Lithium-sulfur battery positive electrode and preparation method thereof

A lithium-sulfur battery and positive electrode technology, applied in the field of lithium-sulfur battery positive electrode and its preparation, can solve the problems of high resistivity of active material sulfur, reduction of electrode active material, complex interlayer manufacturing process, etc., so as to increase the total sulfur content and use The effect of less material and easy control of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

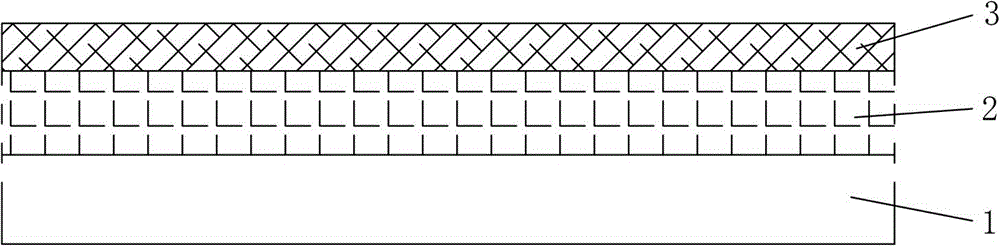

[0026] Disperse elemental sulfur, conductive carbon black and polyvinylidene fluoride in N-methylpyrrolidone (NMP) at a mass ratio of 7:2:1, and after sufficient mechanical stirring, scrape-coat it on the aluminum foil current collector 1 , and vacuum-dried at a temperature of 60° C. for 24 hours to prepare a positive electrode substrate with an active material layer 2 .

[0027] Disperse conductive carbon black and polyvinylidene fluoride in N-methylpyrrolidone (NMP) at a mass ratio of 8:2, use mechanical stirring to mix evenly to obtain a conductive paste, and gently brush the conductive paste on the surface with a brush. A protective layer 3 is formed on the positive electrode substrate with an active material layer 2, and after vacuum drying at a temperature of 60° C., a lithium-sulfur battery positive electrode is obtained, and its structure is as follows: figure 1 As shown, the thickness of the protective layer 3 is 35 μm. Then press it into an electrode sheet with a di...

Embodiment 2

[0030] Mix elemental sulfur, conductive carbon black, and polyvinyl alcohol evenly in a mass ratio of 6:3:1, and after sufficient mechanical stirring, scrape-coat it on the aluminum foil current collector 1, and dry it in vacuum at 70°C for 24 hours , to prepare a positive electrode substrate with an active material layer 2 .

[0031]Disperse conductive carbon black and polyvinylidene fluoride in N-methylpyrrolidone (NMP) at a mass ratio of 7:3, grind them by hand until uniformly mixed to obtain a protective layer slurry, and gently scrape the protective layer slurry A protective layer 3 is formed on the positive electrode substrate with an active material layer 2, and after vacuum drying at a temperature of 80°C, a lithium-sulfur battery positive electrode is obtained, wherein the thickness of the protective layer 3 is 20 μm, and then pressed into an electrode sheet with a diameter of 10 mm .

[0032] With the electrode sheet prepared above as the positive electrode and the ...

Embodiment 3

[0034] Disperse the carbon nanotube-sulfur composite material, conductive carbon black and polyacrylic acid in water at a mass ratio of 8:1:1, grind them by hand until they are evenly mixed, and scrape-coat them on the aluminum foil current collector 1. vacuum drying at high temperature for 24 hours to prepare a positive electrode substrate with an active material layer 2 .

[0035] Disperse carbon nanotubes and polyvinylidene fluoride in N-methylpyrrolidone (NMP) at a mass ratio of 6:4, grind them manually until uniformly mixed to obtain a protective layer slurry, and spray the protective layer slurry Gently spray the material on the positive electrode substrate with the active material layer 2 to form a protective layer 3, and after vacuum drying at a temperature of 50°C, a lithium-sulfur battery positive electrode is obtained, wherein the thickness of the protective layer 3 is 15 μm, and then pressed into a diameter of 10mm electrode pads.

[0036] With the electrode sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com