Energy reclaiming process

a technology of energy reclaiming and process, applied in the field of gaseous sources, can solve the problem of low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

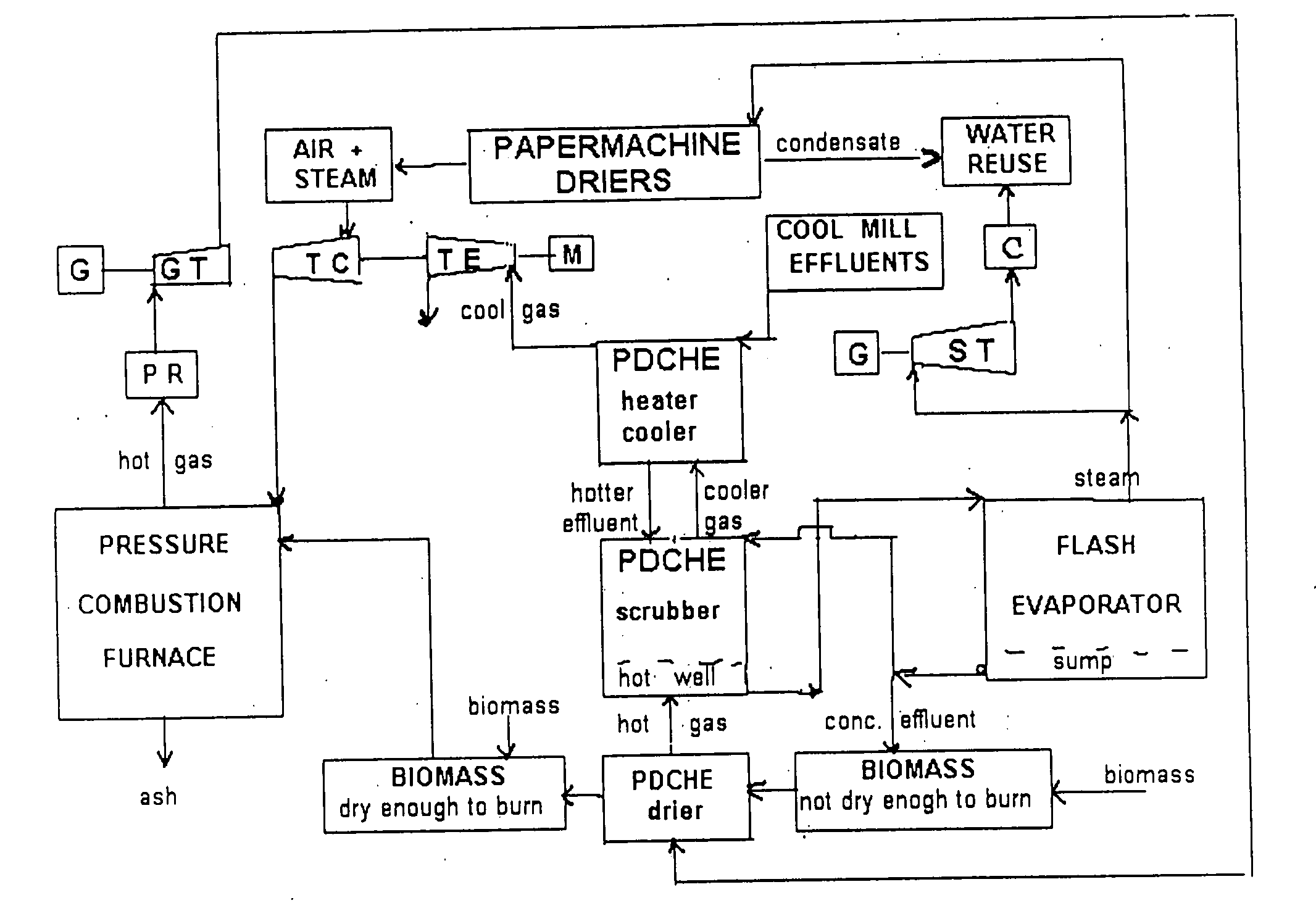

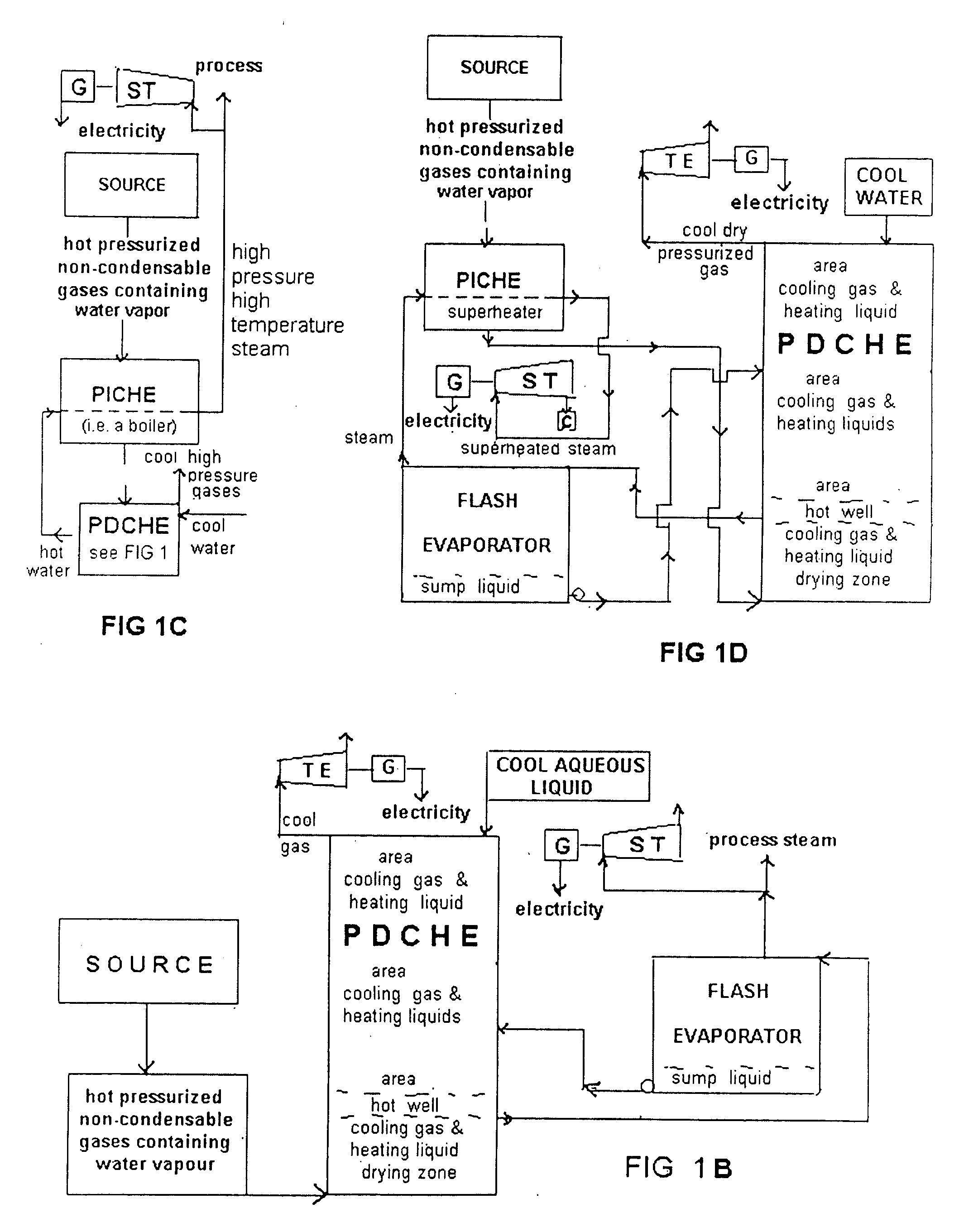

[0058] Combustion / incineration of materials that produce water vapor, e.g. wet combustibles. While some emphasis is on biomass fuels, the process could have application to the combustion of (a) solid / liquid fossils fuels; (b) fuels intermediate between the two i.e. lignite (brown coal), peat, etc, where the high moisture content is a deterrent to their use; (c) Diverse fuels, such as Tire Derived Fuel (TDF), and various sludges, etc. (2) Diverse processes such the smelting of ores; wet oxidation; chemical, electrochemical, metallurgical processes (blast furnaces), and intermediary operations such as: drying; stripping, extraction; boiling and the like.

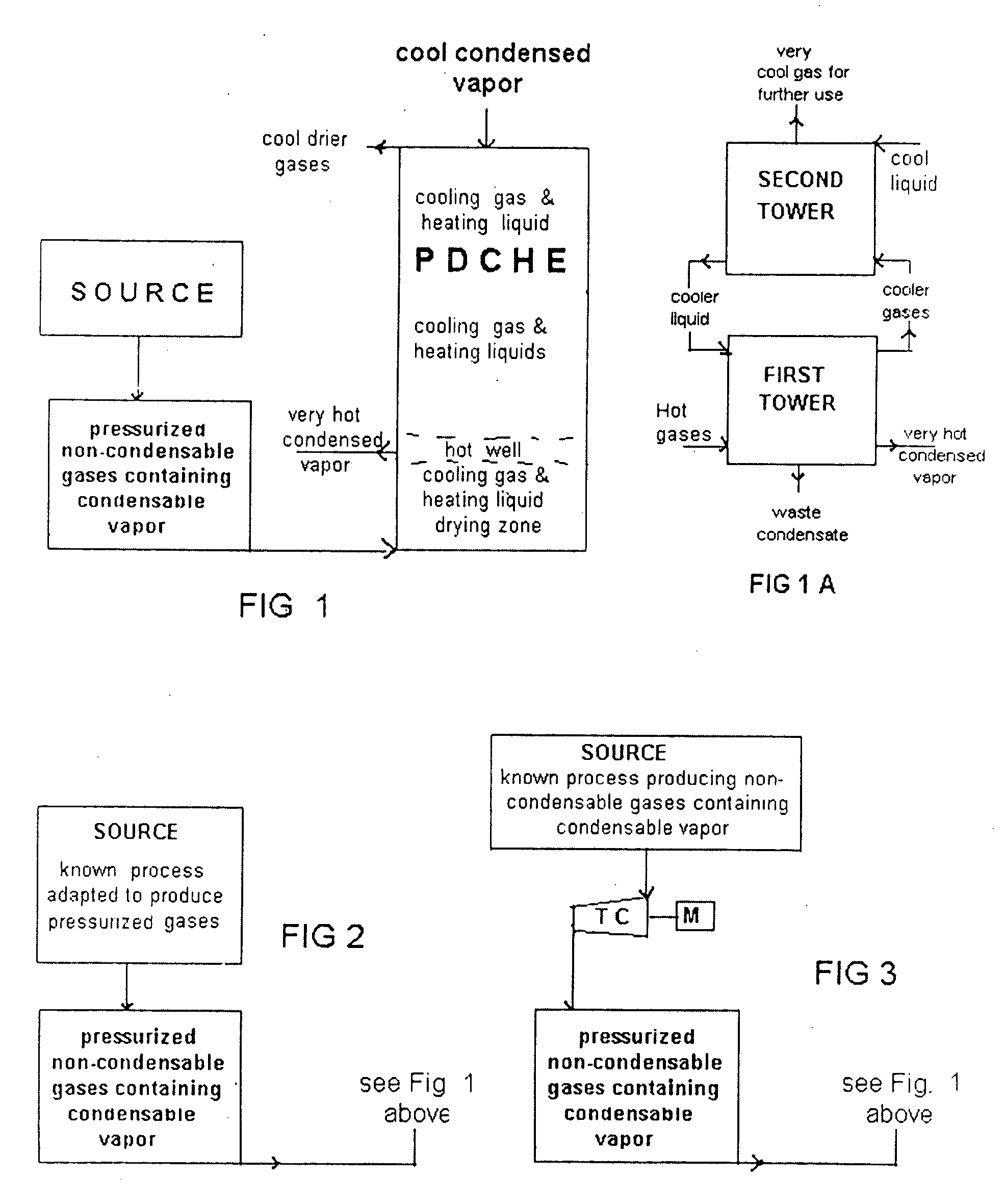

[0059] In FIG. 3, there is shown an arrangement wherein the increase in pressure of the source process cannot be carried out, then the gases from the source process are turbo-compressed to the desired pressure, with the temperature increased by the compression. For example in the drying of pulp or paper, enormous quantities of air and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com