Process for improving germanium recovery rate of electro-zinc system

A recovery rate and electro-zinc technology is applied in the technical field of improving germanium recovery rate of electro-zinc system, which can solve the problems of high production cost, low direct yield, large consumption of zinc powder, etc. effect of science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of technique that improves the recovery rate of germanium of electric zinc system, comprises the following steps:

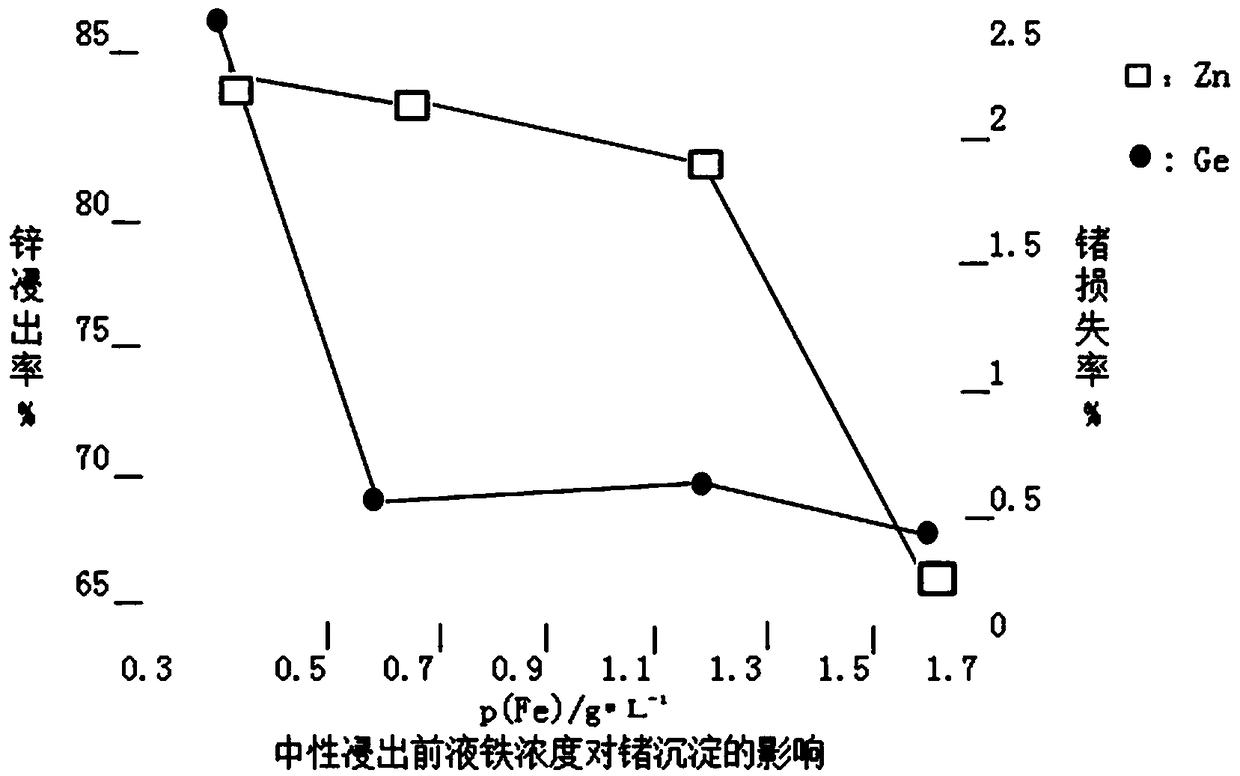

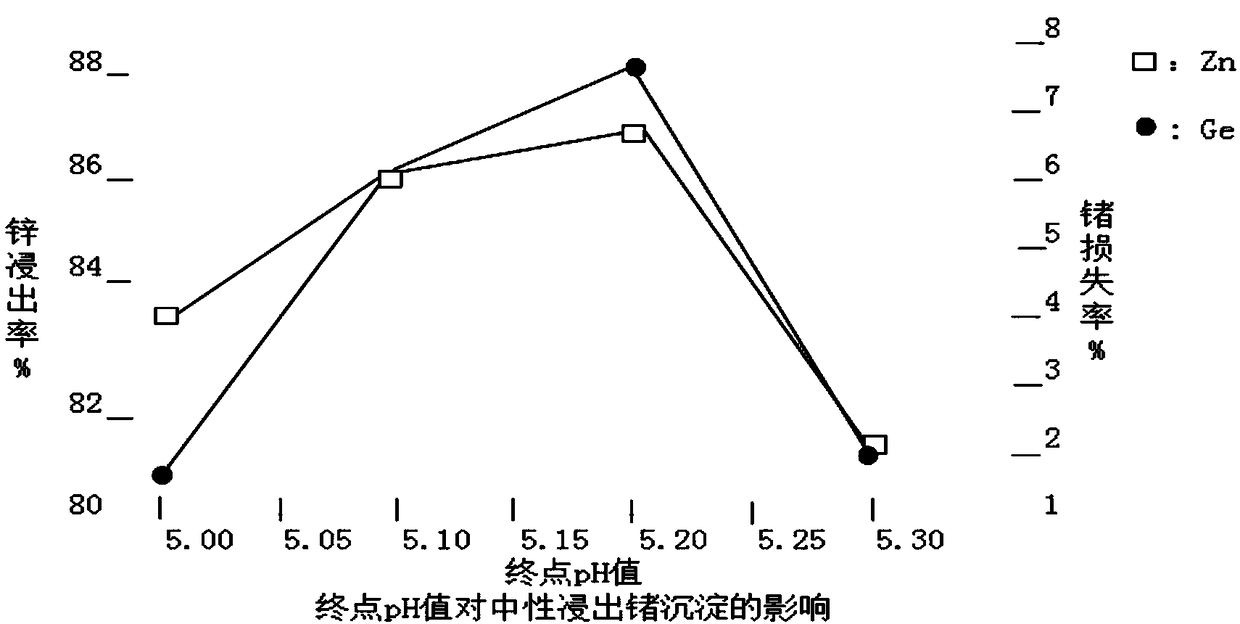

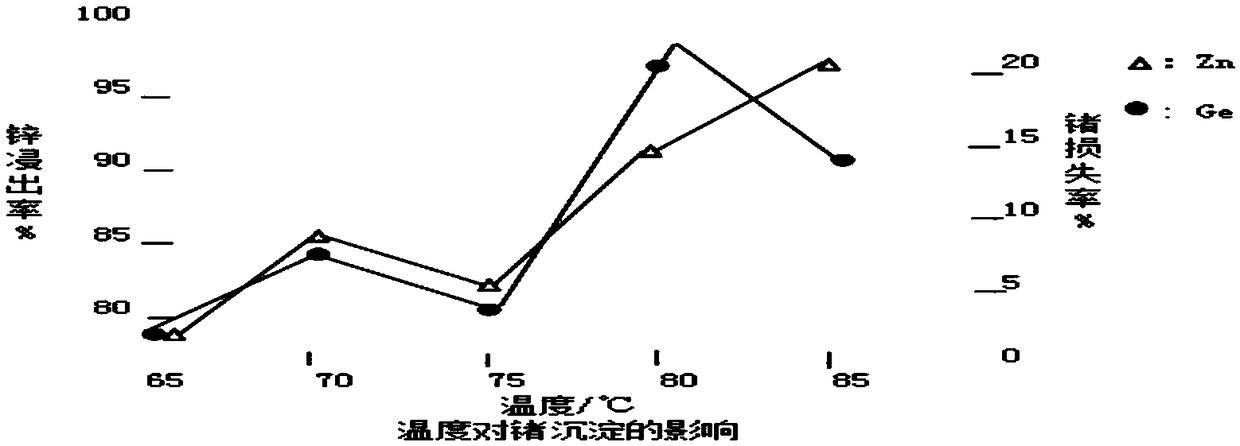

[0030] (1) In the rotary kiln, feed sand coal and zinc leached slag according to the mass ratio of 11:89, and carry out rotary treatment to obtain germanium-containing zinc oxide smoke; (2) control the iron content in the germanium-containing zinc oxide smoke to be 0.5g / L, germanium-containing zinc oxide smoke dust is under the condition of 85 ℃, and the control end point pH is 5.3, carries out neutral leaching 3h, obtains leachate; Add iron powder to the mixture, and filter to obtain high-germanium slag; (4) low-leach high-germanium slag to obtain low-leaching solution; (5) carry out germanium-precipitation with tannic acid at pH 2.4 and 55°C for 30 minutes to obtain Crude tannin germanium; the mass ratio of germanium content to tannic acid in the low leaching solution is 1:25; (6) the crude tannin germanium is wash...

Embodiment 2

[0032] The present embodiment provides a kind of technique that improves the recovery rate of germanium of electric zinc system, comprises the following steps:

[0033] (1) In the rotary kiln, feed sand coal and zinc leached slag according to the mass ratio of 15:85, and carry out rotary treatment to obtain germanium-containing zinc oxide smoke; (2) control the iron content in the germanium-containing zinc oxide smoke to be 0.5g / L, germanium-containing zinc oxide smoke dust is under the condition of 85 ℃, and the control end point pH is 5.3, carries out neutral leaching 3h, obtains leachate; Add iron powder to the mixture, and filter to obtain high-germanium slag; (4) low-leach high-germanium slag to obtain low-leaching solution; (5) carry out germanium-precipitation with tannic acid at pH 2.4 and 55°C for 30 minutes to obtain Crude tannin germanium; the mass ratio of germanium content to tannic acid in the low leaching solution is 1:25; (6) the crude tannin germanium is wash...

Embodiment 3

[0035] The present embodiment provides a kind of technique that improves the recovery rate of germanium of electric zinc system, comprises the following steps:

[0036] (1) Feed coke powder and zinc leached slag into the rotary kiln according to the mass ratio of 13:87, and carry out rotary treatment to obtain germanium-containing zinc oxide smoke; (2) control the iron content in the germanium-containing zinc oxide smoke to be 0.5g / L, germanium-containing zinc oxide smoke dust is under the condition of 85 ℃, and the control end point pH is 5.3, carries out neutral leaching 3h, obtains leachate; Add iron powder to the mixture, and filter to obtain high-germanium slag; (4) low-leach high-germanium slag to obtain low-leaching solution; (5) carry out germanium-precipitation with tannic acid at pH 2.4 and 55°C for 30 minutes to obtain Crude tannin germanium; the mass ratio of germanium content to tannic acid in the low leaching solution is 1:25; (6) the crude tannin germanium is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com