A paddy rice production process for digesting pesticide residues

A technology of pesticide residues and production process, which is applied in agriculture, grain processing, food preparation, etc., can solve the problems of excessive pesticide residues, achieve the effects of low production cost, scientific process design, and effective elimination of pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

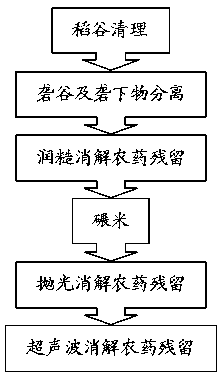

[0024] As shown in the attached figure, this embodiment is a paddy rice production process for digesting pesticide residues, including paddy cleaning, separation of husked rice and husked matter, roughening and digestion of pesticide residues, rice milling, polishing and digestion of pesticide residues, and ultrasonic digestion of pesticides Residue and other processes, the specific process steps are as follows;

[0025] A. paddy cleaning

[0026] Use winnowing and screening equipment, adopt the method of "combining wind (selection) and screening (selection), and focus on screening (selection)" to clean up rice, and can combine specific gravity stone remover and magnetic separation equipment to remove side stones, etc. Sand and metal debris, so that the total amount of impurities in the clean grain should not exceed 0.6%, and the number of sand and stone grains should not exceed 1 grain / kg, and the number of barnyard grains should not exceed 110 grains / kg. The rice that has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com