Recovery method and device for formic acid solvent during metronidazole production

A technology of production process and recovery method, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

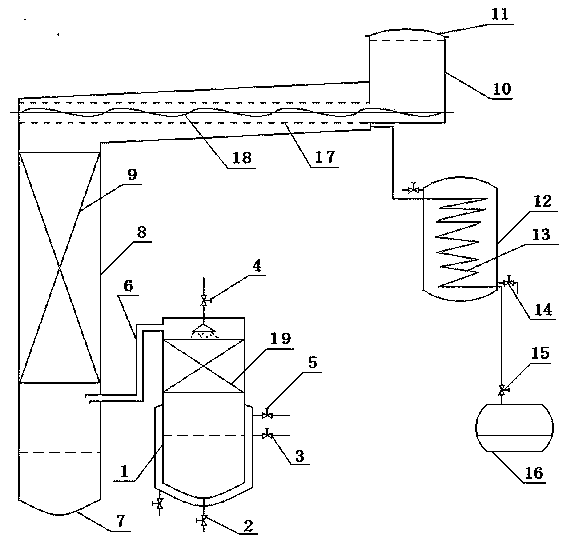

[0023] like figure 1 As shown, a set of formic acid solvent recovery device is added in the production equipment of the metronidazole enterprise. This device is composed of evaporator 1, storage kettle 7, water absorption tower 8, condenser 12 and storage tank 16. The upper part is provided with packing 19, the top is provided with the feed valve 4, the bottom is provided with the slag valve 2, the side wall is provided with the discharge valve 3 and the heating steam valve 5, and is connected between the top of the evaporator 1 packing and the storage kettle 7 through the pipeline 6, The water absorption tower 8 is composed of a vertical section with packing 9 and a slightly upwardly inclined horizontal section of a porous tube 17 with a nylon mesh. The lower end of the vertical section is connected to the storage kettle 7, and a high-level feeding tank is set above the end of the horizontal section. 10, a condenser 12 is arranged below, a screw 18 is arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com