Water chestnut-flavor solid beverage

A technology for solid beverages and water chestnuts, which is applied in food drying, food science and other directions to achieve the effects of being easy to carry, rich in fragrance, and convenient to eat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of the water chestnut flavor solid beverage of the present invention is characterized in that: 94-97 parts of water chestnut microcapsule powder, 2-4 parts of sugar powder, 0.5-1.5 parts of microcrystalline cellulose, 0.05-0.1 part of tricalcium phosphate, two 0.15-0.3 parts of silicon oxide and 0.01-0.02 parts of horseshoe powder essence are mixed.

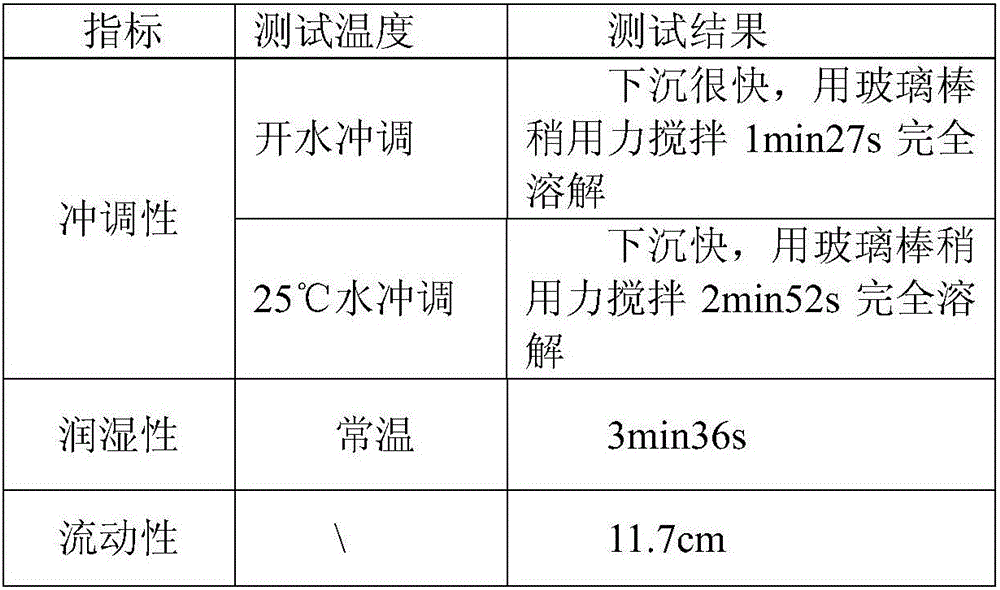

[0017] Product performance indicators:

[0018]

Embodiment 2

[0020] The invention provides a water chestnut-flavored solid beverage, which contains 20-30% of water chestnut pulp; sweetener: 6-8% of powdered sugar and fructose syrup (2:3); solubilizer: maltodextrin, β-cyclodextrin , lecithin (11:1:1) 18-21%; film-forming agent: xanthan gum, gum arabic (1:1) 0.015-0.02%; flavoring agent: horseshoe powder essence, vanillin, ethyl malt Phenol (1.5:1:2) 0.02-0.03%; dispersant: microcrystalline cellulose 0.5-1.5%, tricalcium phosphate, silicon dioxide (1:3) 0.2-0.4%; the rest is water. The percentages are all mass fractions.

[0021] The water chestnut pulp is obtained by peeling fruit-type water chestnuts, and powdered water chestnuts are not suitable.

[0022] The powdered sugar is prepared by crushing white granulated sugar through a 60-mesh sieve; the fructose syrup has a fructose content of 42%, and the other additives are all food grade.

[0023] The numerical ratio in brackets in the present invention is the compounding ratio of addi...

Embodiment 3

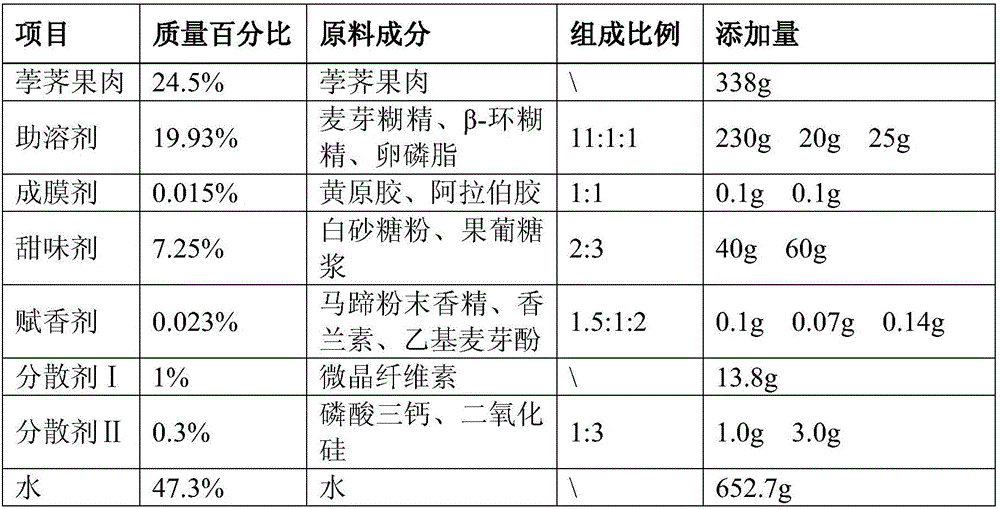

[0039] Raw material formula:

[0040]

[0041] Specific steps are as follows:

[0042] Step 1): Water chestnut raw material pretreatment: water chestnuts are washed, peeled, pulp washed, crushed, and an appropriate amount of water is added, and a soybean milk machine is used at 3000r / min, and beating is performed for 1.5 minutes.

[0043] Step 2): adding ingredients: adding fructose syrup, co-solvent, film-forming agent, vanillin and ethyl maltol to the water chestnut raw material slurry obtained in step 1), and adding all the remaining water and mixing.

[0044] Step 3): Stirring and homogenization: use a high-speed tissue homogenizer at 3000 r / min, homogenize for 3 minutes, and mix the ingredients and water chestnut slurry evenly.

[0045] Step 4): Spray drying: The feed liquid obtained in step 3) is spray-dried under the conditions of an inlet air temperature of 180±5° C., a centrifugal speed of 18000 r / min, and feed peristaltic times of 45 times / min.

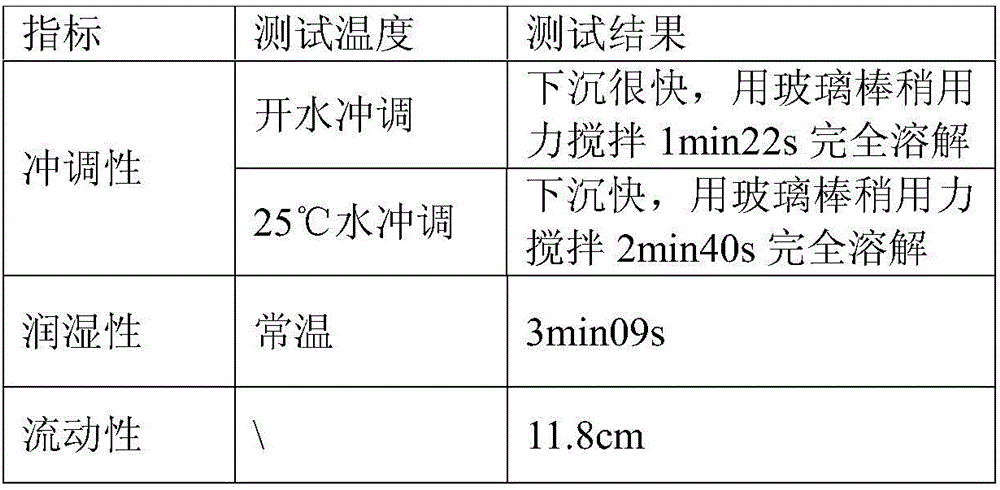

[0046] Step 5): d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com