Rotary continuous microwave drier

A technology of microwave drying and microwave drying oven, which is applied in the direction of heating devices, drying, drying machines, etc., can solve the problems of reducing equipment operation safety, overheating, and poor exhaust capacity of equipment, so as to avoid water vapor accumulation, reduce Small environmental pollution, ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

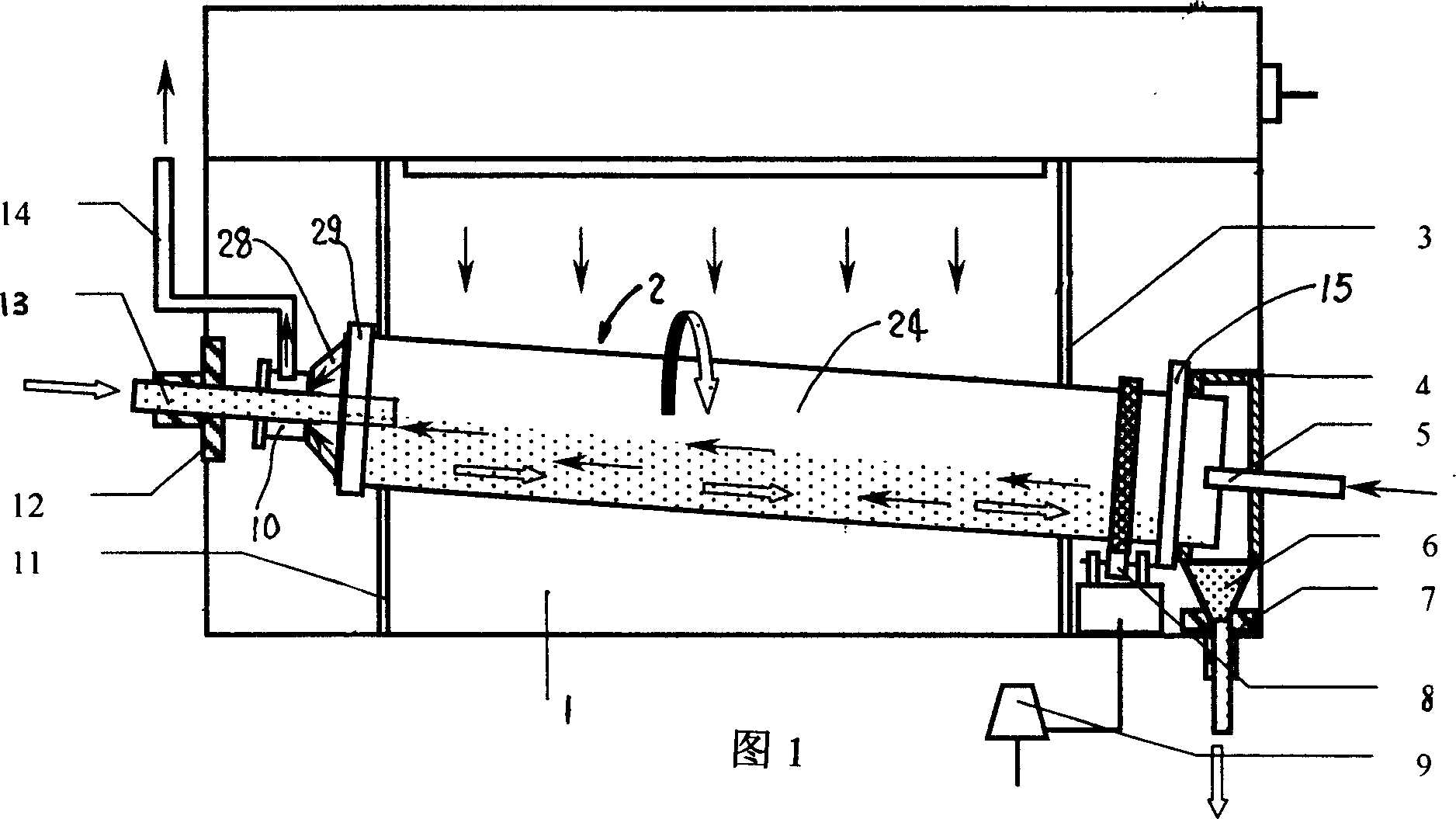

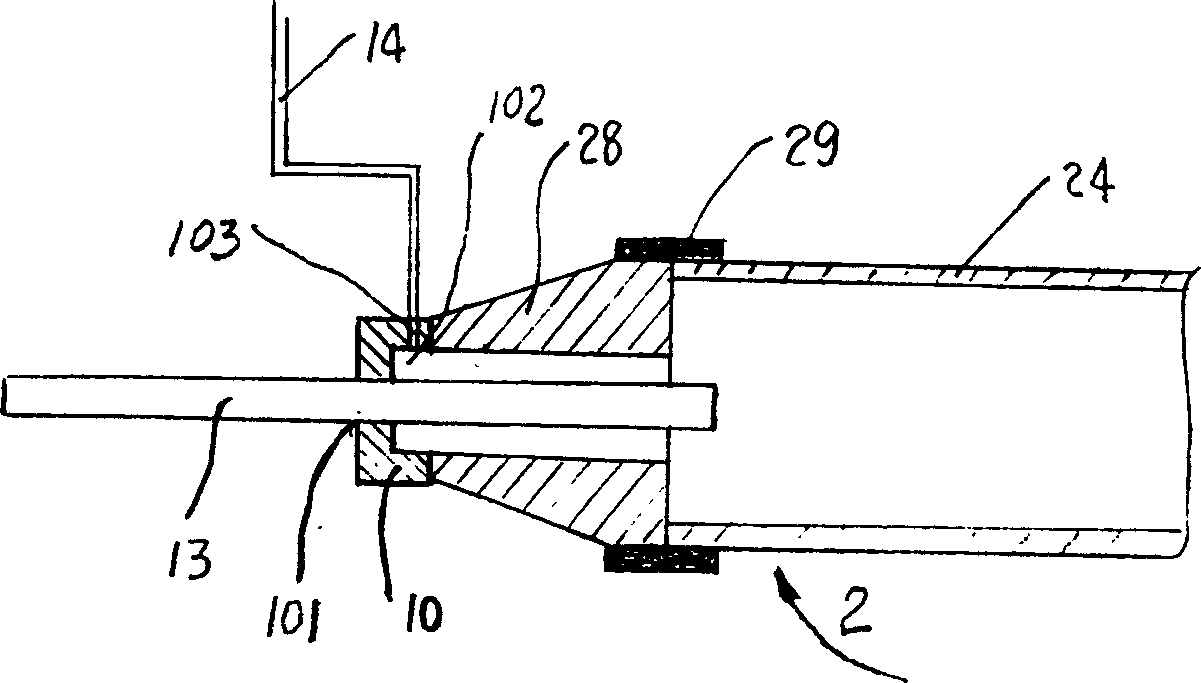

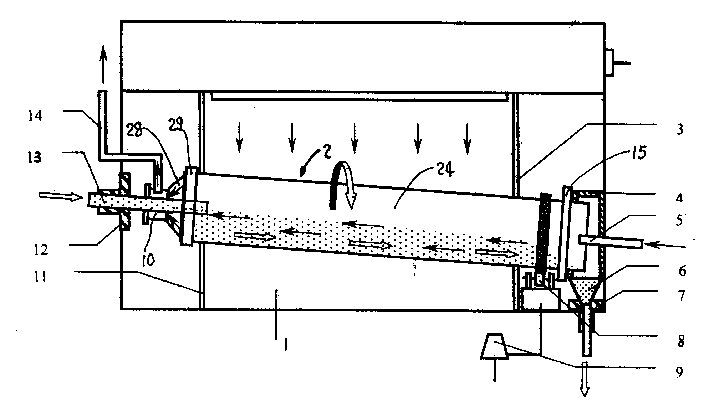

[0019]As can be seen from Fig. 1, the rotary continuous microwave drying device provided by the present invention includes a microwave drying furnace 1, and a layer of polytetrafluoroethylene is sprayed in the heating chamber of the microwave drying furnace 1, and the left and right sides of the heating chamber are Both sides are respectively provided with a left vertical baffle 11 and a right vertical baffle 3, the vertical baffles 11 and 3 are metal plates placed in parallel, the surface of which is sprayed with a layer of polytetrafluoroethylene, and the two vertical baffles 11 A rotatable rotary container 2 placed obliquely is supported between and 3. The high end of the rotary container 2 is provided with a feed pipe 13 and an air outlet pipe 14 protruding from the side wall of the microwave drying oven 1, and the low end of the rotary container 2 is provided with a microwave oven extending out. The outlet pipe 6 and the inlet pipe 5 of the side wall of the drying furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com