Preparation method of highly visible light electron transfer g-C3N4/ Au/TiO2 Z type photocatalyst

An electron transfer and photocatalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high electron-hole recombination rate and weak visible light responsiveness, and achieve enhanced responsiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

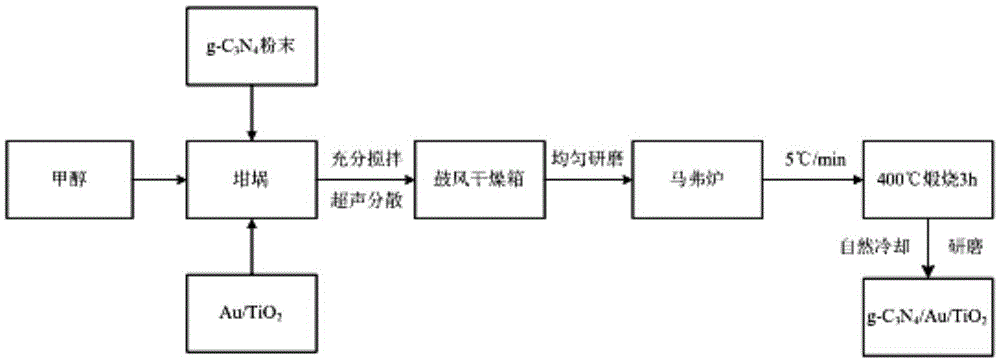

[0036] 1. Photocatalyst g-C 3 N 4 / Au / TiO 2 preparation of

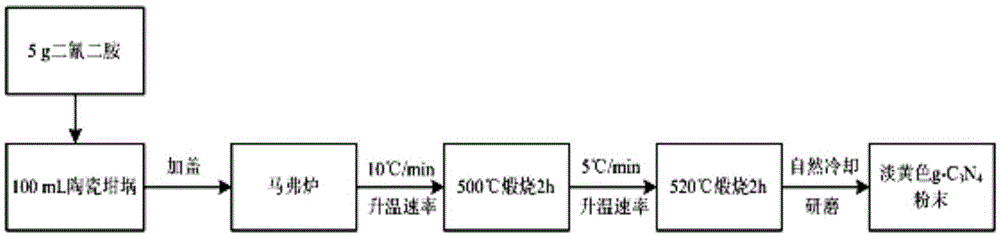

[0037] (1) g-C 3 N 4 Preparation: Precursor pyrolysis polymerization method is adopted. Weigh 5g of dicyandiamide into a covered crucible, first raise it from room temperature to 500°C at a rate of 10°C / min in the muffle furnace, and keep the temperature constant for 2 hours; then raise it to 520°C at a rate of 5°C / min ℃, constant temperature 2h (deammonization process). Allow the system to cool naturally afterwards, and obtain light yellow g-C after grinding 3 N 4 powder.

[0038] (2) Solution preparation: 1gAuCl 3 ·HCl·4H 2 O was dissolved in 100 mL deionized water to make 10 mg / mL AuCl 3 ·HCl·4H 2 O stock solution.

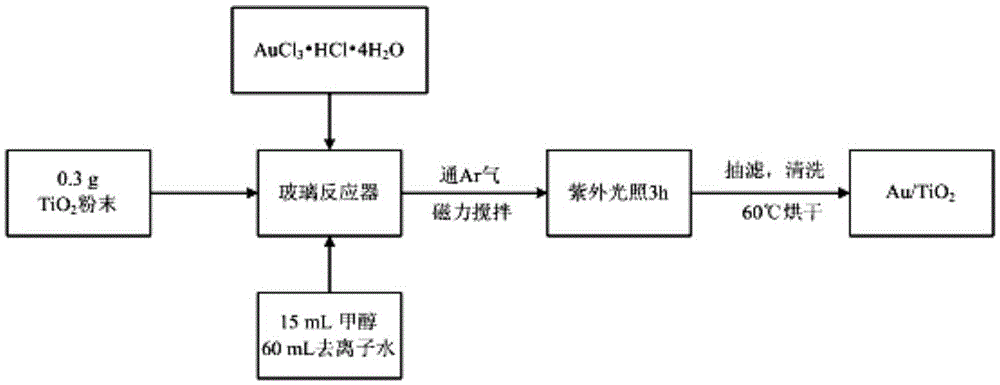

[0039] (3) Au / TiO 2 Preparation: using photoreduction deposition method. 0.3gTiO 2 Add 60mL deionized water and 15mL anhydrous methanol, add 10mg / mLAuCl 3 ·HCl·4H 2 O stock solution 628 μL, first make the Au by magnetic stirring for two hours in the dark 3+ with TiO 2 Full contact....

Embodiment 2

[0042] 1. Photocatalyst g-C 3 N 4 / Au / TiO 2 preparation of

[0043] (1) g-C 3 N 4 Preparation: Precursor pyrolysis polymerization method is adopted. Weigh 2g of dicyandiamide into a covered crucible, first raise it from room temperature to 500°C at a rate of 10°C / min in the muffle furnace, and keep the temperature constant for 2 hours; then raise it to 520°C at a rate of 5°C / min ℃, constant temperature 2h (deammonization process). Allow the system to cool naturally afterwards, and obtain light yellow g-C after grinding 3 N 4 powder.

[0044] (2) Solution preparation: 1gAuCl 3 ·HCl·4H 2 O was dissolved in 100 mL deionized water to make 10 mg / mL AuCl 3 ·HCl·4H 2 O stock solution.

[0045] (3) Au / TiO 2 Preparation: using photoreduction deposition method. 0.3gTiO 2 Add 60mL deionized water and 15mL anhydrous methanol, add 10mg / mLAuCl 3 ·HCl·4H 2 O stock solution 628 μL, first make the Au by magnetic stirring for two hours in the dark 3+ with TiO 2 Full contact....

Embodiment 3

[0048] 1. Photocatalyst g-C 3 N 4 / Au / TiO 2 preparation of

[0049] (1) g-C 3 N 4 Preparation: Precursor pyrolysis polymerization method is adopted. Weigh 4g of dicyandiamide into a covered crucible, first raise it from room temperature to 500°C at a rate of 10°C / min in the muffle furnace, and keep the temperature constant for 2 hours; then raise it to 520°C at a rate of 5°C / min ℃, constant temperature 2h (deammonization process). Allow the system to cool naturally afterwards, and obtain light yellow g-C after grinding 3 N 4 powder.

[0050] (2) Solution preparation: 1gAuCl 3 ·HCl·4H 2 O was dissolved in 100 mL deionized water to make 10 mg / mL AuCl 3 ·HCl·4H 2 O stock solution.

[0051] (3) Au / TiO 2 Preparation: using photoreduction deposition method. 0.3gTiO 2 Add 60mL deionized water and 15mL anhydrous methanol, add 10mg / mLAuCl 3 ·HCl·4H 2 O stock solution 628 μL, first make the Au by magnetic stirring for two hours in the dark 3+ with TiO 2 Full contact....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com