Method and device for controlling conical twin-screw extruder

A twin-screw extruder and twin-screw extrusion technology, applied in the field of plastic processing, can solve the problems of sudden change of material specific gravity screw torque, screw breakage, uneven thickness of pipe products, etc., and achieve the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

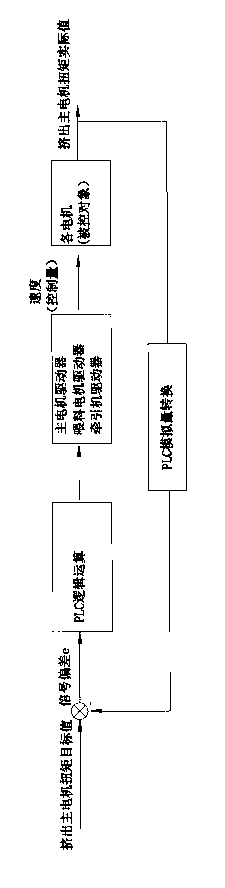

[0026] In the present invention, a low-cost temperature control meter is used to control the temperature of the heating zone, and a conventional electrical circuit is used to control the start and stop of the extruder main engine, the feeding motor and the traction motor, but the motor speed is controlled by a small programmable logic controller integrated machine. Take control. This can not only achieve good control effect, but also lower cost, and it is easier to promote in the industry.

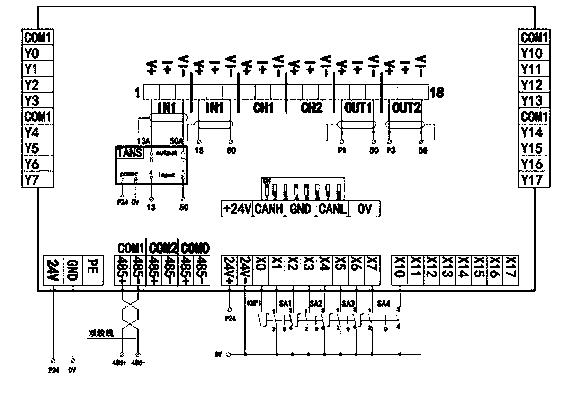

[0027] refer to figure 2 As shown, the main motor startup, synchronous acceleration, synchronous deceleration, main motor acceleration, main motor deceleration, feeding motor acceleration, feeding motor deceleration, traction motor acceleration are respectively connected to pins X0-X7, and the traction motor deceleration is connected to pin X10 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com