Resin glasses free of secondary curing and preparation method thereof

A resin lens and secondary curing technology, applied in the field of glasses, can solve the problems of increasing the production process, time and production cost, failing to produce qualified products, increasing the rate of unqualified products, etc., achieving excellent quality, stable performance, and reducing production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

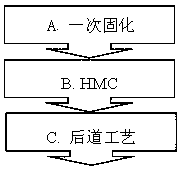

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 As shown, the present invention avoids secondary curing resin lens and its preparation method, specifically as follows:

[0023] A. Process flow

[0024] Original process:

[0025] Lens primary curing → secondary curing → HMC (hardened and UV-resistant coating) → packaging

[0026] change to:

[0027] One-time curing of the lens → HMC (hardening and anti-ultraviolet coating) → packaging

[0028] The function of secondary curing of the lens in the prior art is to further react inside the lens (the temperature of the secondary curing is 105 degrees, 1 hour), and further eliminate the stress inside the lens.

[0029] The present invention combines the HMC hardening step of the lens substrate, and the hardening temperature is 110 degrees for 2 hours in an oven. It not only completes the task of hardening the lens substrate, but also plays a role i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com