Steelmaking device and process for continuously preheating scrap steel

A scrap and process technology, which is applied in the field of steelmaking equipment for continuous preheating of scrap, can solve problems such as water leakage in shafts and finger valves, high scrap preheating temperature, and poor preheating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

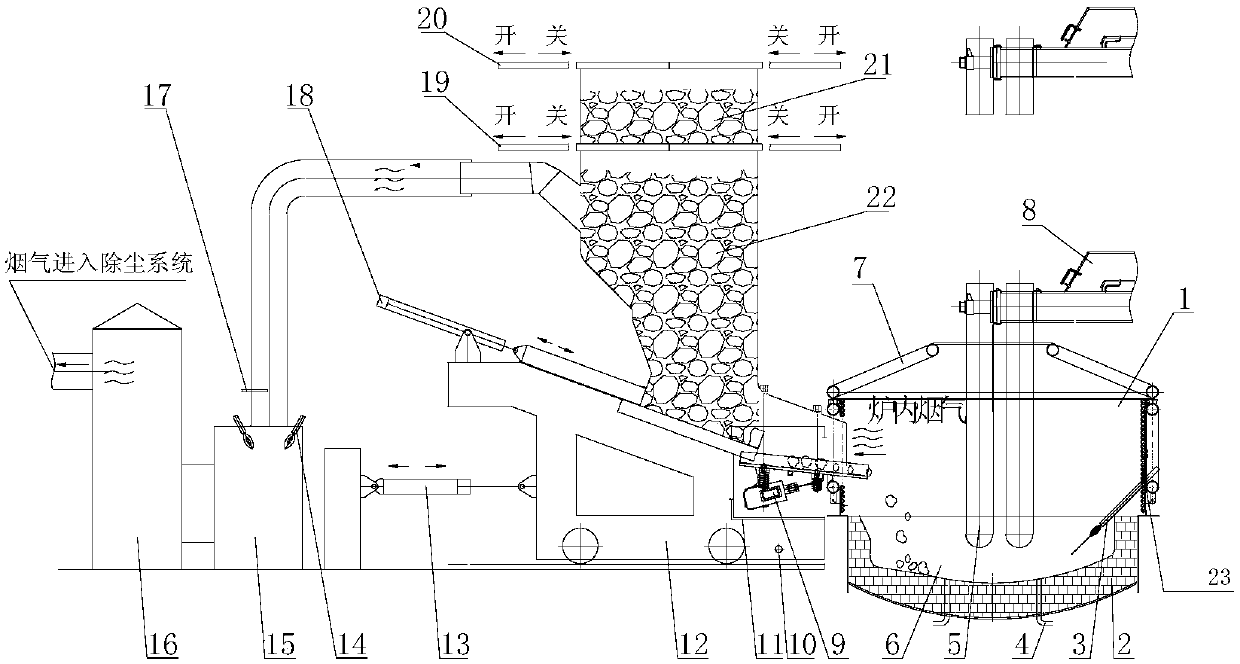

[0067] This embodiment provides a steelmaking device for continuously preheating steel scrap, and its structural schematic diagram is as follows figure 1 shown, from figure 1 As can be seen, the device includes:

[0068] Scrap steel shaft, the scrap steel shaft is divided into scrap steel charging shaft 21 and scrap steel preheating shaft 22 by the second shaft gate 19 arranged on its upper part, and the top of scrap steel charging shaft 21 is provided with the first shaft gate 20 in order to separate it seal;

[0069] The shaft base 12 is used to support the scrap steel shaft; the shaft base 12 is also provided with a locking device 10 for locking the shaft base 12;

[0070] Shaft mobile device 13, this shaft mobile device 13 is connected with shaft base 12, is used for pulling shaft base 12 so that scrap steel shaft is separated from furnace body 1 of electric arc furnace;

[0071] An electric arc furnace, the electric arc furnace includes a furnace cover 7 arranged up an...

Embodiment 2

[0084] This embodiment provides a steelmaking process for continuously preheating steel scrap, which is realized by using the steelmaking device for continuously preheating steel scrap provided in Example 1, wherein the steelmaking process for continuously preheating steel scrap includes the following Specific steps:

[0085] Step (1): Open the furnace lid for the first time to charge.

[0086] This step is mainly applicable to the first smelting of the new furnace lining, and is used to produce remaining steel in the furnace. When there is already remaining steel in the furnace, it starts from step (2). This step (1) specifically includes the following steps: first, the conductive cross arm is raised to lift the electrode into the furnace cover of the electric furnace, and the furnace cover and the electrode pass through the rotating mechanism ( figure 1 Unscrew together, use the scrap steel basket to add a certain amount of scrap steel (the amount that meets the requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com