Anti-coking agent for delaying coking and preparation method of anti-coking agent

A technology of delayed coking and coke inhibitor, which is applied in cracking, non-catalytic thermal cracking, petroleum industry and other directions, can solve the problems of not fully satisfying the delayed coking unit, low coke scale inhibition rate of coke inhibitor, etc. The effect of inhibiting free radical chain reaction and reducing coke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A delayed coking retarder, comprising the following components in mass percentage: 25% pyrolysis activity accelerator, 35% free radical chain reaction inhibitor, 10% anti-scorch agent, 8% antioxidant, and the balance is solvent; After the free radical chain reaction inhibitor is mixed with the solvent, the thermal cracking activity accelerator, the anti-scorch agent and the antioxidant are added to the mixture, and then mixed.

[0026] Wherein, the thermal cracking activity promoter is propylene glycol block polyether with a molecular weight of 8000, the free radical chain reaction inhibitor is pentaerythritol polyoxypropylene ether, and the anti-scorch agent is N-cyclohexyl-2- Benzothiazole sulfenamide, the 2,6-di-tert-butyl-4-methylphenol, and the organic solvent are a mixed solvent of diesel oil and kerosene at a mass ratio of 1:1.

[0027] The delayed coking retarder prepared in this example is named as KC-1 retarder. KC-1 coking inhibitor is a dark oily liquid wit...

Embodiment 2

[0029] A delayed coking retarder, comprising the following components in mass percent: 23% pyrolysis activity accelerator, 32% free radical chain reaction inhibitor, 15% anti-scorch agent, 8% antioxidant, and the balance is solvent; After the free radical chain reaction inhibitor is mixed with the solvent, the thermal cracking activity accelerator, the anti-scorch agent and the antioxidant are added to the mixture, and then mixed.

[0030] Wherein, the thermal cracking activity promoter is propylene glycol block polyether with a molecular weight of 8000, the free radical chain reaction inhibitor is pentaerythritol glycidyl ether, and the anti-scorch agent is N-tert-butyl-2- Benzothiazole sulfenamide and N-cyclohexyl-2-benzothiazole sulfenamide are mixed in a mass ratio of 1:1, the 2,6-di-tert-butyl-4-methylphenol, the organic The solvent is a mixed solvent of diesel oil and kerosene with a mass ratio of 1:1.

[0031] The delayed coking retarder prepared in this example is nam...

Embodiment 3

[0033] The coking retarding effect of the delayed coking retarder of the present invention will be illustrated through experiments below, and an empty package test group is set up to compare with the SB-19 coking retarder commonly used in China. The experiment was carried out according to HG / T2159-1991 "Determination of Corrosion Inhibition Performance of Corrosion Inhibitors by Coupon Method"; the removal of the test piece after the test was carried out according to GB / T16545-1996 "Corrosion of Metals and Alloys, Removal of Corrosion Products on Corrosion Samples" "conduct.

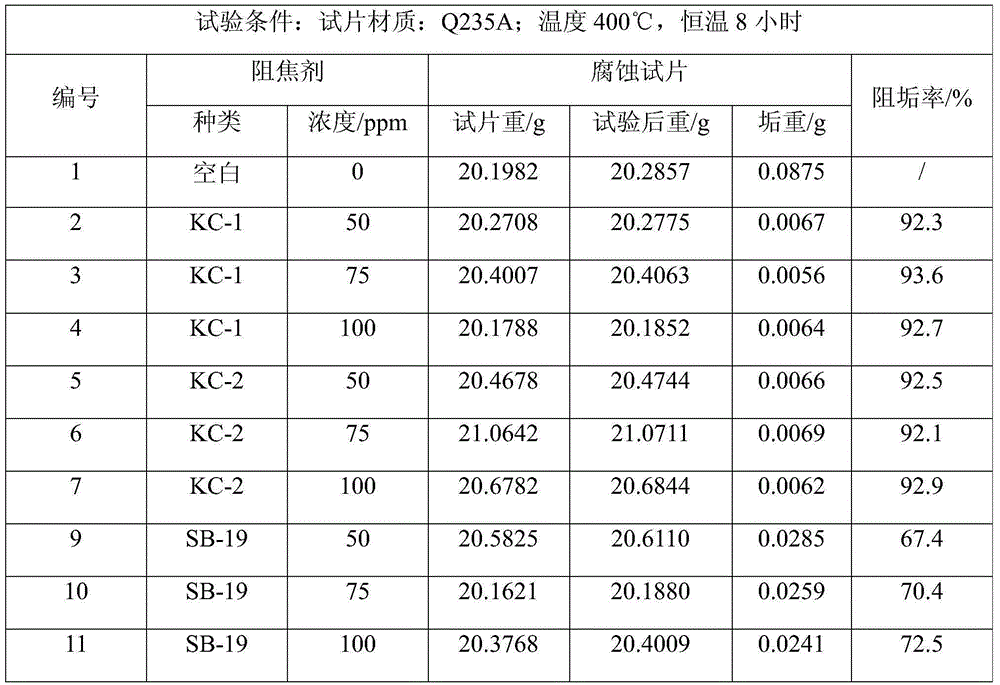

[0034] Table 2 coke retarder test

[0035]

[0036] It can be seen from Table 2 that KC-1 and KC-2 coking inhibitors all show high scale inhibition rate in the concentration range of 50-100ppm, and the scale inhibition rate is above 92%. Its scale inhibition rate is also higher than that of SB-19 coking inhibitor with the same concentration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com