A kind of feed oil adding method

A technology of oil and feed, which is applied in the direction of feed, non-electric variable control, and simultaneous control of multiple variables. It can solve the problems of fault protection system, uneven feed mixing, and low adding precision, and achieve real-time effective oil temperature, The effect of controlling the temperature of grease and ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

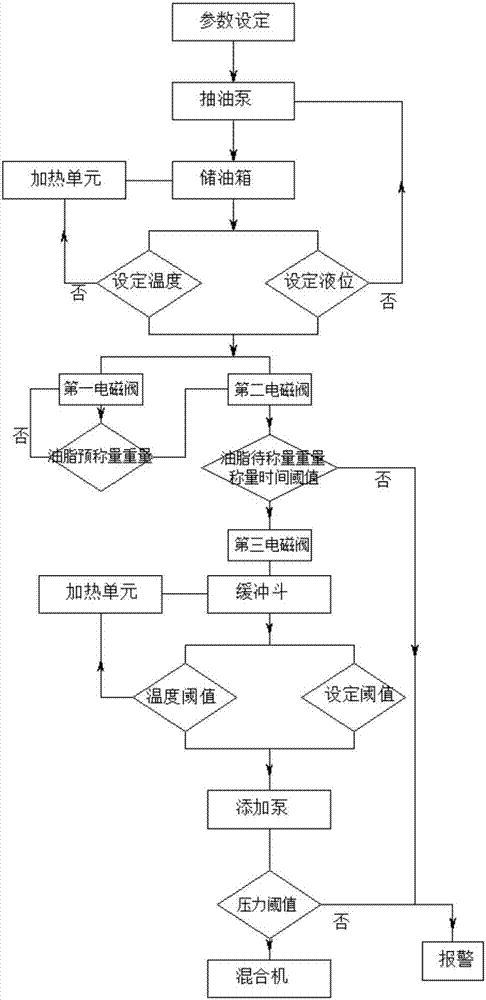

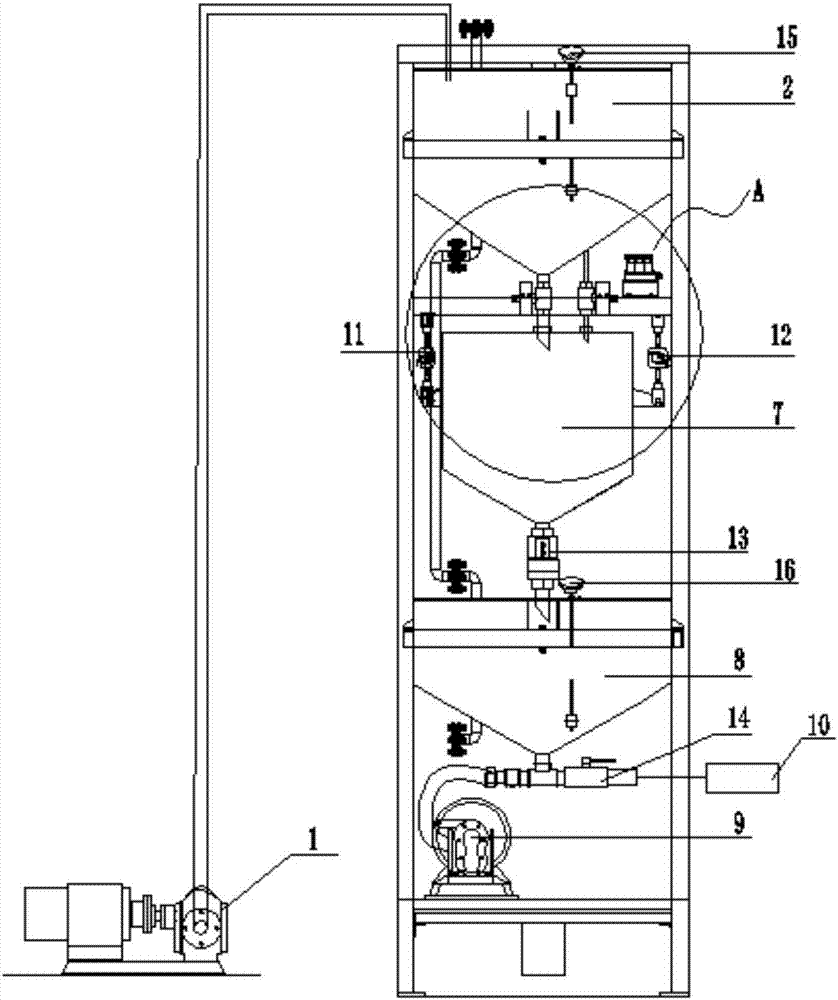

[0018] The method for adding feed oil involved in the present embodiment is implemented in a high-precision feed oil adding device, which includes the following steps:

[0019] (1) Parameter setting: according to the actual needs, first set the process parameters in the external control center: temperature threshold, liquid level threshold, grease pre-weighed weight, grease to be weighed weight, weighing time threshold and pressure threshold;

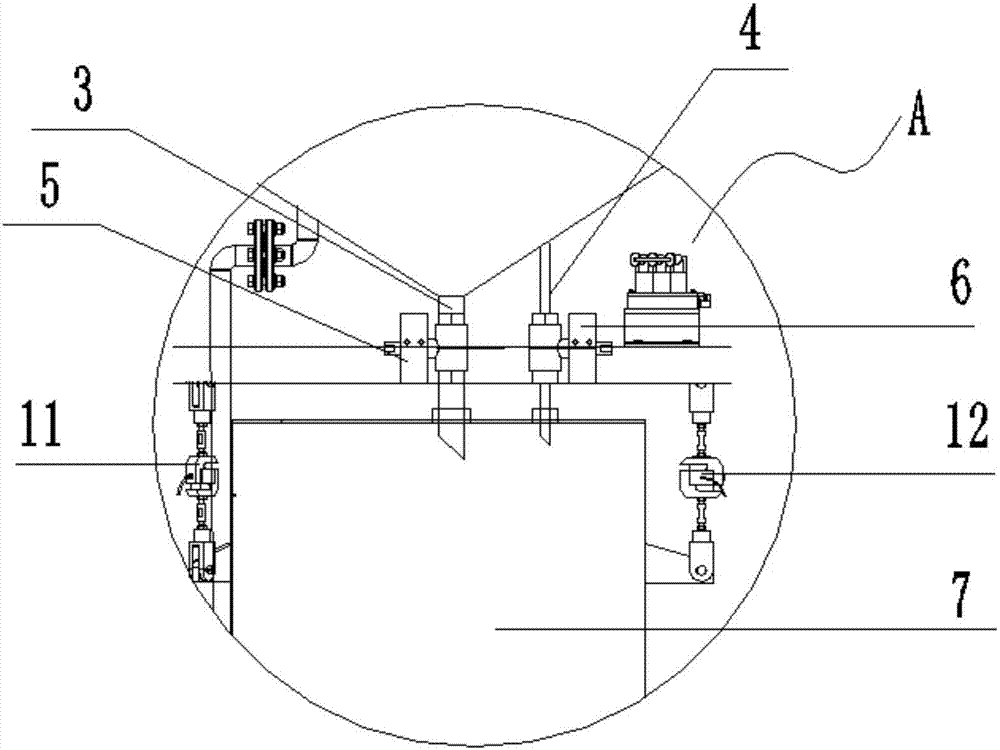

[0020] (2) Grease feeding: transport the grease to the oil storage tank 2, and realize the feeding method of fast adding grease first and then slowly adding grease by setting and controlling the opening and closing of the thick oil drain pipe 3 and the thin oil drain pipe 4. A solenoid valve 5 and a second solenoid valve 6 are used for the thick oil drain pipe 3 and the thin oil drain pipe 4 to add grease at the same time. When the weighing weight of the valve 5 and the weighing bucket 7 reaches the set grease to be weighed, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com