ITO coating film target material and preparation method thereof

A target and wet technology, which is applied in the field of ITO coating target and its preparation, can solve the problems of poor uniformity of indium tin oxide, high requirements for production equipment, and difficulty in industrial production, and achieve safe function, good adhesion, and preparation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

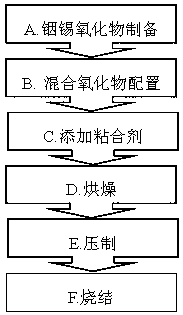

[0025] see figure 1 Shown, preparation method of the present invention, as following steps:

[0026] A. Preparation of Indium Tin Oxide

[0027] The ITO target is mainly made of indium oxide (In 2 o 3 ) and tin oxide (SnO 2 ) composed of nanometer metal oxides, has good electrical conductivity, transparency, heat insulation, UV protection and other properties, and In can be adjusted according to different uses 2 o 3 and SnO 2 The proportion of ITO targets with different characteristics can be obtained. Regular products are In 2 o 3 :SnO 2 =9:1. In the oxide conductive film, the In doped with Sn 2 o 3 (ITO) film has the highest light transmittance and good electrical conductivity, and it is easy to etch fine patterns in acid solution, of which the light transmittance is over 90%. In ITO, its light transmittance and resistance can be determined by In 2 o 3 with SnO 2 ratio to control.

[0028] The steps of the method adopted in this embodiment are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com