Efficient quick non-damaged cleaning equipment of fresh tea leaves

A technology for fresh tea leaves and cleaning equipment, applied in lighting and heating equipment, cleaning methods using liquids, tea processing before extraction, etc. Food safety incidents, the effect of improving taste and quality, and improving cleaning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

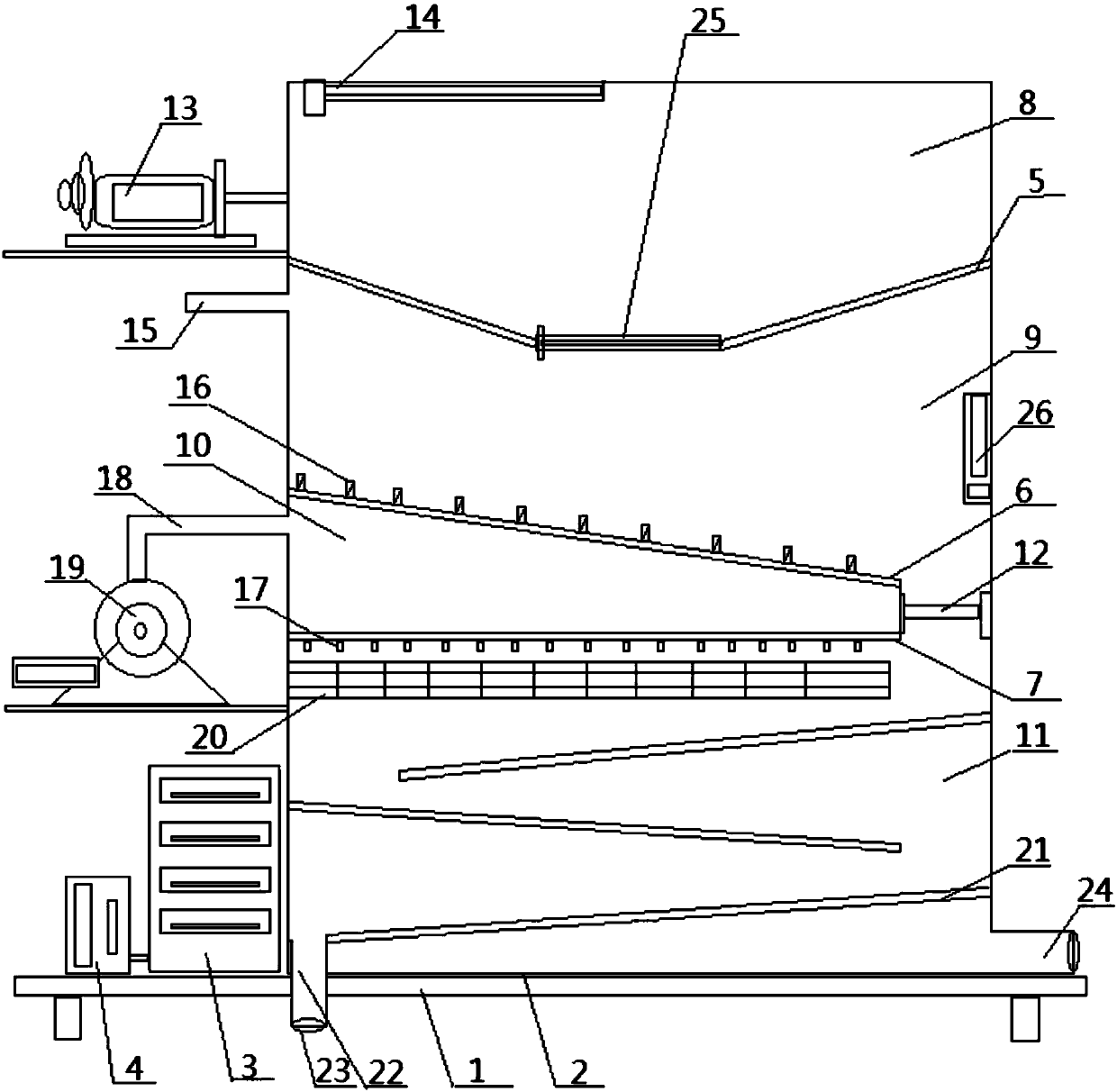

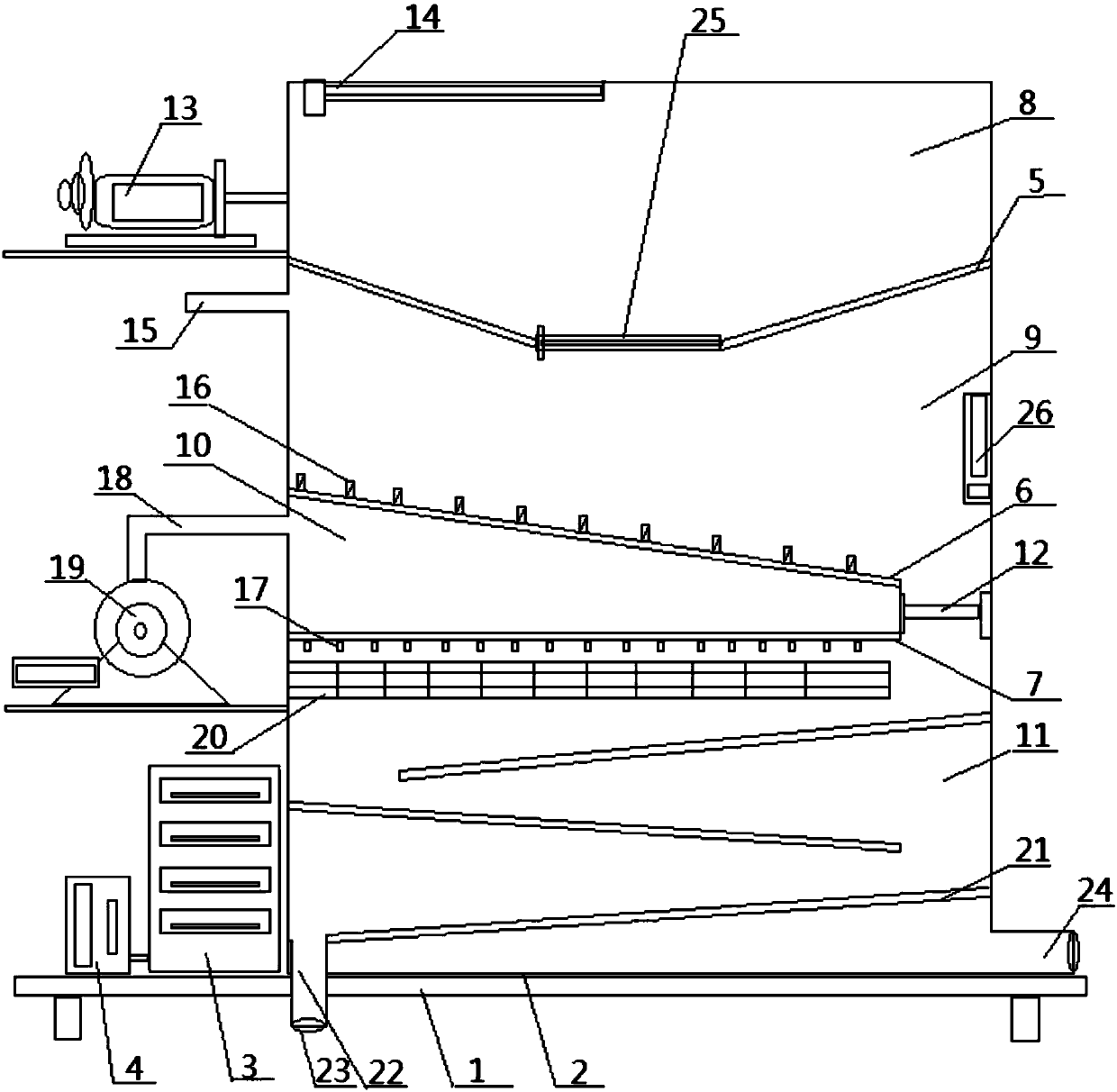

[0029] In the following, the technical scheme of the high-efficiency, rapid and non-destructive cleaning equipment for fresh tea leaves provided by the present invention will be further described in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0030] See figure 1 , a high-efficiency, fast and non-destructive cleaning equipment for fresh tea, comprising a fixed base 1, a tea cleaning cabinet 2, a device controller 3 and an external power supply 4, the tea cleaning cabinet 2, the device controller 3 and the external power supply 4 are respectively arranged on the fixed base 1 On the top, the tea cleaning cabinet 2 is provided with a pre-cooling box partition 5, a cleaning box partition 6 and a drying box partition 7 from top to bottom, a pre-cooling box partition 5, a cleaning box partition 6 and a drying box The partition 7 divides the tea cleaning cabinet 2 from top to bottom into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com