Patents

Literature

60 results about "Short paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for classifying short texts based on probability topic

InactiveCN101621391AAllocation is accurateHigh precisionSpecial service provision for substationQuestion answerSubject specific

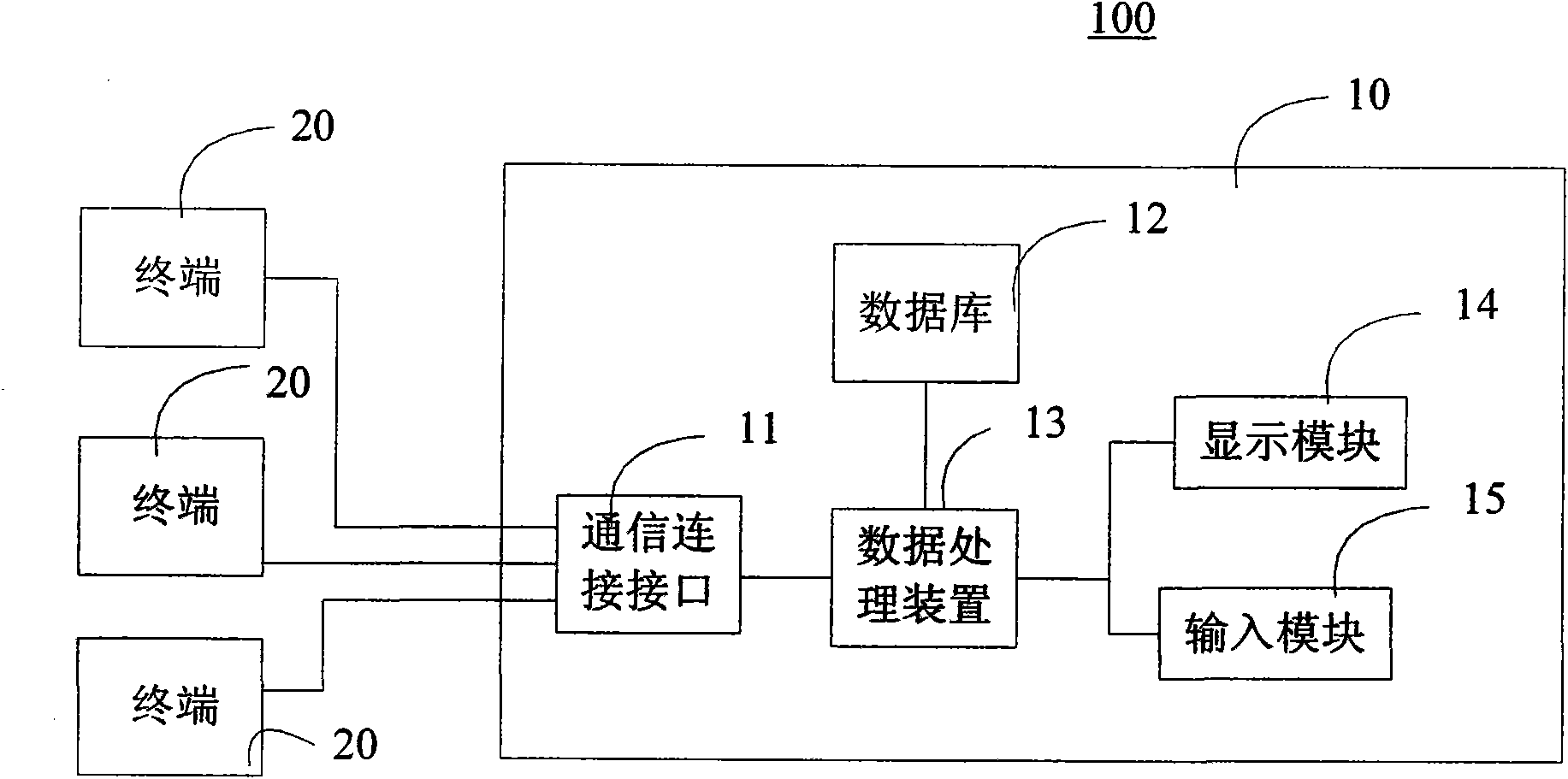

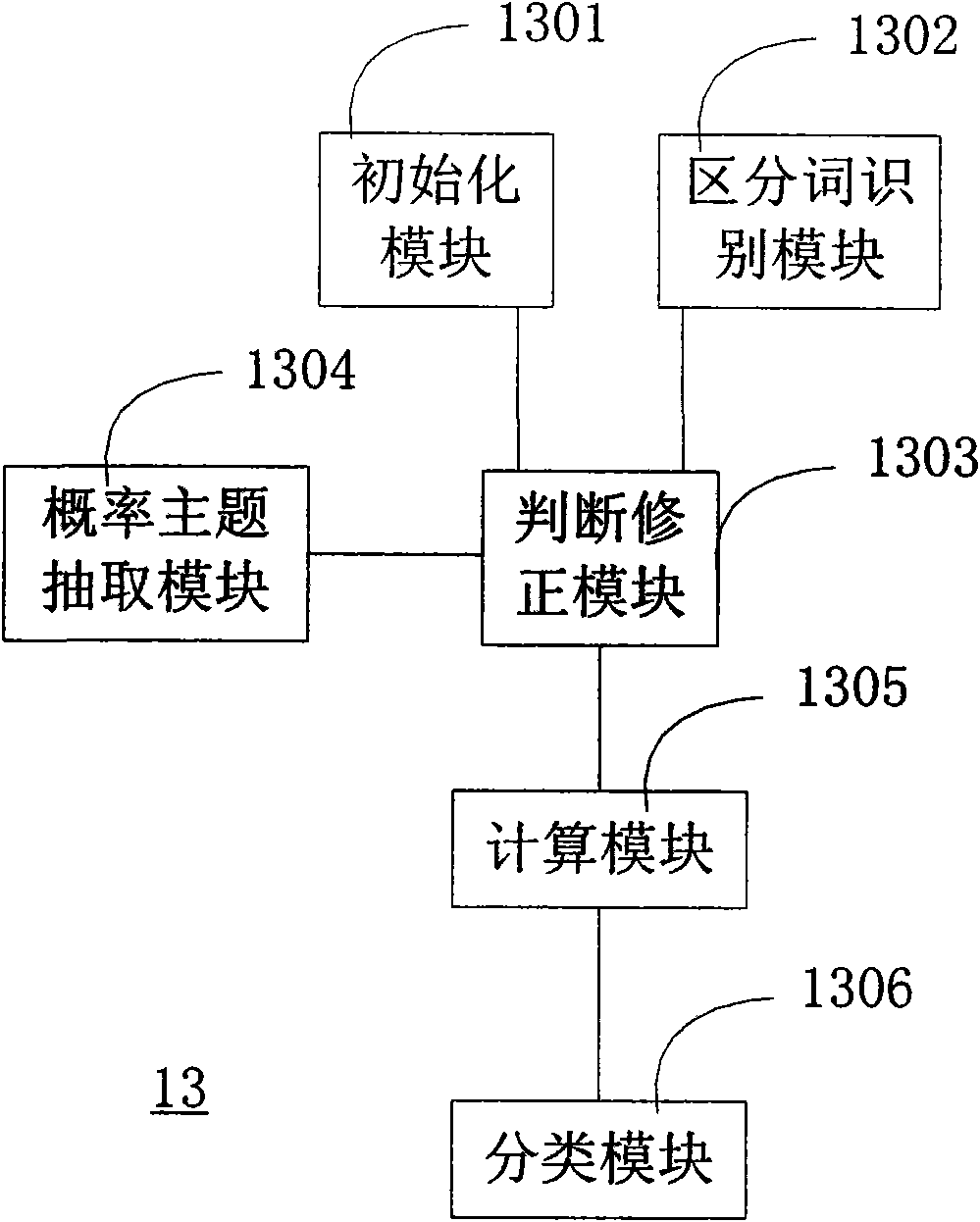

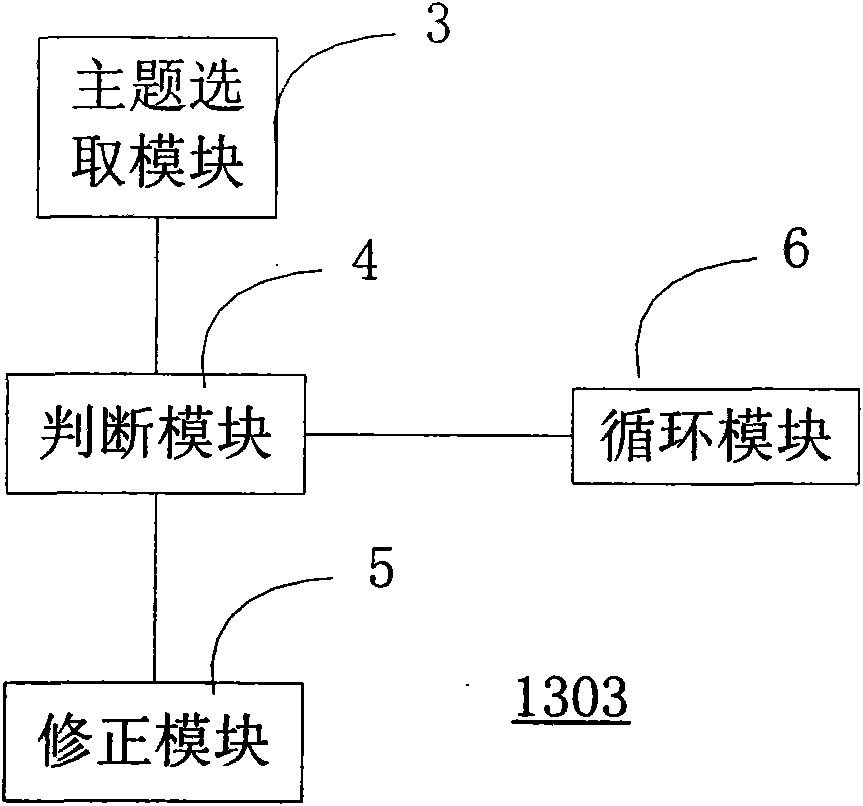

The invention discloses a method and a system for classifying short texts based on the probability topic; the method is used in a data processing device of a question answering system for classifying the short texts according to the similarity of the short texts. The method comprises the following steps: respectively acquiring initialized text vectors according to an input target short text and a short text acquired from the database of the question answering system; scanning the two short texts to respectively acquire differentiating words of the two short texts; when the relevance degrees of the differentiating words of the two short texts and a probability topic are higher than a threshold, modifying the text vectors of the two short texts according to the relevance degrees; working out the similarity of the two short texts according to the modified text vectors of the two short texts; acquiring another short text form the database of the question answering system till all short texts in the database are traversed; and then executing a scanning step; classifying the target short text according to the similarity.

Owner:北京百问百答网络技术有限公司

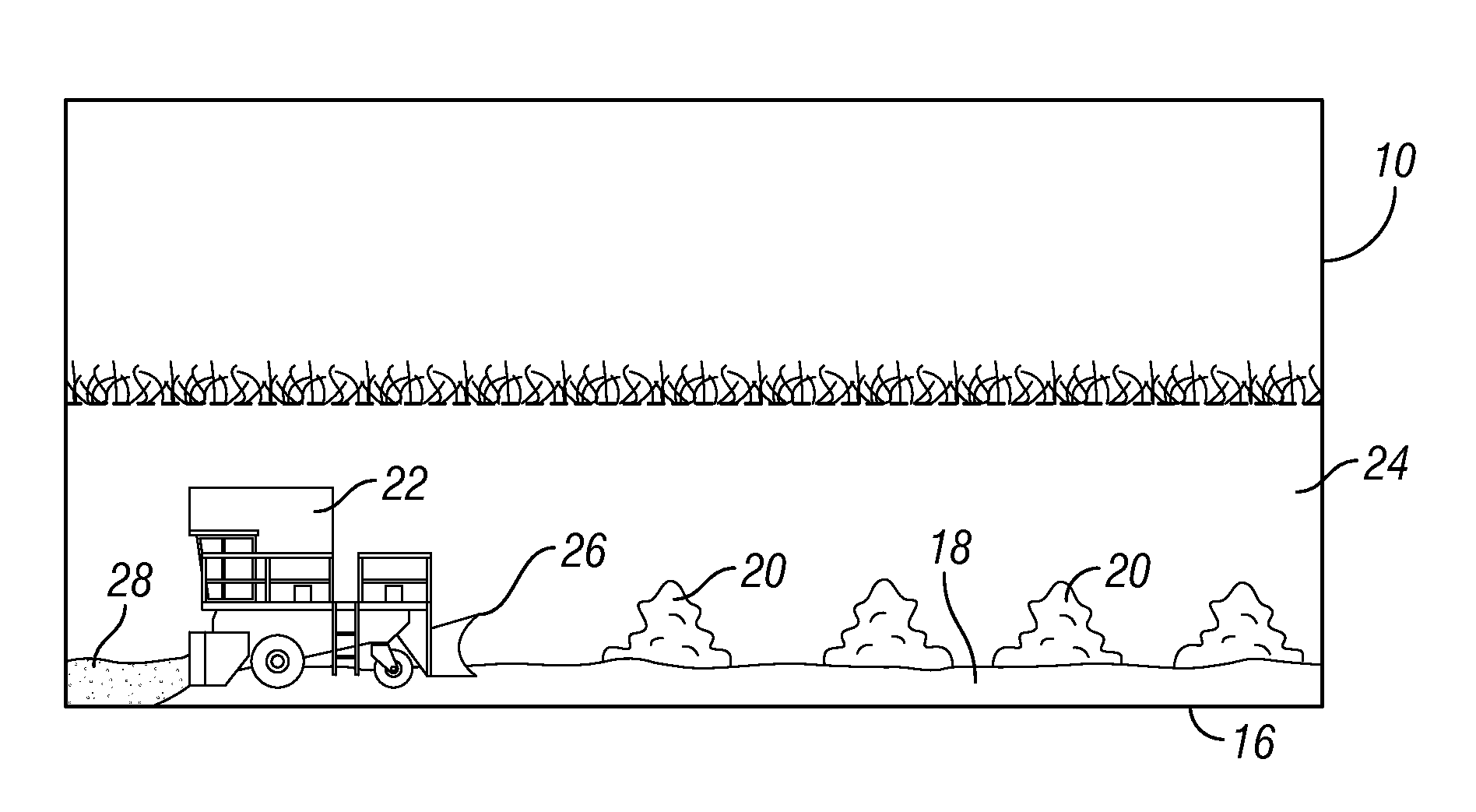

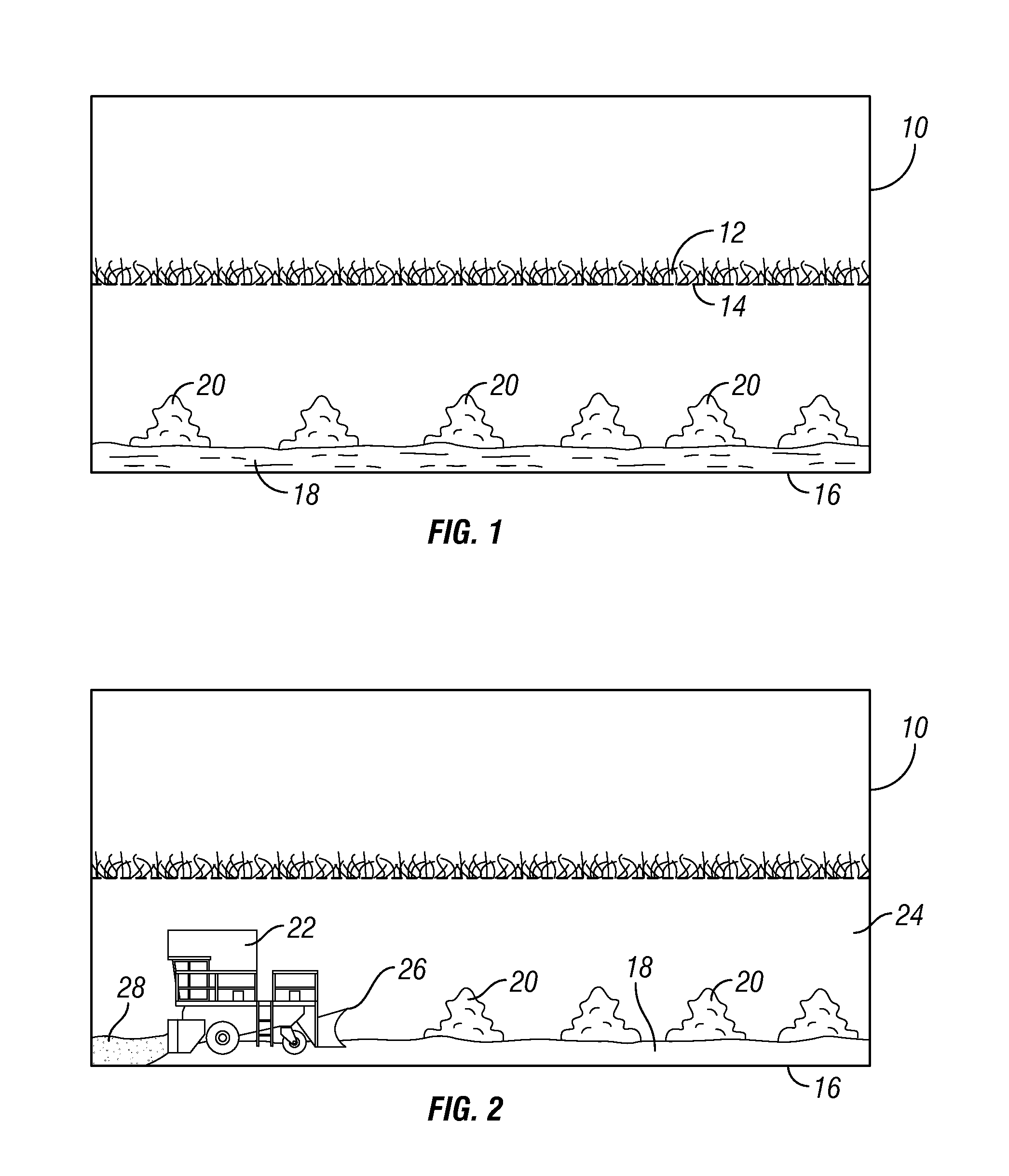

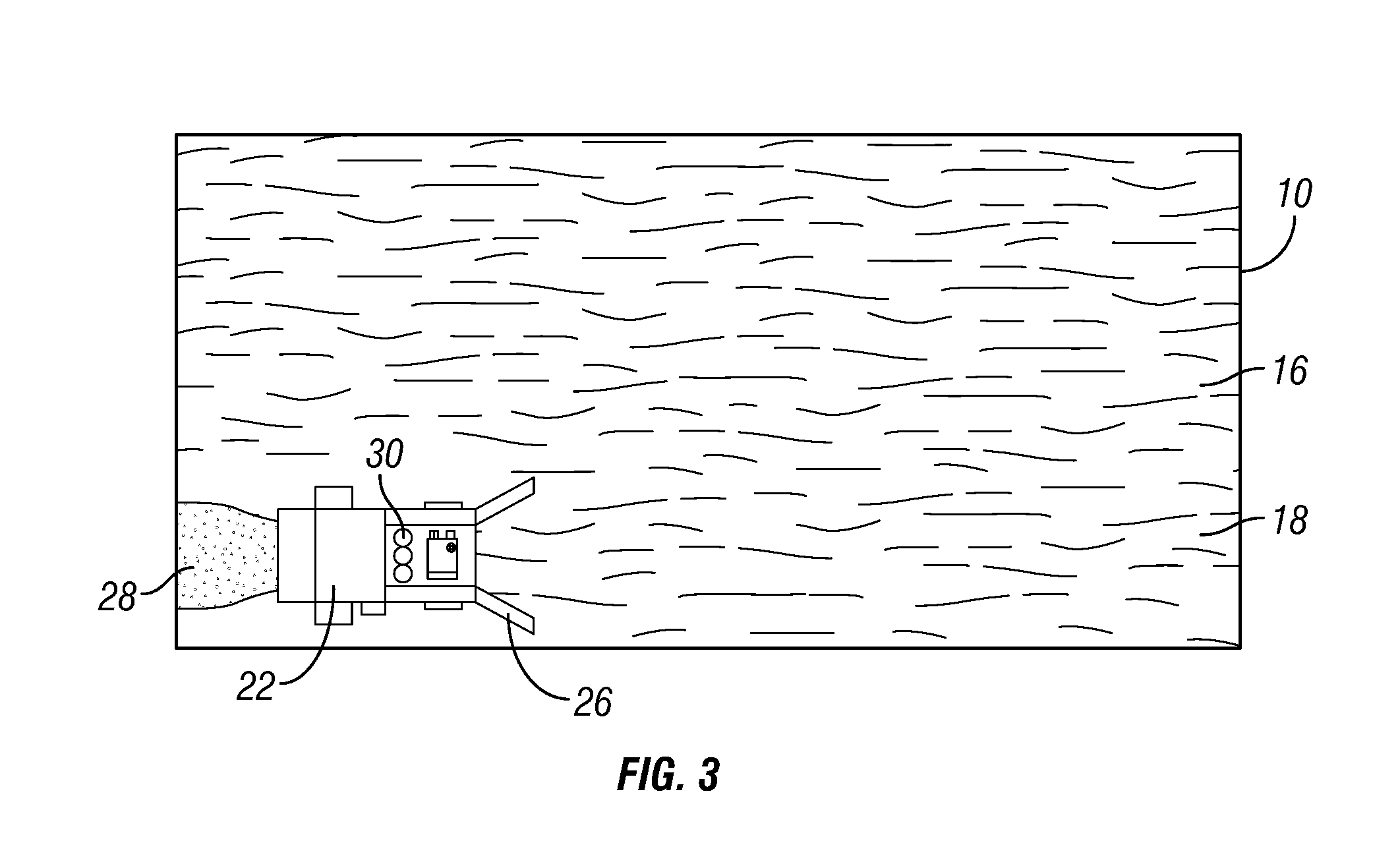

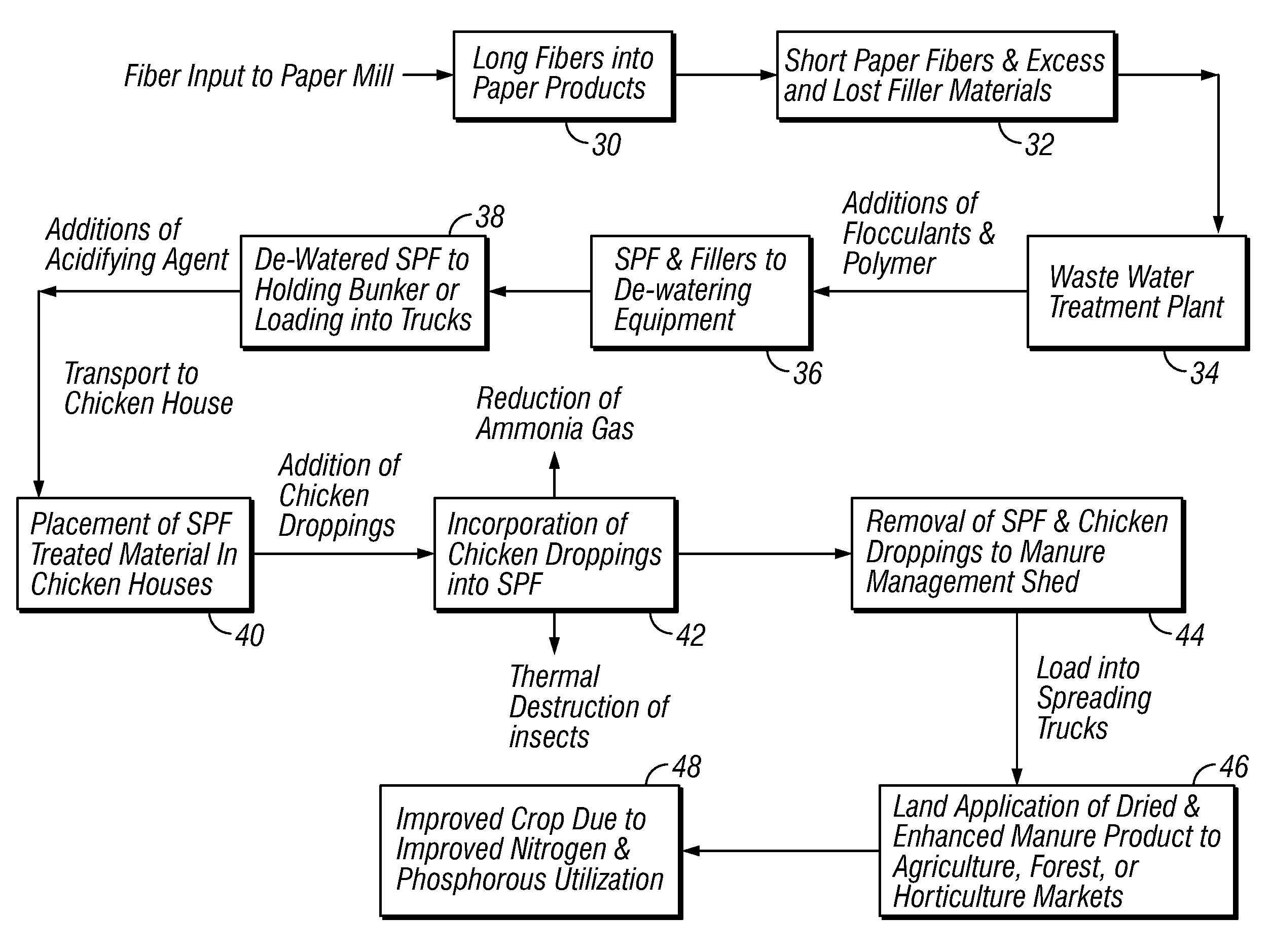

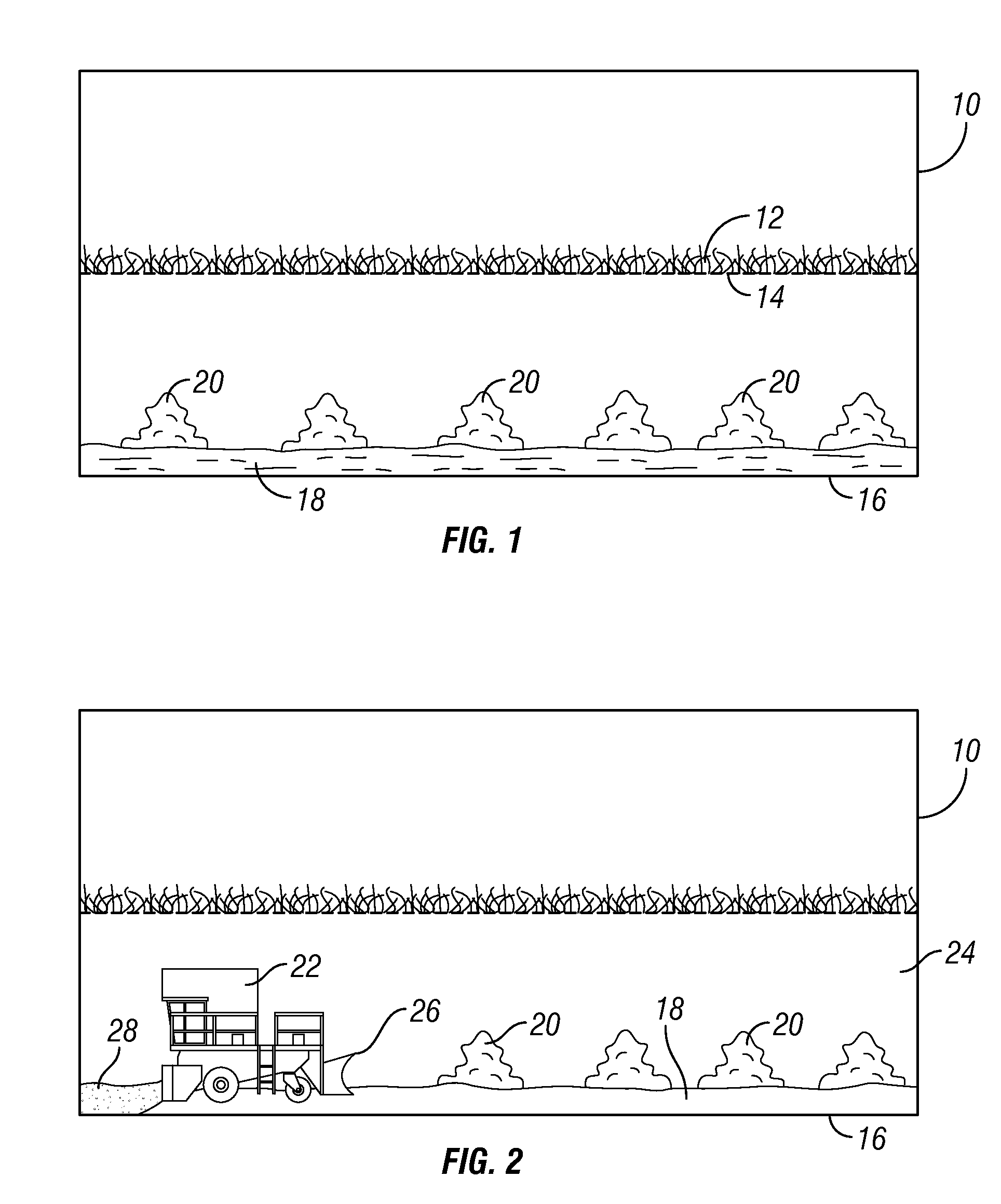

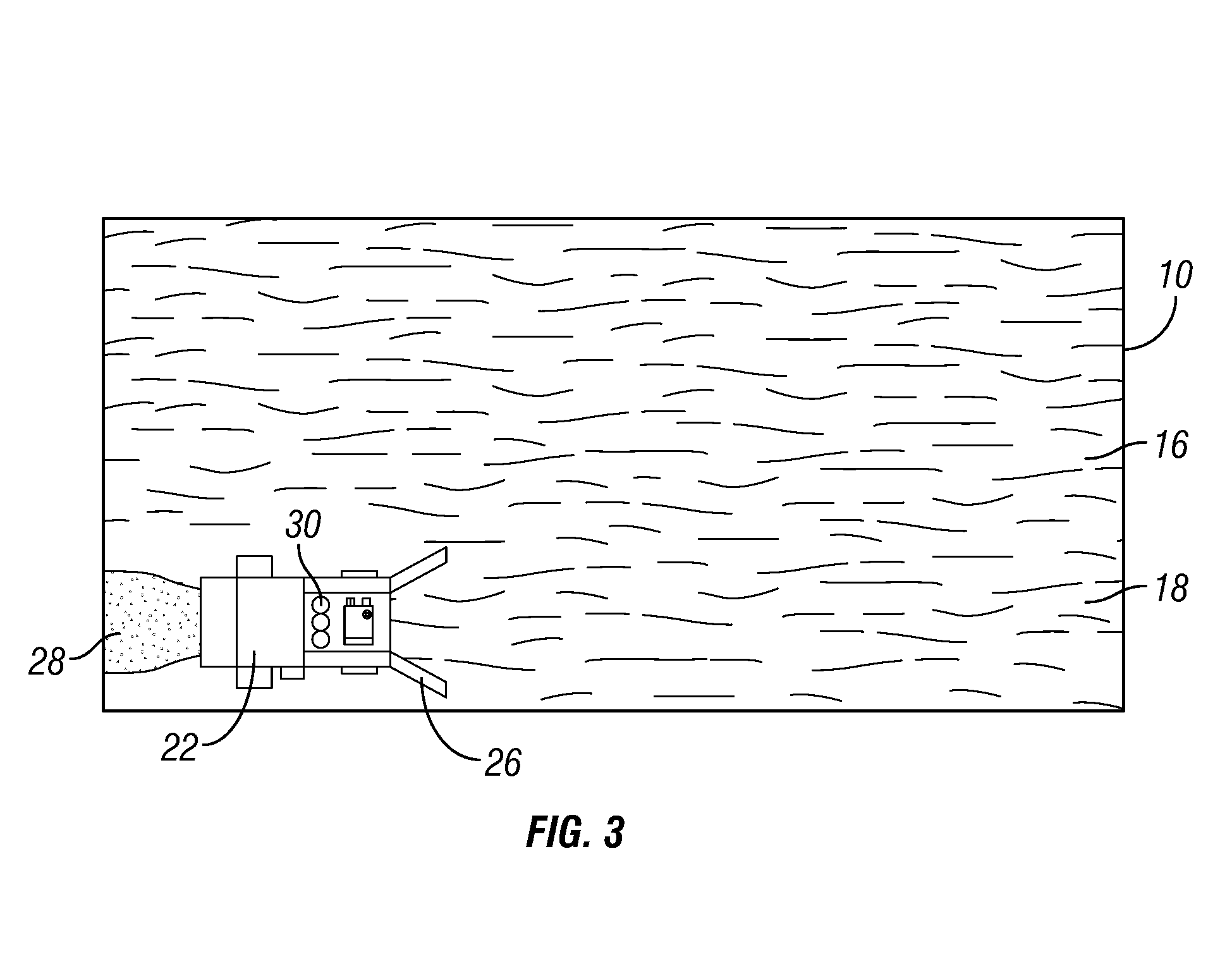

Methods of Treating Waste from a Chicken House using Short Paper Fibers

A method of treating waste from poultry such as chickens in a chicken house is described wherein the method includes applying a layer of short paper fibers over a floor of the chicken house horizontally below the chickens in the chicken house, mixing manure from the chickens with the layer of short paper fibers, and removing the mixed manure and short paper fibers from the chicken house. The manure is turned with the layer of short paper fibers such that the manure and the short paper fibers are intimately mixed together. The removed mixture can be spread over land as fertilizer, mulch, or the like.

Owner:LAUBENSTEIN JOSEPH W

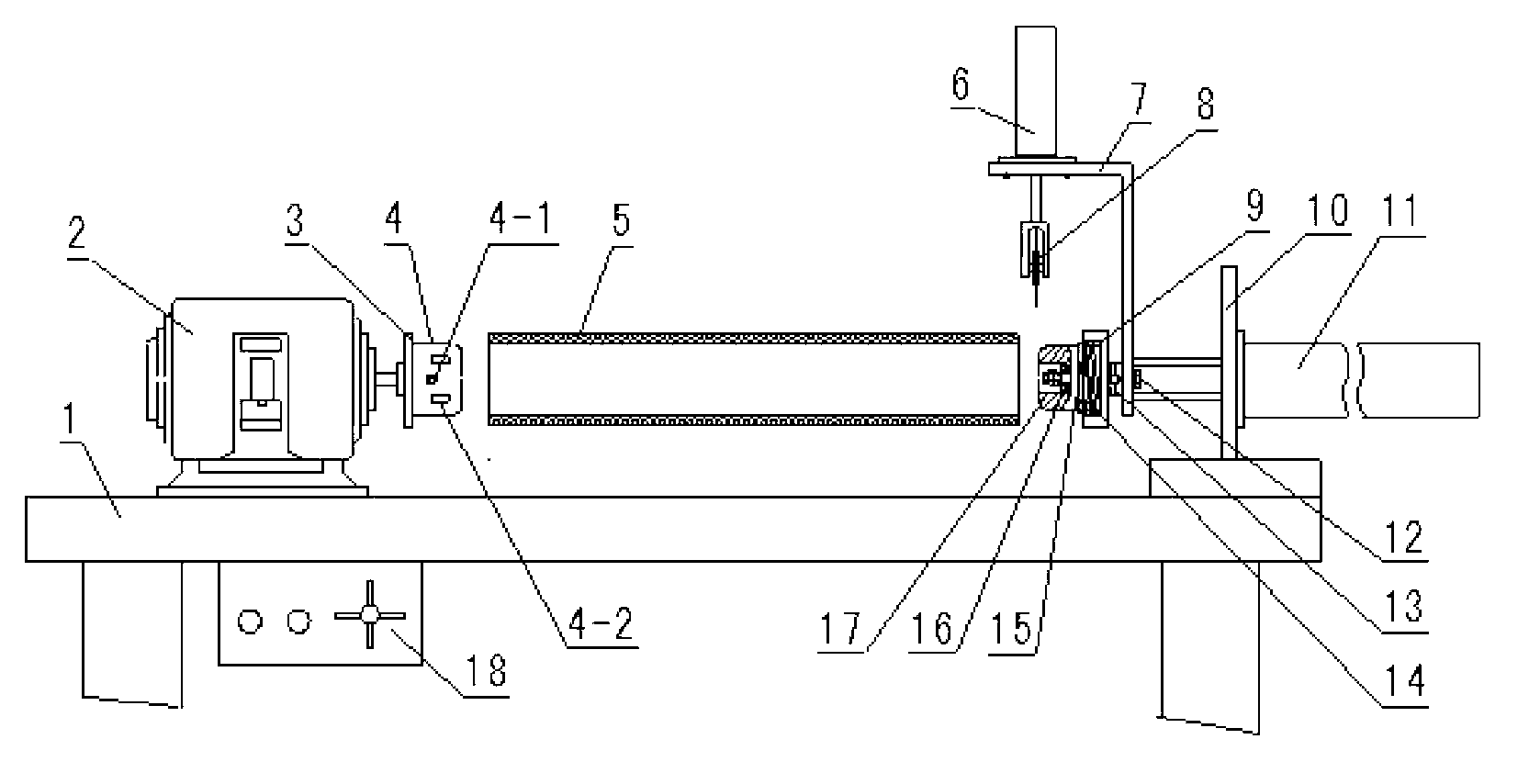

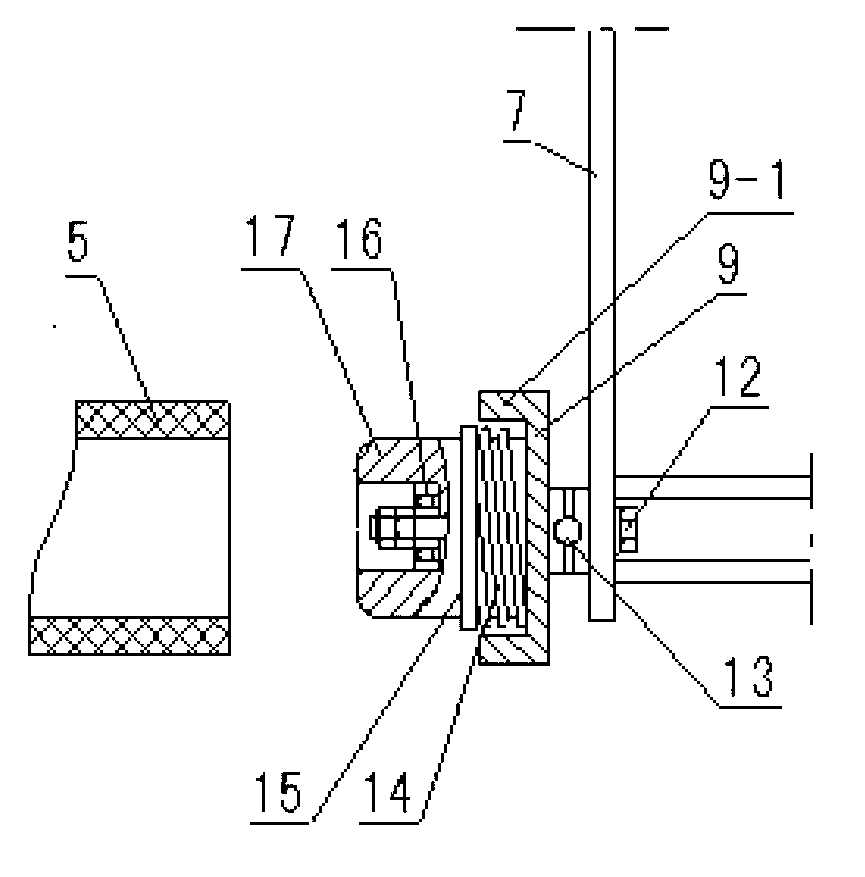

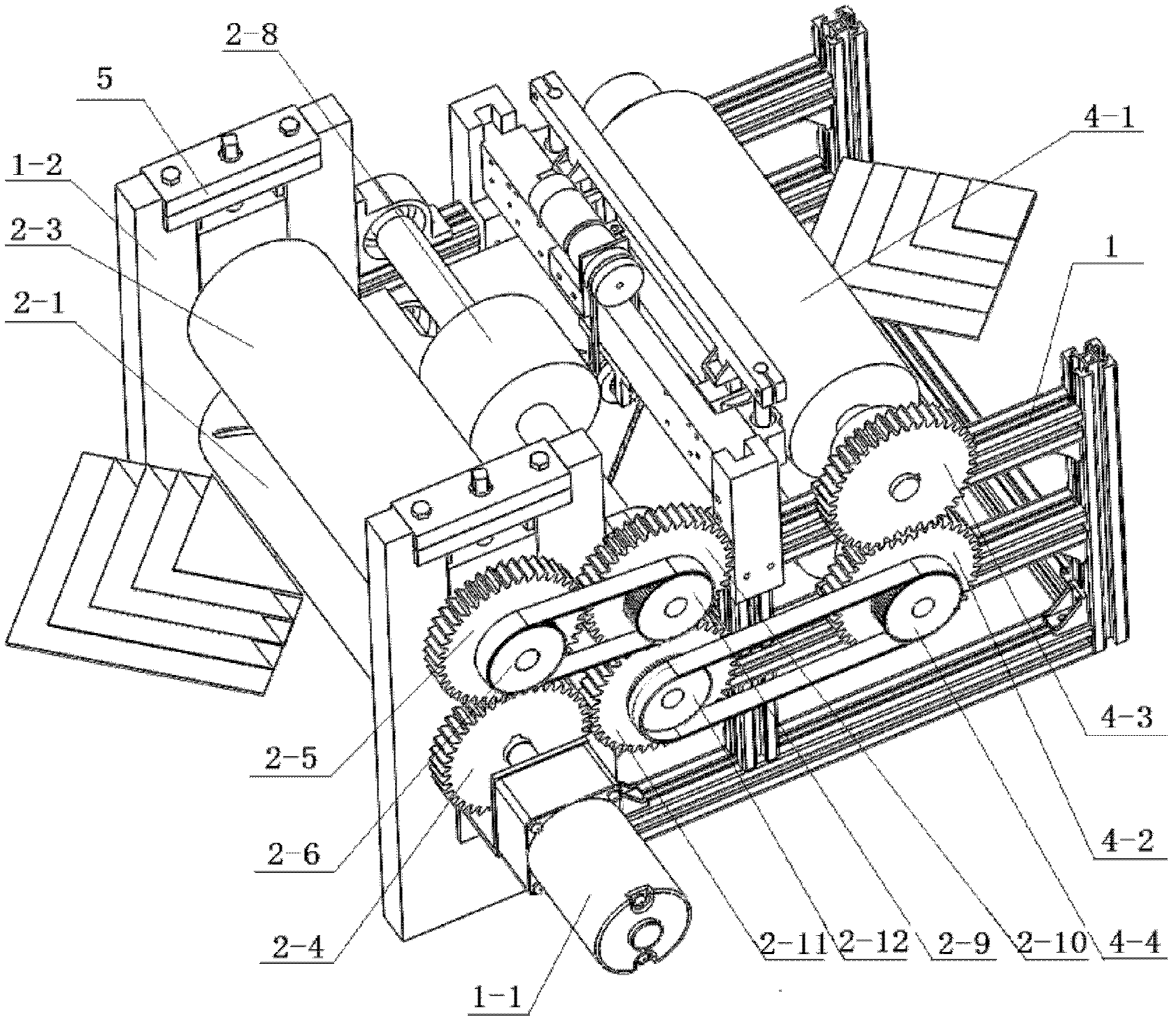

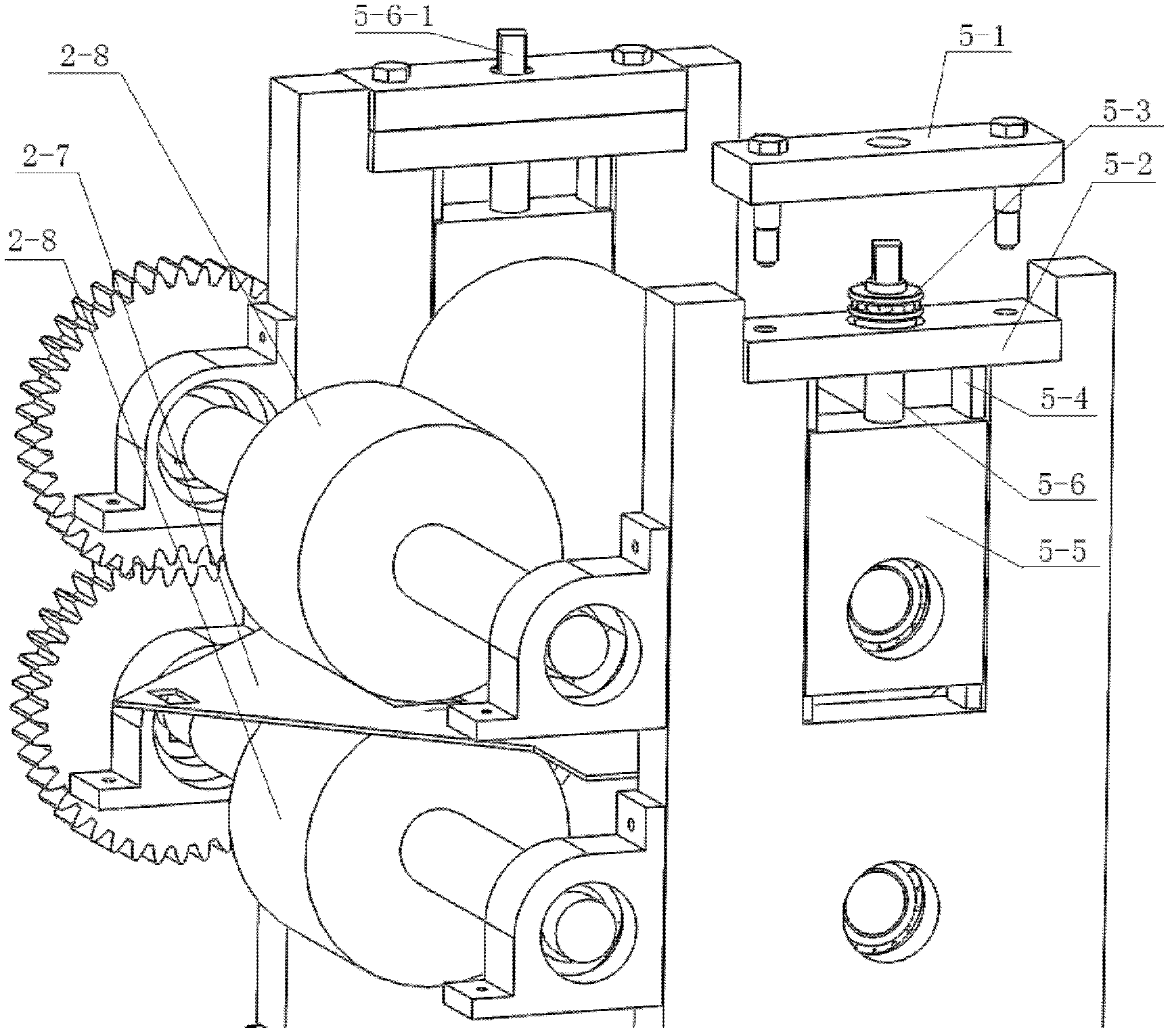

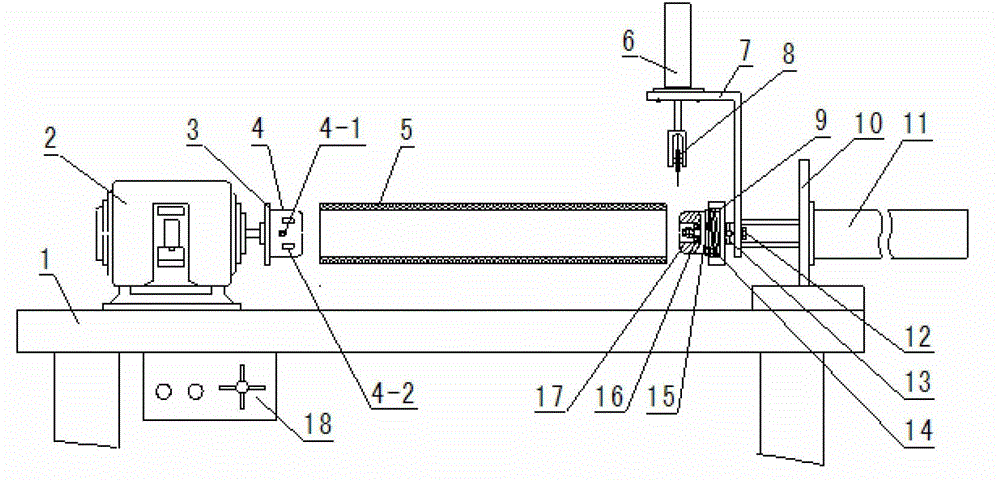

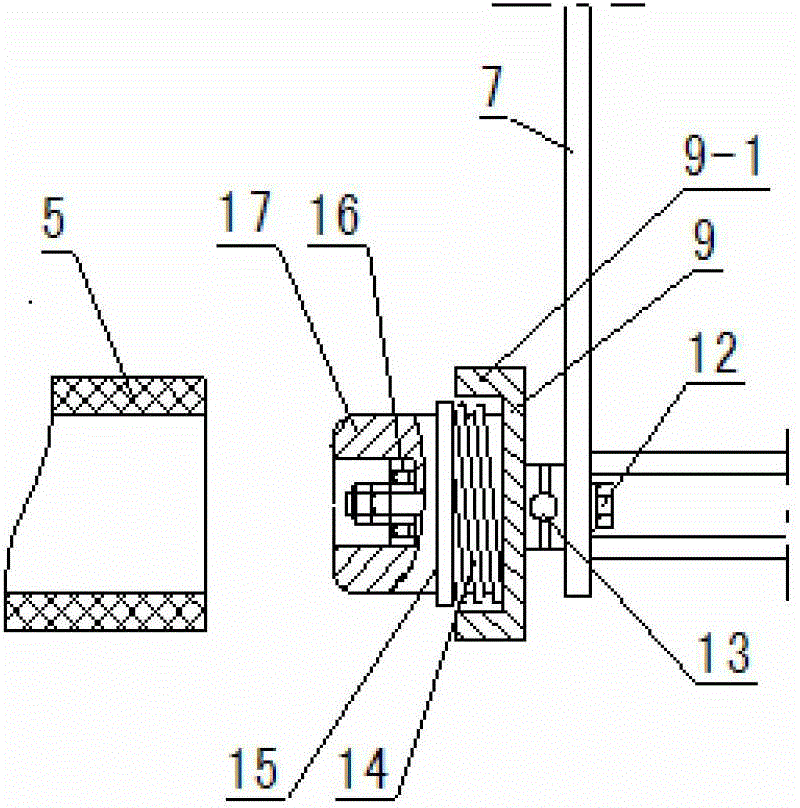

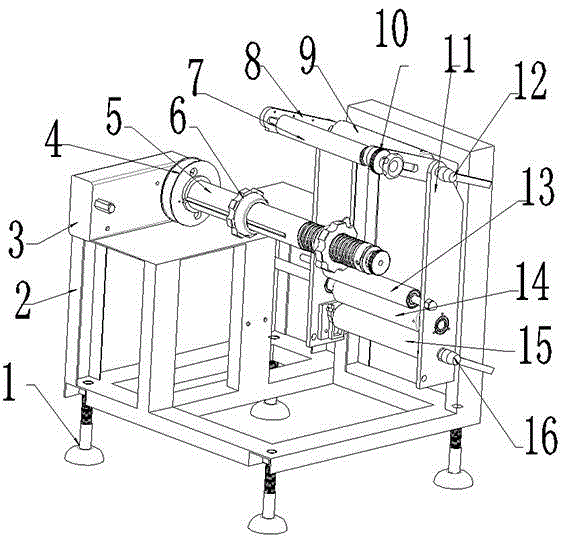

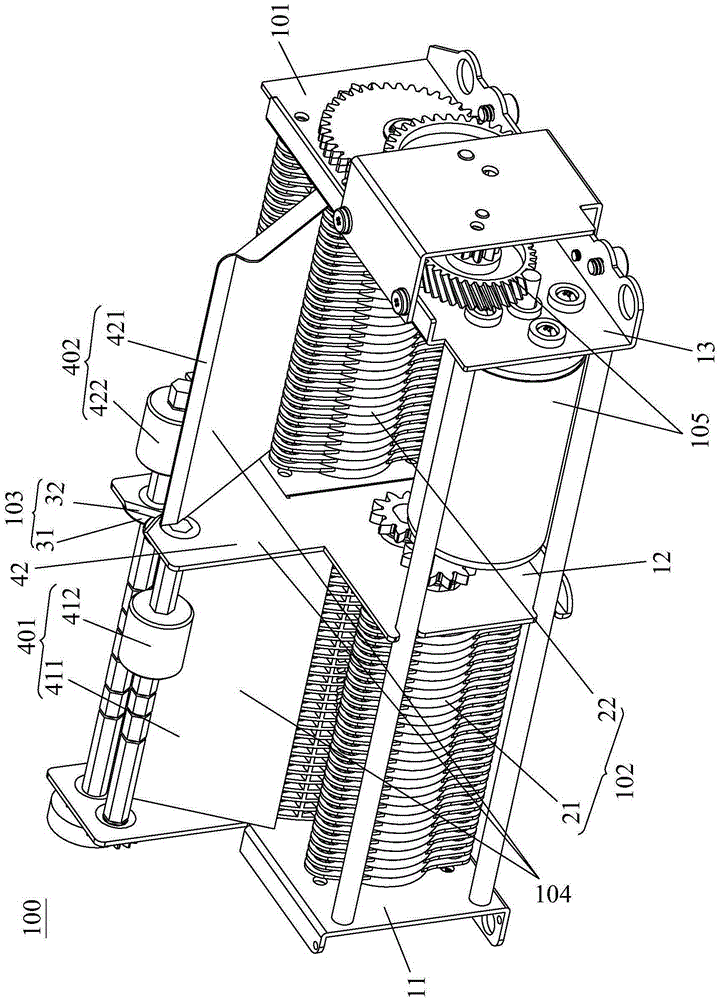

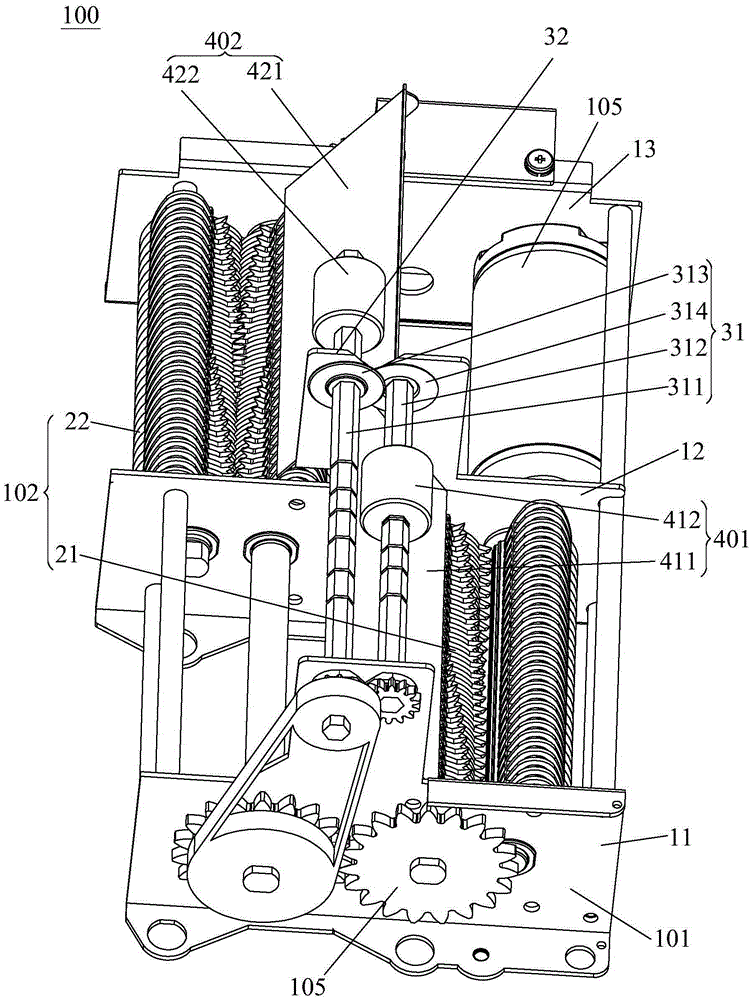

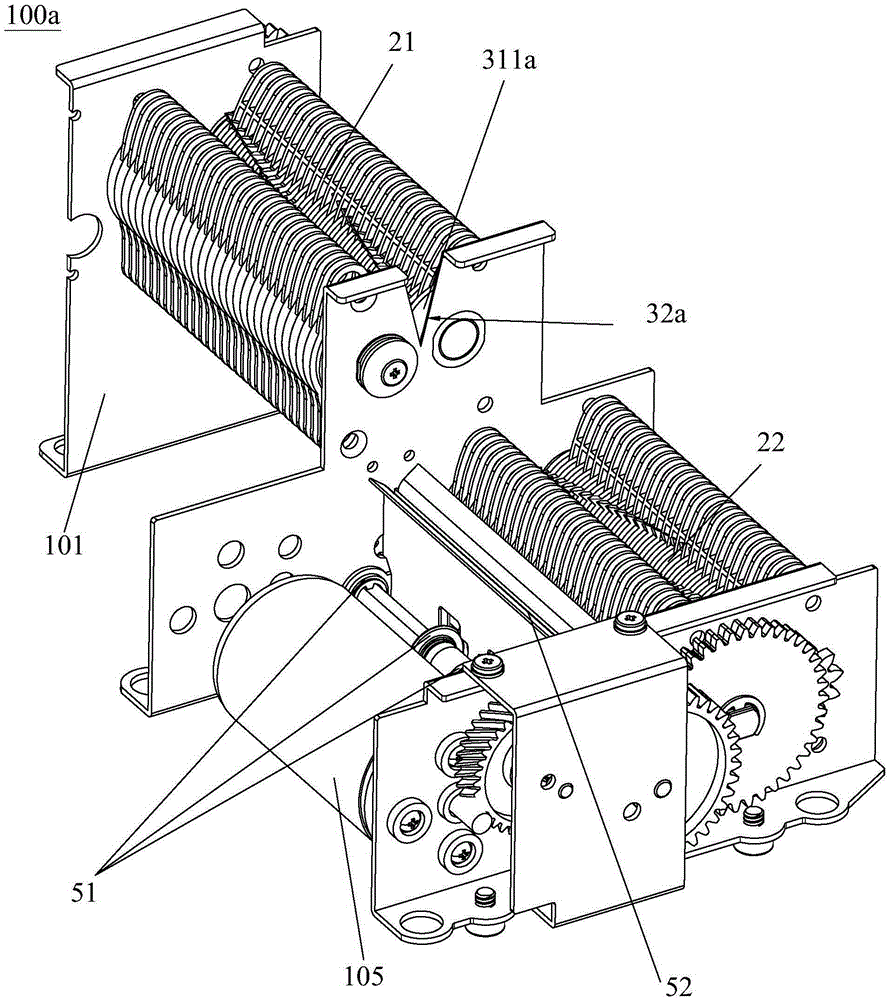

Paper tube cutting machine

ActiveCN103009418AOvercoming the disadvantages of deflectionChange widthMetal working apparatusPulp and paper industryControl switch

The invention discloses a paper tube cutting machine. In the paper tube cutting machine, an output shaft of an adjustable-speed motor is provided with a first clamping disk and an expansion shaft; dual projection rods of a dual-projection-rod air cylinder are used for fixing a bracket of a cutting air cylinder; the bracket is provided with a fixed shaft; the fixed shaft is used for rotationally supporting a second clamping disk and a support shaft; the second clamping disk is provided with an edge boss which is jointed on a long paper tube; and the support shaft is sleeved with a long paper tube cut part ejection mechanism constructed by a spring and a push disk. The dual-protection-rod air cylinder can be used for realizing propulsion of the support shaft and the second clamping disk for tightening a long paper tube under the control of an electromagnetic valve control switch, and the edge boss of the second clamping disk is used for driving the spring to accumulate energy and driving the push disk to retract after being jointed with the long paper tube. The cutting air cylinder can be used for applying a pressure to a circular cutter under the control of the electromagnetic valve control switch, and the circular cutter returns back along with the cutting air cylinder after cutting is completed. The position of the cutting air cylinder on the bracket can be adjusted for changing the width of a short paper tube. The paper tube cutting machine has the outstanding advantages of simple and practical structure, high cutting efficiency and good quality.

Owner:TIANJIN JINSHANYIDE PLASTIC PACKAGING CO LTD

Paper sludge processing for animal bedding

A method for making an animal bedding fiber product, the method includes providing fiber from paper sludge, formulating the fiber in a mixture including a first desiccant agent including ash, so as to form a friable aggregate. Further, a fiber product including at least one short paper fiber from a secondary fiber, one or more inorganic fillers including kaolin clay; and a first desiccant agent including ash. Further still, a heatless process for making a fiber product including providing fiber from paper sludge, formulating the fiber in a non-active heat generating mixture including a first desiccant agent including ash, so as to form a waste fiber product.

Owner:CASELLA WASTE SYSTEMS

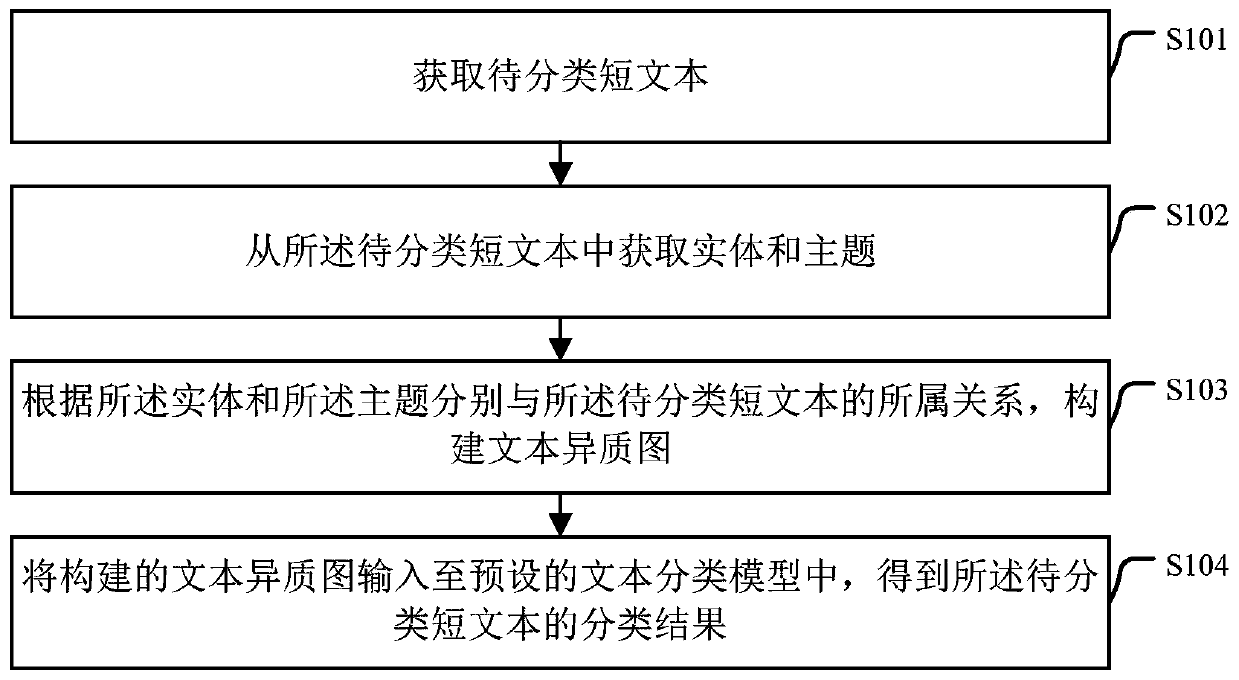

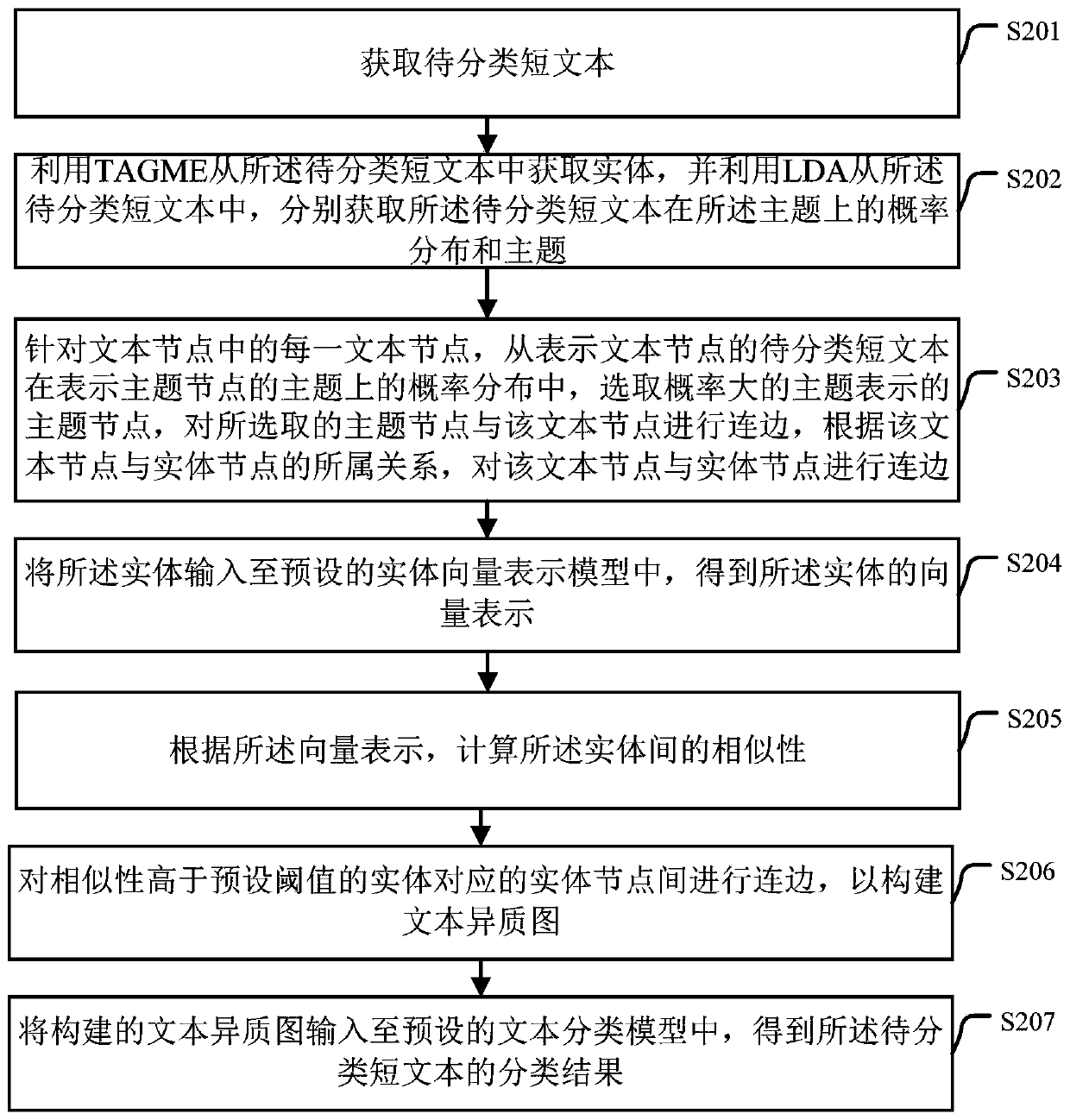

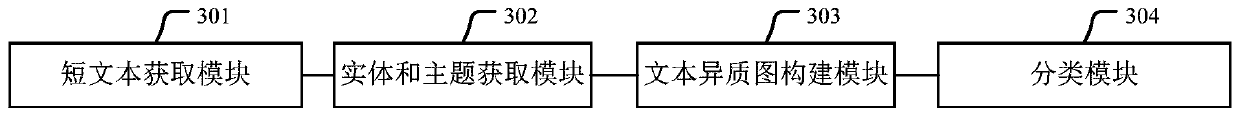

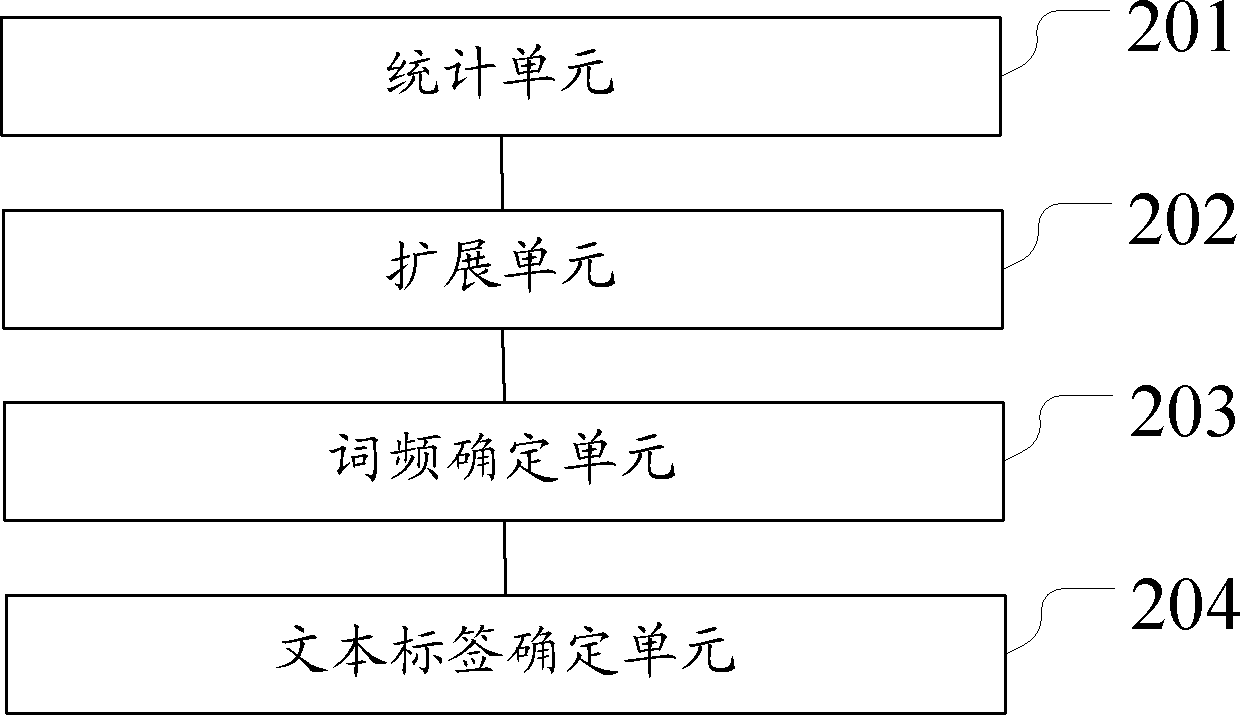

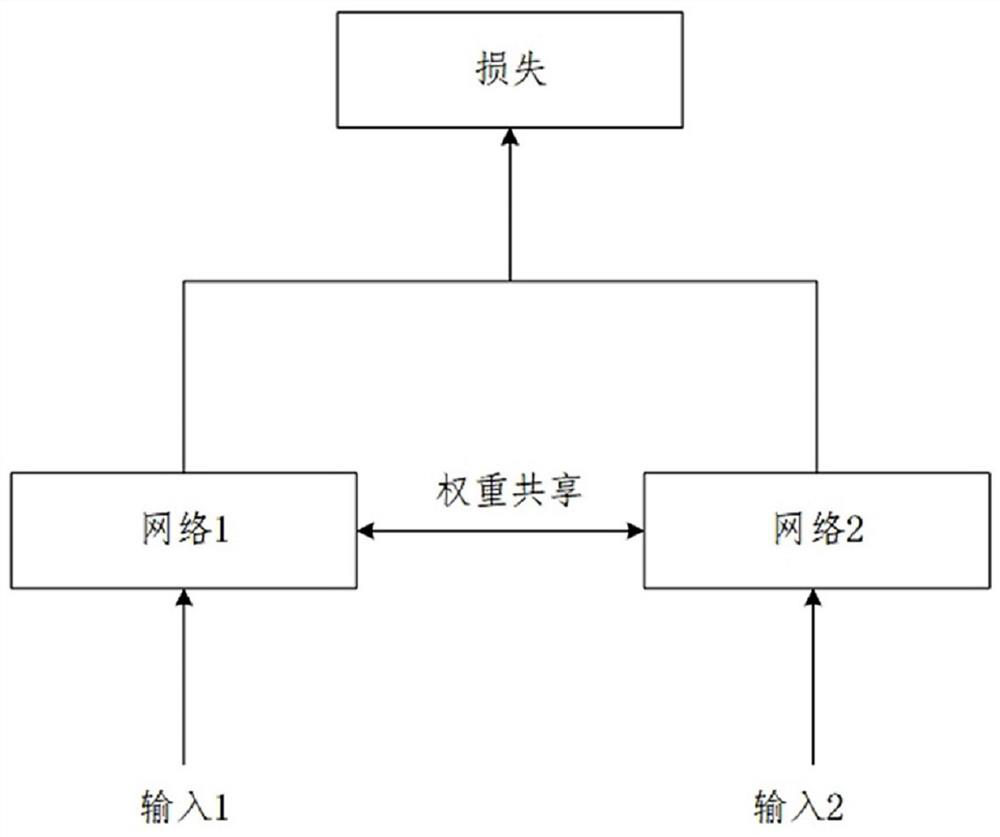

Classification method and device for short texts

ActiveCN110704626AImprove accuracyNeural architecturesNeural learning methodsText categorizationClassification methods

The embodiment of the invention provides a classification method and device for short texts. According to the method, to-be-classified short texts are classified; according to the entities obtained from the to-be-classified short texts and the affiliation relationships between the topics and the to-be-classified short texts, the to-be-classified short texts are classified; TEXT HETEROGENEOGRAPHICSare constructed, the constructed text heterogeneous graph is input into a preset text classification model; a classification result of the to-be-classified short text is obtained. By applying the text heterogeneous graph constructed by the embodiment of the invention, the semantic relationship in the to-be-classified short text can be captured; moreover, the heterogeneous graph convolutional neural network does not need too much annotation data during training, so that the accuracy of the trained text classification model during short text classification is higher, and therefore, the accuracy of short text classification can be improved by applying the method provided by the embodiment of the invention.

Owner:BEIJING UNIV OF POSTS & TELECOMM

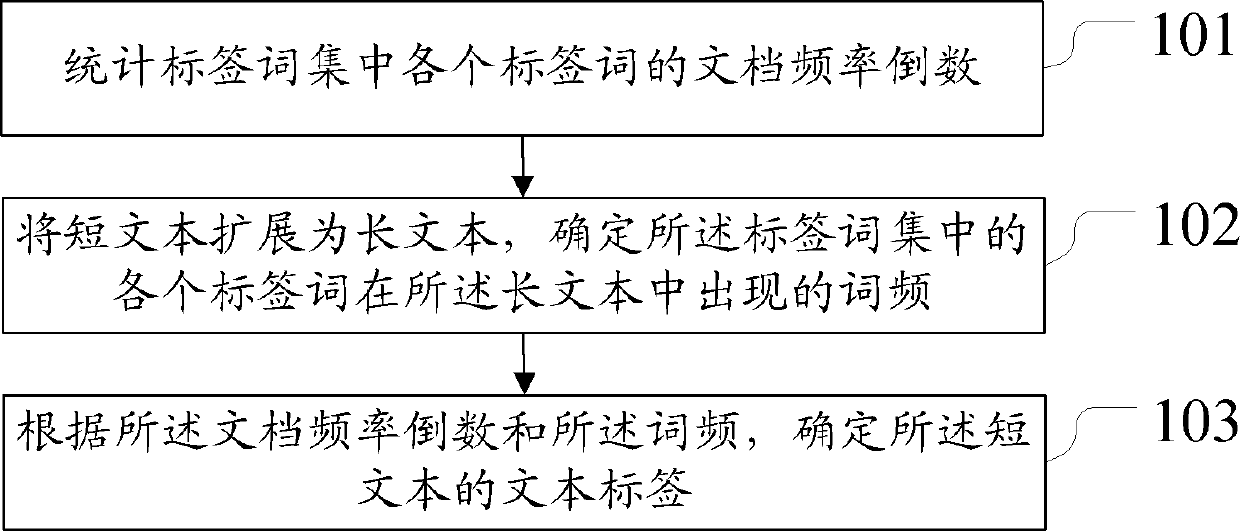

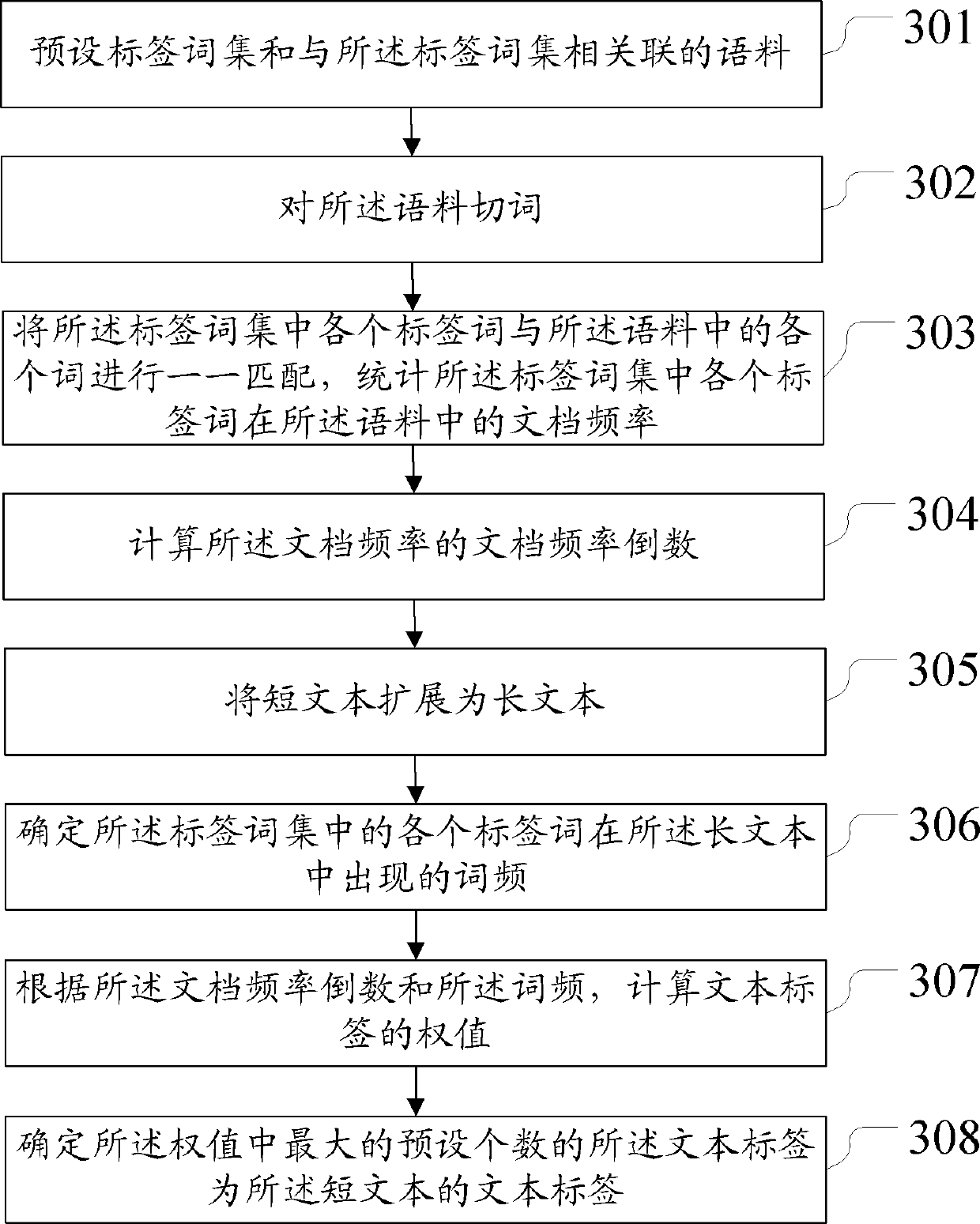

Method and device for adding tags to short texts automatically

ActiveCN103377185AImprove accuracyEasy to operateSpecial data processing applicationsThe InternetDocumentation

The invention discloses a method and a device for adding tags to short texts automatically and relates to the technical field of the Internet. By the aid of the method and the device, the tags can be added to the short texts automatically, and the accuracy of the added tags is improved. According to the method and the device, through statistics of inverse document frequencies of various tag words in tag word sets, the short texts are extended into long texts, word frequencies of appearance of the various tag words of the tag word sets in the long texts are determined, and according to the inverse document frequencies and the word frequencies, the text tags of the short texts are determined. The method and the device are applicable to adding of the tags to the short texts.

Owner:SHENZHEN SHI JI GUANG SU INFORMATION TECH

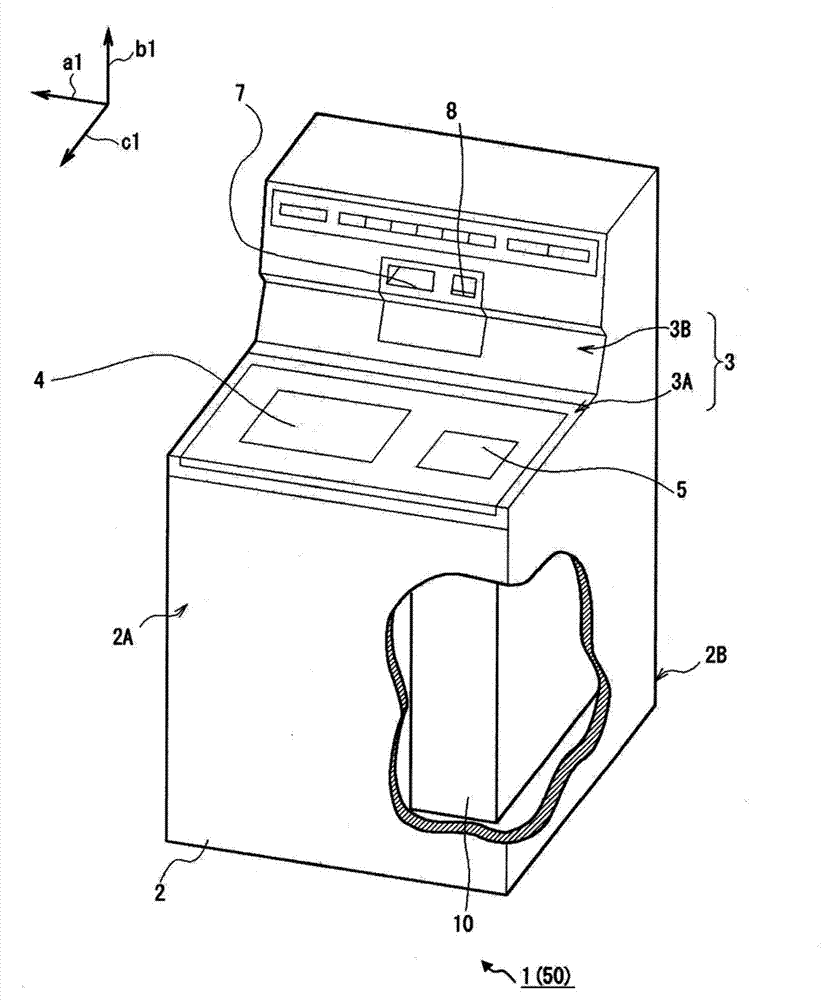

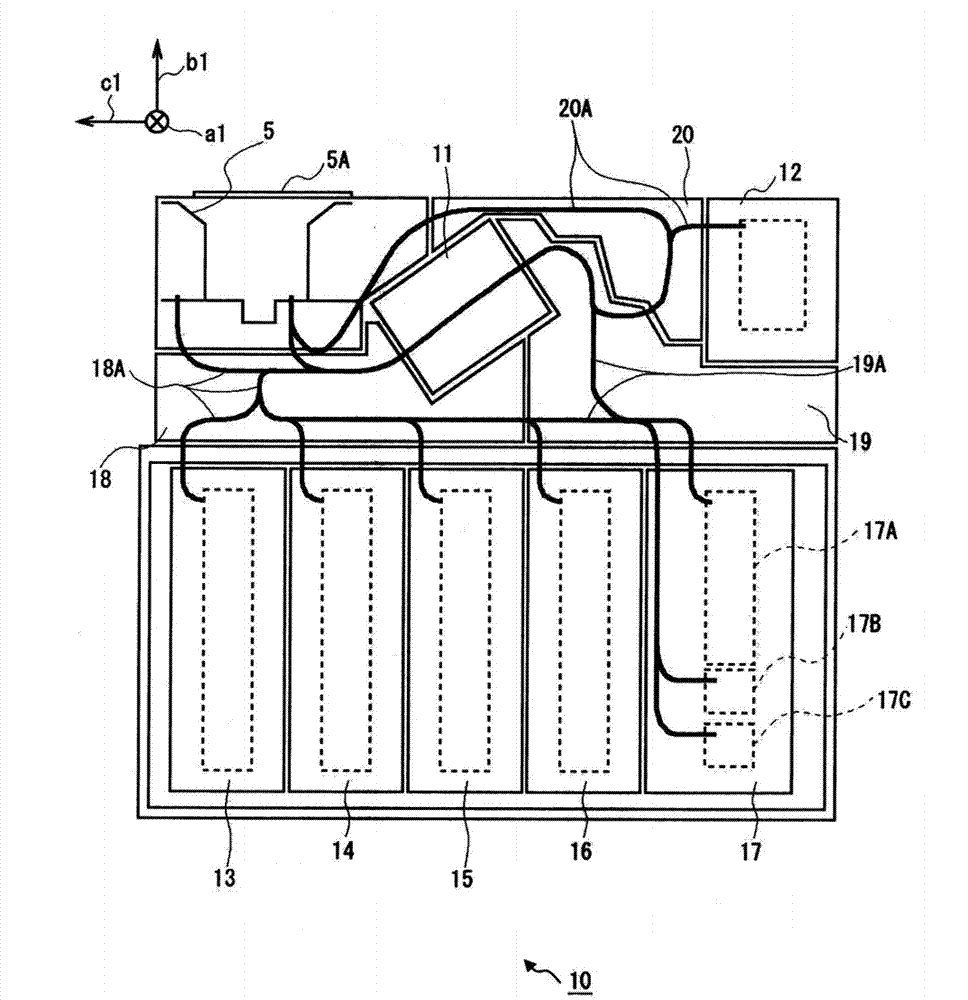

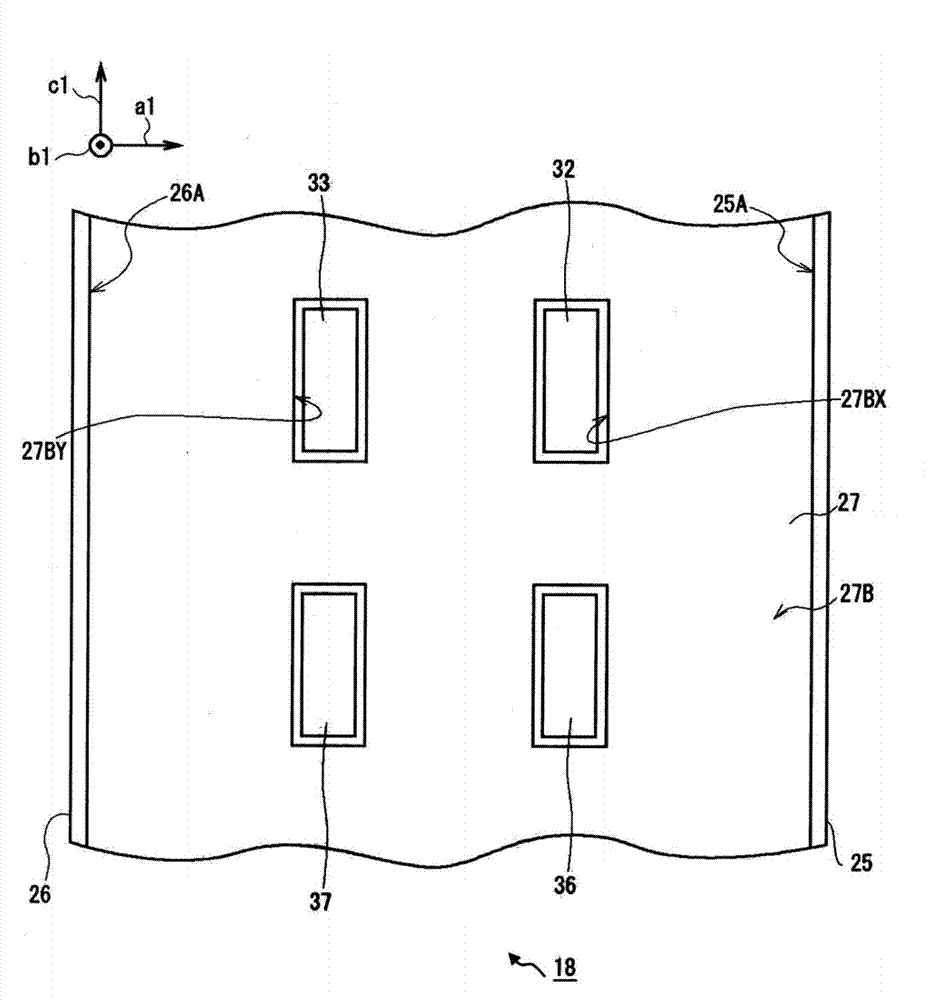

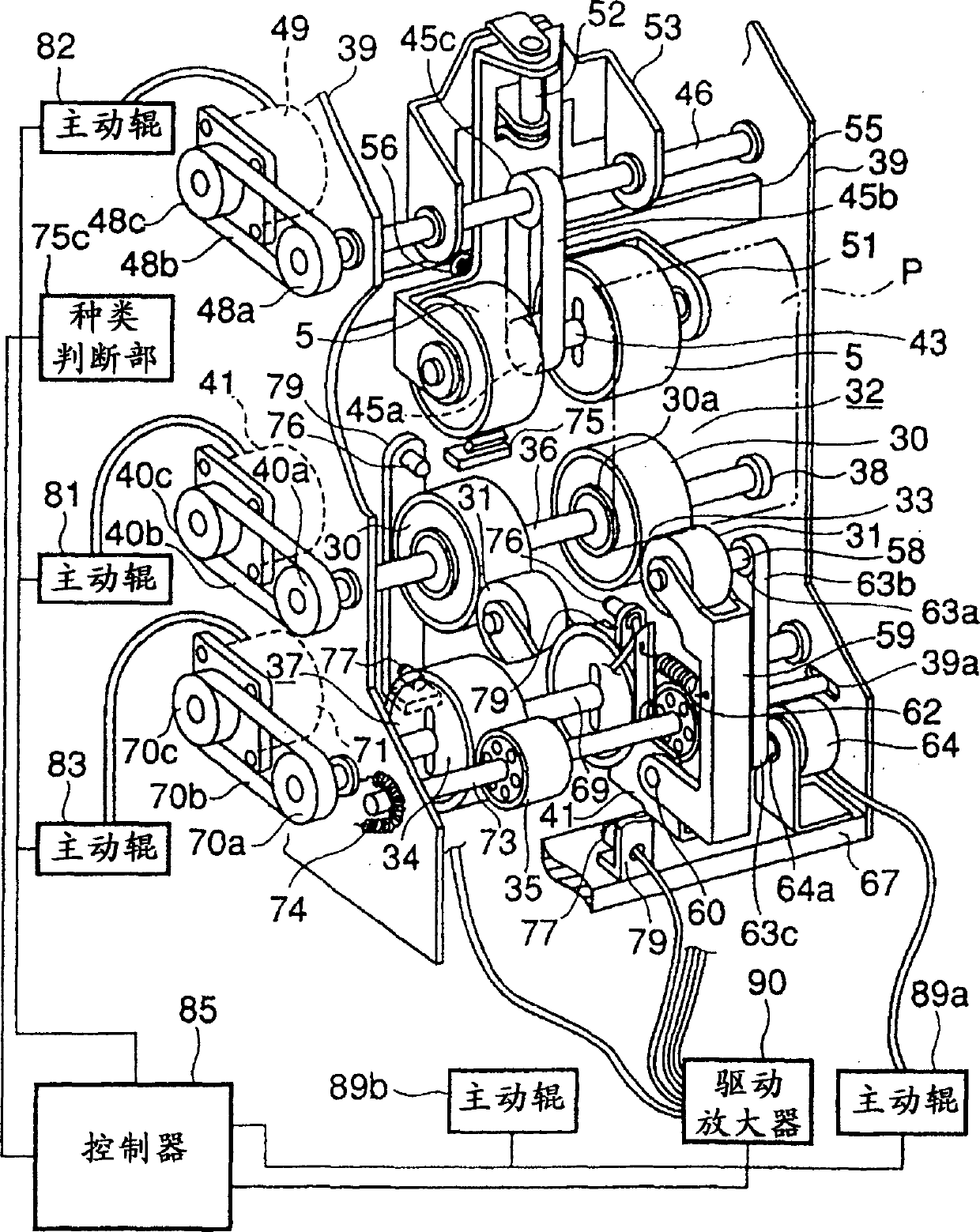

Paper sheet conveying device and paper sheet processing device

The present invention provides a paper sheet conveying device and a paper sheet processing device. Between a pair of frames configured with a conveying path width corresponding to a long edge length of a long edge longest paper sheet, more than two rollers used for conveying paper sheets are configured successively in a direction of the conveying path width, one roller is configured to enable the center of a roller width direction to be located at a position nearer to one frame than the position of the length of the long edge of a long edge shortest paper sheet from one frame to the other frame side, the other roller is configured to enable the center of a roller width direction to be located at a position nearer to the other frame than the position of the length of the long edge of the long edge shortest paper sheet from the other frame to one frame side. For this reason, in the case of enabling the long edge shortest paper sheet to pass through any position relative to the direction of the conveying path width in a conveying posture that one long edge is towards a conveying direction, the two rollers can be used to perform conveying all the way, any side of rectangular paper sheets with different sizes can be accurately conveyed in a conveying posture that one long edge is towards a conveying direction.

Owner:OKI ELECTRIC IND CO LTD

Quick-drying brilliant offset printing ink

The invention discloses a fast-drying high-gloss offset printing ink. The weight proportion of the oil ink is: 50 to 70 portions of binder material, 13 to 20 portions of pigment, 5 to 15 portions of ink oil, and 5 to 15 portions of auxiliary agent, wherein, the binder material is rosin modified phenolic resin which is prepared through the following steps that: phenolic aldehyde condensation is performed; the condensed phenolic aldehyde undergoes addition operation; a semi-finished product is produced through an esterification reaction; whether the semi-finished product is qualified is checked; and qualified semi-finished product undergoes oil refining to produce a finished product. The ink has high density, less ink flying, short paper drying time and good wear-resistant effect, so the oil ink has good transfer performance, can achieve the effect of quick-drying high gloss, and be suitable for high-speed printing.

Owner:SHANGHAI PEONY PRINTING INK

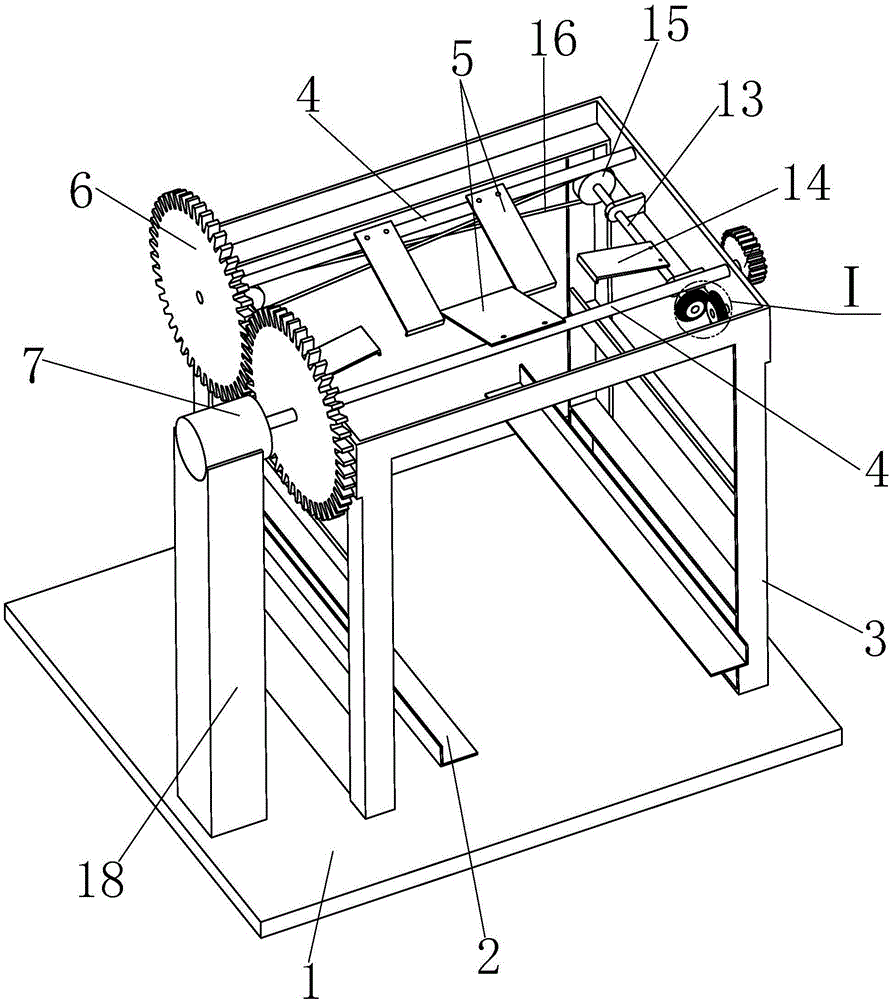

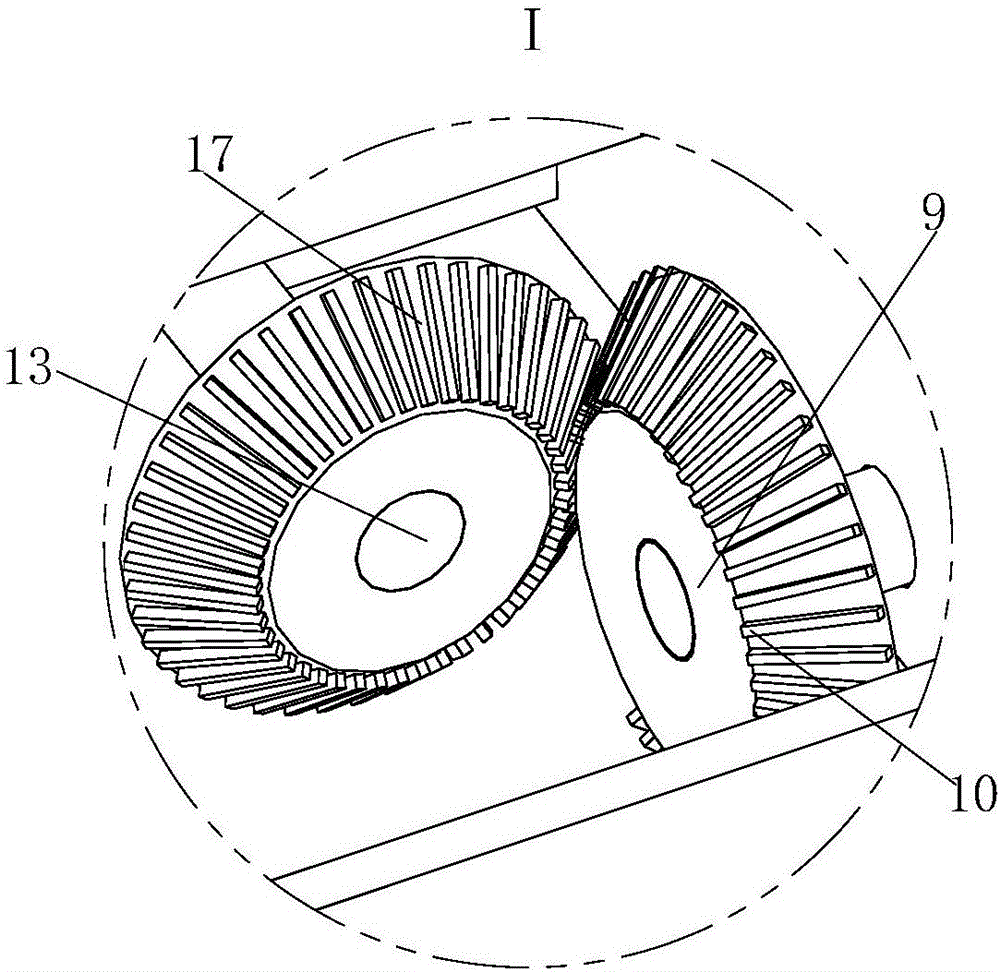

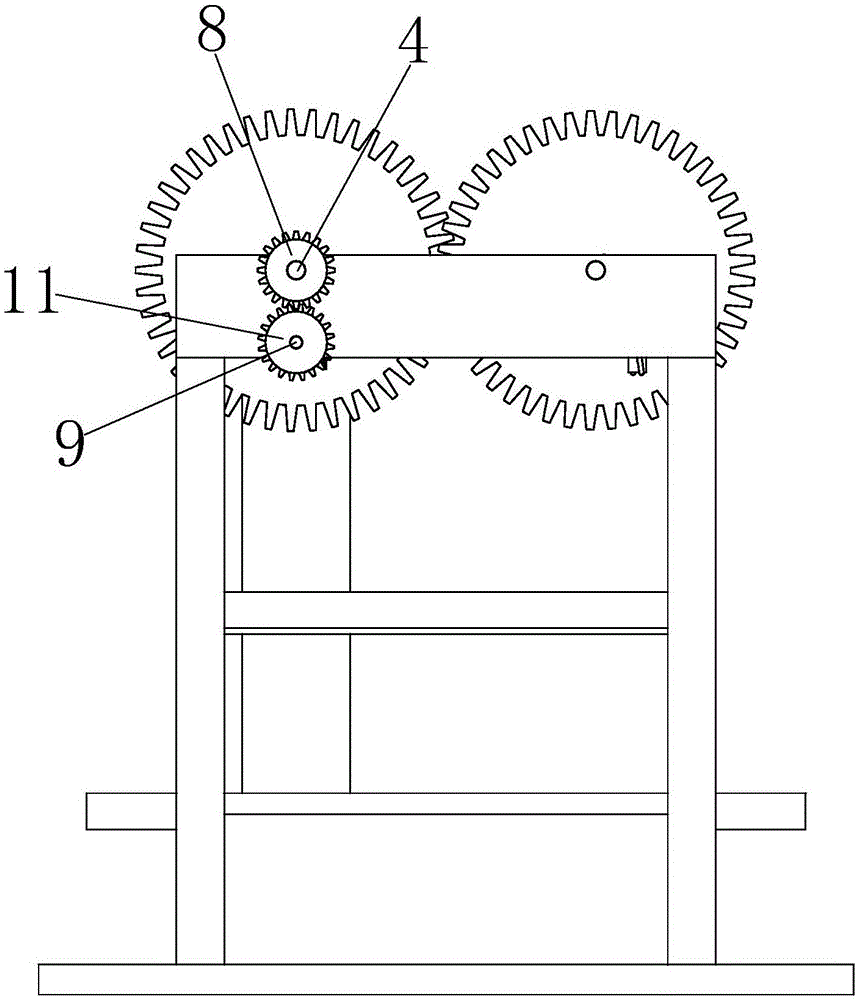

Automatic case unpacking machine for packing

The invention relates to an automatic case unpacking machine for packing. The automatic case unpacking machine comprises a base plate and a transverse beam frame installed over the base plate, a conveyor rail is fixedly installed at the lower portion of the transverse beam frame, two long rods are installed at the front portion and the back portion of the upper end of the transverse beam frame through bearing blocks correspondingly, the middle portions of the two long rods are provided with long cover opening plates, and two large gears are installed on the left portions of the two long rods and are meshed; a motor and an upper gear are correspondingly connected to the left end and the right end of the long rod, located on the front side, of the two long rods, and the right side of the transverse beam frame is provided with a transmission shaft through a bearing; and an incomplete bevel gear and a lower gear are correspondingly installed at the left end and the right end of the transmission shaft, and the lower gear is meshed with the upper gear. The automatic case unpacking machine is high in automatic degree, two long paper covers and two short paper covers can be automatically opened in sequence through wheel gear transmission and belt conveying under driving of single control elements, the effects of saving manpower and convenient to pack are achieved, and control is relatively convenient.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

Paper taking-out device

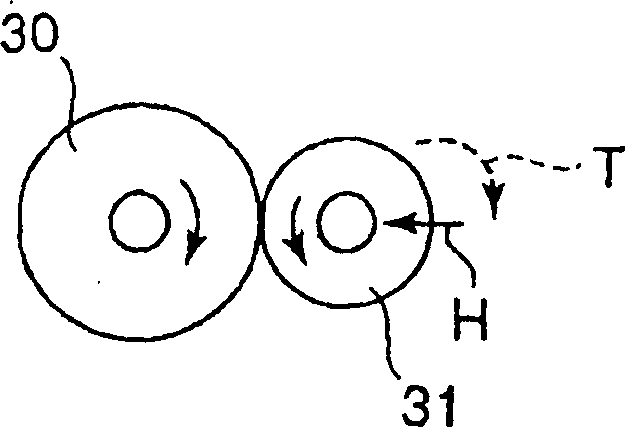

The invention provides a paper sheet taking out device capable of stably taking out paper sheets without receiving influence of thickness and friction coefficient of paper sheets and of nicely taking out from short paper sheets to long paper sheets without sacrificing diameter or layout of a feeding roller, a taking out roller and a carrying roller. An optical reflection reading apparatus 75 photoelectrically converting a surface of a bill P and a type judging part judging a type of a bill P taken out by the taking out roller 30 based on output signal of the optical reflection reading apparatus 75 are provided between a pick up roller 5 and the taking out roller 30. The type of the bill P is judged before taking in the bill P, based on the judgment result, a first detector 76 right after the taking out roller 30, and a second detector 77 right after the carrying roller 34, drive of the pick up roller 5 and the taking out roller 30 are controlled respectively.

Owner:KK TOSHIBA

Method of treating waste from a chicken house using short paper fibers

A method of treating waste from chickens in a chicken house includes applying a layer of short paper fibers over a floor of the chicken house horizontally below the chickens in the chicken house, mixing manure from the chickens with the layer of short paper fibers, and removing the mixed manure and short paper fibers from the chicken house. The manure is turned with the layer of short paper fibers such that the manure and the short paper fibers are intimately mixed together. The removed mixture can be spread over land.

Owner:LAUBENSTEIN JOSEPH W

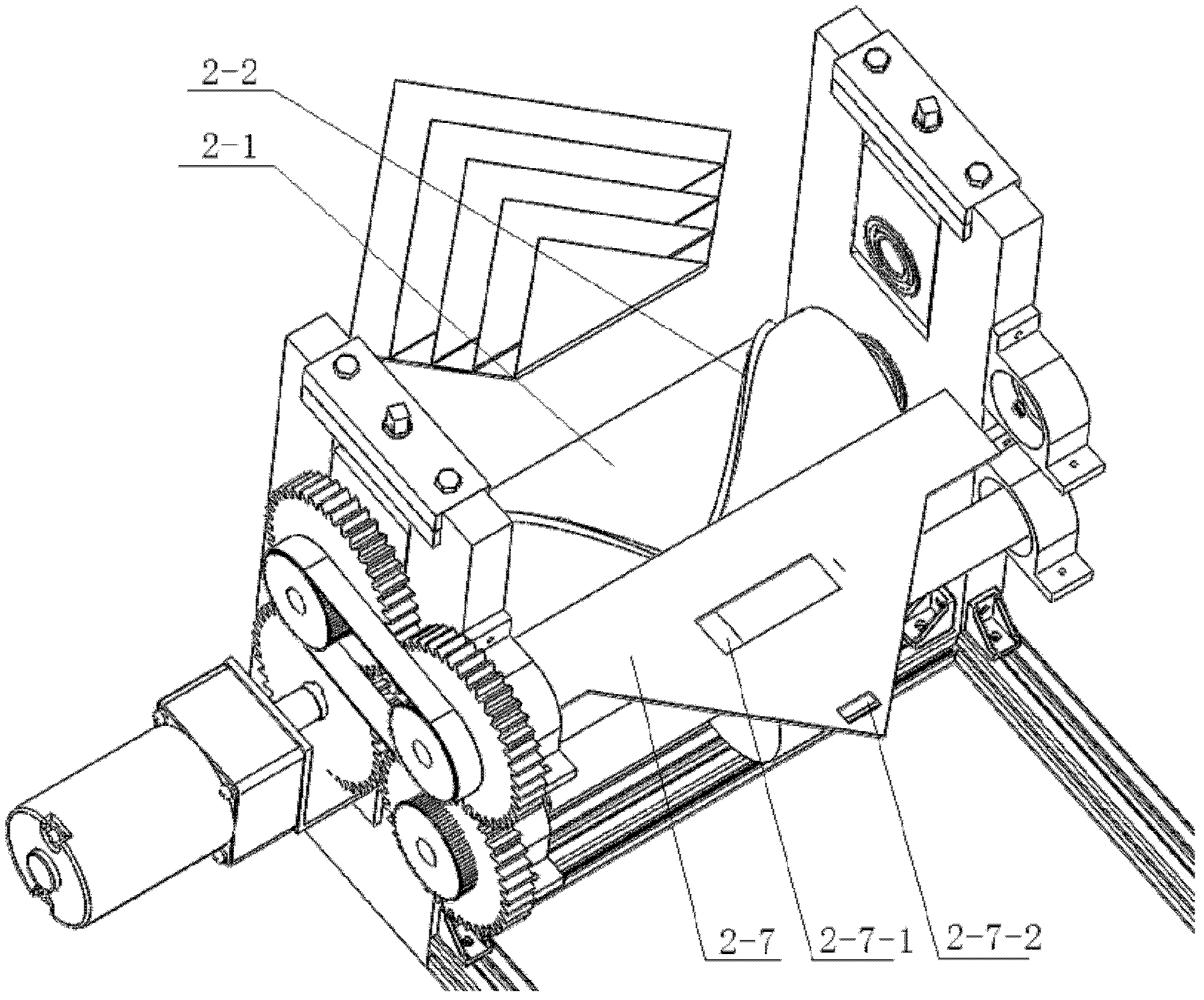

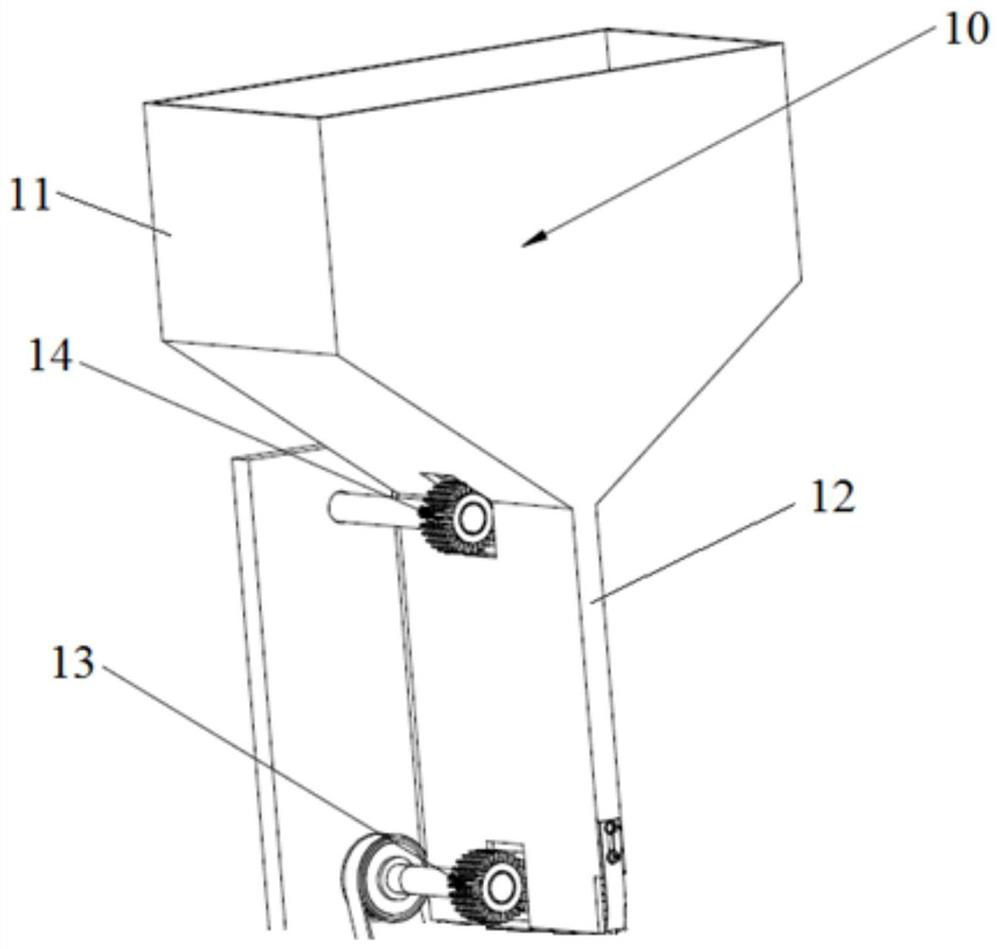

Crease folding module of napkin folding production line

InactiveCN102423922AImprove foldabilityStable and beautiful hemsPaper/cardboard articlesOptical axisAgricultural engineering

The invention discloses a crease folding module of a napkin folding production line. The module comprises a frame, vertical plates, a speed reducing motor, a creasing device and a folding device, wherein the two vertical plates are fixed on the frame; a first creasing roller and a second creasing roller are rotatably mounted on the vertical plates; two short paper pressing rollers are mounted on the frame through a plummer block; a paper folding roller is fixedly mounted on the frame through a plummer block; the speed reducing motor is in transmission connection with the creasing device and the folding device; the crease folding module also comprises a crease bending device; a crease bending device mounting plate is mounted on the frame through a frame connection plate; an electromagnet and a slider are symmetrically distributed and fixed on the crease bending device mounting plate; an optical shaft is sleeved in the slider and can slide up and down; the upper ends of two optical shafts are fixedly connected by an optical shaft connection plate; a crease bending plate is fixedly mounted at the lower end of the optical shaft; and an armature of the electromagnet is fixedly connected with the optical shaft connection plate. Through the invention, the crease folding process is realized, the folding effect is good, and the folded edge is stable.

Owner:ZHEJIANG UNIV

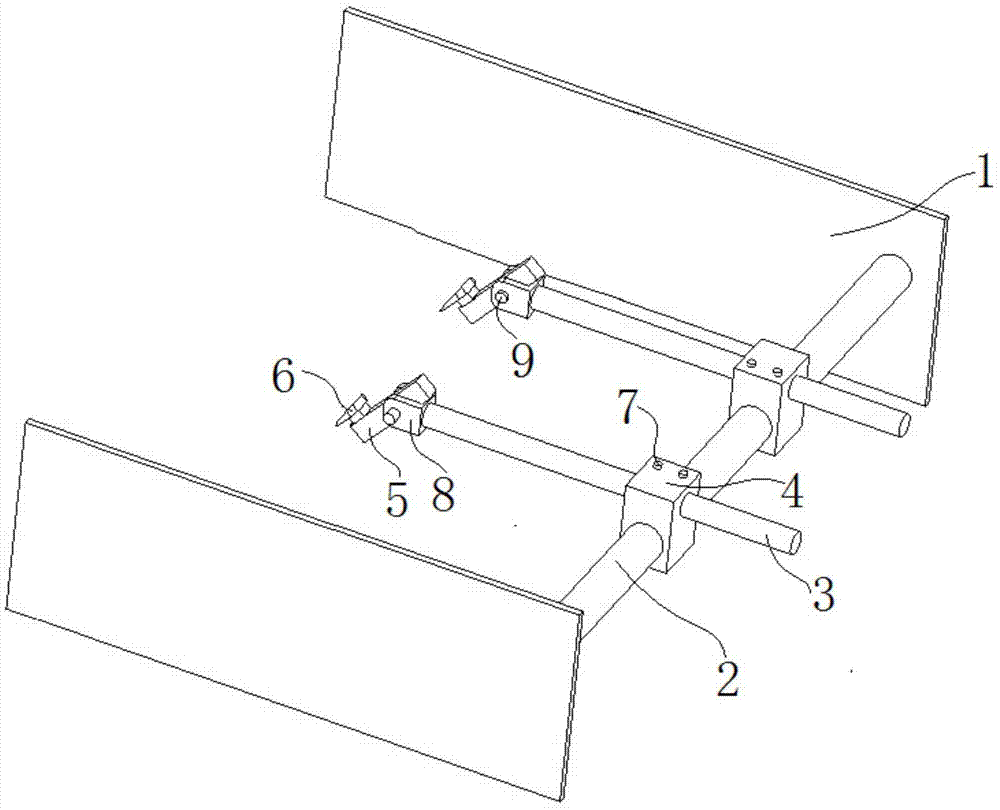

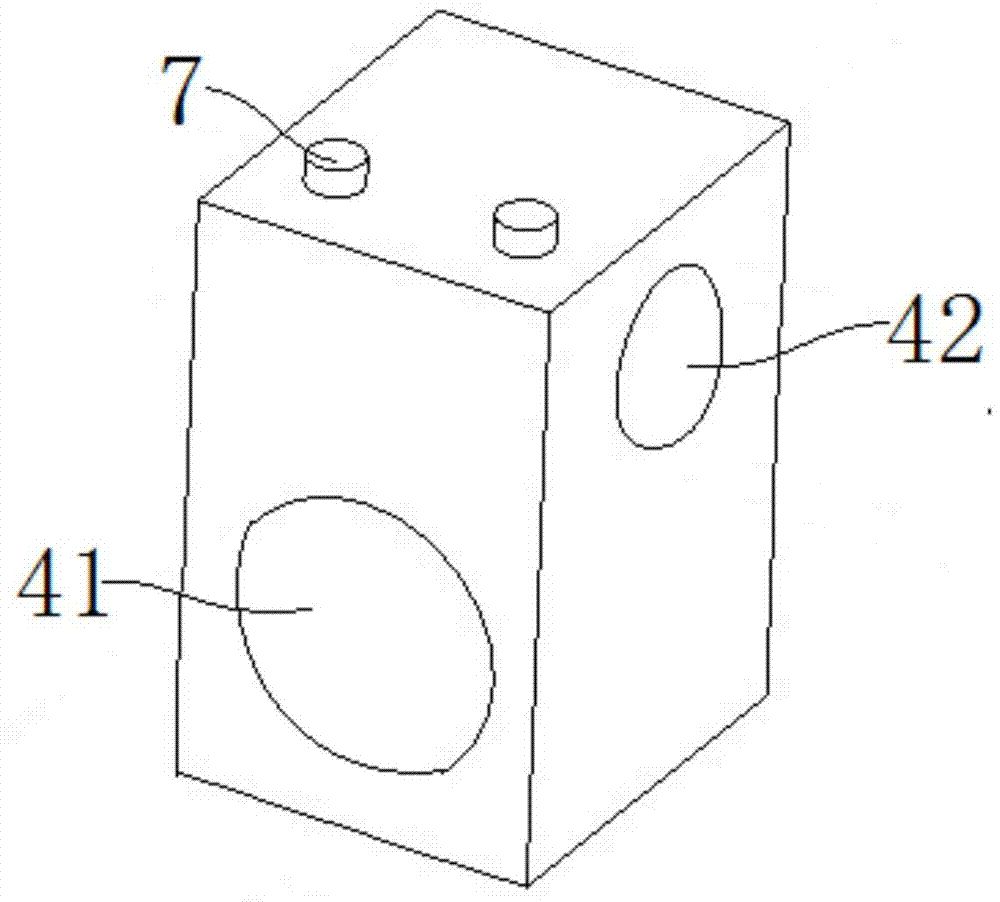

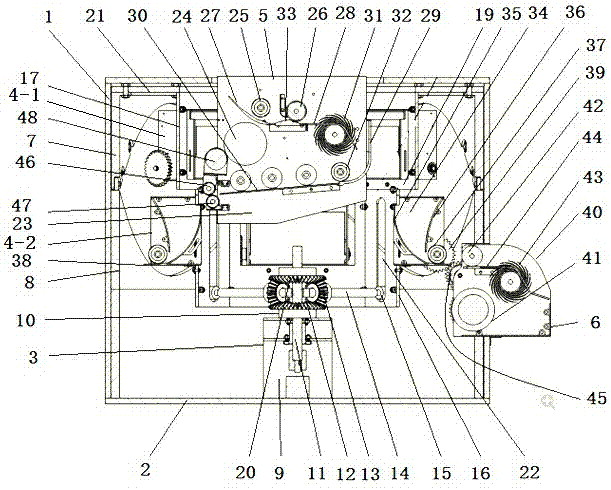

Paper tube cutting machine

ActiveCN103009418BOvercoming the disadvantages of deflectionChange widthMetal working apparatusPulp and paper industryControl switch

The invention discloses a paper tube cutting machine. In the paper tube cutting machine, an output shaft of an adjustable-speed motor is provided with a first clamping disk and an expansion shaft; dual projection rods of a dual-projection-rod air cylinder are used for fixing a bracket of a cutting air cylinder; the bracket is provided with a fixed shaft; the fixed shaft is used for rotationally supporting a second clamping disk and a support shaft; the second clamping disk is provided with an edge boss which is jointed on a long paper tube; and the support shaft is sleeved with a long paper tube cut part ejection mechanism constructed by a spring and a push disk. The dual-protection-rod air cylinder can be used for realizing propulsion of the support shaft and the second clamping disk for tightening a long paper tube under the control of an electromagnetic valve control switch, and the edge boss of the second clamping disk is used for driving the spring to accumulate energy and driving the push disk to retract after being jointed with the long paper tube. The cutting air cylinder can be used for applying a pressure to a circular cutter under the control of the electromagnetic valve control switch, and the circular cutter returns back along with the cutting air cylinder after cutting is completed. The position of the cutting air cylinder on the bracket can be adjusted for changing the width of a short paper tube. The paper tube cutting machine has the outstanding advantages of simple and practical structure, high cutting efficiency and good quality.

Owner:TIANJIN JINSHANYIDE PLASTIC PACKAGING CO LTD

Paper straw beveling device

The invention discloses a paper straw beveling device. The device comprises a feeding device, a conveying mechanism and a cutting device, wherein the feeding device is provided with a containing cavity for containing a paper straw and a feeding opening communicating with the containing cavity, the conveying mechanism comprises a bearing part and a pressing part matched with the bearing part, strawgrooves which are formed at intervals and correspond to the feeding opening are formed in the bearing part, the pressing part is used for pressing the paper straw in the corresponding straw groove, apreset included angle is formed between the moving direction of the paper straw on the conveying mechanism and the length direction of the paper straw, a cutting groove is formed in the bearing part,the cutting device is arranged on a conveying path of the conveying mechanism and corresponds to the cutting groove, the cutting device is provided with a cutter, the cutting direction of the cutteris consistent with the moving direction of the conveying mechanism, the cutter cuts the paper straw on the conveying mechanism, and the long paper straw is obliquely cut into two short paper straw with tips. By arranging the feeding device, the conveying mechanism and the cutting device, the device obliquely cuts the long paper straw into the two short paper straws with the tips.

Owner:GREATVIEW ASEPTIC PACKAGING SHANDONGCO

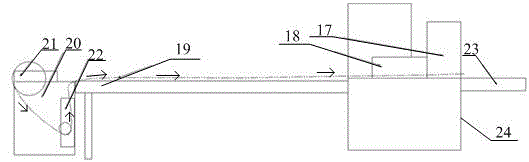

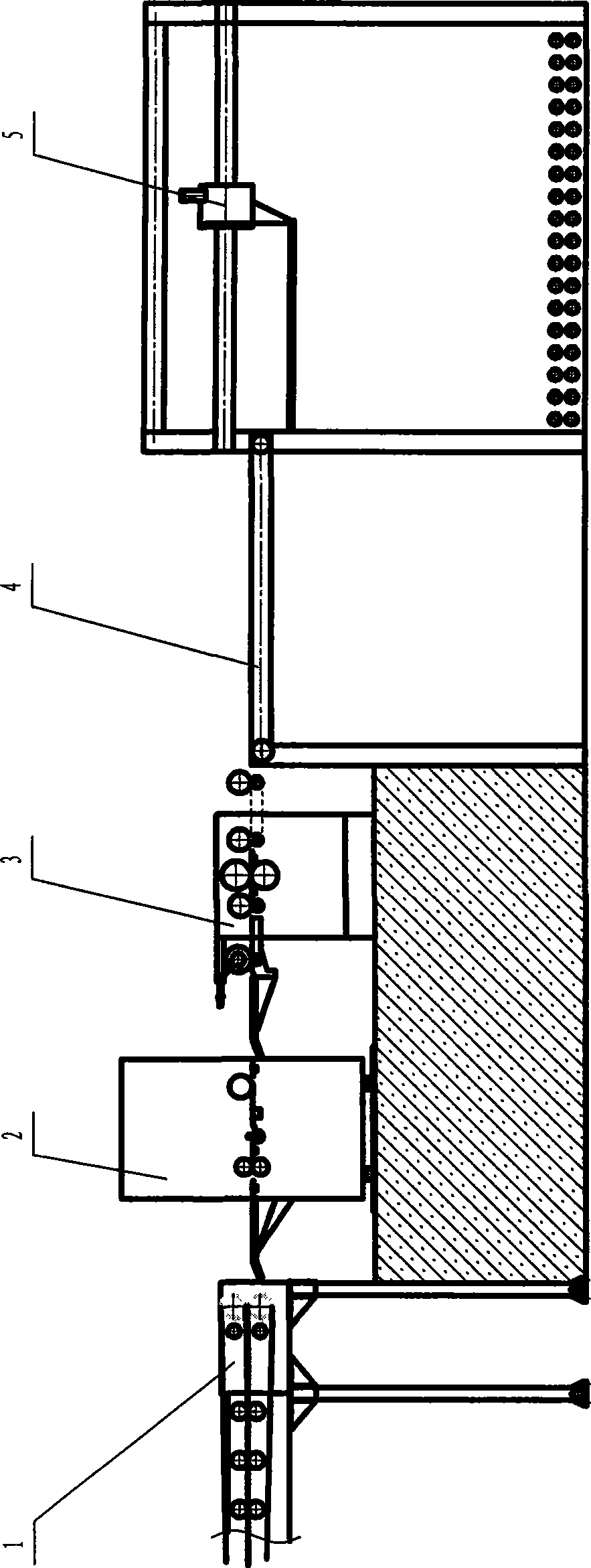

Pillow type packaging machine with ultra-short paper feeding path

InactiveCN104590619AShorten the paper pathIncrease profitWrapping material feeding apparatusPulp and paper industryPaper sheet

The invention relates to the field of pillow type packaging machines, in particular to a pillow type packaging machine with an ultra-short paper feeding path. The pillow type packaging machine with the ultra-short paper feeding path comprises a machine frame, a knife sealing mechanism, a middle sealing mechanism, a tail frame and an output mechanism and is characterized in that the rear end of the tail frame is provided with a paper supporting and feeding mechanism assembly, and the paper supporting and feeding mechanism assembly is composed of an assembly frame, a paper supporting mechanism and a paper feeding mechanism. According to the pillow type packaging machine with the ultra-short paper feeding path, the packaging paper feeding path is greatly shortened, the effects that paper bags do not deform and cutting is accurate can be achieved even when no much packaging paper is left, paper replacement is not needed, accordingly, the packaging paper utilization rate is improved, and waste is reduced.

Owner:SHANDONG SONGYUAN AUTOMATION EQUIP

Paper-feeding accumulation structure of corrugated paper board production line

InactiveCN101508185AIncrease heightReasonable useMechanical working/deformationProduction linePulp and paper industry

The invention belongs to the technical field of packing and relates to a paper stacking structure of a corrugated board production line, in particular to a structure for bonding finished corrugated boards in a compound channel of the corrugated board production line and then outputting, slitting, transversely cutting and stacking the finished corrugated boards. The stacking structure mainly comprises the compound channel of the corrugated board production line, a slitting mechanism, a transverse cutting unit and a stacking machine, wherein the compound channel of the corrugated board production line is connected with the transverse cutting unit and the transverse cutting unit is connected with the slitting mechanism. The stacking structure is characterized in that the rear part of the transverse cutting unit is connected with a paper overpass and that the paper overpass and is connected with the stacking machine. The structure improves the height of the compound channel of the corrugated board production line, the slitting height and the transverse cutting height, uses short paper overpass to send the boards into the stacking machine for stacking, makes more reasonable use of production space and occupies small floor area.

Owner:朱振华

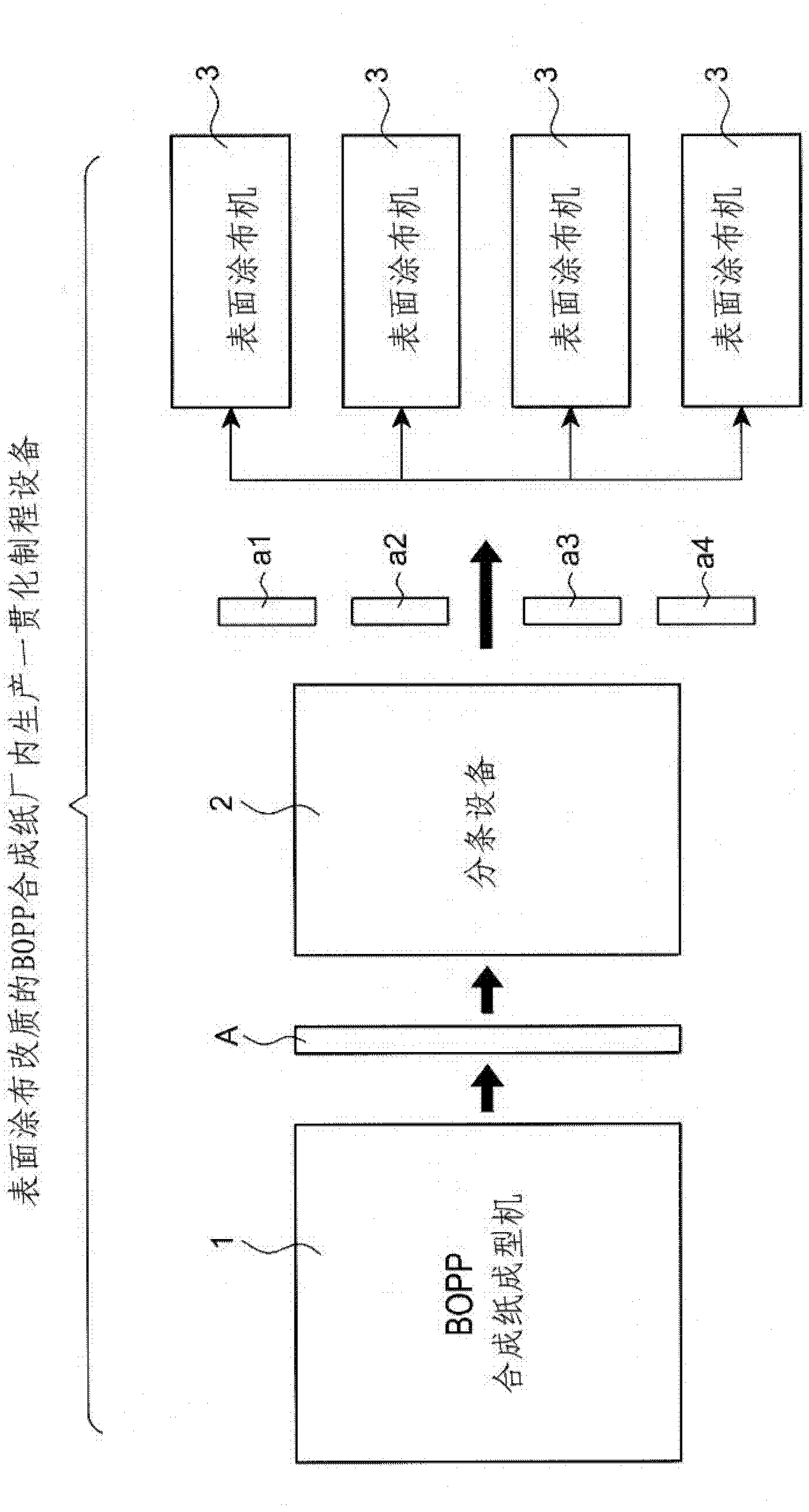

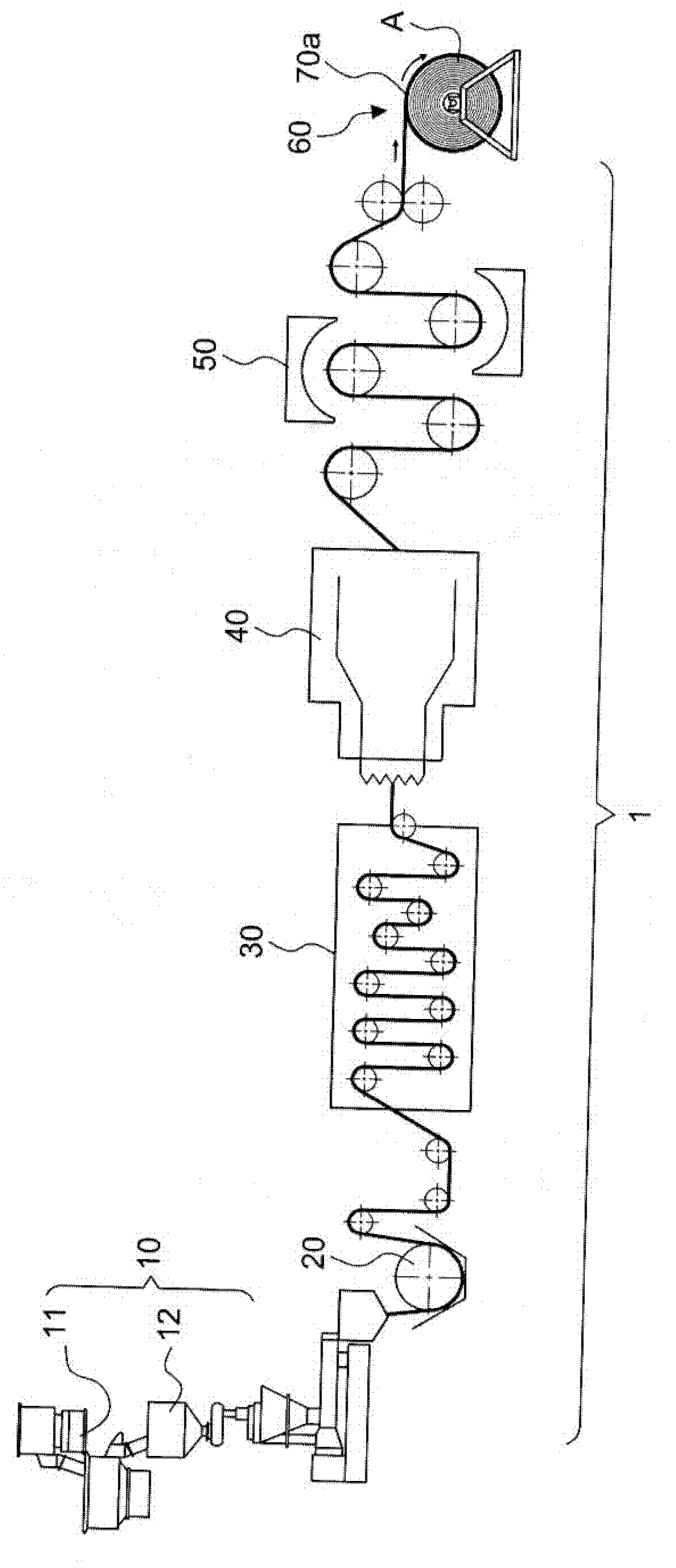

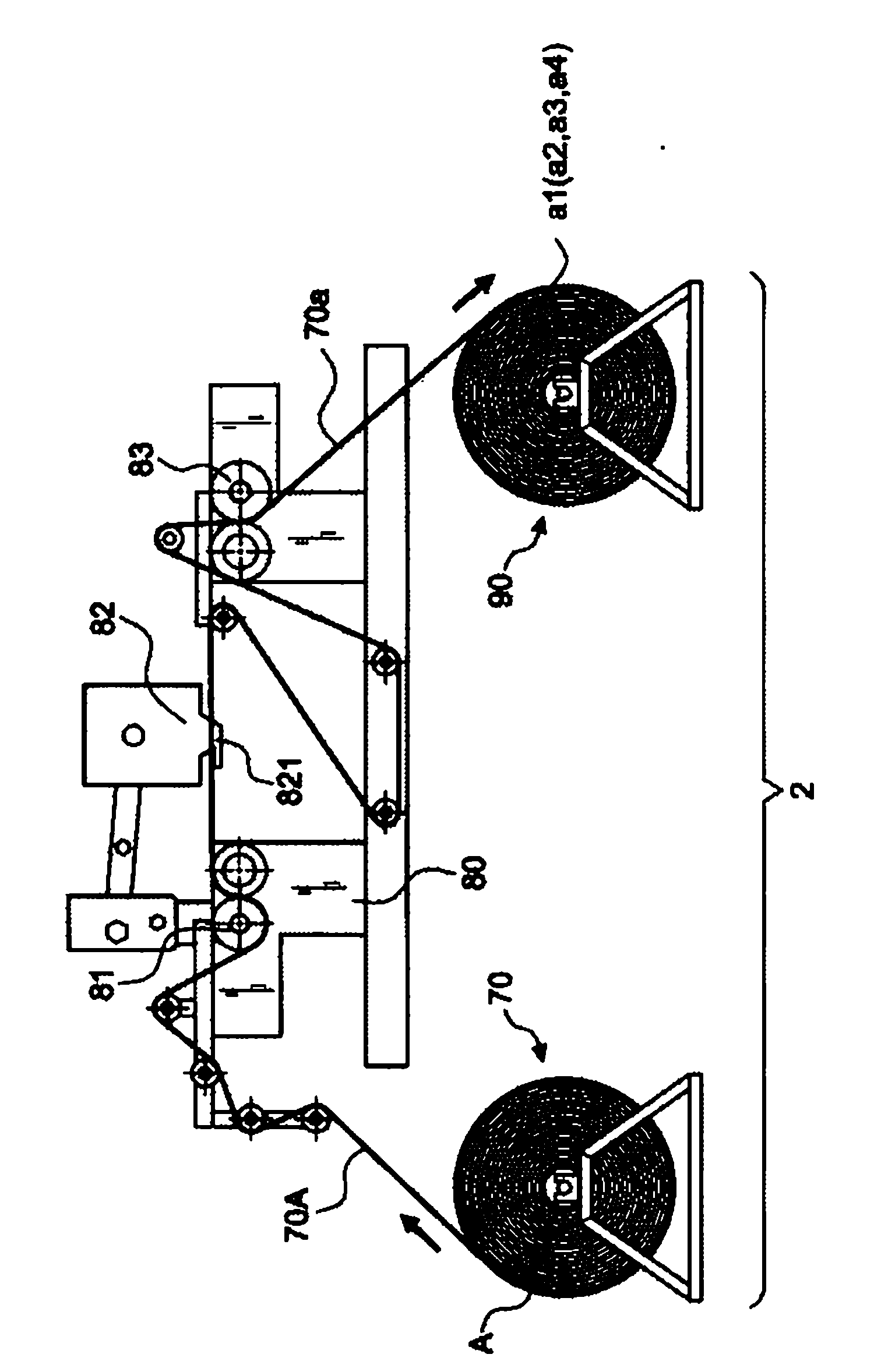

Integrated processing device of in-plant production of surface-coated and modified BOPP (Biaxially Oriented Polypropylene) synthetic paper

InactiveCN103009647AMonitor qualityReduce labor costsFlat articlesCoatingsSurface layerPulp and paper industry

The invention relates to an integrated processing device of in-plant production of a surface-coated and modified BOPP (Biaxially Oriented Polypropylene) synthetic paper. The integrated processing device comprises a BOPP synthetic paper forming machine, a stripping device and at least one surface coating machine, wherein the BOPP synthetic paper forming machine is used for machining compositions mainly comprising polypropylene to finish primary blank synthetic paper and reeling the primary-blank synthetic paper to a long paper roll with the width of eight meters; then the stripping device is used for cutting the long paper roll with the width of eight meters into multiple segments of short paper rolls by a cutting tool; and the at least one surface coating machine is used for carrying out surface coating and modifying on stripped short paper roll primary blanks to form a paper surface layer having multiple superfine air hole volumes and an air hole series connection degree similar to the natural paper. According to the integrative processing device of the in-plant production of the surface-coated and modified BOPP synthetic paper, the in-plant integrative production is realized, the cultural paper or the packaging paper can be produced with the lowest cost and production process, and the target of protecting environmental resources is accorded.

Owner:陈博彦

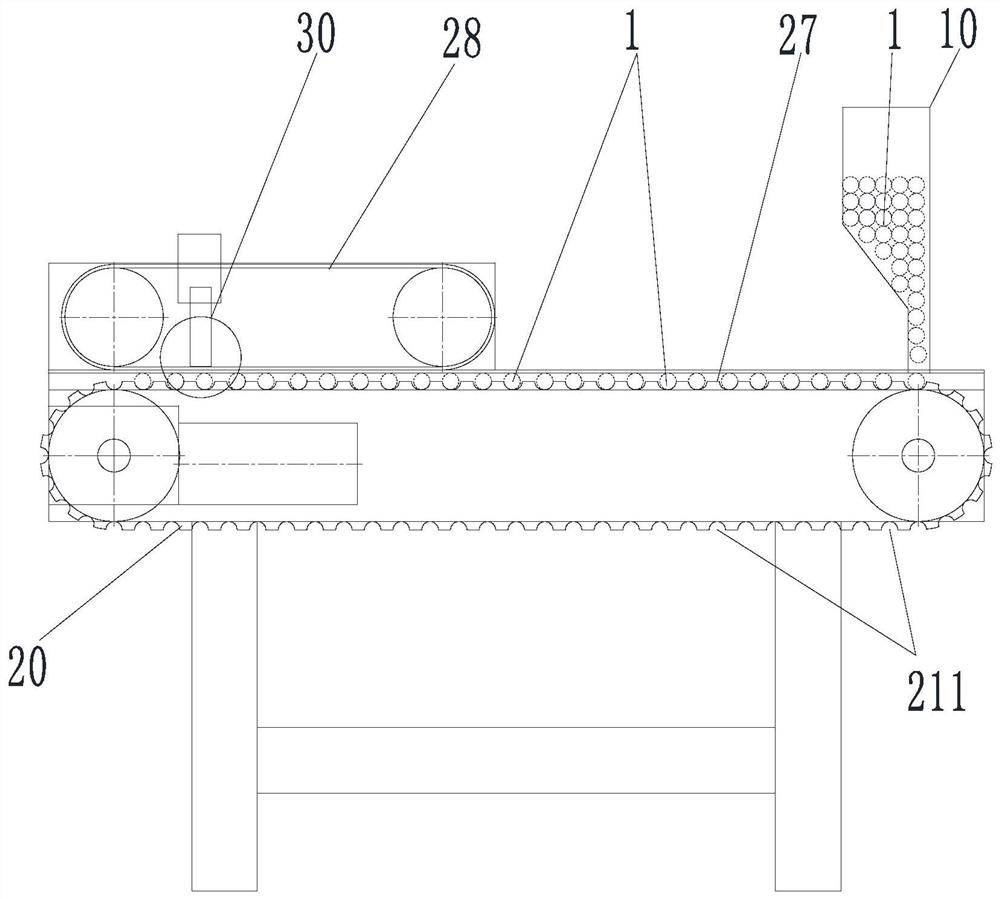

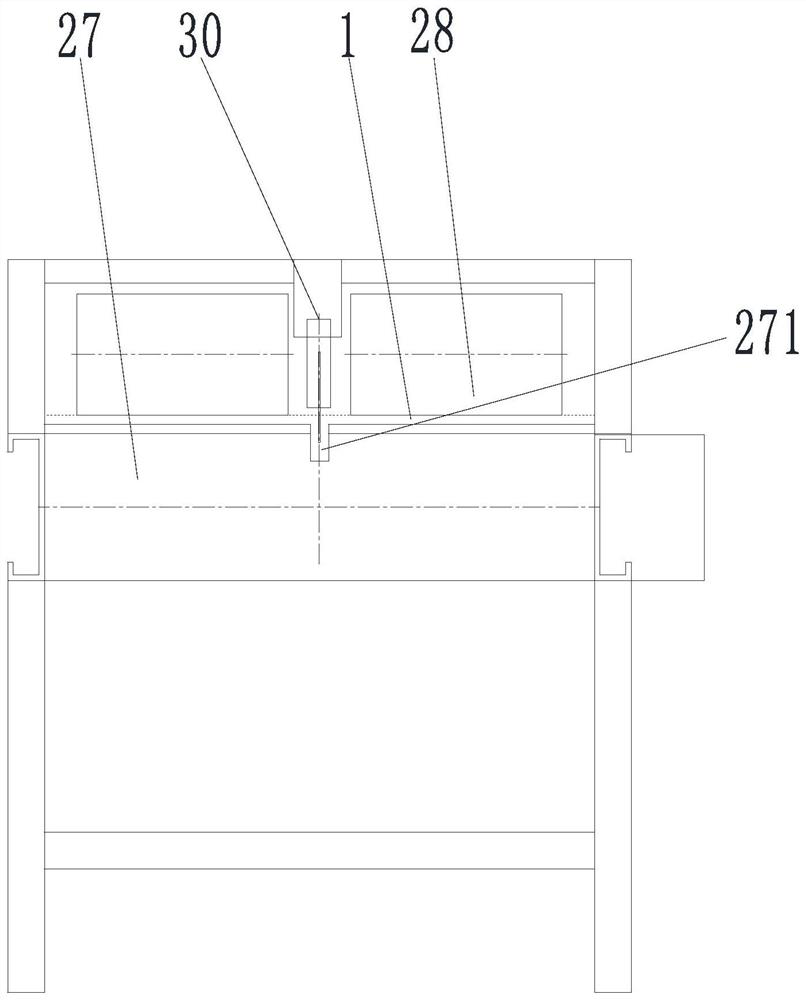

Full-automatic paper mounting machine paper feeding mechanism capable of conveying short paper pieces

The invention discloses a full-automatic paper mounting machine paper feeding mechanism capable of conveying short paper pieces and belongs to the technical field of packaging machinery. The full-automatic paper mounting machine paper feeding mechanism comprises racks, a fixed shaft and two distance adjusting devices, and through the arrangement of the distance adjusting devices, the short paper pieces can be conveyed conveniently. The two distance adjusting devices are arranged on the fixed shaft in a sleeved mode. The fixed shaft is fixedly arranged on the racks. The paper feeding mechanism is ingenious in structural design, convenient to disassemble, assemble and operate and capable of adapting to processing more paper pieces with different sizes, especially the short paper pieces.

Owner:江苏东方印务有限公司

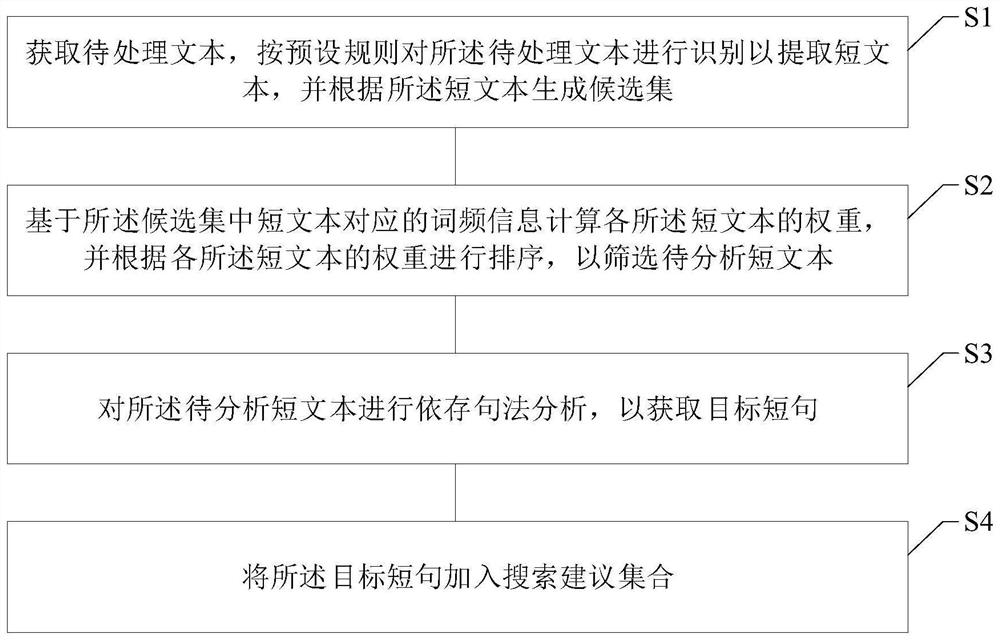

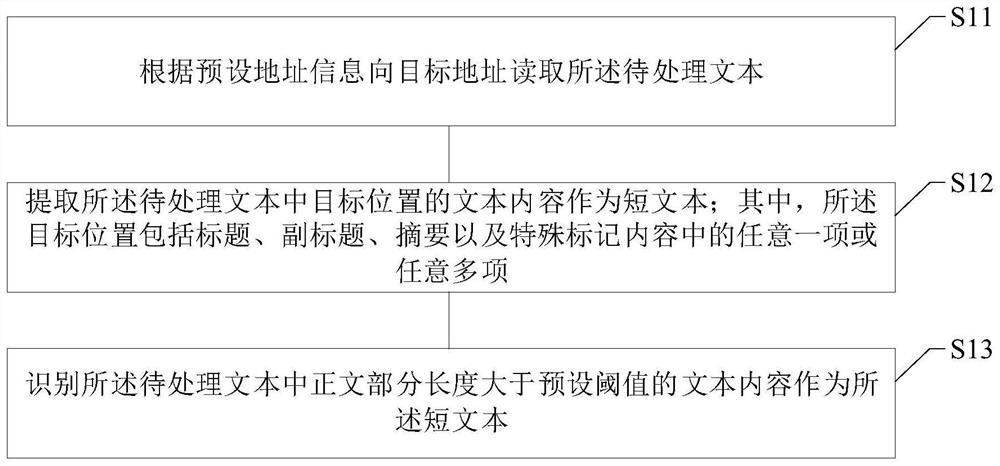

Content-based search suggestion generation method and device

PendingCN112711695AImprove timelinessAvoid brushing the data volume of search suggestion termsNatural language data processingWeb data queryingThe InternetEngineering

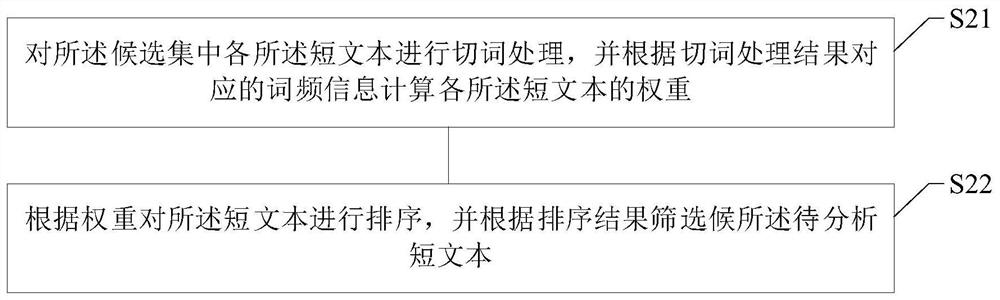

The embodiment of the invention relates to the technical field of the Internet, in particular to a content-based search suggestion generation method and device, a storage medium and electronic equipment. The method comprises the steps of obtaining a to-be-processed text, identifying the to-be-processed text according to a preset rule to extract a short text, and generating a candidate set according to the short text; calculating the weight of each short text based on the word frequency information corresponding to the short texts in the candidate set, and sorting according to the weight of each short text to screen short texts to be analyzed; performing dependency syntax analysis on the to-be-analyzed short text to obtain a target short sentence; and adding the target short sentence into a search suggestion set. According to the method, the timeliness of the generated search suggested entries can be effectively improved, and entries with higher real-time performance can be recommended to users. Especially for the news field, the timeliness of related recommended entries can be greatly improved.

Owner:NETEASE MEDIA TECH BEIJING

Domain-adaptive chemical potential safety hazard short text classification method and system

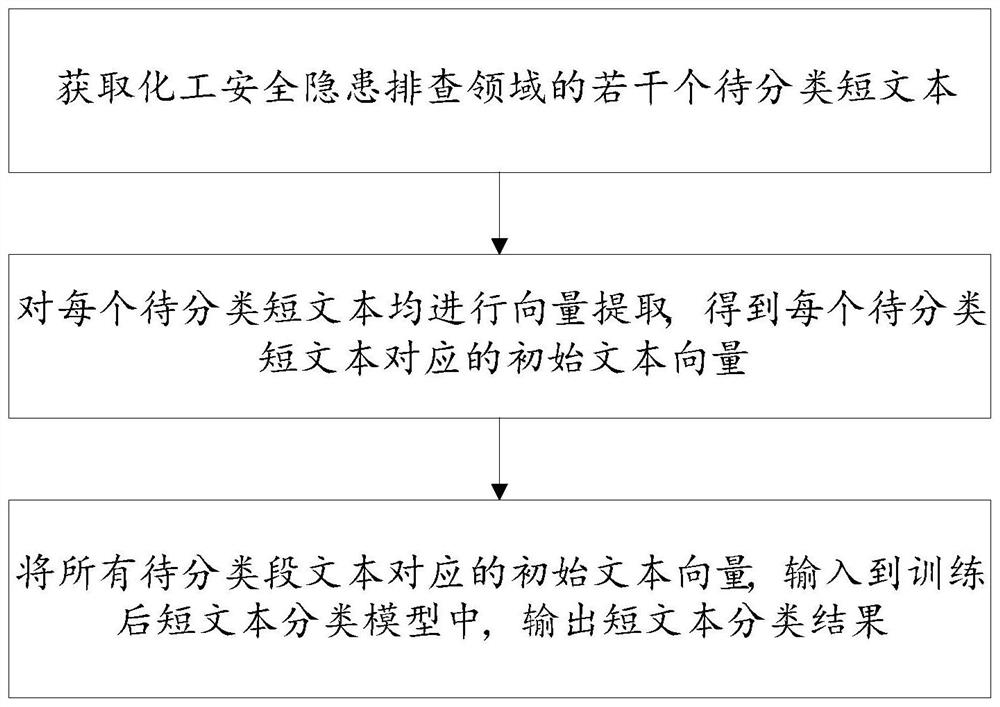

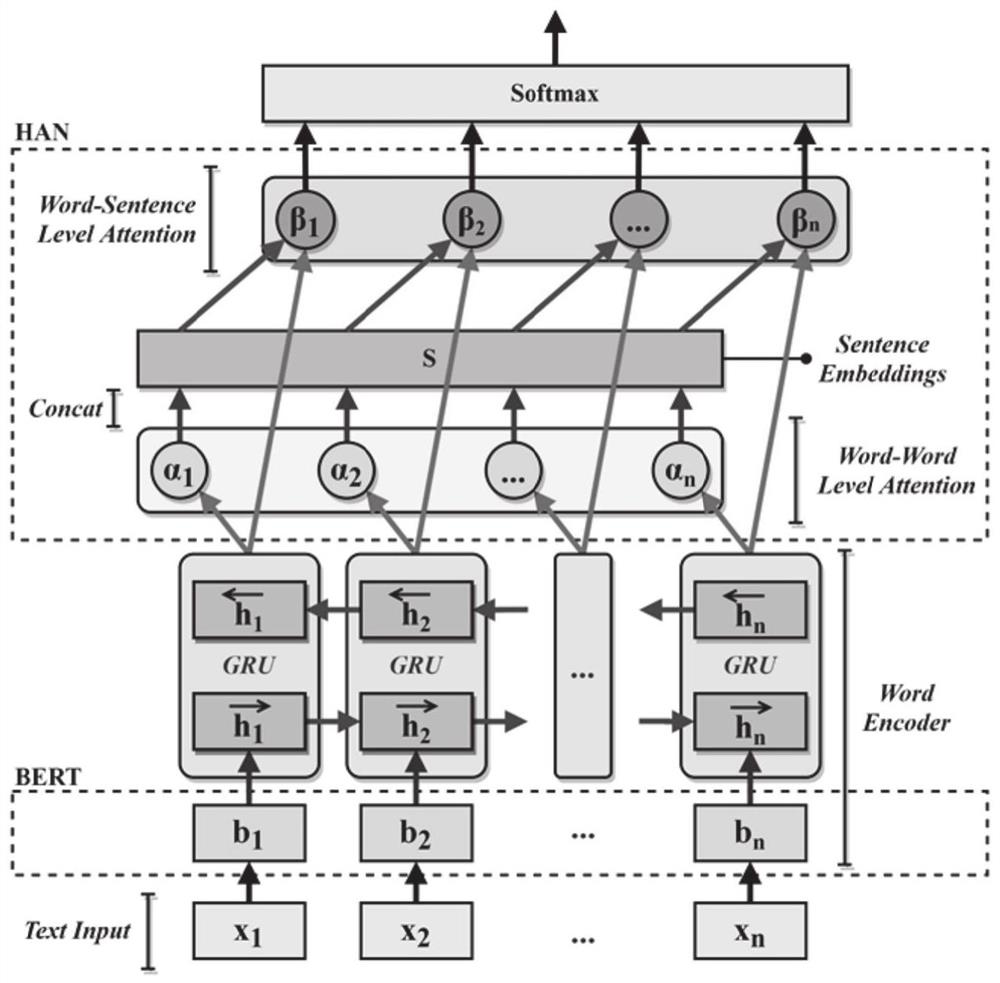

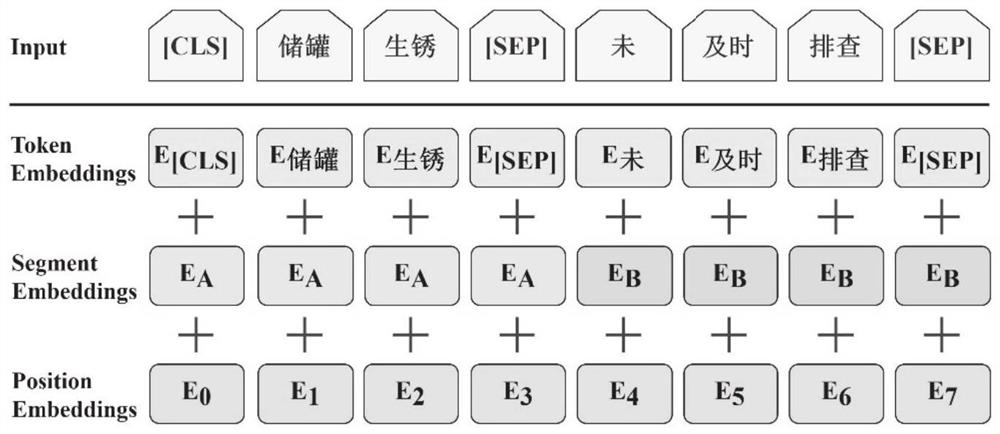

PendingCN113139057AEnhanced general feature representationMake up for deviationsSemantic analysisCharacter and pattern recognitionClassification methodsEngineering

The invention discloses a domain-adaptive chemical potential safety hazard short text classification method and system. The method comprises the steps of acquiring a plurality of to-be-classified short texts in a chemical potential safety hazard investigation field; performing vector extraction on each to-be-classified short text to obtain an initial text vector corresponding to each to-be-classified short text; and inputting the initial text vectors corresponding to all the to-be-classified short texts into the trained short text classification model, and outputting a short text classification result. Information fusion representation of different levels of characters, words and sentences in a specific field of the short text is learned by adopting GRU + HAN, the problem of field information deviation of a general corpus short text is solved, and a better classification effect is shown in a classification task of chemical potential safety hazard investigation.

Owner:QINGDAO UNIV OF SCI & TECH

Wood fiber microfilament dissociation method based on soft nanometer paper base material

ActiveCN103952939AEnhance water absorption and swellingEasy to peelPulp beating methodsFiberMicrometer

The invention provides a wood fiber microfilament dissociation method based on a soft nanometer paper base material. The wood fiber microfilament dissociation method comprises the following steps: cutting off and cutting short paper pulp fibers by a pulping machine, and controlling the length of the cut fibers between 500 micrometers and 1000 micrometers; squashing the cut paper pulp fibers by hammering force which is perpendicular to the axial direction of the fibers until the primary cell wall and secondary cell wall outer layers of the fibers are broken or peeled; then utilizing rubbing and shearing force perpendicular to the axial direction of the fibers to separate microfilament layers so as to obtain primarily nano-crystallized fiber microfilaments; finally carrying out high-shear flattening treatment on the primarily nano-crystallized fiber microfilaments to obtain the soft nanometer fibers with uniform size. The method has the advantages of high product yield, uniform size and capability of batch preparing.

Owner:NANJING FORESTRY UNIV

Hot topic determination method and device, storage medium and electronic equipment

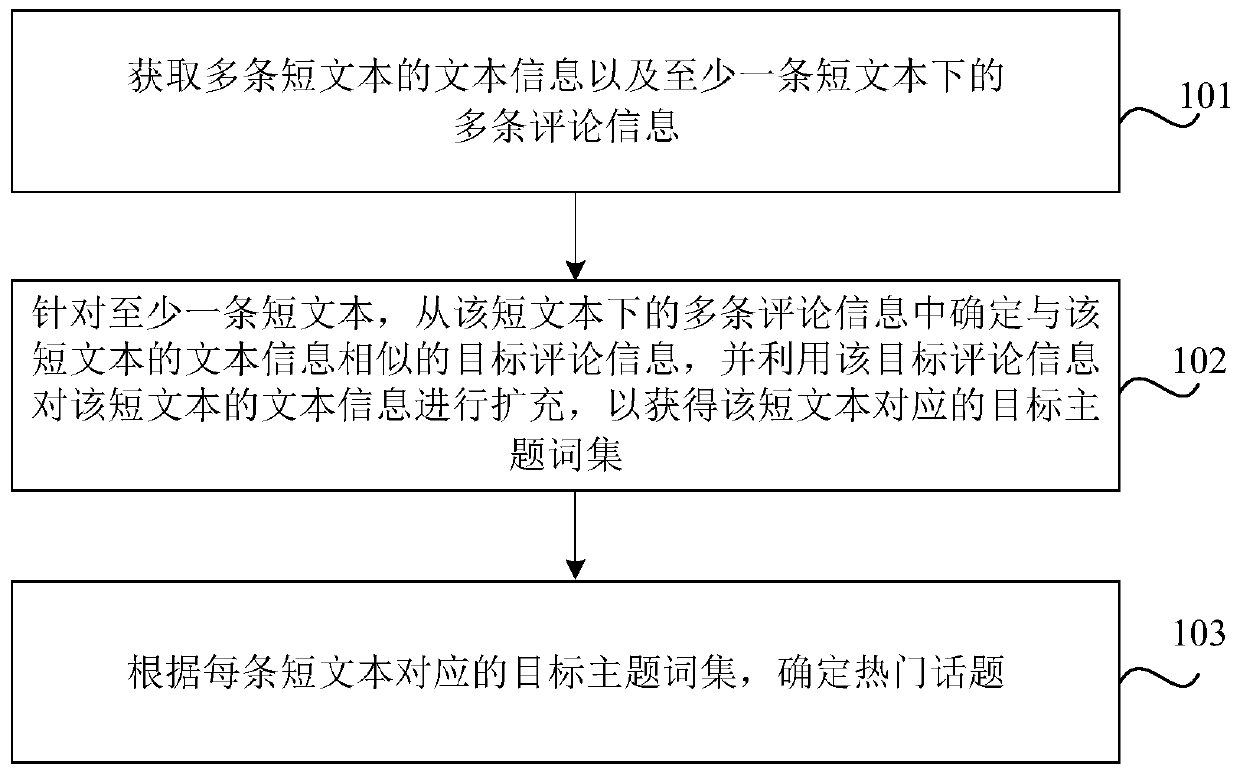

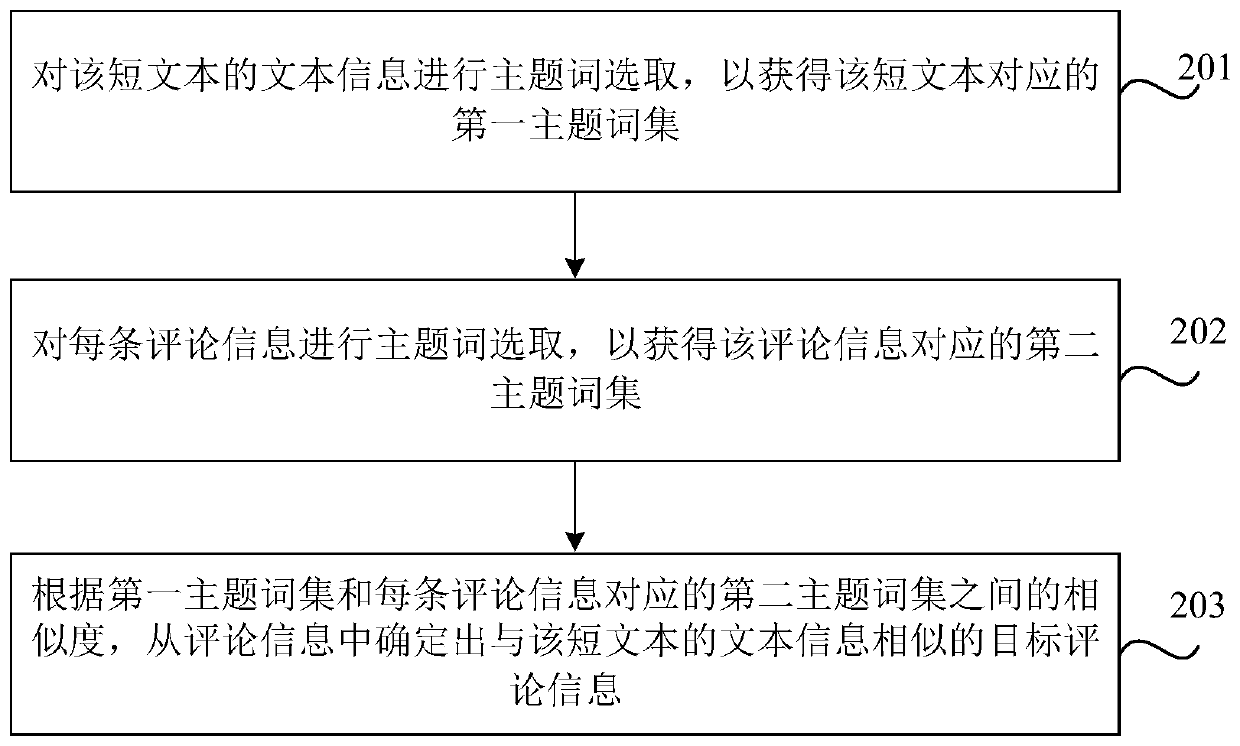

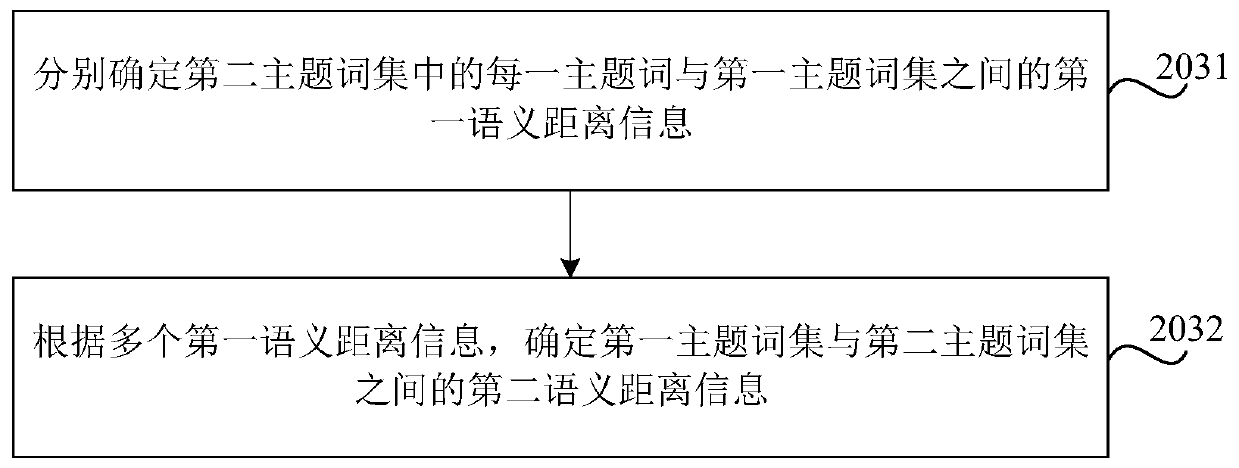

PendingCN111125305ASolve the sparsity problemIncrease the number ofText database indexingText database queryingEngineeringDatabase

The invention relates to a hot topic determination method and device, a storage medium and electronic equipment. The method comprises the steps of acquiring text information of multiple short texts and multiple pieces of comment information under at least one short text; for at least one short text, determining target comment information similar to the text information of the short text from themultiple pieces of comment information under the short text, and expanding the text information of the short text by utilizing the target comment information to obtain a target subject term set corresponding to the short text; and determining a hot topic according to the target subject term set corresponding to each short text. Through the technical scheme, the problem of sparsity of the short text can be effectively solved, and meanwhile, the meaning of the target subject term set corresponding to the short text obtained after expansion does not change compared with the meaning to be expressed by the short text. Moreover, the target subject term set obtained after the short text is expanded can provide an accurate basis for determining hot topics.

Owner:NEUSOFT CORP +1

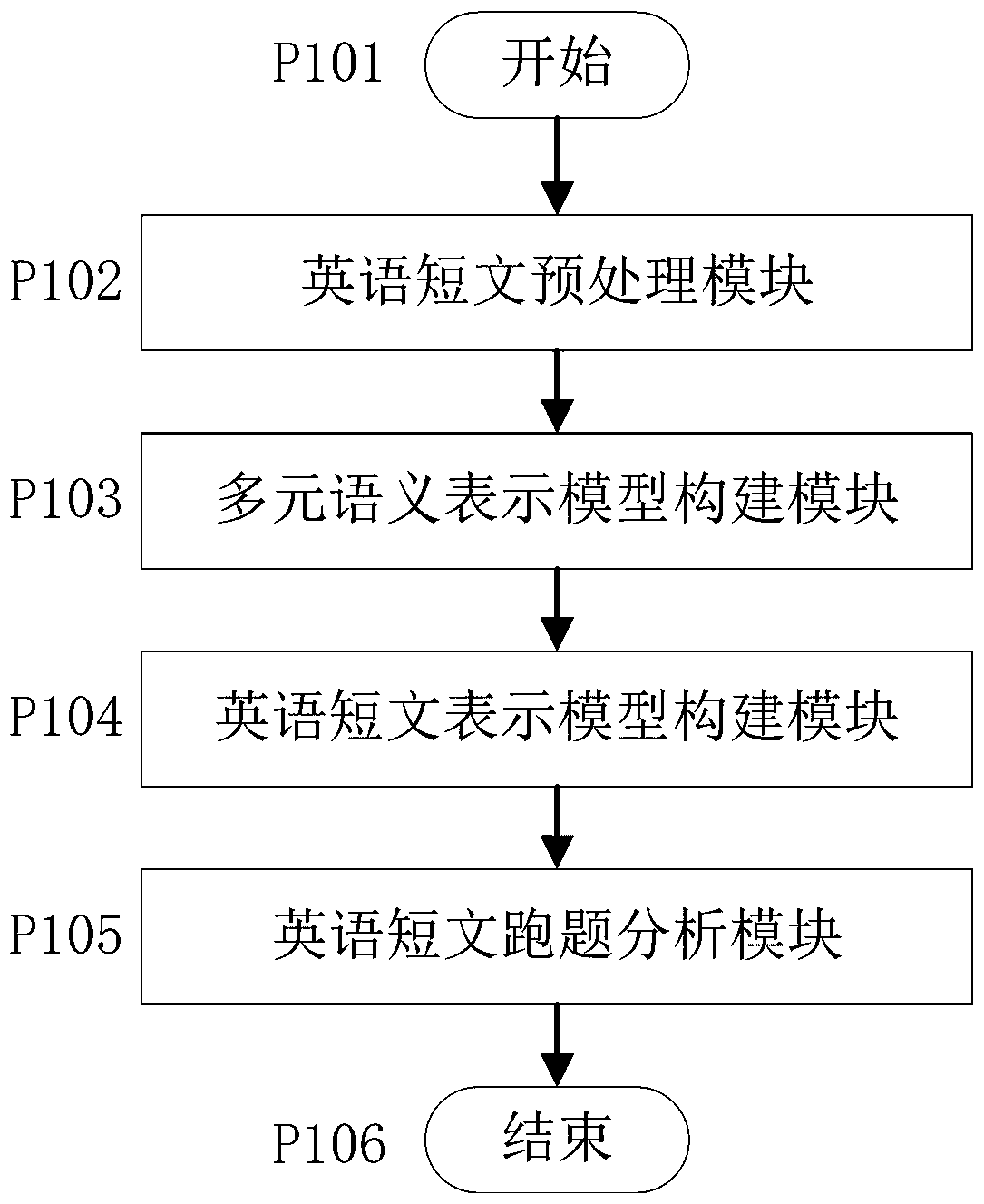

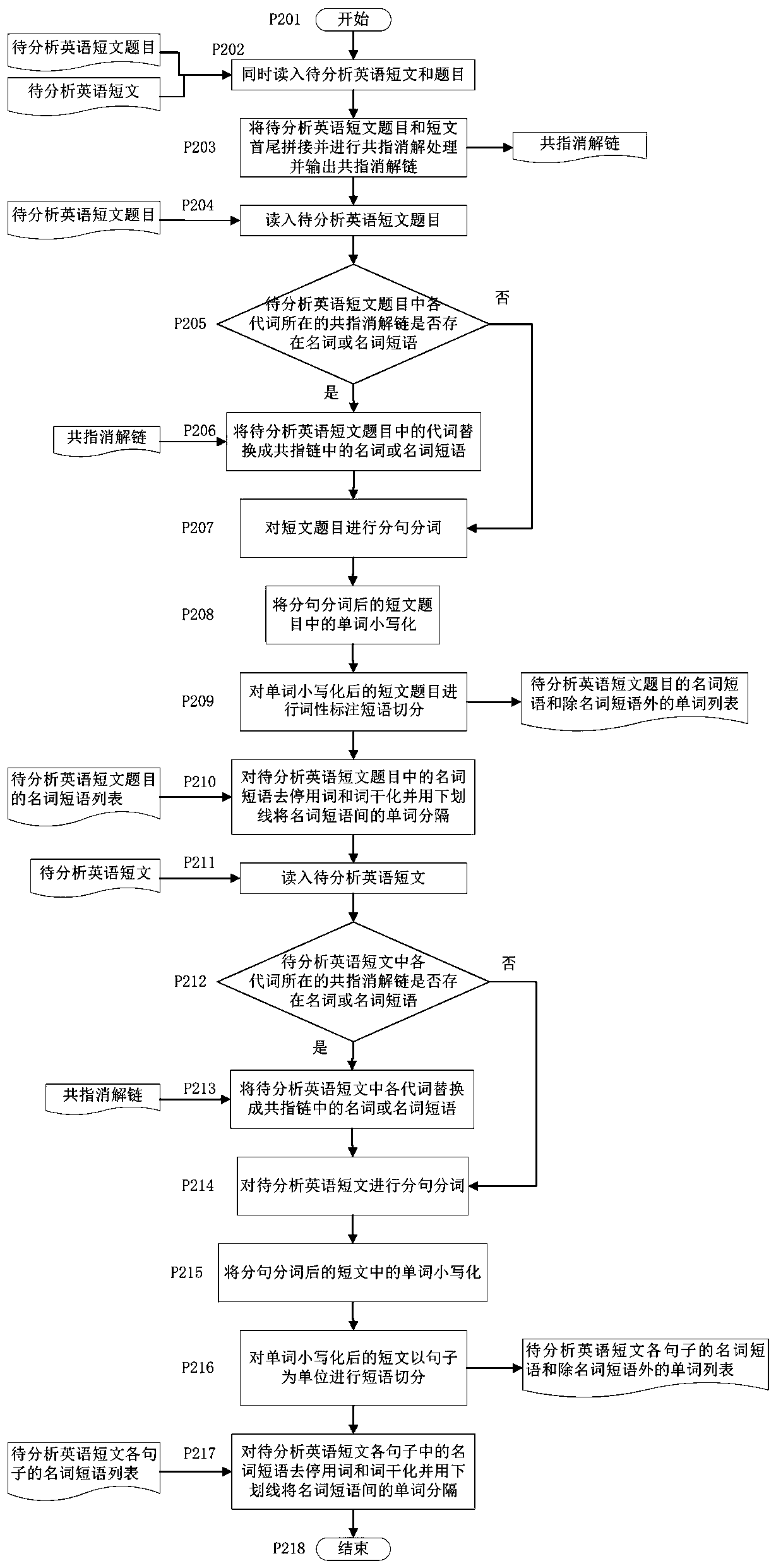

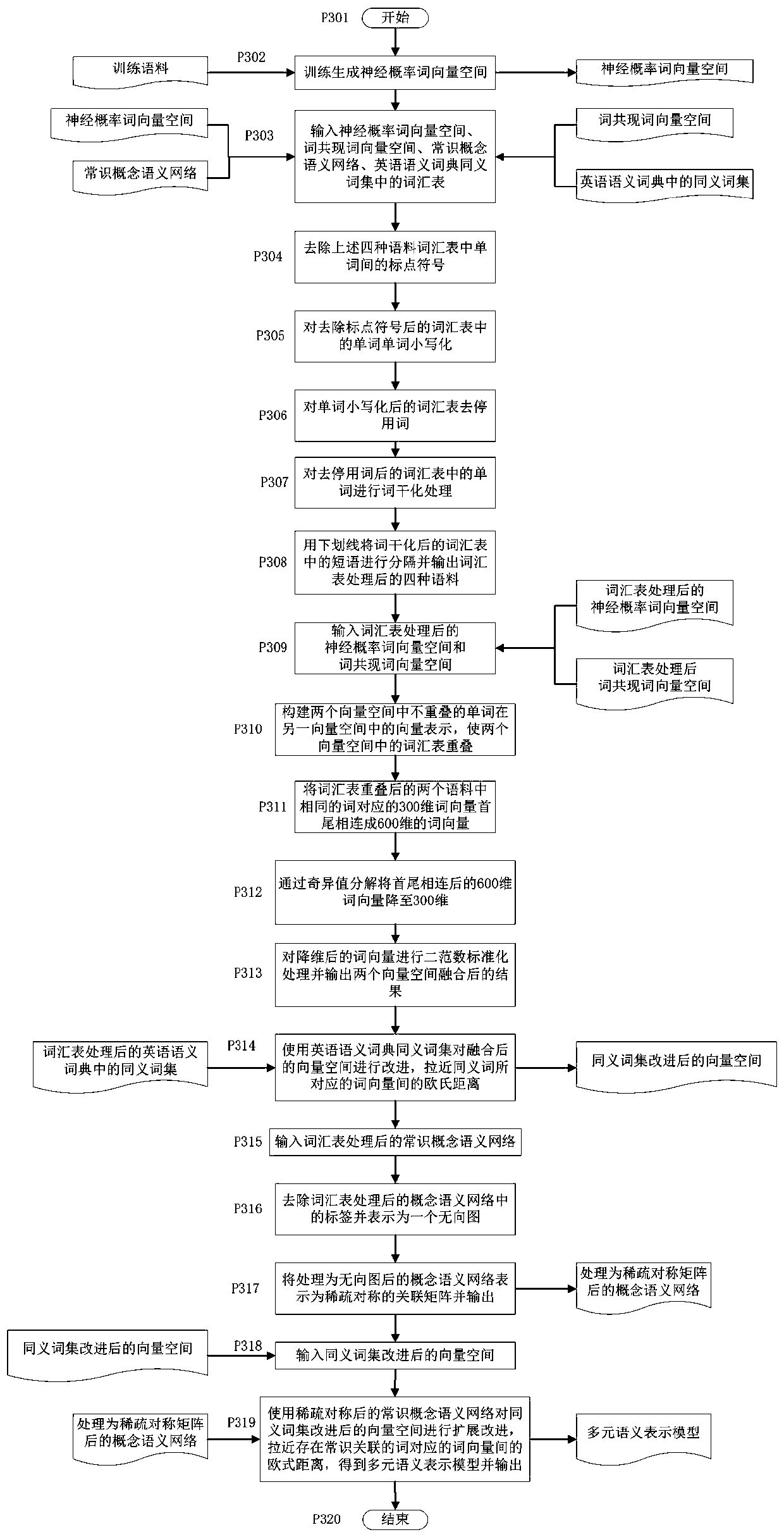

Unsupervised English short text sentence running analysis method

The invention discloses an unsupervised English short text sentence running analysis method. An analysis system is composed of an English short text preprocessing module, a multivariate semantic representation model construction module, an English short text representation model construction module and an English short text sentence running analysis module which are sequentially connected. After an English short text is processed by the analysis system, a sentence of a question running in the English short text, and a question running degree score and a comment of the sentence of the English short text can be finally obtained. According to the method, the problems that a traditional unsupervised English short text sentence running analysis method neglects semantic correlation between words, so that the running sentences cannot be accurately analyzed during English short text sentence running analysis, and the running degree score is poor are solved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

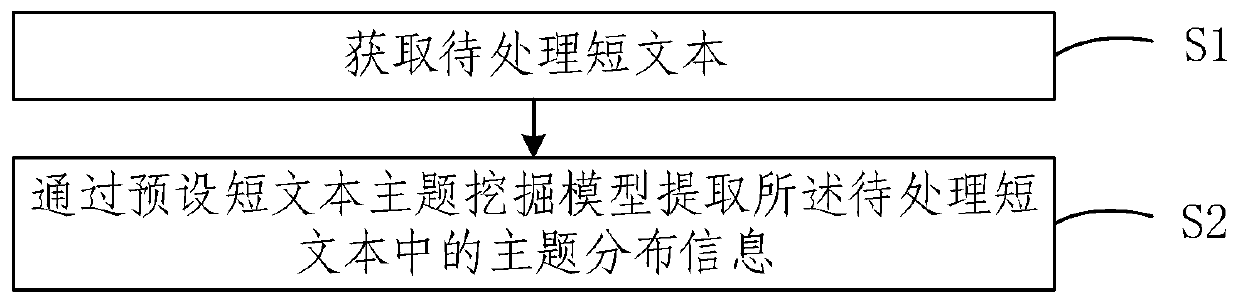

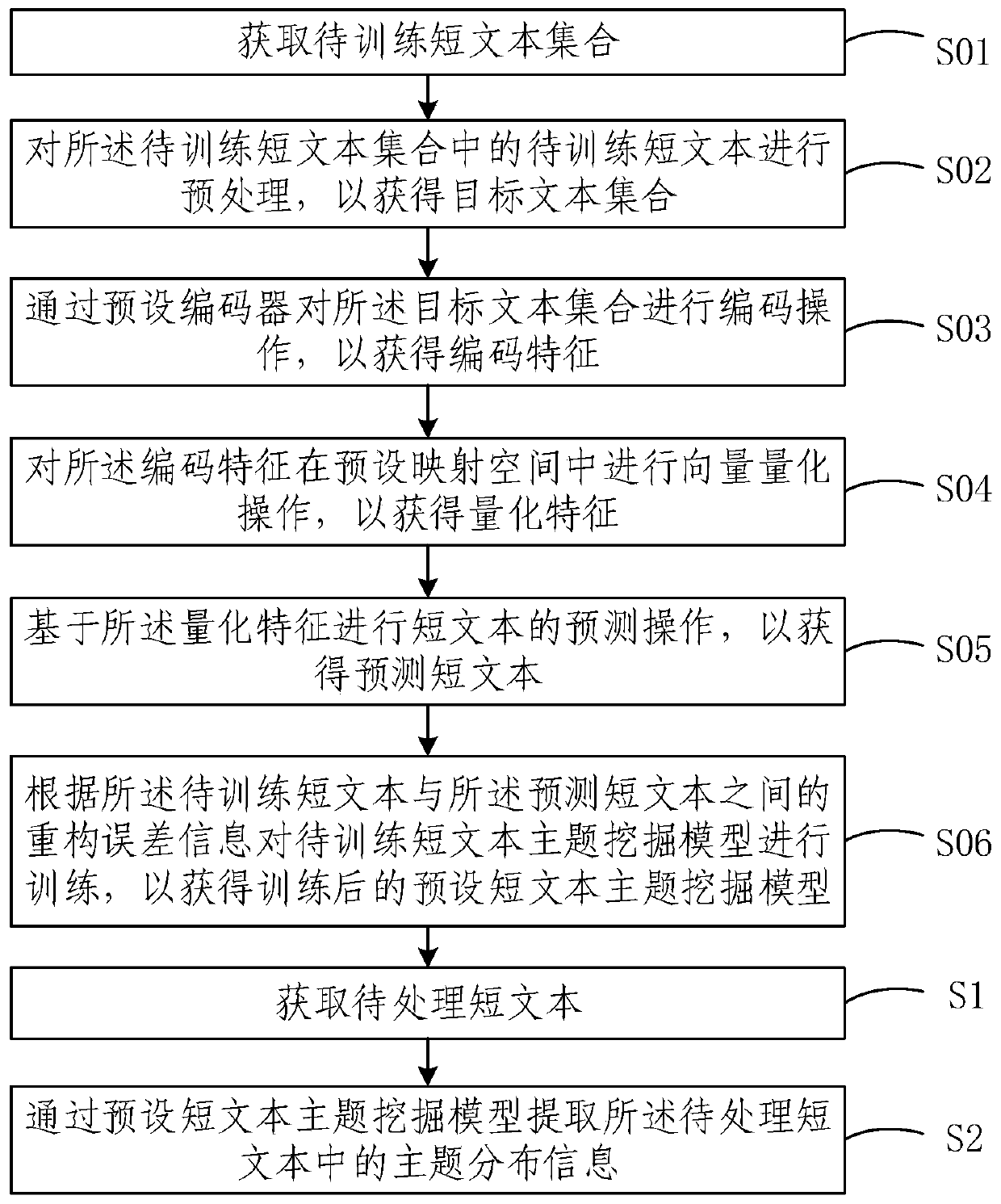

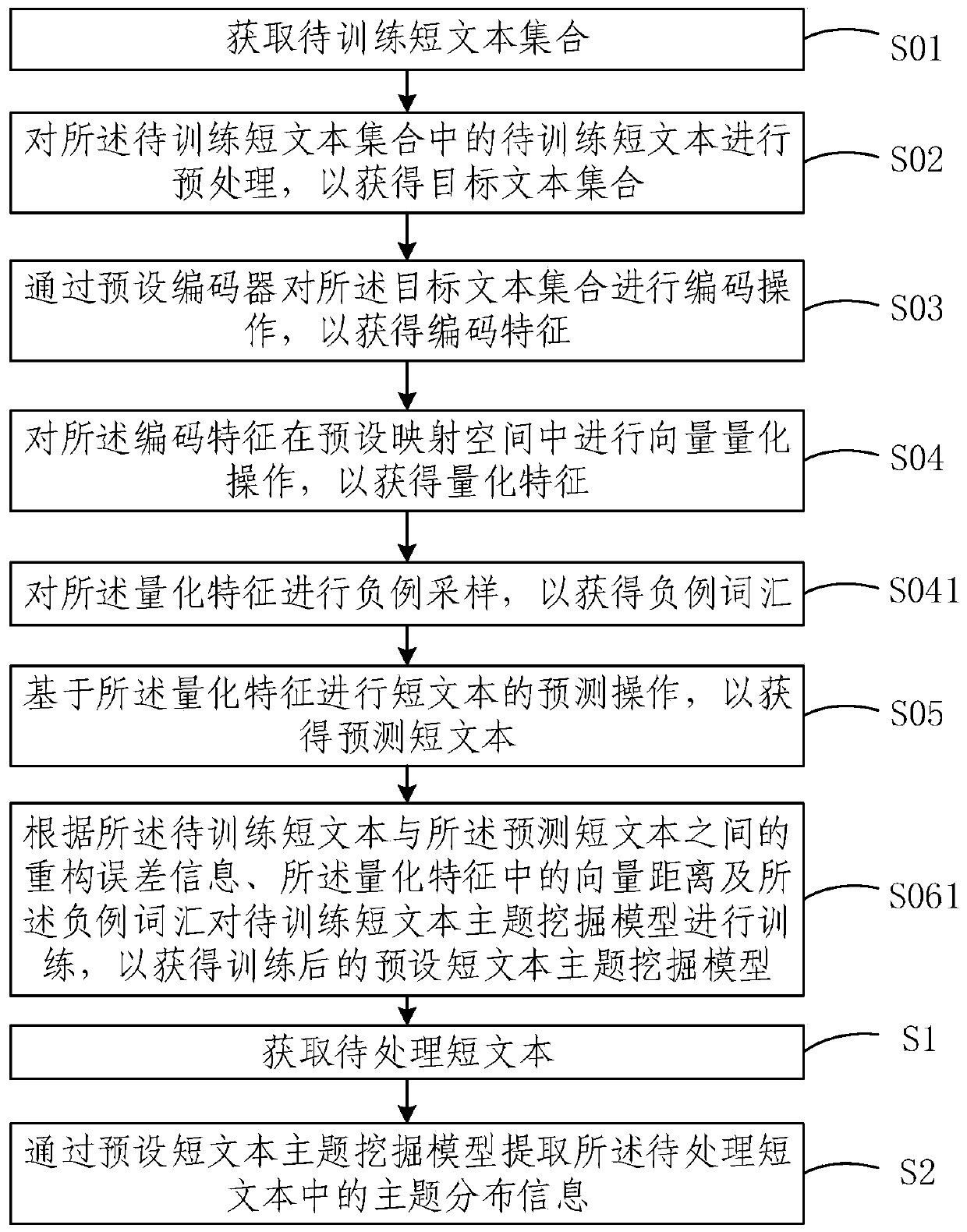

Topic mining method, system and device based on short text and storage medium

PendingCN111460105AExcavate accuratelyNatural language data processingText database queryingSubject matterEngineering

The embodiment of the invention relates to the technical field of text data processing, and discloses a topic mining method, system and device based on a short text and a storage medium. The method comprises the steps of firstly obtaining a to-be-processed short text; and extracting topic distribution information in the to-be-processed short text through a preset short text topic mining model. Visibly, according to the embodiment of the invention, the topic mining operation of the short text is processed by applying the topic mining model special for short text processing, so that the topic ofthe short text can be accurately mined, and the technical problem that the topic of the high-quality short text is difficult to accurately mine is solved.

Owner:TSINGHUA UNIV

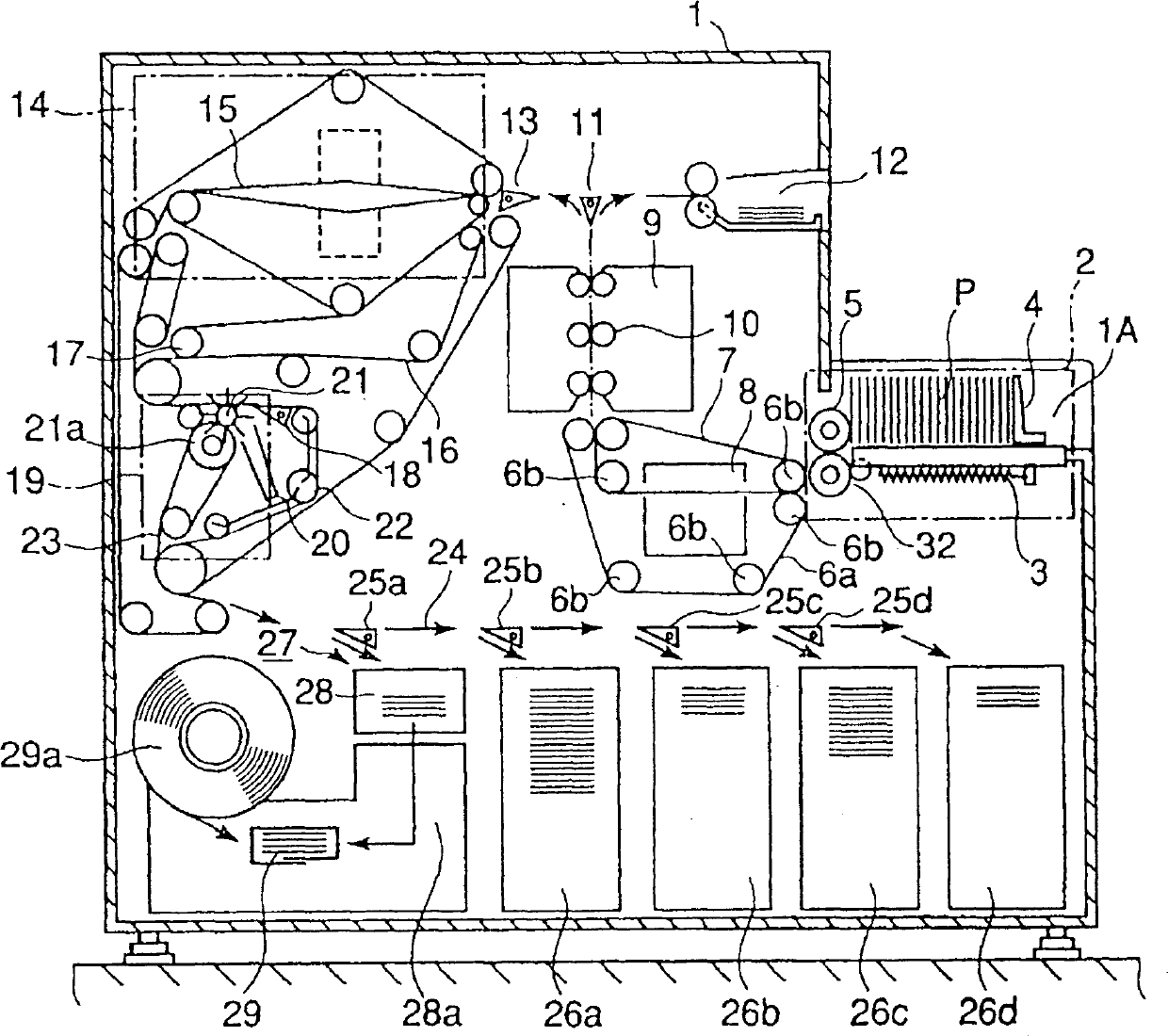

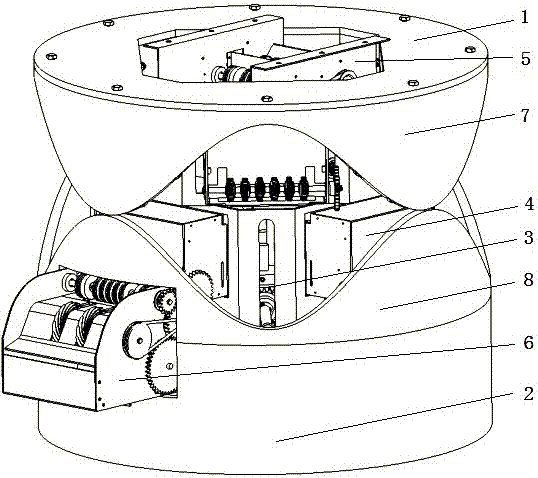

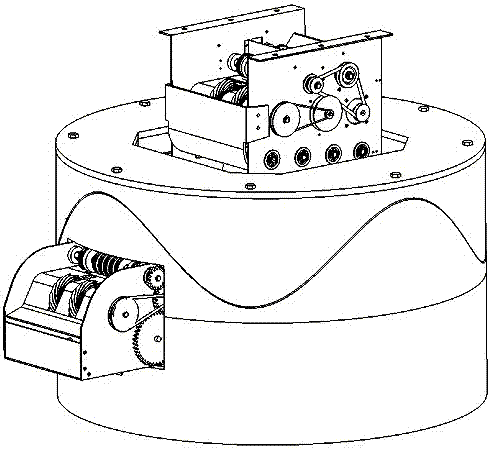

Rotary paper currency automatic sorting device

InactiveCN106997636ANovel structureSmall footprintPaper-money testing devicesCoin/currency accepting devicesControl systemPulp and paper industry

The invention discloses a rotary paper currency automatic sorting device comprising an outer housing and a control system. The rotary paper currency automatic sorting device is characterized in that the upper end of the outer housing is provided with an upper cover plate, and the lower end of the outer housing is provided with a base; a rotary housing, a rotary driving device, paper currency receiving devices, a paper currency detection device, and a paper currency outlet device are disposed in the outer housing; the rotary driving device, the paper currency receiving devices, and the paper currency detection device are connected with the control system; the rotary housing is constituted by an upper housing and a lower housing; the upper end of the upper housing is connected with a connecting plate, and the periphery of the lower end surface is provided with a waveform lower accidented surface; the periphery of the upper end surface of the lower housing is provided with a waveform upper accidented surface, and the lower end is fixedly connected with the base; one side of the lower housing is provided with the paper currency outlet device; the lower accidented surface of the upper housing and the upper accidented surface of the lower housing are cooperated with each other; the upper end of the paper currency detection device is fixedly connected with the paper currency inlet of the outer housing, and an outer periphery of a paper currency chamber fixing rack is uniformly provided with four upper paper currency receiving devices, and an outer periphery of an elevating fixing rack is uniformly provided with four lower paper currency receiving devices and an elevating slot hole. The rotary paper currency automatic sorting device has advantages of novel structure, accurate sorting, short paper currency running time, and rapid paper currency withdrawing.

Owner:SHANDONG UNIV

Paper sludge processing for animal bedding

A method for making an animal bedding fiber product, the method includes providing fiber from paper sludge, formulating the fiber in a mixture including a first desiccant agent including ash, so as to form a friable aggregate. Further, a fiber product including at least one short paper fiber from a secondary fiber, one or more inorganic fillers including kaolin clay; and a first desiccant agent including ash. Further still, a heatless process for making a fiber product including providing fiber from paper sludge, formulating the fiber in a non-active heat generating mixture including a first desiccant agent including ash, so as to form a waste fiber product.

Owner:CASELLA WASTE SYSTEMS

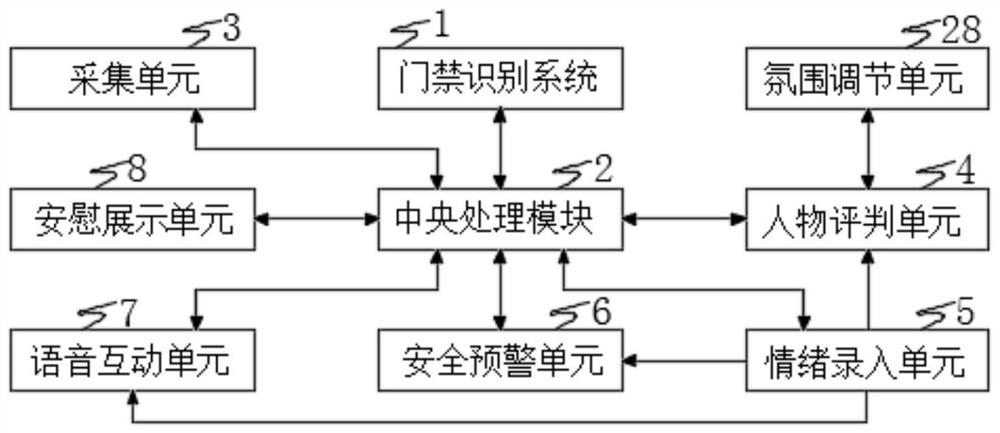

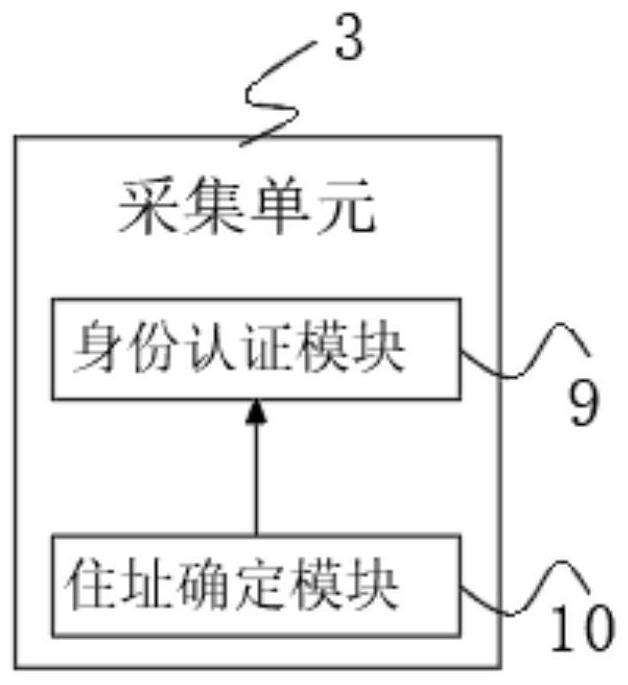

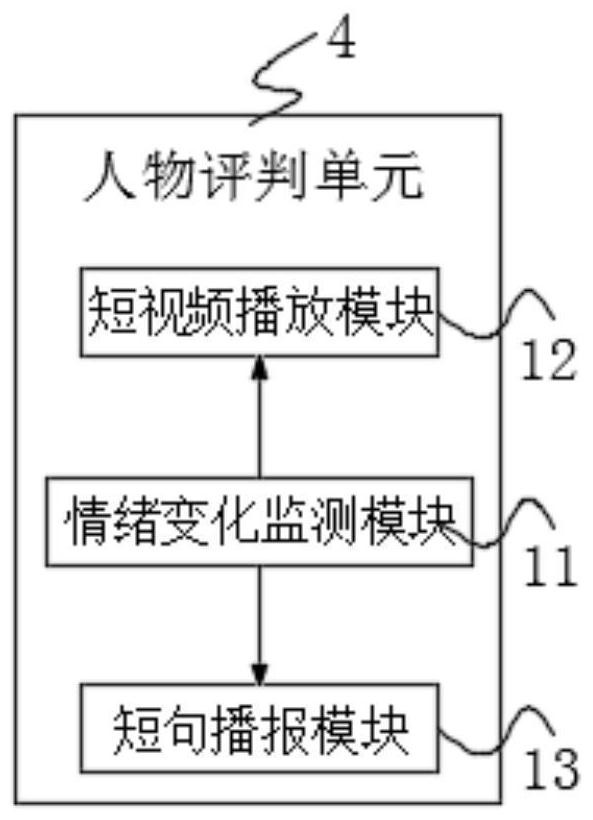

Control method based on face recognition

ActiveCN113409507AImprove recovery rateHave positive emotionsCharacter and pattern recognitionIndividual entry/exit registersMoodSimulation

The invention discloses a control method based on face recognition. The control method specifically comprises the following steps: step 1, face acquisition; step 2, safety early warning; step 3, paper calling by network; and step 4, interactive comforting. The invention relates to the technical field of access control recognition. According to the control method based on face recognition, the facial expression of a person is recognized, when it is detected that the emotion of the person is negative, the atmosphere adjusting unit comforts the person in a short video and short text reciting mode, emotion changes of the person are monitored in real time during comforting, and when the emotion worsening situation occurs, the comfort mode is changed in time, the emotions of the personnel are continuously and tentatively relieved, and different comfort modes are flexibly generated for different personnel, so that the probability that the emotions of the personnel are improved is effectively improved, and comfort retention is carried out on the personnel at the doorway of the community while the personnel have positive emotions after entering the community; and convenient conditions are provided for construction of a harmonious community.

Owner:SHENZHEN NEWABEL ELECTRONICS

Multi-segment slitting type paper shredder and paper shredding method

The invention discloses a multi-segment slitting type paper shredder. The multi-segment slitting type paper shredder comprises a rack, N paper shredding mechanisms, a paper dividing mechanism, a paper guiding mechanism and a driving mechanism, wherein the N paper shredding mechanisms, the paper dividing mechanism, the paper guiding mechanism and the driving mechanism are mounted on the rack, and N is an integer which is equal to or greater than two; the paper dividing mechanism is used for dividing a piece of paper into N parts in the longitudinal direction of the paper; the paper guiding mechanism comprises N paper guiding channels, and the N paper parts obtained through division are conveyed to the N paper shredding mechanisms through the N paper guiding channels; and the driving mechanism is used for driving the paper shredding mechanisms and the paper dividing mechanism to act. According to the multi-segment slitting type paper shredder, cutter shafts of the paper shredding mechanisms can be made quite short, so that paper shredding cutters are made high in strength and low in cost; and the driving mechanism drives the short paper shredding cutters to rotate, so that labor is saved, consumption is reduced, impact force of the paper shredding cutters during paper feeding is reduced, the load power needing to be borne by the driving mechanism is reduced, and the service life of the paper shredder is prolonged. In addition, the invention discloses a corresponding multi-segment slitting type paper shredding method.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD

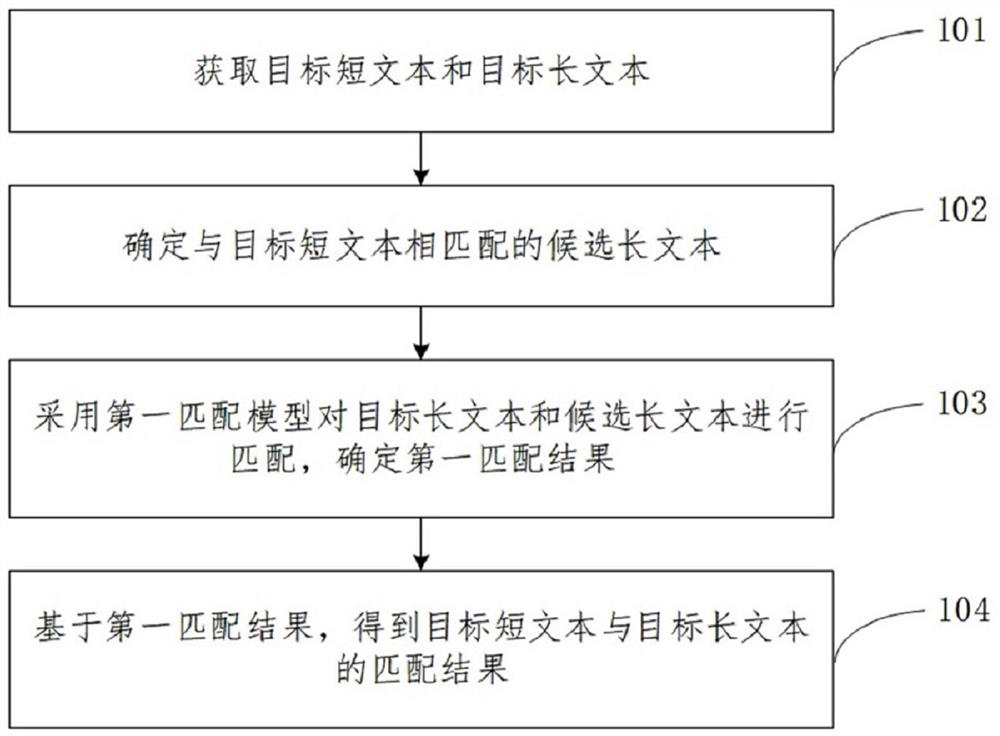

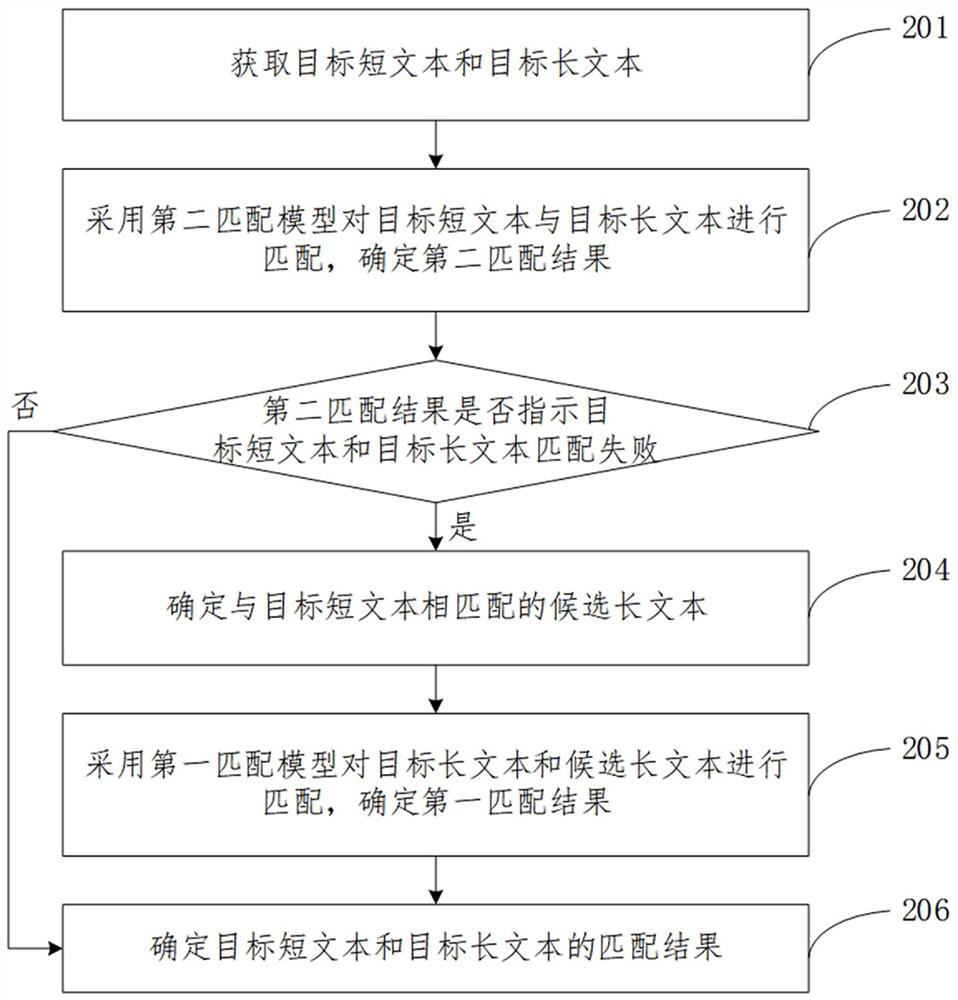

Text matching method and device, equipment and medium

ActiveCN112632232AImprove accuracyAvoid the problem of inaccurate matchingSemantic analysisText database queryingInformation quantityEngineering

Embodiments of the invention relate to a text matching method and and device, equipment and a medium. The method comprises the steps of obtaining a target short text and a target long text; determining a candidate long text matched with the target short text; matching the target long text with the candidate long text by adopting a first matching model, and determining a first matching result; and obtaining a first matching result of the target short text and the target long text based on the first matching result. By the adoption of the technical scheme, matching between the short text and the long text is converted into matching between the two long texts, the problem that matching is inaccurate due to the fact that the information amount of the short text is too small or the information of the short text and the information of the long text are not equal can be solved, and the matching accuracy between the short text and the long text is improved.

Owner:BEIJING CENTURY TAL EDUCATION TECH CO LTD

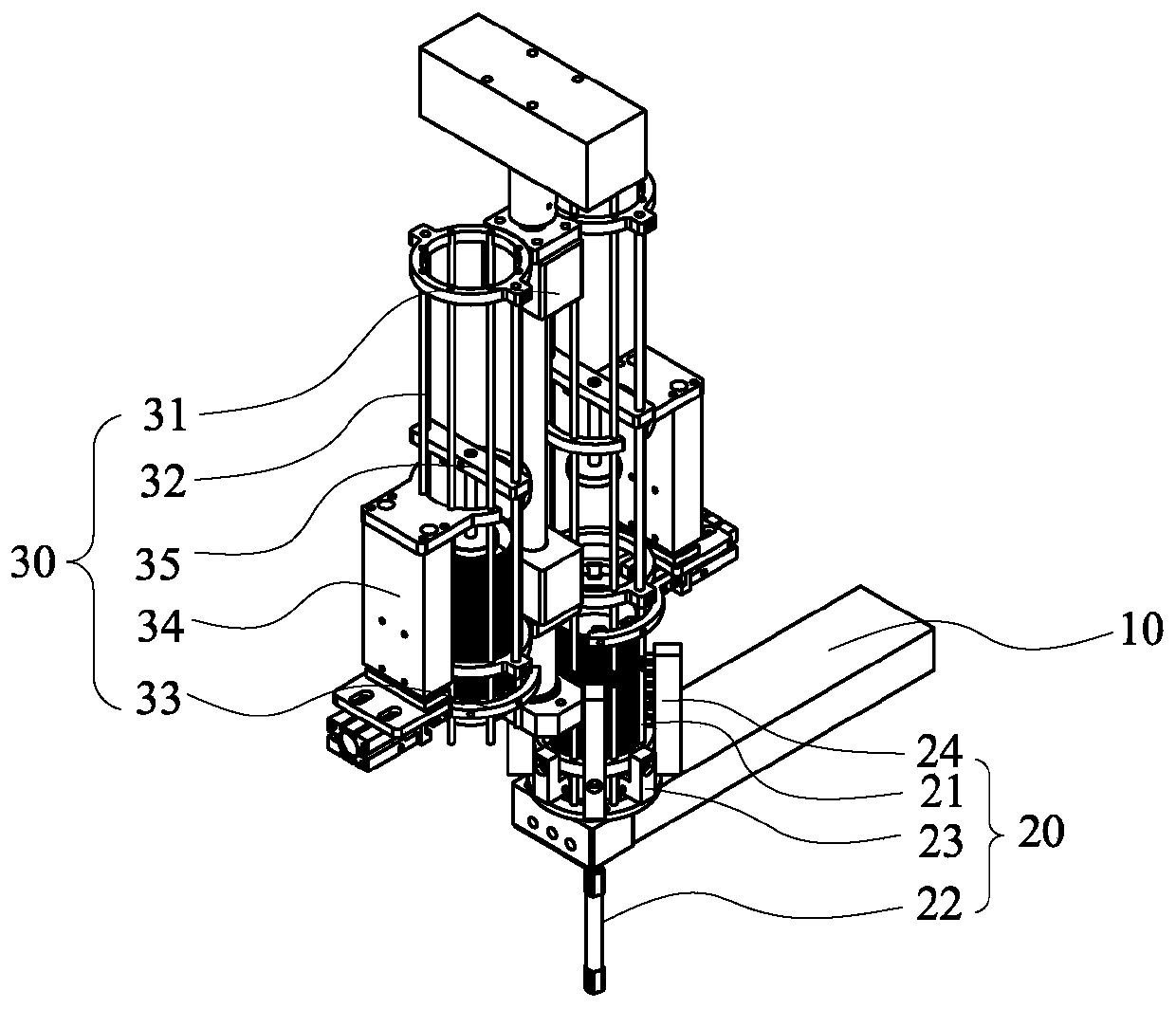

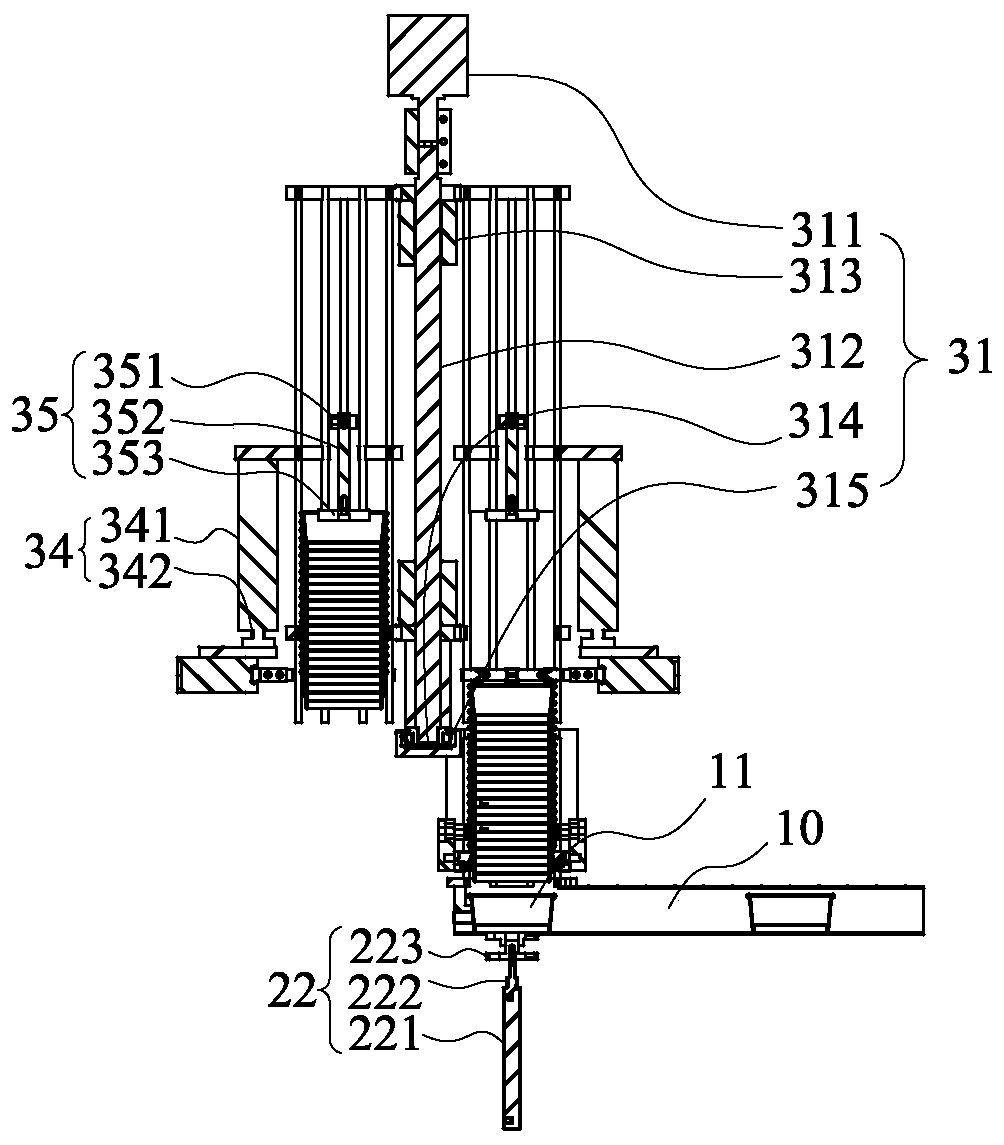

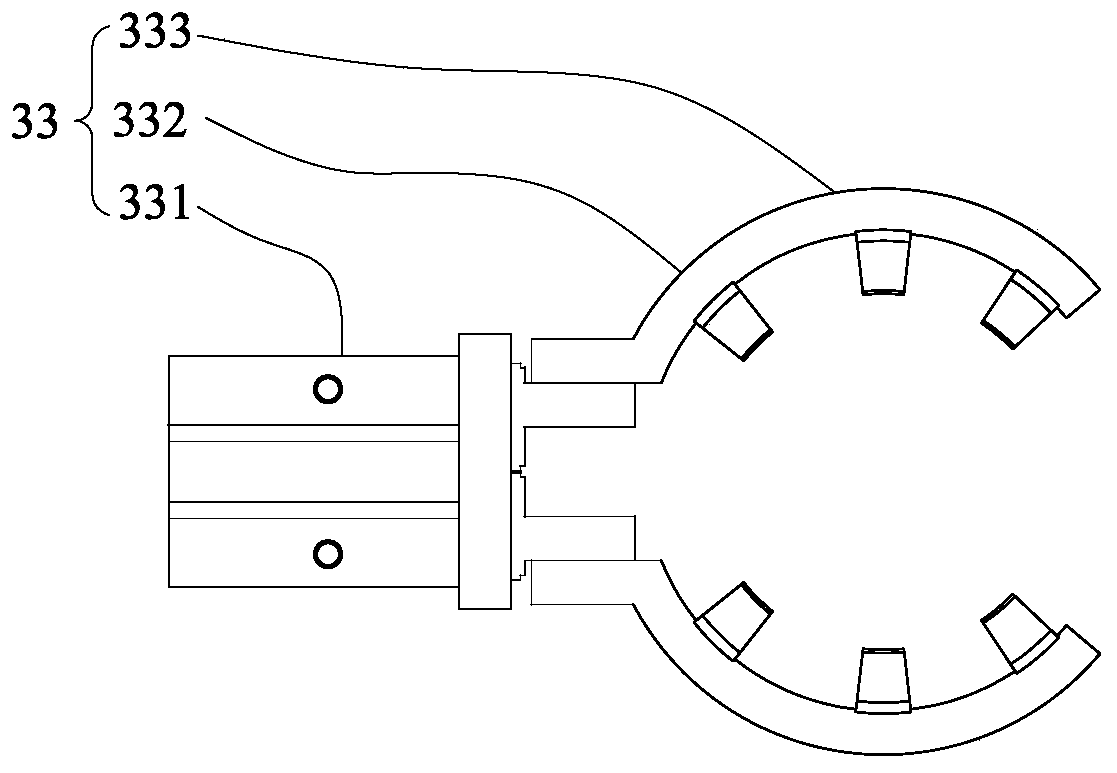

Short paper cup collecting device

The invention provides a short paper cup collecting device which is used for collecting short paper cups. The short paper cup collecting device comprises a cup feeding channel, a transition lifting mechanism and a paper cup collecting mechanism. The transition lifting mechanism comprises a transition cup cage communicating with the cup feeding channel, a cup jacking structure arranged in the cup feeding channel in a penetrating mode and positioned below a receding hole, and at least two cup supporting pieces circumferentially arranged on the transition cup cage. The paper cup collecting mechanism comprises a rotating frame, at least two cup collecting cages arranged on the rotating frame and corresponding to the transition cup cage, a cup clamping structure arranged on the cup collecting cages, and a lifting structure arranged on the cup collecting cages and driving the cup clamping structure to move along the cup collecting cages. According to the short paper cup collecting device, the guiding performance of paper cup stacking is better, the paper cups are not prone to getting stuck in a multi-section conveying mode, the automation degree of the whole device is high, and collecting and discharging operation can be conducted at the same time.

Owner:ZHEJAING DISCOVER MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com