Integrated processing device of in-plant production of surface-coated and modified BOPP (Biaxially Oriented Polypropylene) synthetic paper

A technology for surface coating and synthetic paper, which is applied to devices for coating liquid on surfaces, special surfaces, coatings, etc., which can solve problems such as influence, increase in printing operation time and cost, and complex production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

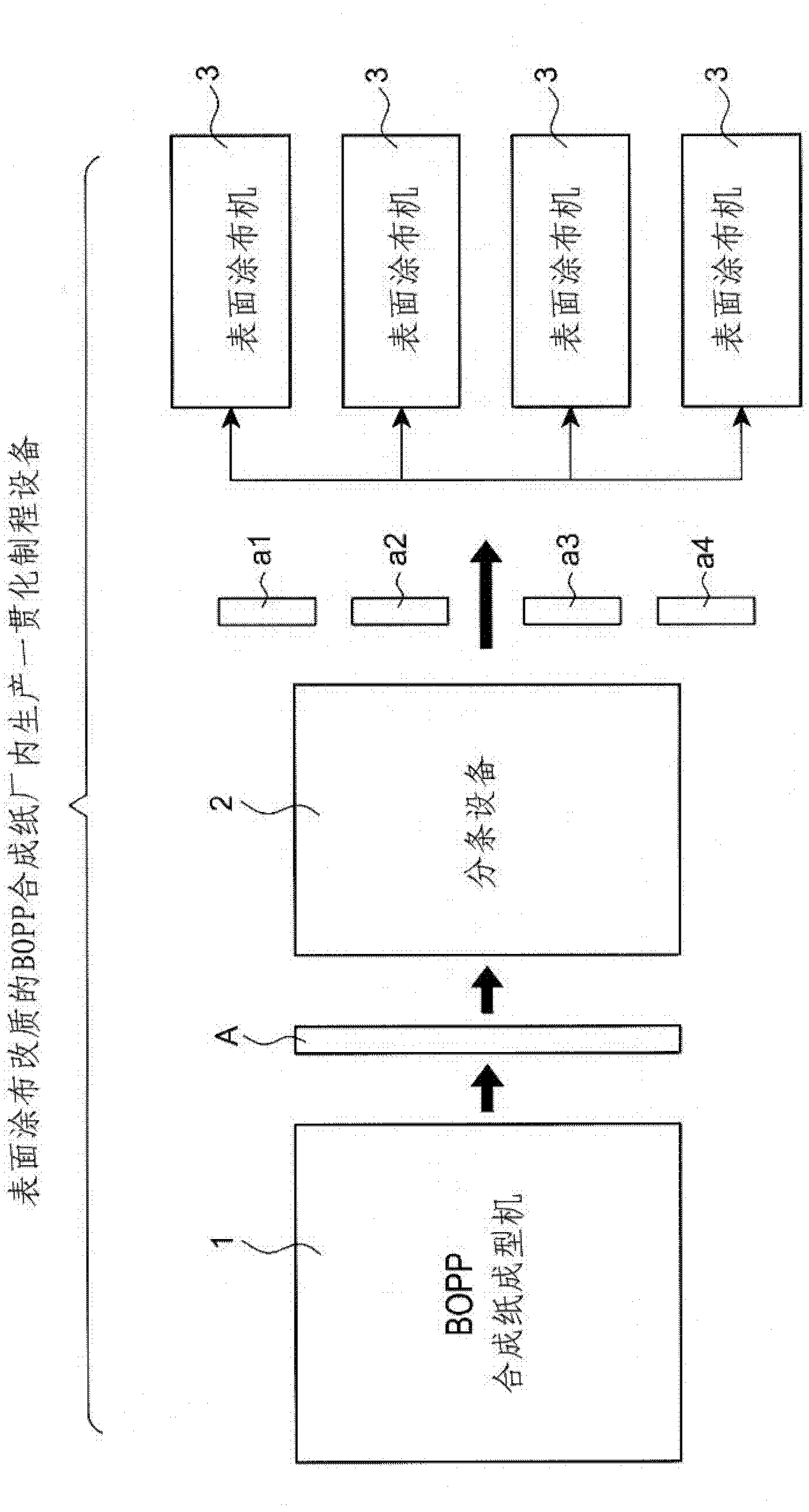

[0054] First, see figure 1 As shown, the preferred embodiment of the consistent production process equipment in the BOPP synthetic paper factory with surface coating and modification of the present invention includes:

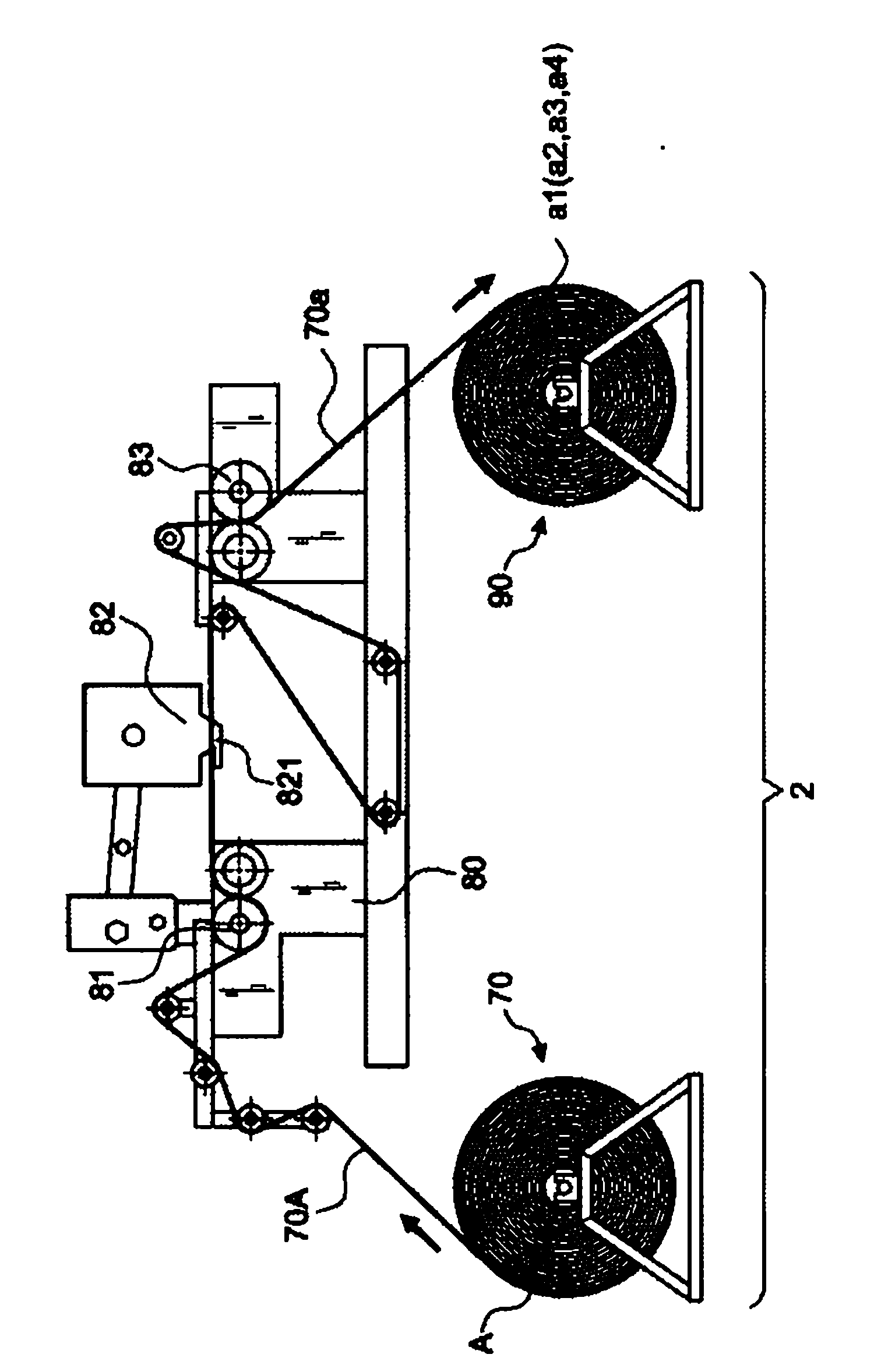

[0055]A BOPP synthetic paper forming machine 1, a slitting device 2 and at least one surface coating machine 3, the BOPP synthetic paper forming machine 1 is processed into a long paper roll A and sent to the slitting device 2, and the slitting After the strip equipment 2 is cut into several short rolls a1, a2, a3, a4, and then at least one surface coating machine 3 is used to modify the surface of the synthetic paper, the above-mentioned integration enables the manufacture of Synthetic paper is consistent from forming, slitting to coating.

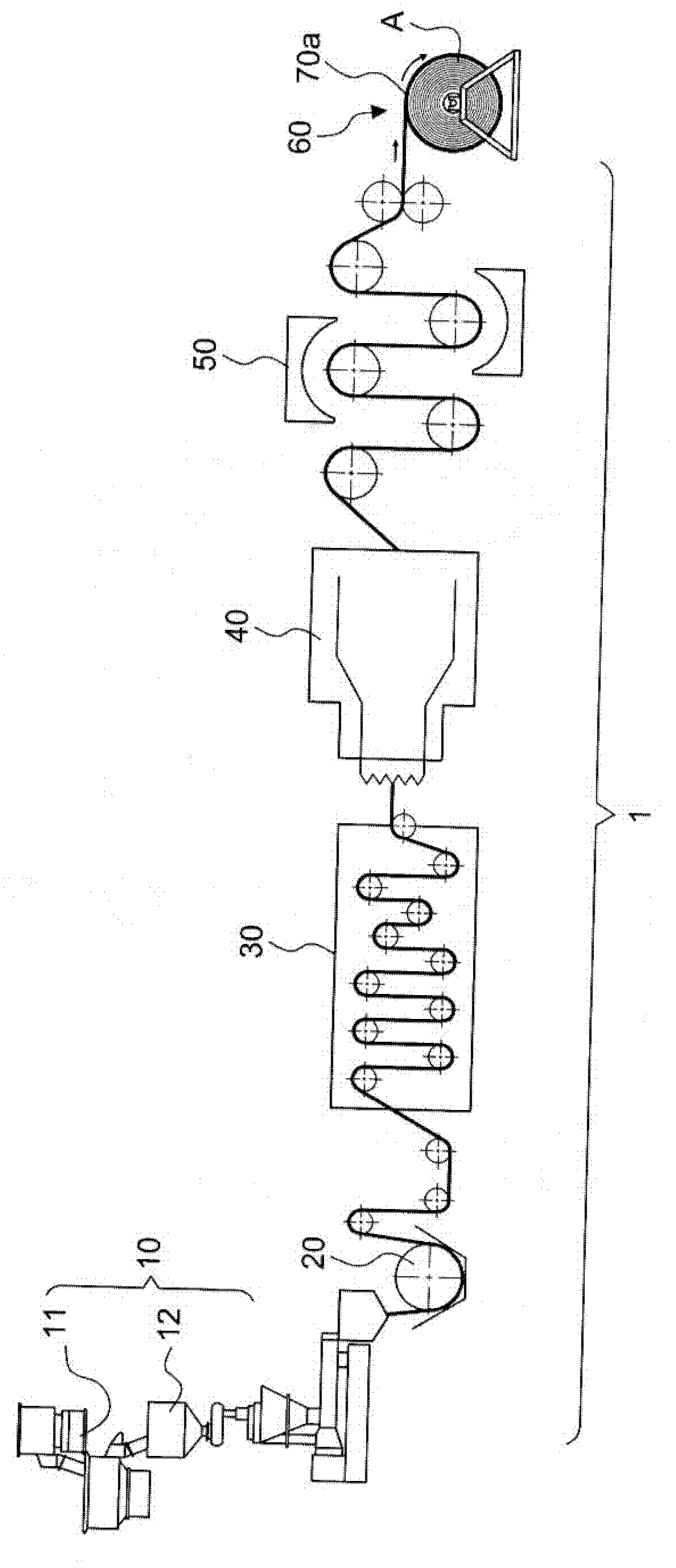

[0056] Also, if figure 2 As shown, a BOPP synthetic paper forming machine 1 includes: an extrusion device 10, equipped with a mixer 11, a feeding barrel 12 and an extruder 13. In this embodiment, the polypropylene comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com