Processing method for castoff of food and drink

A catering waste and treatment method technology, applied in the field of catering waste treatment, can solve the problems of waste oil and residue clogging sewers, polluting the environment, etc., and achieve the effects of protecting the environment, improving economic benefits, and being suitable for large-scale treatment and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

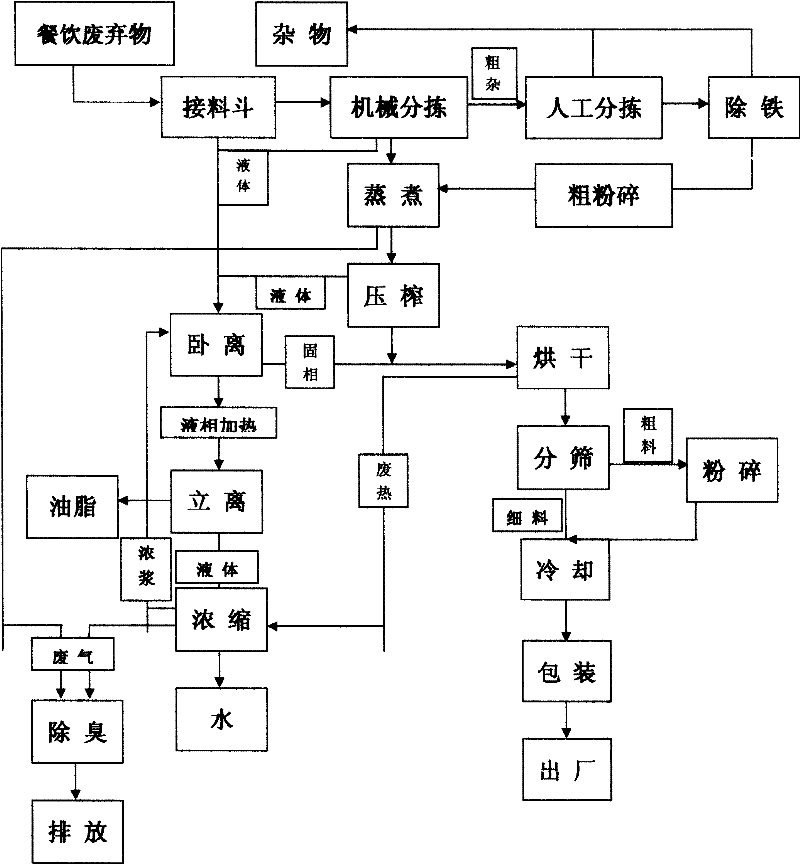

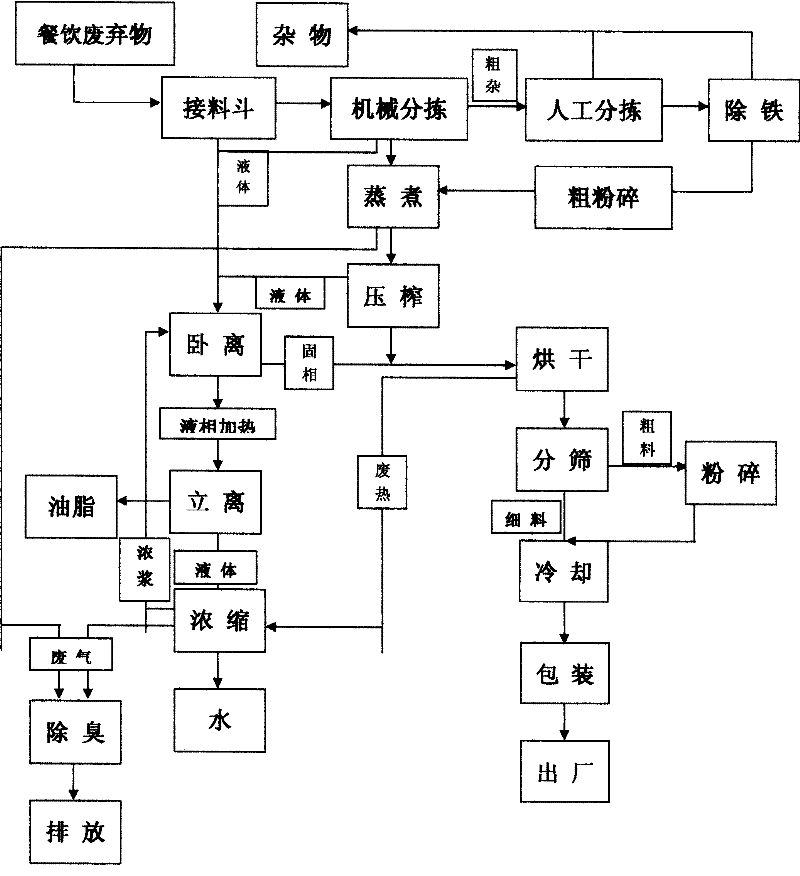

[0022] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0023] A method for treating catering waste, the basic steps of which are as follows:

[0024] (1) Sorting step, first collect catering waste, then pick up and stack, store catering waste through the storage hopper, which is convenient for stacking and use, collect a batch of catering waste, and first carry out mechanical processing on the sorting machine Sorting, separating objects with a diameter of less than 25 mm and sending them directly to the cooking step; objects with a diameter greater than 25 mm are manually sorted through a belt conveyor, and then iron is removed by a magnet, including plastics, metals, glass, and ceramics. , Wood can not be used as feed debris, and then the available materials with a diameter greater than 25 mm are coarsely pulverized with a coarse pulverizer, and pulverized into particles with a diameter of less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com