Castoff processing method and system

A technology of treatment system and treatment method, applied in the field of waste treatment and waste treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

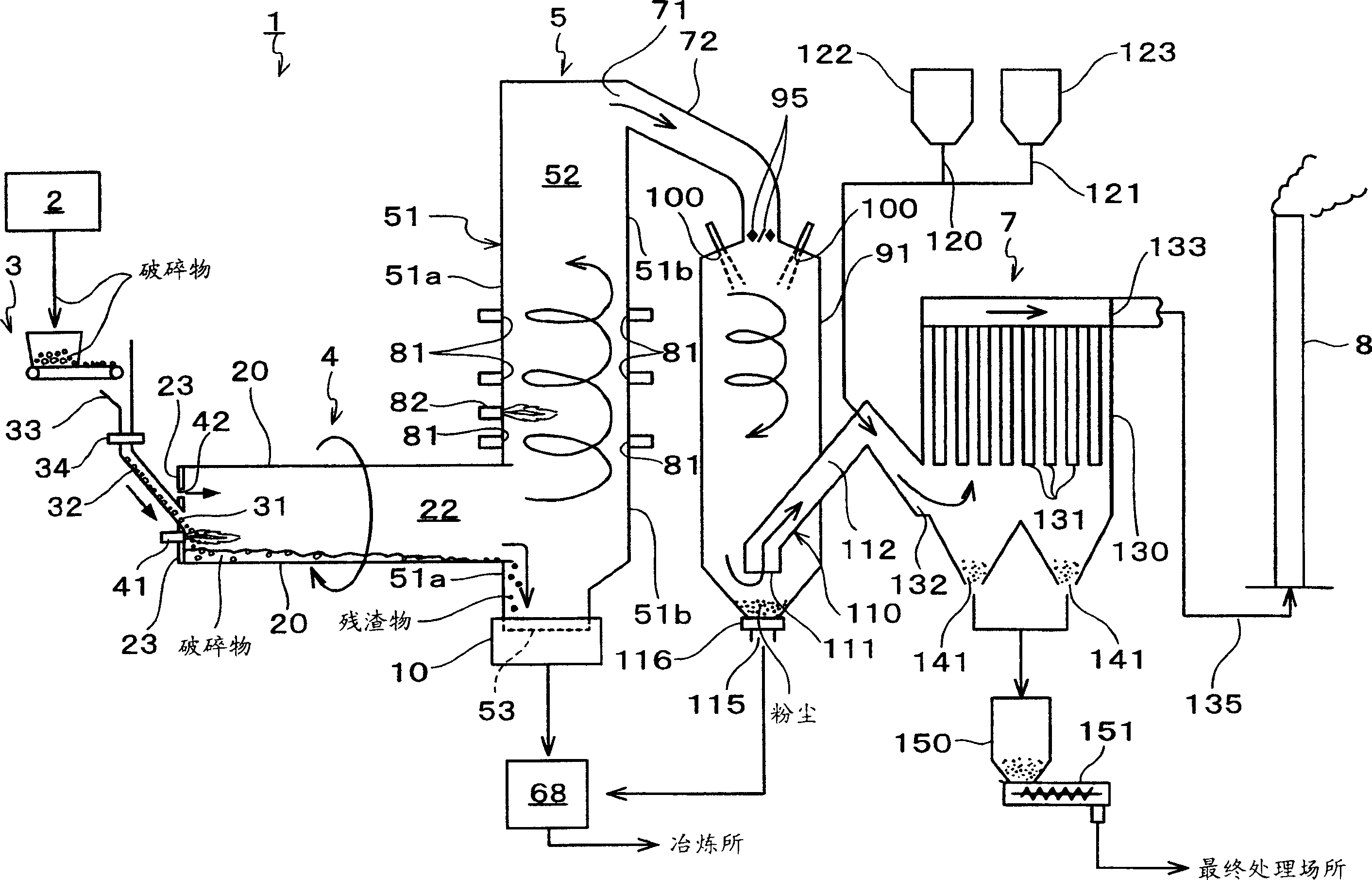

[0041] Hereinafter, preferred embodiments of the present invention will be described based on a waste disposal system for processing waste printed circuit boards. In the present invention, waste refers to waste printed circuit boards (including waste products and obsolete products), which have a structure in which valuable metals such as gold and copper are placed on a substrate obtained by coagulating glass fibers with resin. Printed circuit wiring, and further, capacitors or terminals using valuable metals such as gold, silver, copper, and platinum are mounted.

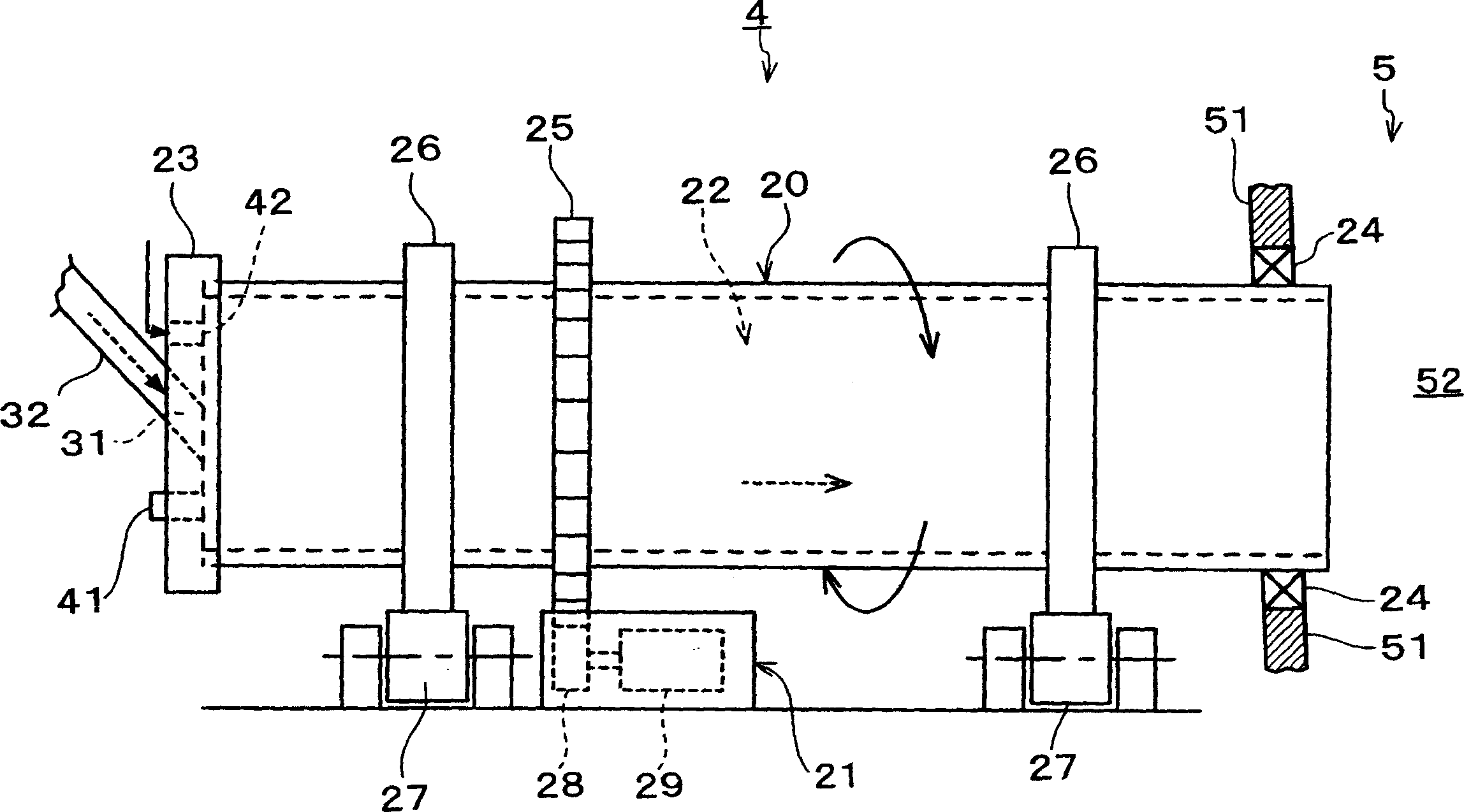

[0042] Such as figure 1 As shown, the waste treatment system 1 is equipped with a crushing device 2 for crushing waste printed circuit boards, a quantitative supply device 3 such as a belt feeder for quantitatively transporting the crushed materials crushed in the crushing device 2, and as a combustion crushed product. The rotary furnace device 4 which is an example of the primary combustion device, the secondary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com