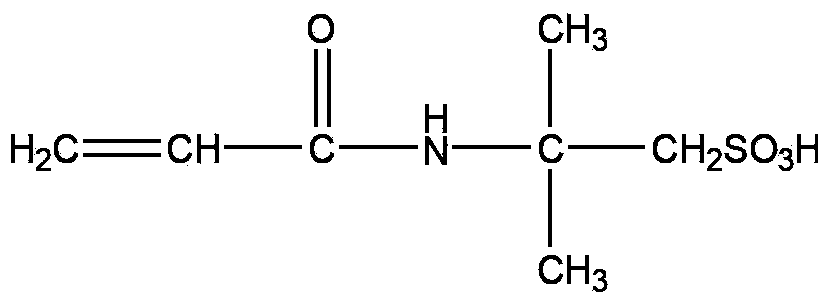

Method for continuous production of 2-acryloylamino-2-methyl propanesulfonic acid

A methylpropanesulfonic acid and acrylamide-based technology, which is applied in the preparation of sulfonic acid and organic chemistry, can solve the problems that the product quality does not meet the high-purity requirements of polymerization, shorten the reaction cycle, scientifically design the process flow, and improve quality The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Preparation of 2-acrylamido-2-methylpropanesulfonic acid

[0021] Add acrylonitrile and sulfur trioxide to a glass container with a stirring device at a flow rate of 200g / h and 25g / h respectively by a metering pump for mixing. The glass container is cooled by an outer jacket, and the internal temperature is controlled at 6°C . Along with the mixing of acrylonitrile and sulfur trioxide, the mixed solution continuously flows into the primary reactor with stirring device through the overflow port in the middle of the glass container. At the same time, isobutene was vaporized and fed into the primary reactor at a feed rate of 17.5 g / h, and the temperature in the primary reactor was controlled at 30° C. with a water bath. The reaction liquid flows into the secondary reactor through the overflow port in the middle of the primary reactor. At the same time, the vaporized isobutene and sulfur trioxide were fed into the secondary reactor at a feed rate of 17.5 g / h and 25 g / h...

Embodiment 2

[0027] 1) Preparation of 2-acrylamido-2-methylpropanesulfonic acid

[0028]Add acrylonitrile and sulfur trioxide into a glass container with a stirring device at a flow rate of 225g / h and 30g / h respectively by a metering pump for mixing. The glass container is cooled by an outer jacket, and the internal temperature is controlled at 8°C . Along with the mixing of acrylonitrile and sulfur trioxide, the mixed solution continuously flows into the primary reactor with stirring device through the overflow port in the middle of the glass vessel. At the same time, isobutene was vaporized and fed into the primary reactor at a feed rate of 22.6 g / h, and the temperature in the primary reactor was controlled at 35° C. with a water bath. The reaction liquid flows into the secondary reactor through the overflow port in the middle of the primary reactor. At the same time, the vaporized isobutene and sulfur trioxide were fed into the secondary reactor at feed rates of 17.4 g / h and 20 g / h re...

Embodiment 3

[0034] 1) Preparation of 2-acrylamido-2-methylpropanesulfonic acid

[0035] Add acrylonitrile and sulfur trioxide into a glass container with a stirring device at a flow rate of 275g / h and 25g / h respectively by a metering pump for mixing. The glass container is cooled by an outer jacket, and the internal temperature is controlled at 10°C . Along with the mixing of acrylonitrile and sulfur trioxide, the mixed solution continuously flows into the primary reactor with stirring device through the overflow port in the middle of the glass vessel. At the same time, isobutene was vaporized and fed into the primary reactor at a feed rate of 22 g / h, and the temperature in the primary reactor was controlled at 40° C. with a water bath. The reaction liquid flows into the secondary reactor through the overflow port in the middle of the primary reactor. At the same time, the vaporized isobutene and sulfur trioxide were fed into the secondary reactor at a feed rate of 12.9 g / h and 25 g / h r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com