Battery negative electrode material and preparation method thereof

A battery negative electrode, quinoline technology, applied in the field of preparing carbonaceous battery negative electrode materials, can solve problems such as endangering the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

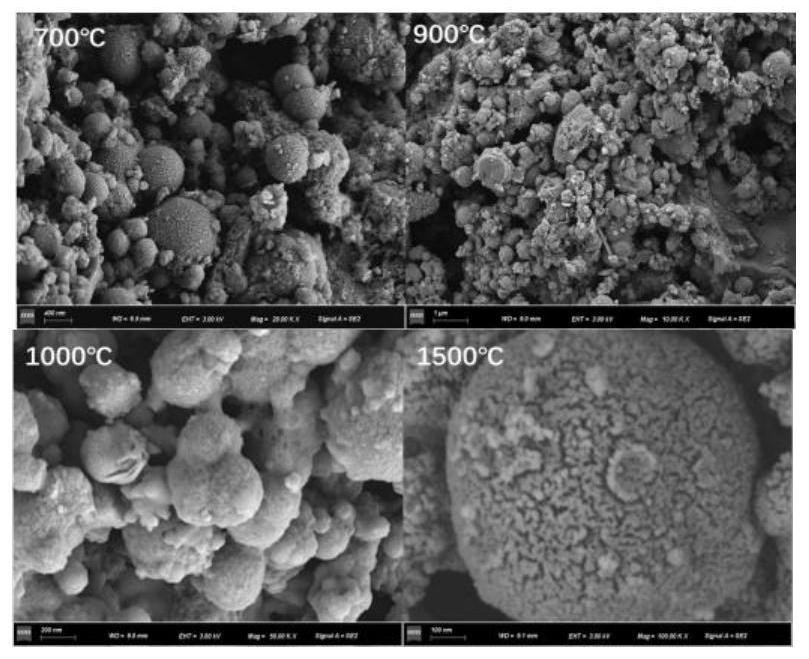

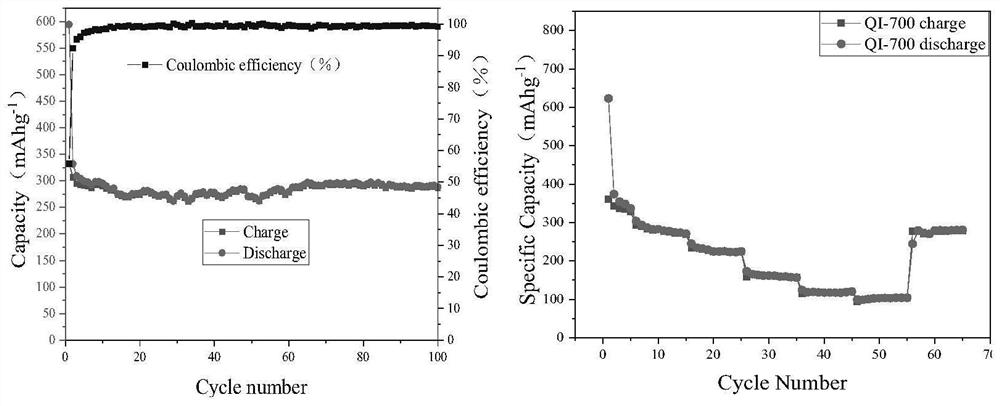

Embodiment 1

[0051] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent with a ratio of 0.4 to aromatic resin (that is, the mass ratio of solvent to coal tar pitch is 2:1) into the reactor, and pressurize to 1.0Mpa after purging with nitrogen After raising the temperature to 130°C, stir mechanically for 1 hour, maintain the temperature and pressure and let it settle for 4 hours, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0052] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to ultrasonically disperse under heating conditions, after fully dispersed, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0053] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0054] d) The washed solid is ...

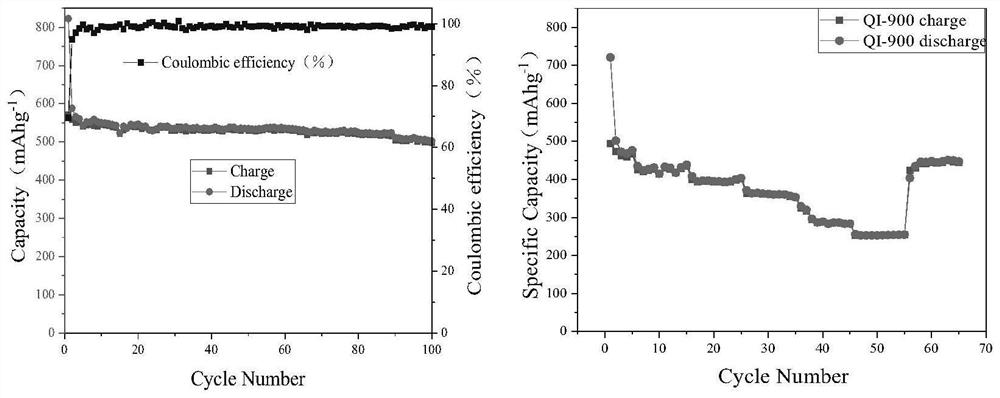

Embodiment 2

[0059] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent with a ratio of 0.4 to aromatic resin (that is, the mass ratio of solvent to coal tar pitch is 2:1) into the reactor, and pressurize to 1.0Mpa after purging with nitrogen After raising the temperature to 130°C, stir mechanically for 1 hour, maintain the temperature and pressure and let it settle for 4 hours, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0060] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to ultrasonically disperse under heating conditions, after fully dispersed, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0061] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0062] d) placing the washed s...

Embodiment 3

[0067] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent with a ratio of 0.4 to aromatic resin (that is, the mass ratio of solvent to coal tar pitch is 2:1) into the reactor, and pressurize to 1.0Mpa after purging with nitrogen After raising the temperature to 130°C, stir mechanically for 1 hour, maintain the temperature and pressure and let it settle for 4 hours, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0068] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to ultrasonically disperse under heating conditions, after fully dispersed, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0069] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0070] d) placing the washed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com