Method for preparing mold lubricant through oxidation modification of waste engine oil

A technology of oxidative modification and waste engine oil, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of long recycling process cycle, low economic value, refractory waste water and waste residue, etc., and achieves excellent hydrophilicity and dispersibility, The effect of simple operation for operators and low equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

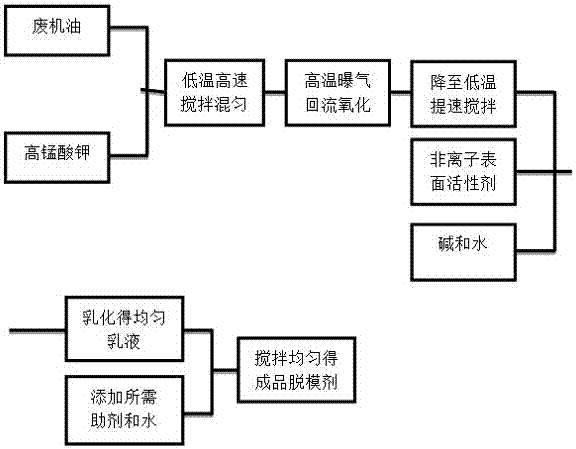

Image

Examples

Embodiment 1

[0016] Add 100Kg of waste engine oil and 0.3Kg of potassium permanganate into the reactor, heat up to 100°C and stir and emulsify to evaporate the water, reduce the stirring speed and raise the temperature to 180°C to fully aerate, the amount of aeration per minute is the reactor Twice the volume of the reactant, after reacting for 5 hours, measure the acid value of the reactant to be 210-220KOHmg / g, then cool down to 80°C and add triethanolamine to adjust the pH of the reactant to 9, and then add 1% of the total weight of the reactant to be hydrophilic Non-ionic surfactant Tween 80, then add 200Kg of deionized water, keep the temperature at 70°C to get a glossy black, evenly flowing, smooth and delicate release agent.

Embodiment 2

[0018] Add 100Kg of waste engine oil and 0.5Kg of nano-manganese dioxide into the reactor, heat up to 120°C and stir and emulsify to evaporate the water, reduce the stirring rate and raise the temperature to 200°C to fully aerate, the amount of aeration per minute is the reactor 3 times the volume, after 5 hours of reaction, the acid value of the reactant was determined to be 210-220KOHmg / g, and then the temperature was lowered to 80°C and the pH of the reactant was adjusted by adding an aqueous solution of sodium bicarbonate to 9, and then 5% of the total weight of the above reactant was added. Add water-based non-ionic surfactant OP-10, then add 300Kg deionized water, keep the temperature at 80°C to get a glossy black, evenly flowing, smooth and fine release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com