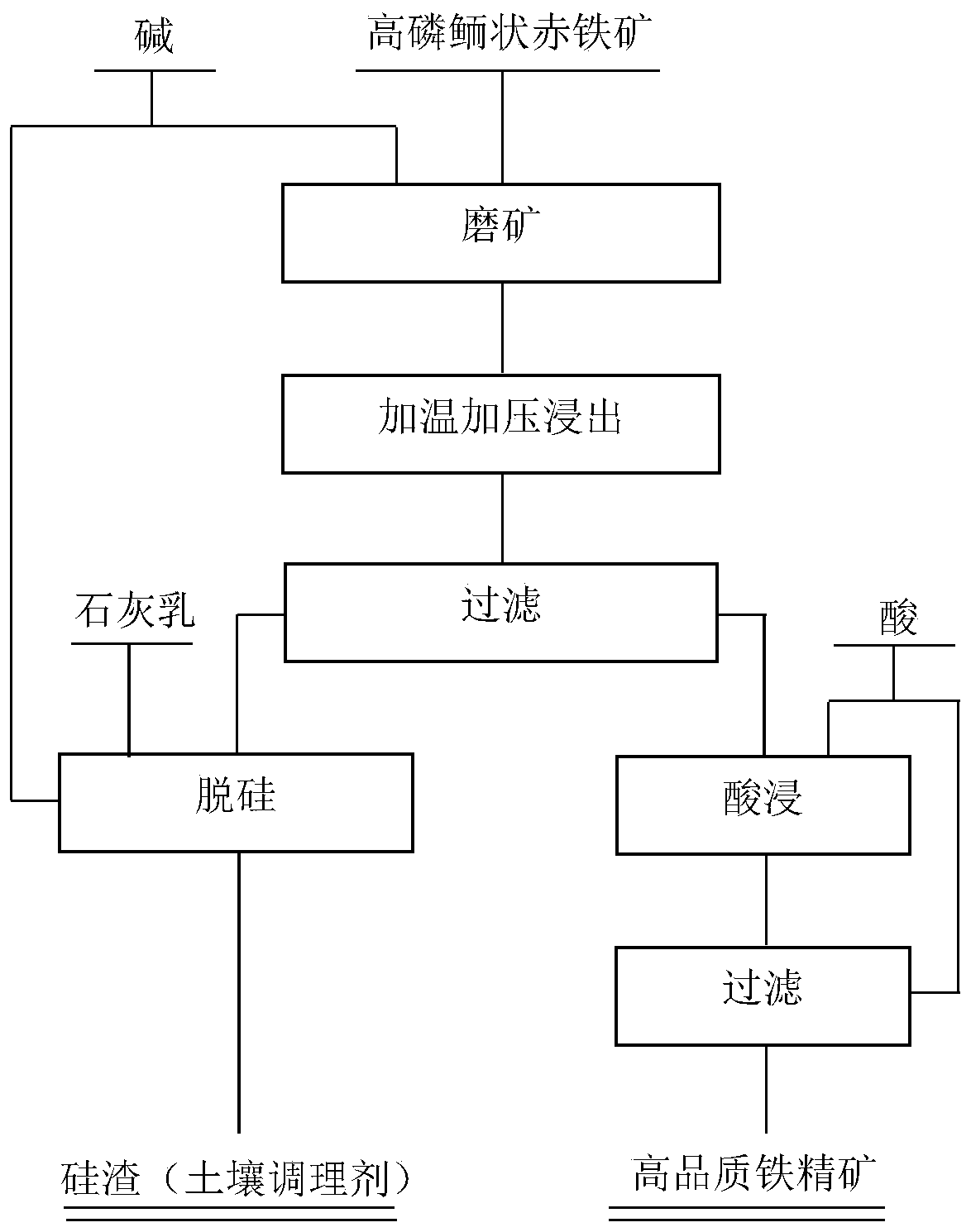

Method for preparing high-quality iron mineral concentrates from high phosphorus oolitic hematite through chemical impurity reduction

A technology of oolitic hematite and iron concentrate, applied in the field of mineral processing engineering, can solve the problems of difficult development and utilization, serious discharge pollution, etc., and achieve the effects of improving grade, high iron recovery rate, and changing microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A high-phosphorus oolitic hematite in Guizhou, with a grade of 39.52% iron and SiO 2 26.35%, containing Al 2 o 3 5.44%, containing 1.32% phosphorus, the ore is reddish-brown to brown-red, the main useful mineral red (brown) iron ore is 72.4%, oolitic structure, oolitic grains are ellipsoidal or oblate, oolitic grains are closely packed, and oolitic grains Between them are cemented by hematite and clay minerals; the gangue minerals are mainly quartz, dolomite and collophosite, the contents of which are 14.5%, 8% and 3.5% respectively. The alkali ore ratio is 1:3, the grinding concentration is 60%, and the ore is ground to -200 mesh 75%. Stir and leaching in the high-pressure reactor for 1 hour, the leaching temperature is 250°C, and the leaching pressure is 2MPa. After filtering, add lime to the filtrate milk SiO 2 、Al 2 o 3 The concentration is reduced to below 1g / l and circulated as a leaching agent, and the precipitated silicon slag is effectively SiO 2 And high...

Embodiment 2

[0044] The main iron mineral of high-phosphorus oolitic hematite in a certain place in Hubei is hematite, which has high content of harmful impurities phosphorus, silicon and aluminum, which is difficult to be effectively utilized. For this crude ore, the iron grade is 46.31%, and the phosphorus content is 1.25% high phosphorus oolitic hematite crude ore. The alkali-mineral ratio is 1:5, the grinding concentration is 80%, and the ore is ground to -200 mesh 80%, stirred and leached in a high-pressure reactor for 2 hours, the leaching temperature is 150°C, and the leaching pressure is 0.5MPa. Cool down and filter, and the filtrate SiO 2 Concentration and Al 2 o 3 The concentration is reduced to below 1g / l and circulated as a leaching agent, and the precipitated silicon slag is effectively SiO 2 And higher CaO, can be directly used as soil conditioner. After the filter residue was washed, it was stirred and leached with 3% sulfuric acid at normal temperature and pressure for ...

Embodiment 3

[0046] A high-phosphorus oolitic hematite in Yunnan, with a grade of 31.52% iron and SiO 2 10.96%, containing Al 2 o 3 4.93%, containing 0.87% phosphorus, the main useful element in the ore is iron, and the main harmful impurity is phosphorus. The alkali ore ratio is 1:2, the grinding concentration is 75%, and the ore is ground to -200 mesh 85%, stirred and leached in the high-pressure reactor for 0.5 hours, the leaching temperature is 300°C, the leaching pressure is 3MPa, the temperature is cooled and filtered, and the filtrate is added milk of lime SiO 2 Concentration and Al 2 o 3 The concentration is reduced to below 1g / l and circulated as leaching agent. Filter residue washing, precipitated silicon slag effective SiO 2 And higher CaO, can be directly used as soil conditioner. After washing, stir and leaching with 6% oxalic acid at normal temperature and pressure for 1 hour, filter and wash to obtain iron grade of 68.43%, containing SiO 2 1.05%, containing Al 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com