Paper-feeding accumulation structure of corrugated paper board production line

A corrugated board and production line technology, applied in the direction of mechanical processing/deformation, etc., can solve the problem of difficult to solve the problem of paper feeding to the final accumulation, and achieve the effect of small footprint, simple structure, convenient and operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

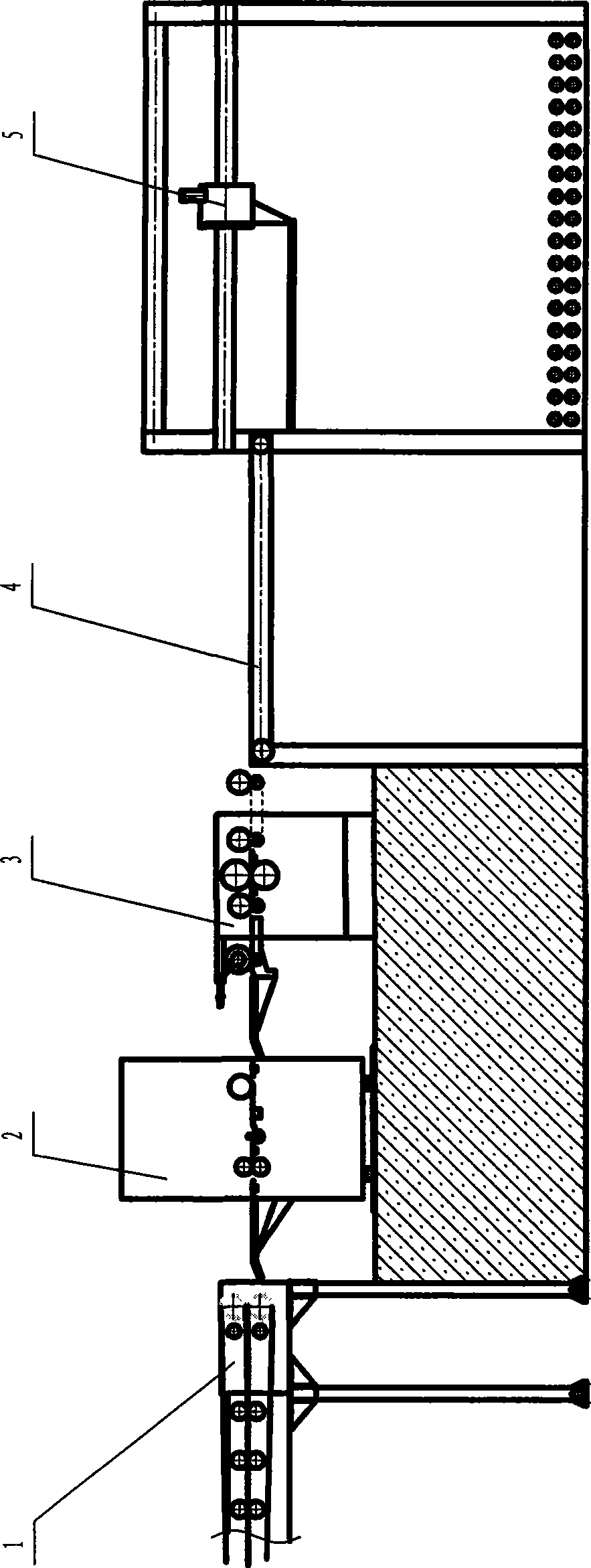

[0013] Such as figure 1 As shown, it includes compound lane 1 of corrugated cardboard production line, slitting machine 2, cross cutting machine 3, paper overpass 4, and stacker 5.

[0014] The present invention adopts the corrugated cardboard production line compound road 1 to connect the cross cutter 3, and the cross cutter 3 connects the slitting machine 2. The rear part of the cross-cutting machine 3 is connected with a paper bridge 4, and the paper bridge 4 is connected with a stacker 5, and the paper bridge 4 is composed of a roller and a conveyor belt. After the corrugated cardboard is bonded in the composite channel 1 of the corrugated cardboard production line, it is cut by the slitting machine 2 and the cross-cutting machine 3, and then the finished corrugated cardboard is sent to the required height by the paper bridge 4, and then sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com