Patents

Literature

63results about How to "Low ODP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard polyurethane foam

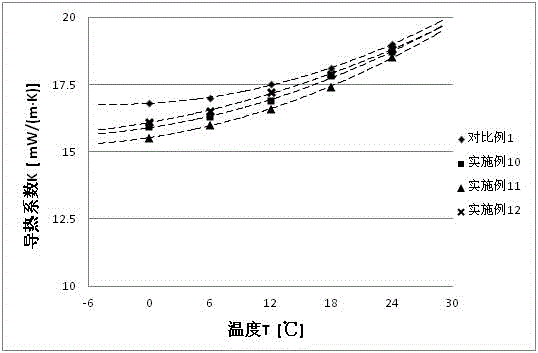

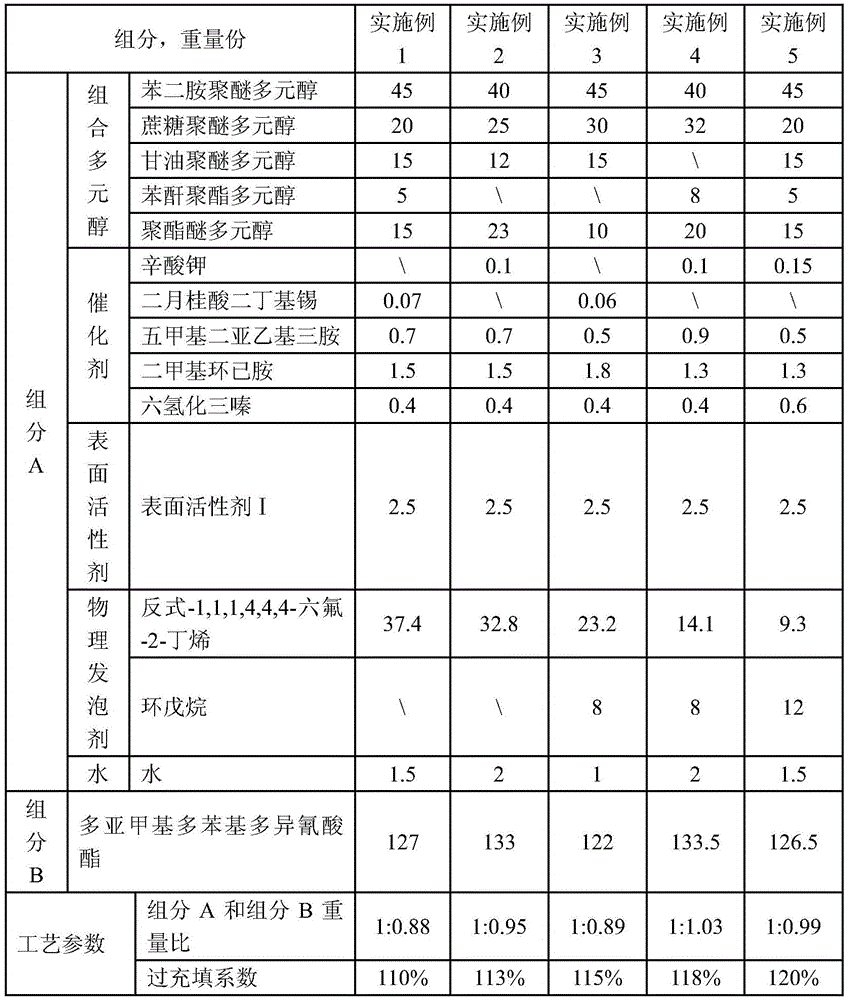

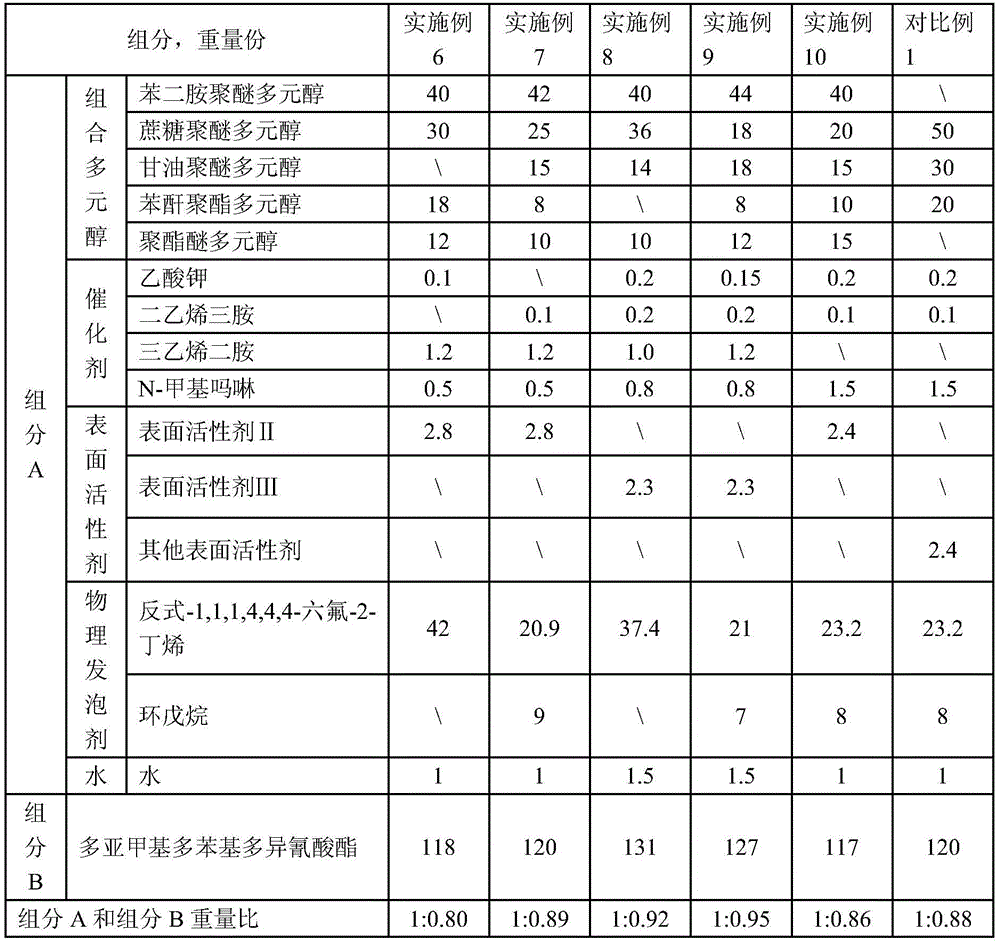

The invention relates to a hard polyurethane foam. The hard polyurethane foam is composed of a component A and a component B at a weight ratio of 1:0.7-1.2. The component A comprises, by weight, 100 parts of a compound polyhydric alcohol containing phenylenediamine polyether glycol and polyester ether polyhydric alcohol, 10 to 50 parts of a physical foaming agent containing trans-1,1,1,4,4,4-hexafluoro-2-butene, 1 to 4 parts of a catalyst, 1 to 5 parts of a surfactant, and 0.5 to 3.0 parts of water; and the component B is polymethylene polyphenyl isocyanate. The foams of the hard polyurethane foam are fine and uniform; heat conductivity coefficient is low; comprehensive properties are excellent; and K value<=19.0mW / (m.K) at 24 DEG C, and K value<=17.0mW / (m.K) at 0 DEG C.

Owner:NANJING HONGBAOLI POLYURETHANE

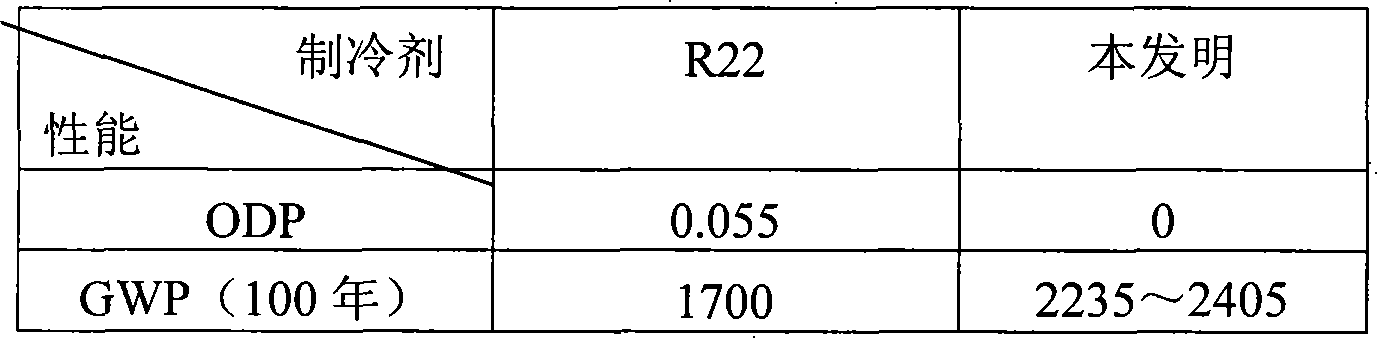

Refrigerant composition with low GWP (Global Warming Potential) value

InactiveCN101864277AMeet the protection requirementsLow ODPHeat-exchange elementsOzone depletion potentialClimate change

The invention discloses a refrigerant composition with a low GWP value. The composition consists of 2,3,3,3-tetrafluoropropene(HFO-1234yf), 1,1-difluoroethane (HFC-152a) and dimethyl ether (DME). The preparation method comprises the step of physically mixing the above components at normal temperature in corresponding proportion. The refrigerant composition has zero Ozone-Depletion Potential (ODP), and very low global warming potential (GWP), meets the requirement of environmental protection, has physical property equivalent to HFC-134a, and can be directly used in the traditional HFC-134a system without redesigning a compressor.

Owner:JIMEI UNIV

Laser-Assisted Etching Using Gas Compositions Comprising Unsaturated Fluorocarbons

InactiveUS20080191163A1Low ODPMeet ratioHalogenated hydrocarbon preparationSurface treatment compositionsGas compositionMedicine

Owner:EI DU PONT DE NEMOURS & CO

Compositions and methods for detecting leaks in HVAC/R systems

ActiveUS8418530B1Low ODPHigh sensitivityDetection of fluid at leakage pointOther chemical processesChemistryHVAC

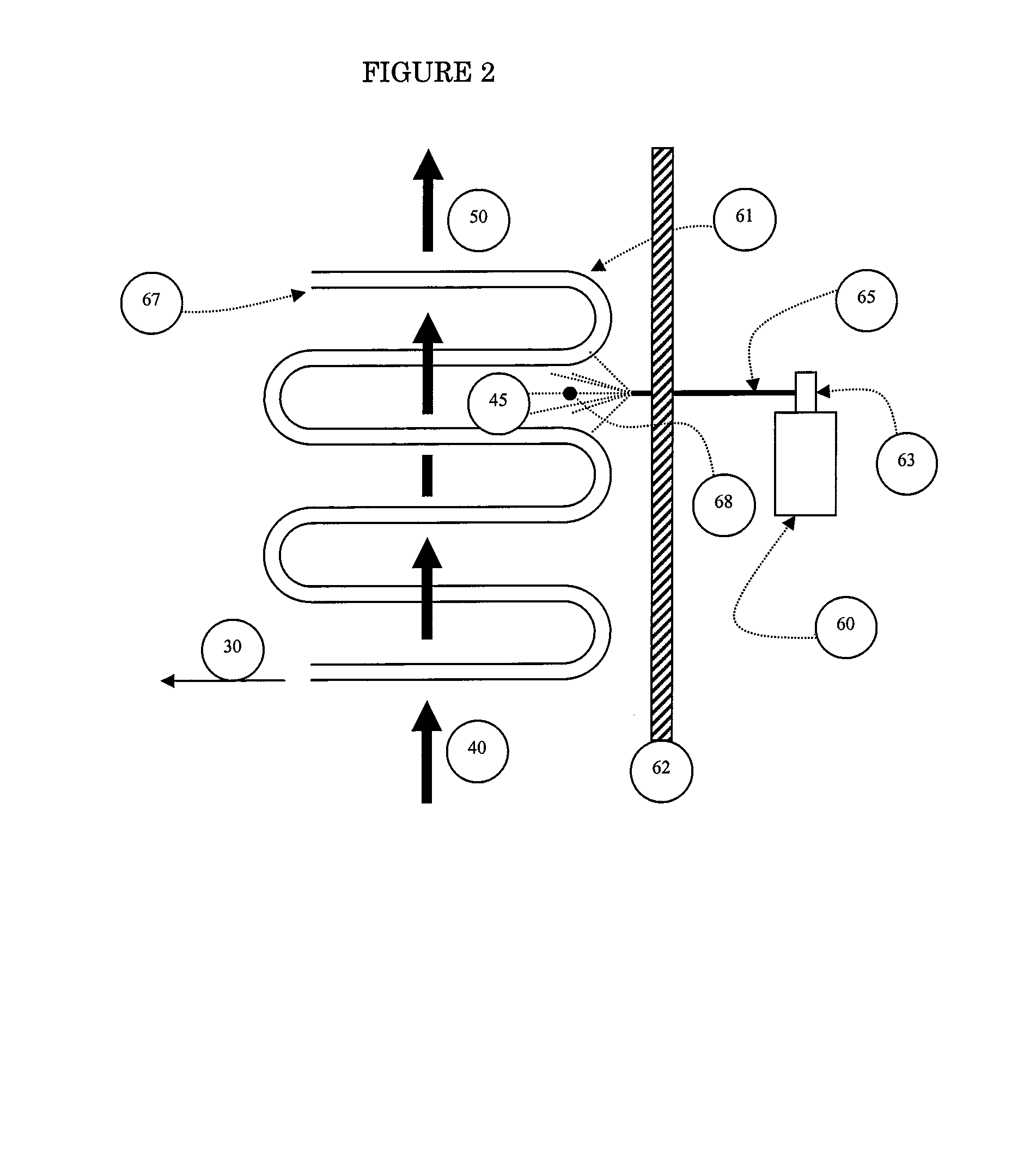

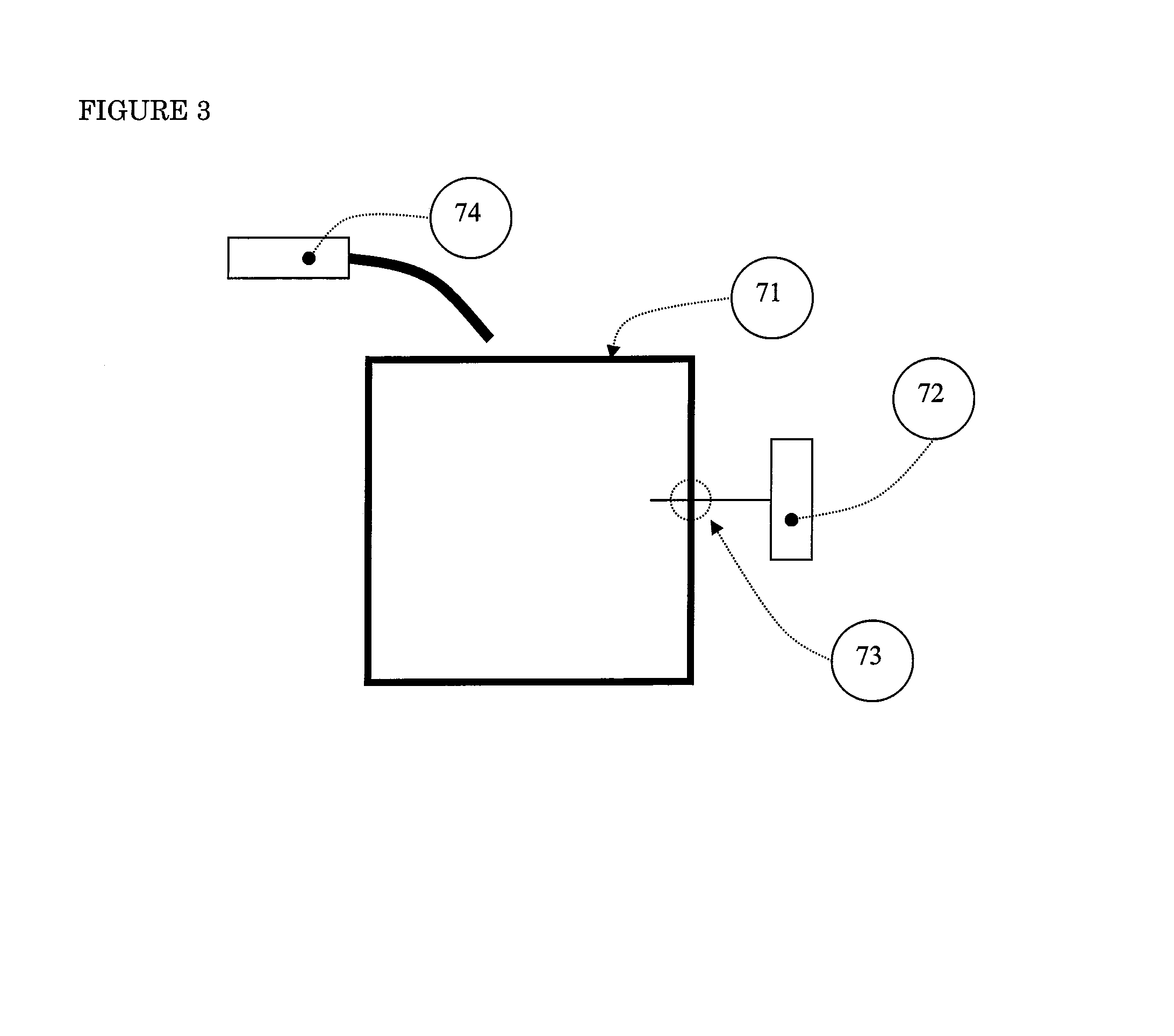

Compositions and related methods for detecting leaks in HVAC / R components such as furnaces, portable gas heaters, swimming pool heaters, air conditioners, heat pumps, refrigerators, freezers, and other closed loop vapor compression systems, as well as heat exchangers. These compositions provide more sensitive detection of leaks in inaccessible areas of furnaces using low ODP and non-flammable compounds classified as hydrofluorochloro-ethers (HFCE's), hydrobromochlorofluoro-alkenes (HBCFA's) hydrofluoro-ethers (HFE's), and halogenated compounds which are either alkanes, alcohols, diones, acetates, ketones (e.g., butanones, pentanones), esters (e.g., propanoates), anhydrides, cycloalkanes (cycloparaffins), cycloalkenes (cycloolefins), heterocyclics (e.g., furans), and aromatics.

Owner:MAINSTREAM ENG

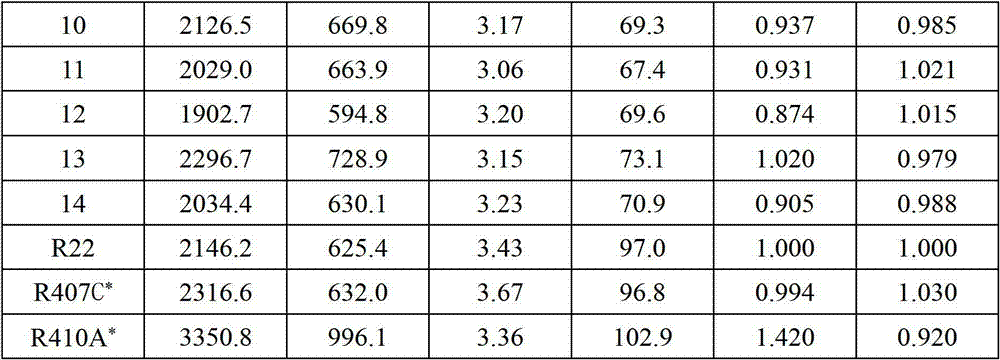

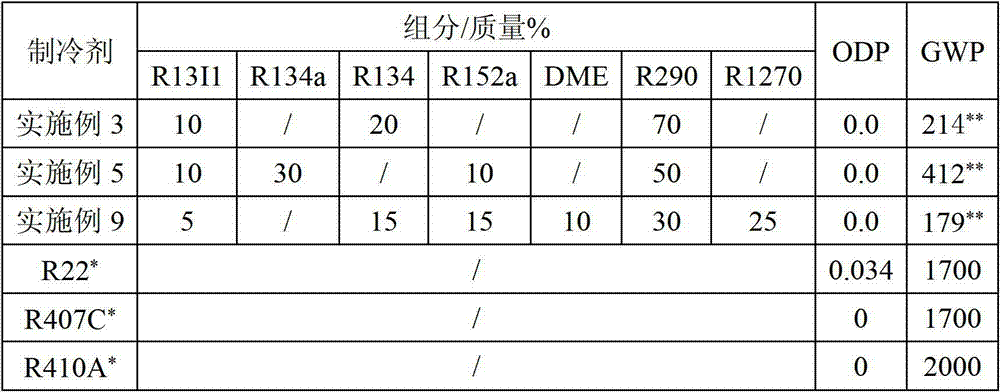

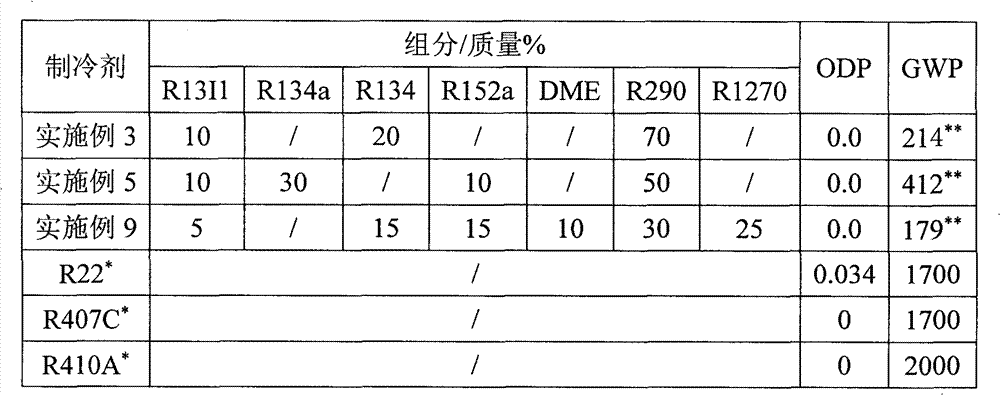

Trifluoroiodomethane-containing mixed refrigerant

InactiveCN101824305AReduce flammabilityWon't breakHeat-exchange elementsRefrigerationTrifluoroiodomethane

The invention relates to a trifluoroiodomethane-containing mixed refrigerant. The trifluoroiodomethane-containing mixed refrigerant is prepared by mixing component 1, a component 2 and a component 3, wherein the component 1 is trifluoroiodomethane with the combustion and explosion inhibiting effect; the component 2 comprises 1,1,1,2-tetrafluoroethane, 1,1,2,2-tetrafluoroethane or mixture of the 1,1,1,2-tetrafluoroethane and 1,1,2,2-tetrafluoroethane; the component 3 comprises propane, propylene or mixture of the propane and propylene; in the mixed refrigerant, the content of the component 1 is between 1 and 10 weight percent; the content of the component 2 is between 20 and 40 weight percent; the content of the component 3 is between 50 and 75 weight percent; the ODP value of the mixed refrigerant is zero; the GWP value is far less than that of a routine HFCs work substance; and the trifluoroiodomethane-containing mixed refrigerant has good lube intersolubility, can directly substitute an R22 working substance without making large alteration on a refrigeration system; and as the mixed refrigerant has the combustion inhibiting component, the combustibility of the refrigerant is greatly reduced or even the refrigerant is completely incombustible so that the safety of the refrigeration system is greatly improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

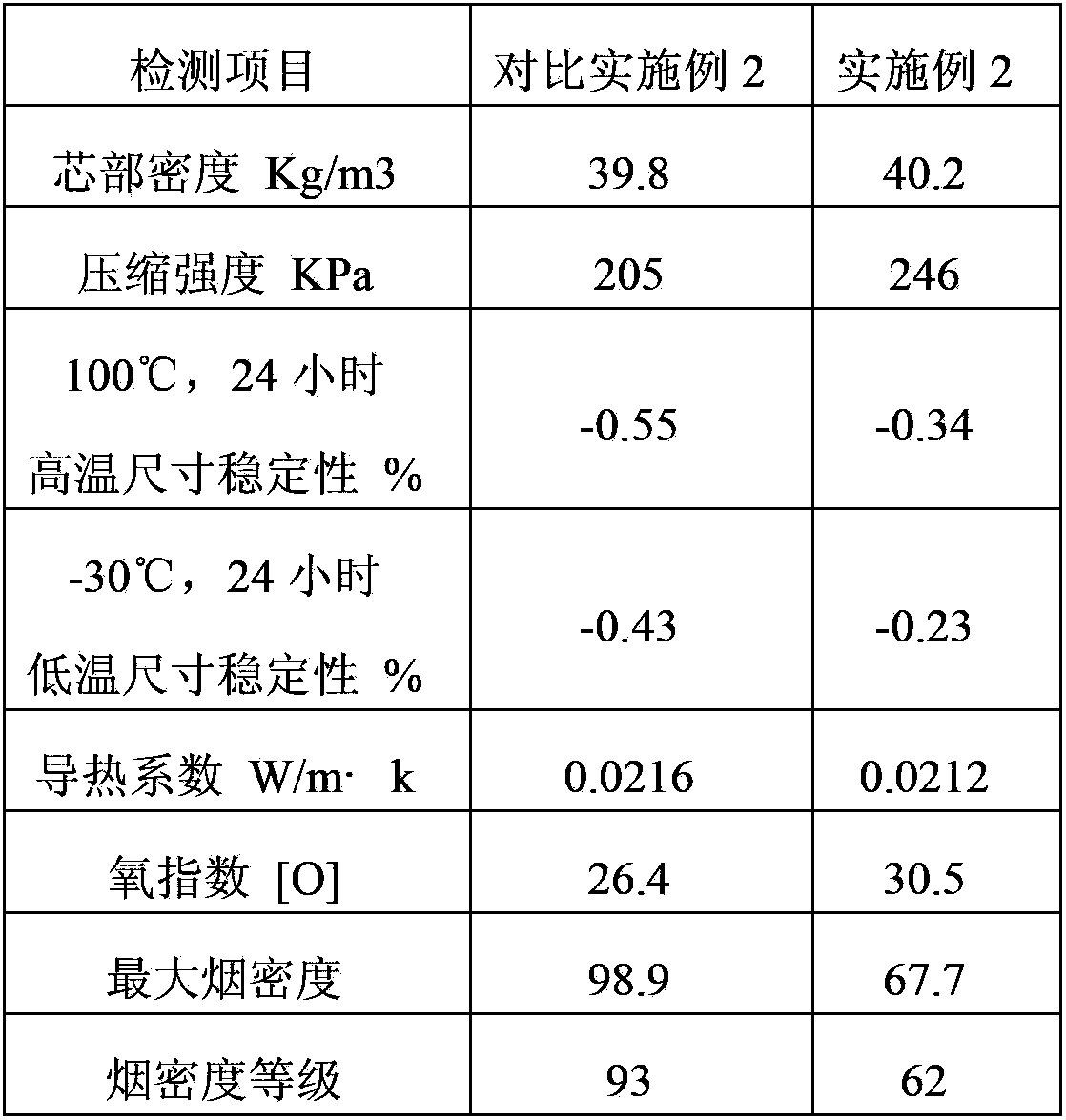

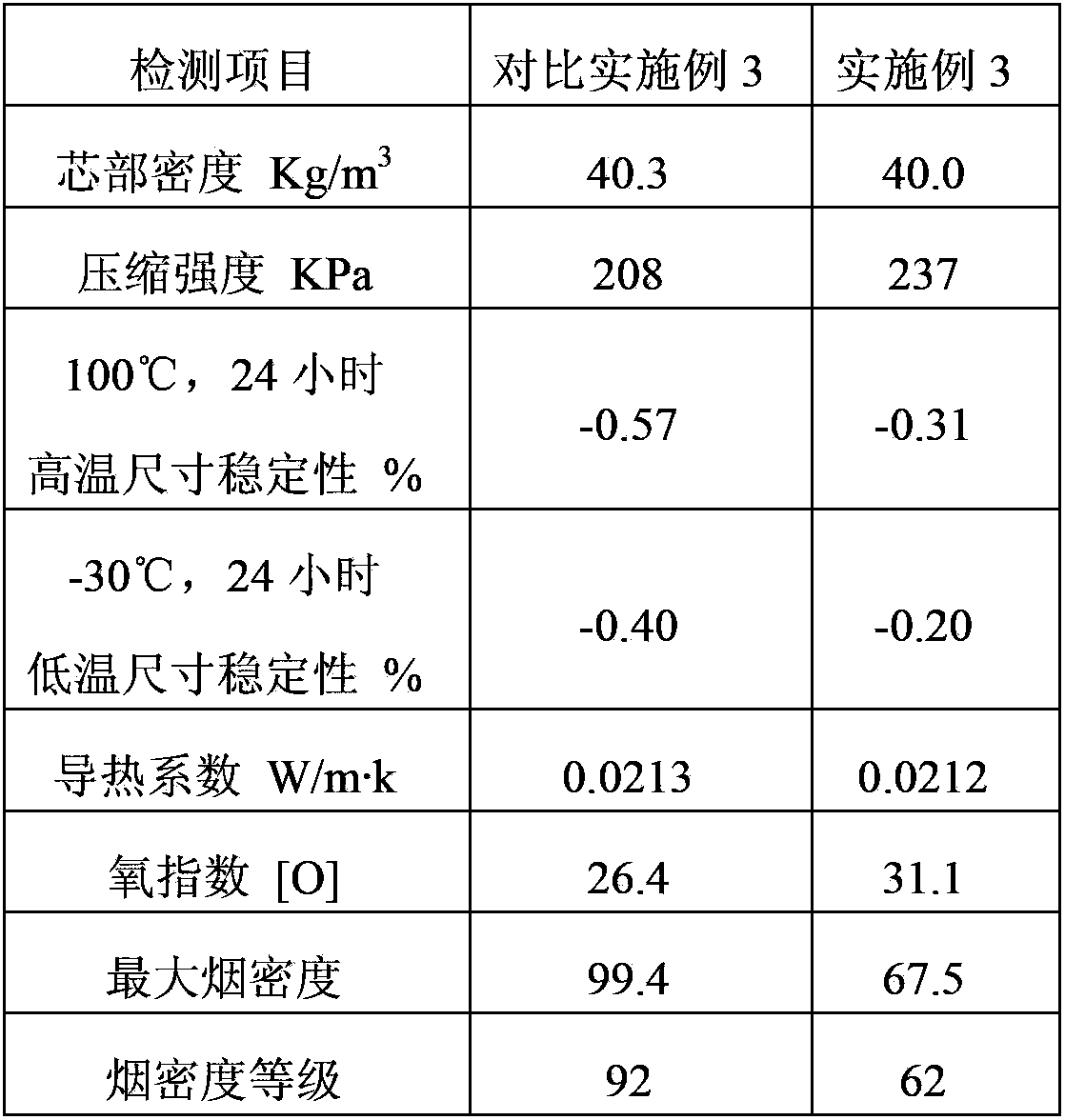

Composite polyether for environmentally-friendly sheet material, polyurethane raw material composition, rigid polyurethane foam and preparation method and use of rigid polyurethane foam

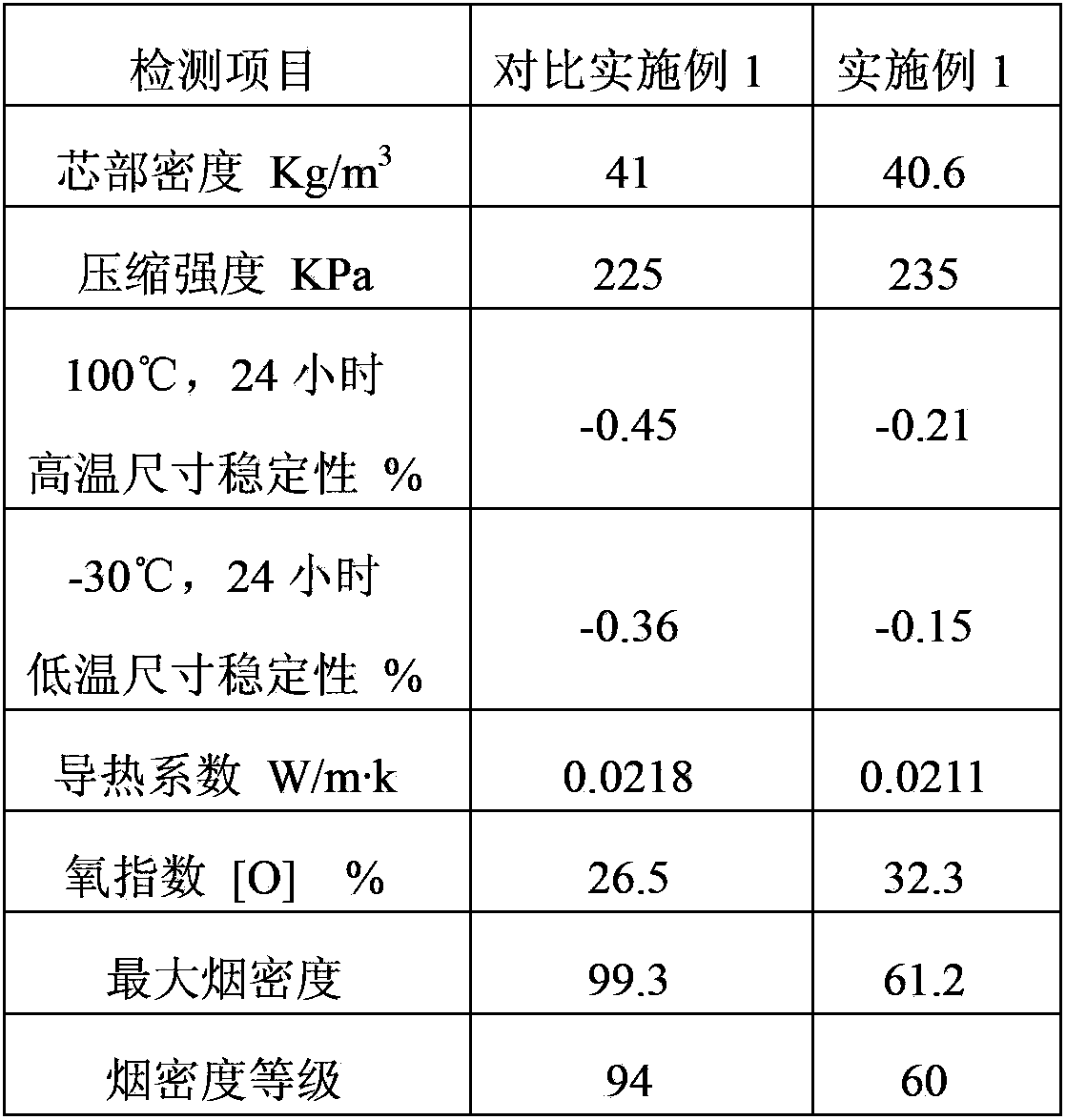

The invention discloses a composite polyether for an environmentally-friendly sheet material, rigid polyurethane foam and a preparation method of the rigid polyurethane foam. The composite polyether comprises, by weight, 2-4 parts of polyether polyol SU-450L, 6-8 parts of polyester polyol PS-2352, 0.2-0.3 parts of a foam stabilizer, 0.3-0.5 parts of a catalyst, 0.8-1.0 part of an alkane foaming agent, 0.18-0.22 parts of water and 2-3 parts of a fire retardant. Through use of the alkane foaming agent, the composite polyether has an ODP value of 0 and a low GWP value. The rigid polyurethane foam has excellent flame retardation, side stability and compressive strength. The polyurethane raw material composition has low smoke density in use, is environmentally friendly, and has strong operationality and wide application prospects in the building industry.

Owner:SHANGHAI DONGDA POLYURETHANE

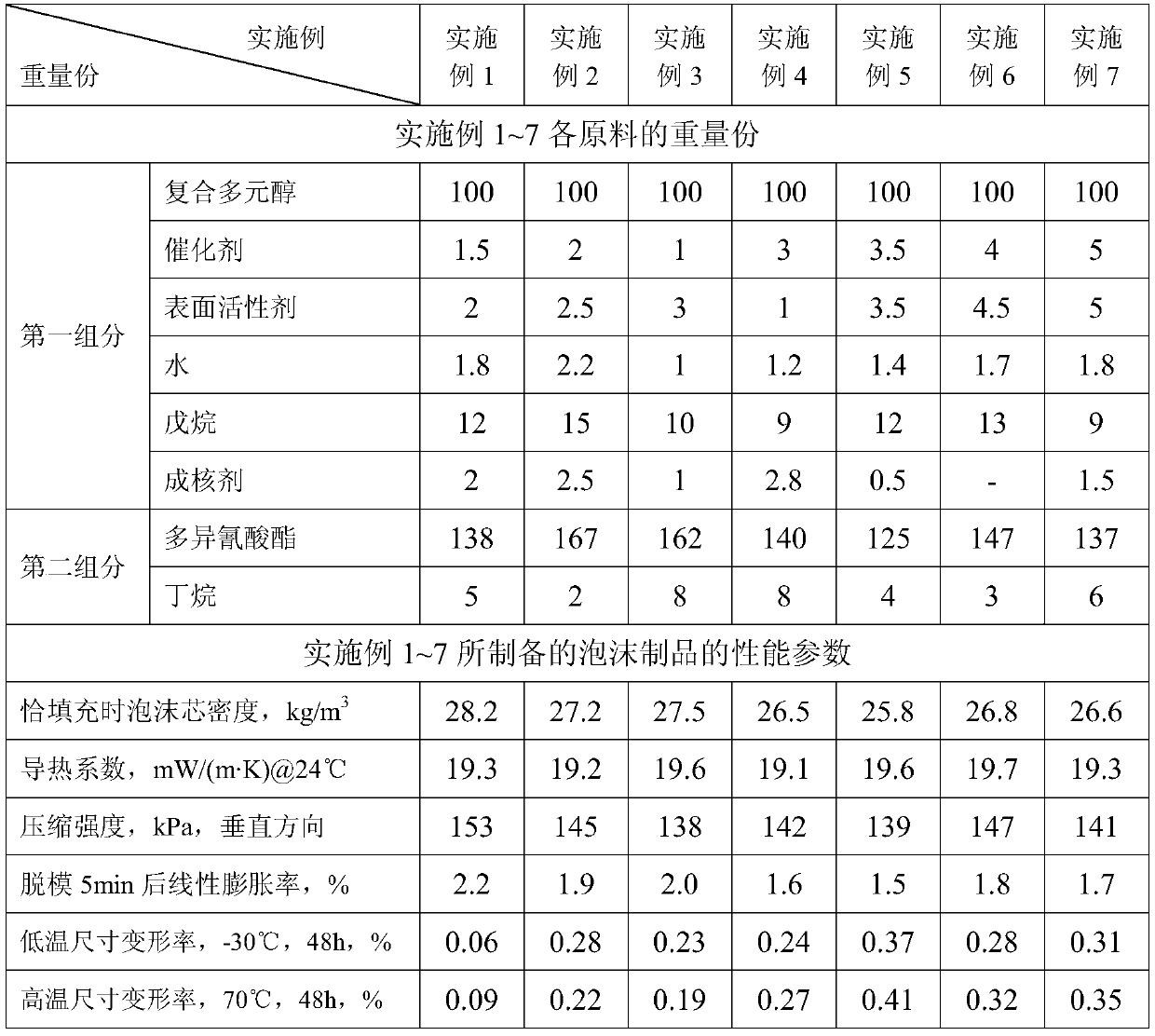

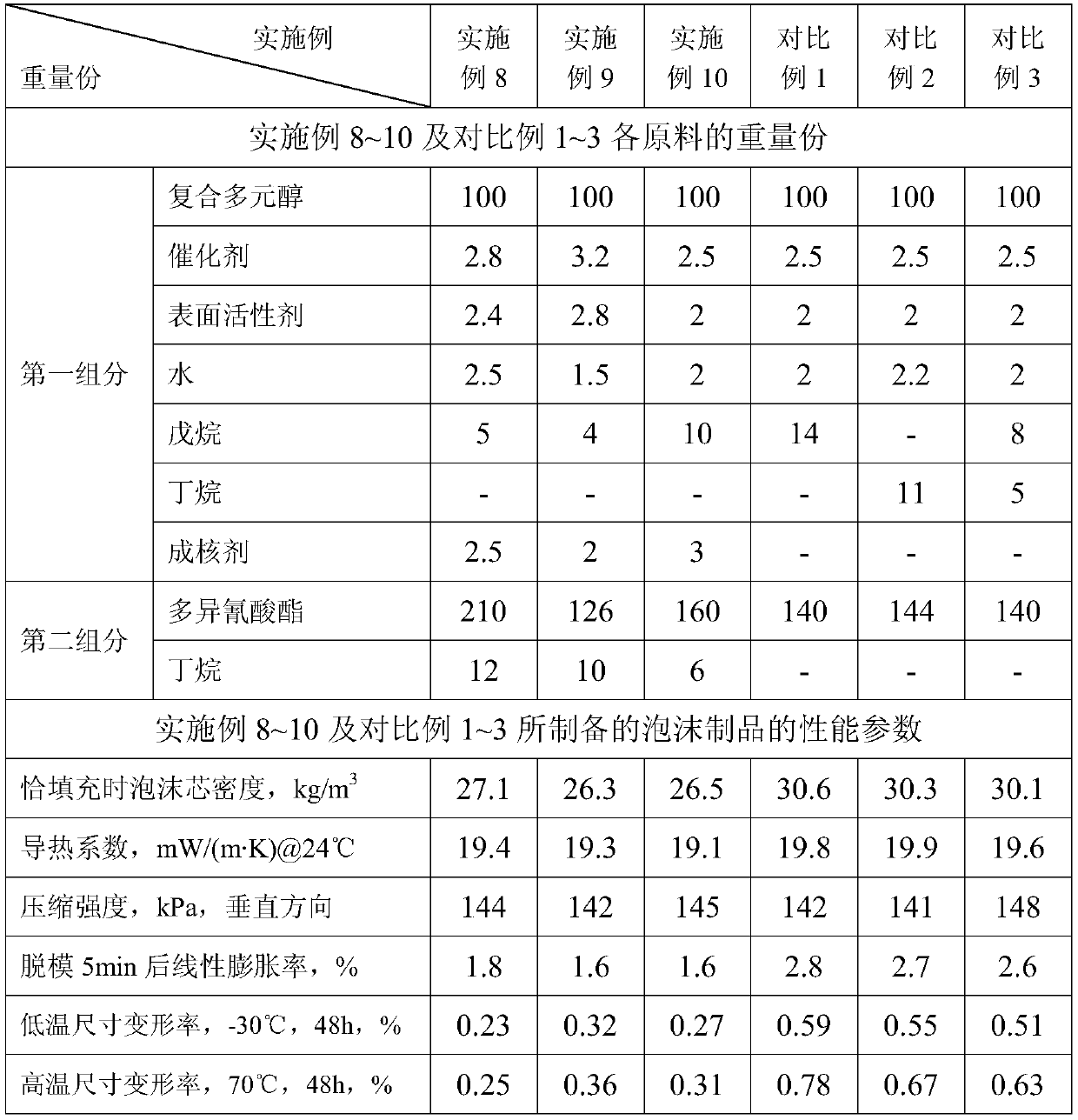

Ultra-low-density rigid polyurethane foam and preparation method thereof

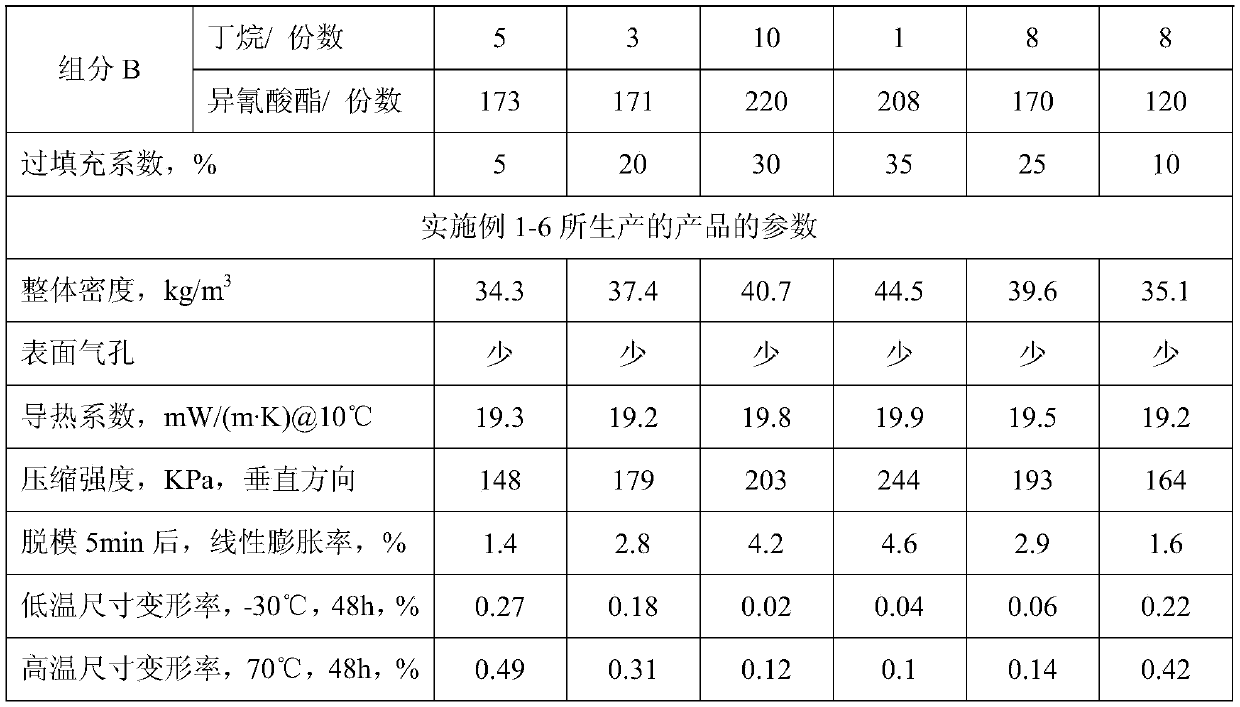

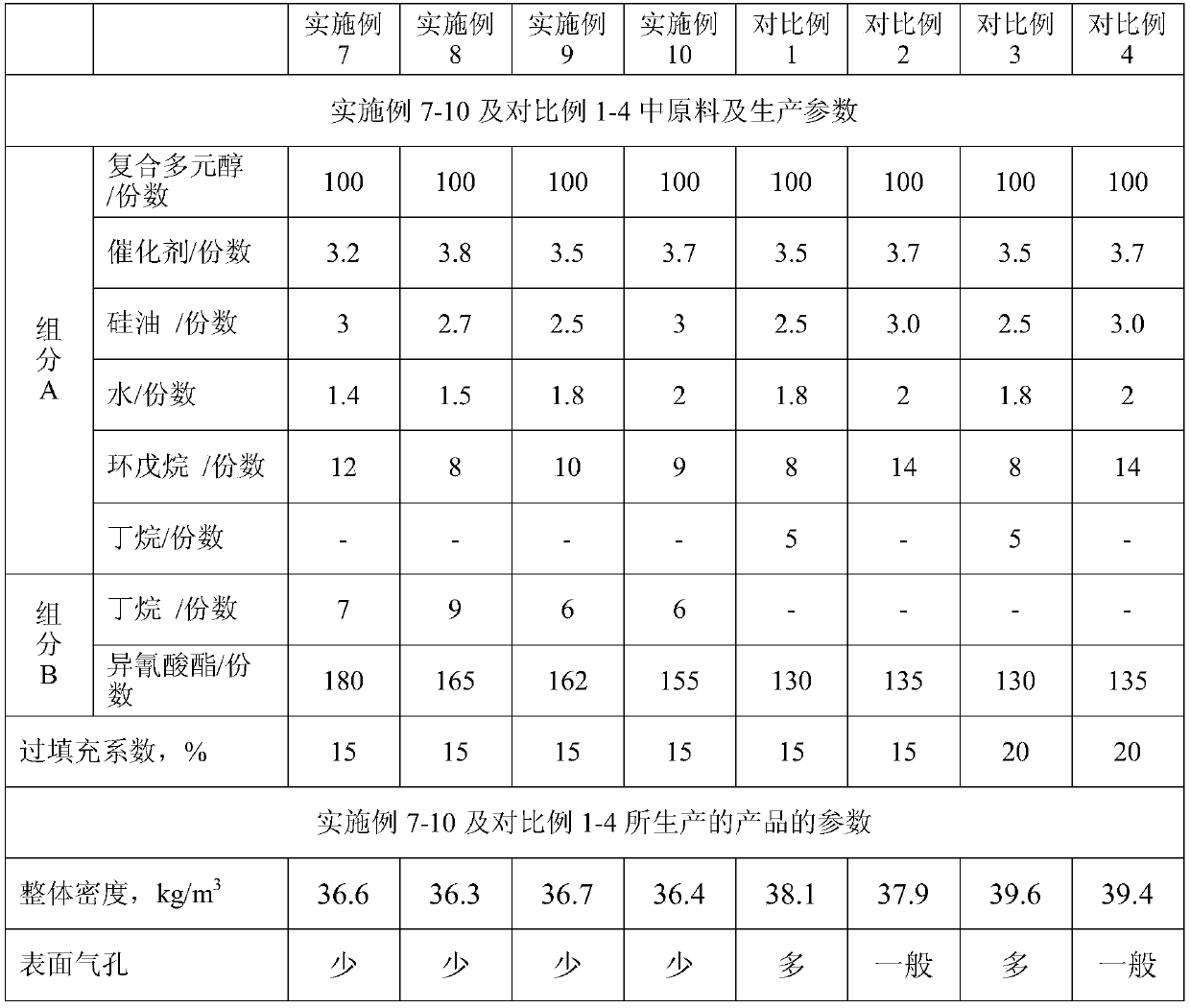

The invention relates to ultra-low-density rigid polyurethane foam with pentane and butane as foaming agents. The ultra-low-density rigid polyurethane foam is prepared by well premixing a component Aand a component B, and then well mechanically mixing and foaming the component A and the component B, wherein the component A is prepared from the components in parts by weight: 100 parts of pluronicpolyols, 4-15 parts of the pentane, 1-5 parts of a catalyst, 1-5 parts of an organosilicon surfactant, 1-2.5 parts of water and 0-3 parts of a nucleating agent, the component B is prepared from the components in parts by weight: 2-12 parts of the butane and 120-210 parts of polyisocyanates, and raw materials are based on 100 parts of pluronic polyols. According to the prepared foam, foam holes arefine and uniform, the heat conductivity coefficient is small, the compression strength is high, and the overall performance is excellent. The invention further discloses a preparation method of the rigid polyurethane foam.

Owner:NANJING HONGBAOLI POLYURETHANE

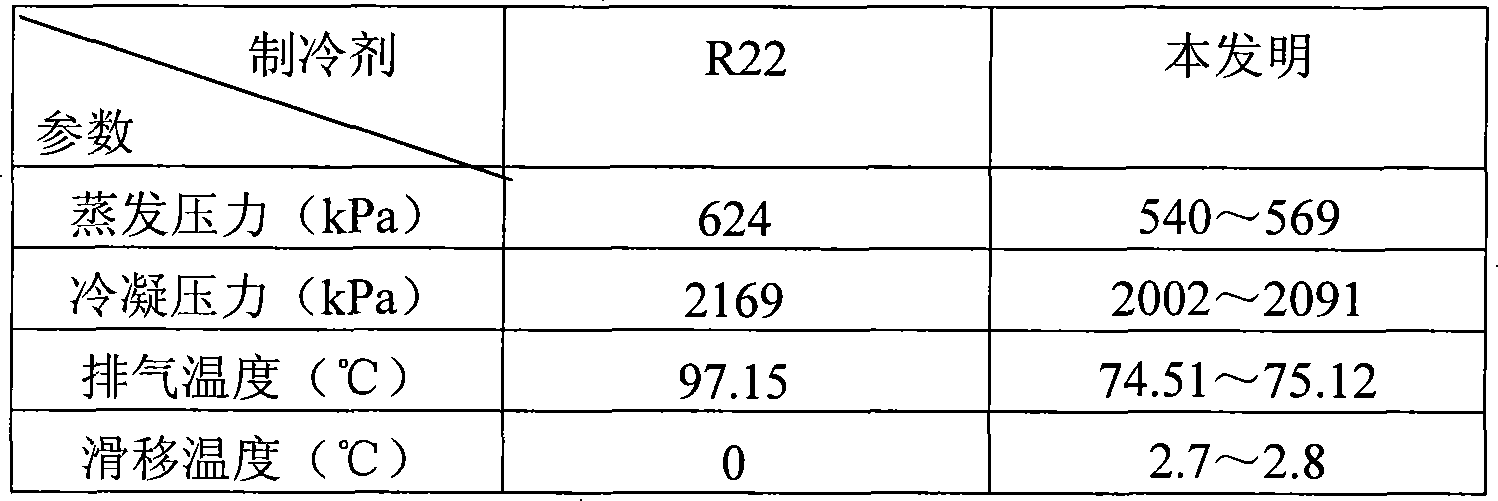

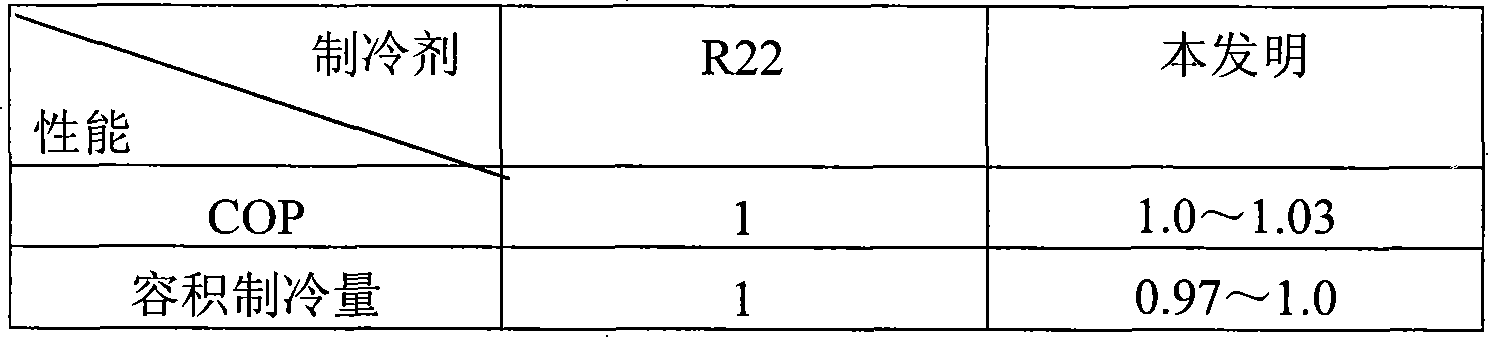

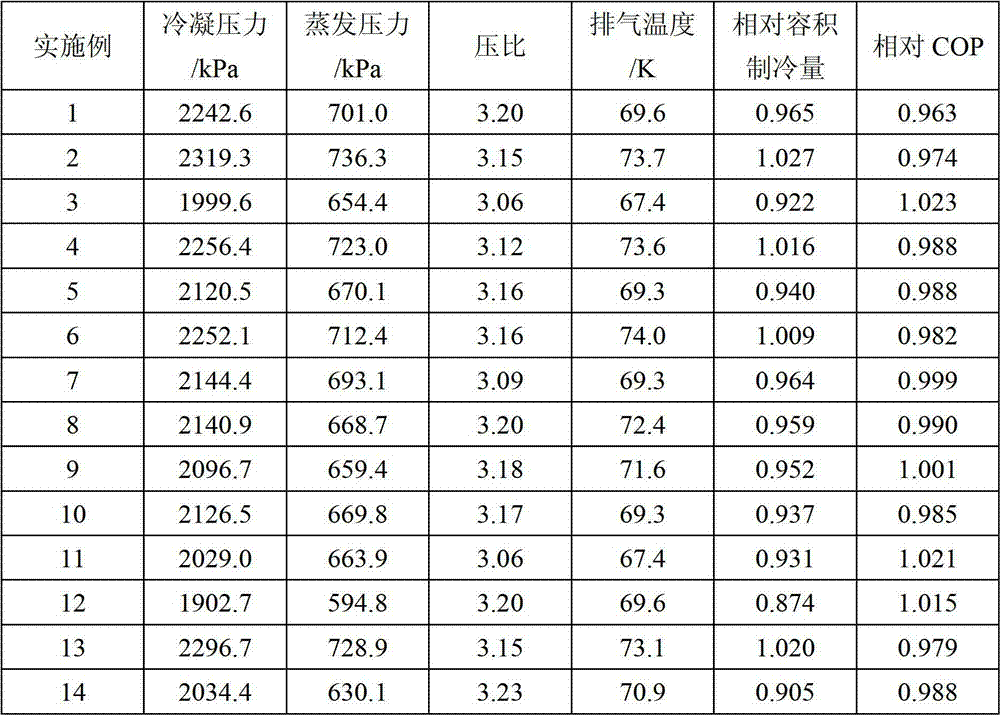

Refrigerant capable of directly filling to substitute R22

ActiveCN101245238ALow GWP valueMeet the protection requirementsHeat-exchange elementsEngineeringDimethyl ether

The invention provides a refrigerant combination which can be directly filled to replace R22 in systems like domestic air-conditioners and heat pumps, and consists of pentafluoroethane(R125), 1,1,1,2-tetrafluorothane(R134a) and dimethylether(DME or RE170), the preparation method is that each component is done with physical mixture in liquid phase according to corresponding proportions, the refrigerant completely meets the requirements of environmental protection, the value of ODP is zero, the value of GWP is low, the thermal performance and parameters are rather near to R22, the pressure and the exhaust temperature of a compressor are lower than R22, the refrigerant can be directly filled without adjusting or exchanging any part or lubricating oil in present R22 systems, moreover, the cycle performance is similar to or slightly higher than R22.

Owner:SHANDONG DONGYUE CHEM

Composite polyether, polyurethane foam and raw material composition and preparation method of polyurethane foam

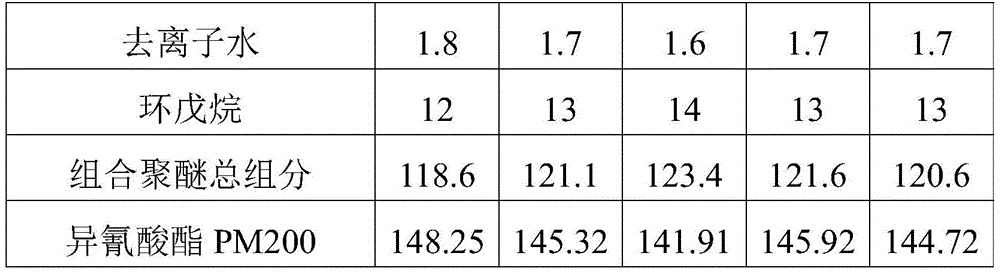

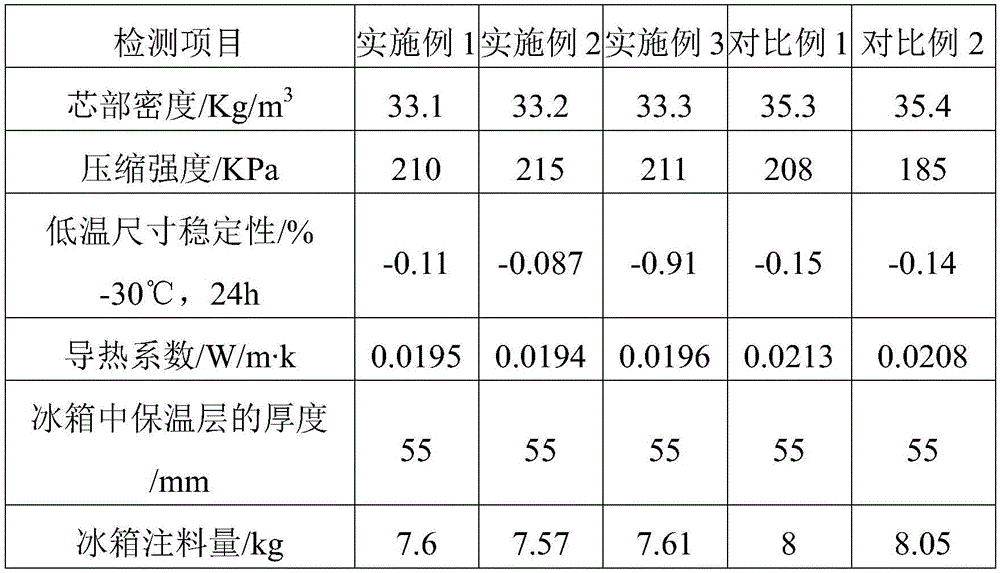

The invention discloses composite polyether, polyurethane foam and raw material composition and a preparation method of the polyurethane foam. The composite polyether is prepared from, by weight, 30-50 parts of polyether polyol A, 10-20 parts of polyether polyol B, 30-40 parts of polyether polyol C, 5-15 parts of polyether polyol D, 2-3 parts of foam stabilizer, 2-5 parts of catalysts, 12-14 parts of foaming agent and 1.6-1.8 parts of water. The foaming agent is cyclopentane. The polyurethane foam adopts the composite polyether, the environment-friendly property is remarkably improved, the foam heat conductivity coefficient, the molding density and the refrigerator injection dosage are reduced, production cost is lowered, and compression strength and low-temperature size stability are improved.

Owner:SHANGHAI DONGDA POLYURETHANE

Green mixed refrigerant

InactiveCN102516946ALow ODPImprove thermal performanceHeat-exchange elementsDifluoroethyneEngineering

The invention discloses a green mixed refrigerant, comprising 20-60 wt% of 2,3,3,3-tetrafluoro propylene or trans-1,3,3,3-tetrafluoro propylene, 5-30 wt% of 1,1-difluoroethane or 1,1,1,2-tetrafluoro ethane, and 35-60 wt% of difluoromethane. The preparation method is characterized by physically mixing the above ingredients according to corresponding ratio at normal temperature. According to the invention, because the volume refrigerating capacity of the green mixed refrigerant is very close to that of HCFC-22 and the condensation pressure of the green mixed refrigerant is lower than that of R410A, the green mixed refrigerant can be directly filled in existing refrigeration, air-conditioning or heat pump sets which use HCFC-22; and when HCFC-22 is replaced, the components and pipeline of the system have no need of redesigning. The green mixed refrigerant can be an alternative refrigerant to HCFC-22 and R410A.

Owner:JIMEI UNIV

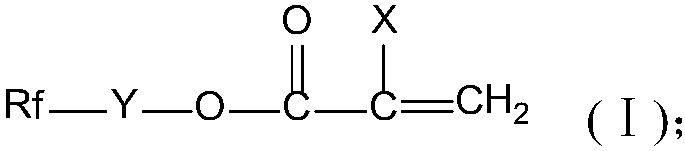

Novel oil-resistant, water-resistant and antifouling electron coating agent

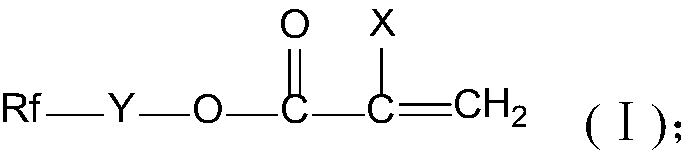

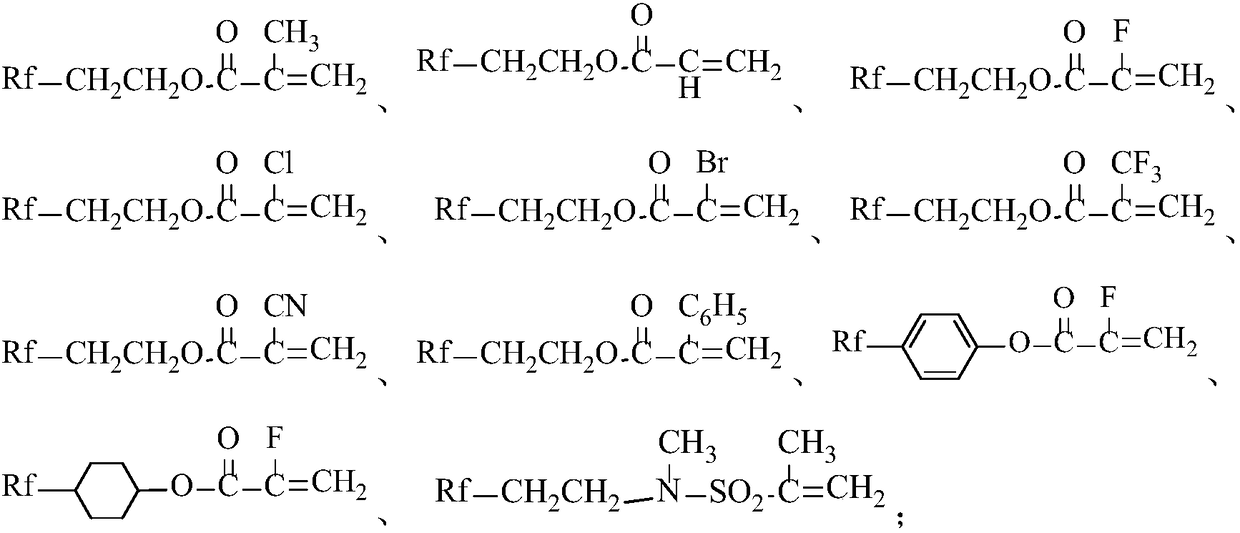

InactiveCN108276863AImprove high temperature resistanceExcellent water and oil repellencyCoatingsCross-linkOrganic solvent

The invention discloses a novel oil-resistant, water-resistant and antifouling electron coating agent, which comprises, by mass, 0.1-10 parts of a fluorine-containing polymer and 90-99.9 parts of an organic solvent, wherein the fluorine-containing polymer contains a forming unit based on a fluorine-containing monomer (A), a forming unit based on a monomer (B), and a forming unit based on a cross-linking monomer (C), and the organic solvent is hydrofluoroether. According to the present invention, the electron coating agent has the advantages of excellent high-temperature resistance, excellent water resistance, excellent oil resistance and excellent antifouling performance through the fluorine-containing polymer, has the advantages of rapid drying and environment protection through the hydrofluoroether solvent, and is particularly suitable for the treatment of printing circuit boards (PCBs), electrical equipment, semiconductors, sensors, transducers, hybrid circuits and the like.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

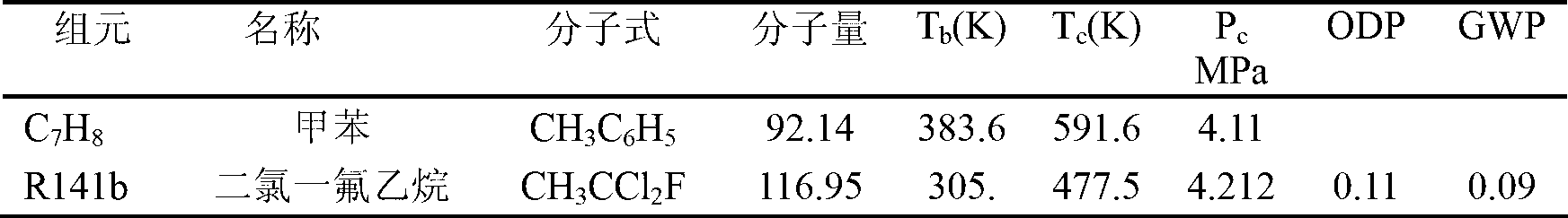

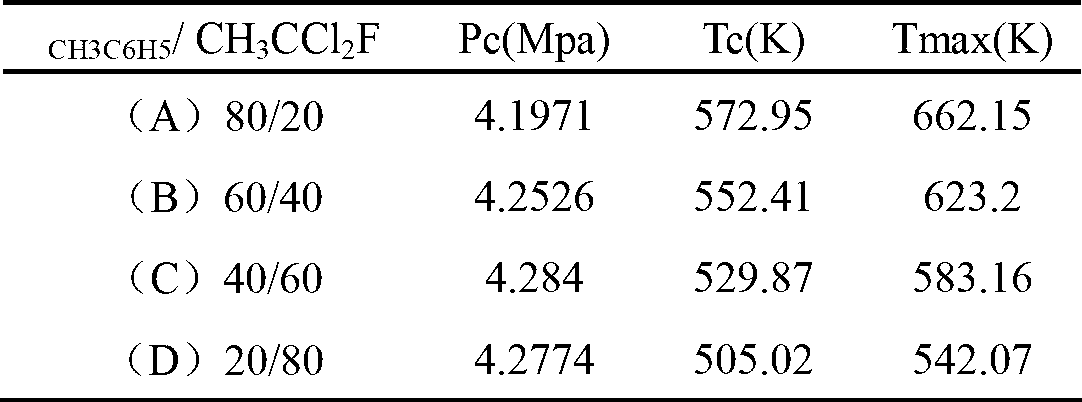

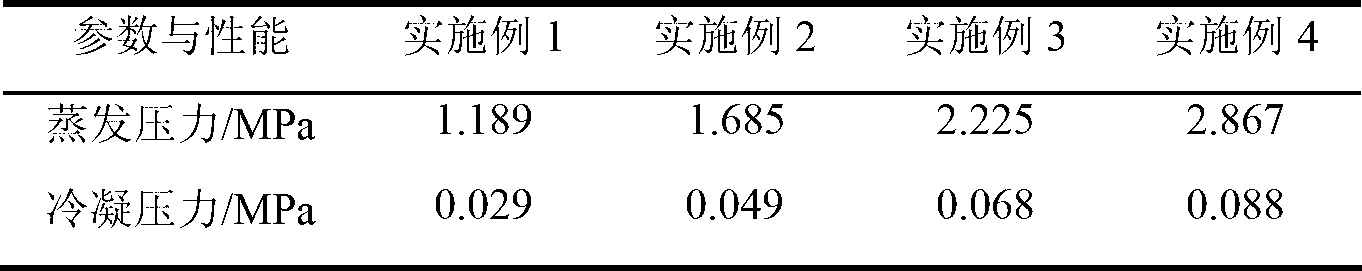

Organic Rankine cycle mixed working medium containing toluene

InactiveCN103013450AComply with protectionLow ODPHeat-exchange elementsOrganic Rankine cycleEngineering

The invention discloses an organic Rankine cycle mixed working medium containing toluene, which is applied to an engine waste heat system. The working medium is a two-component mixture composed of toluene and dichloro-fluoroethane in different mass percentages, and is suitable for being used as a working medium of a high-temperature ORC system in which the temperature of a heat source is 400 DEG C to 700 DEG C. The preparation method is as follows: performing physical mixing on the components according to designated matching at normal temperature, so as to obtain the corresponding mixed working medium. The ODP of the working medium is almost zero and the GWP is lower. The working medium has a good environmental property, conforms to the requirements for protecting the ozone layer and reducing the greenhouse effect, and can be directly applied to the high-temperature exhaust waste heat ORC system of an engine.

Owner:TIANJIN UNIV

Low-density hard polyurethane foam and preparation method thereof

The invention discloses low-density hard polyurethane foam which is prepared by respectively premixing components A and components B, jointly mixing and foaming. The components A include, by weight, 100 parts of composite polyol, 5-15 parts of cyclopentane, 1.5-6 parts of amine catalyst, 1-5 parts of silicon surfactant and 0.8-2.5 parts of water, and the components B include, by weight, 1-10 partsof butane and 120-220 parts of isocyanate, wherein each raw material above is based on 100 parts of composite polyol. The preparation method includes following steps: (1), preparing the components A;(2), preparing the components B; (3), injecting the components A and the components B into a closed mold, allowing sufficient reaction, and demolding to obtain the hard polyurethane foam. The low-density hard polyurethane foam is environment-friendly and excellent in performance.

Owner:HONGBAOLI GRP CO LTD

Heat preservation rigid polyurethane foam and preparation method thereof

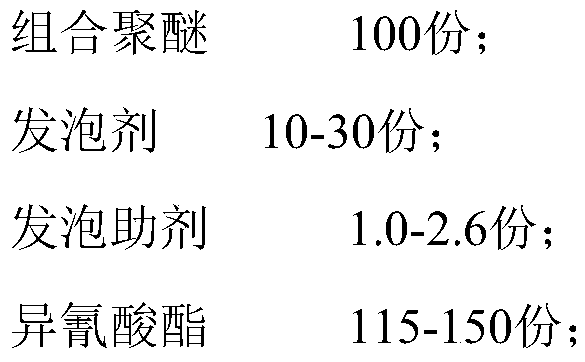

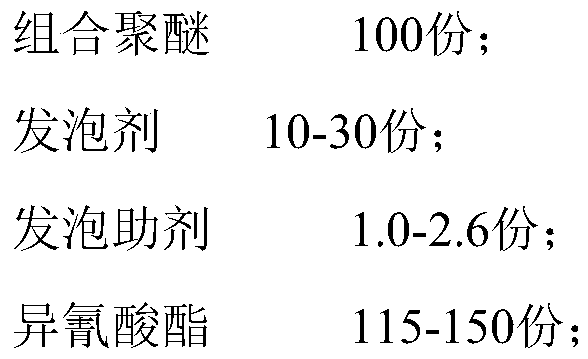

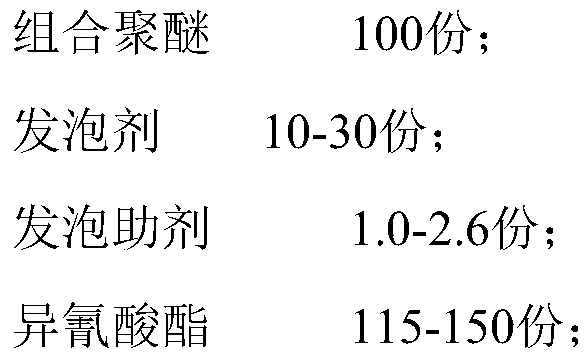

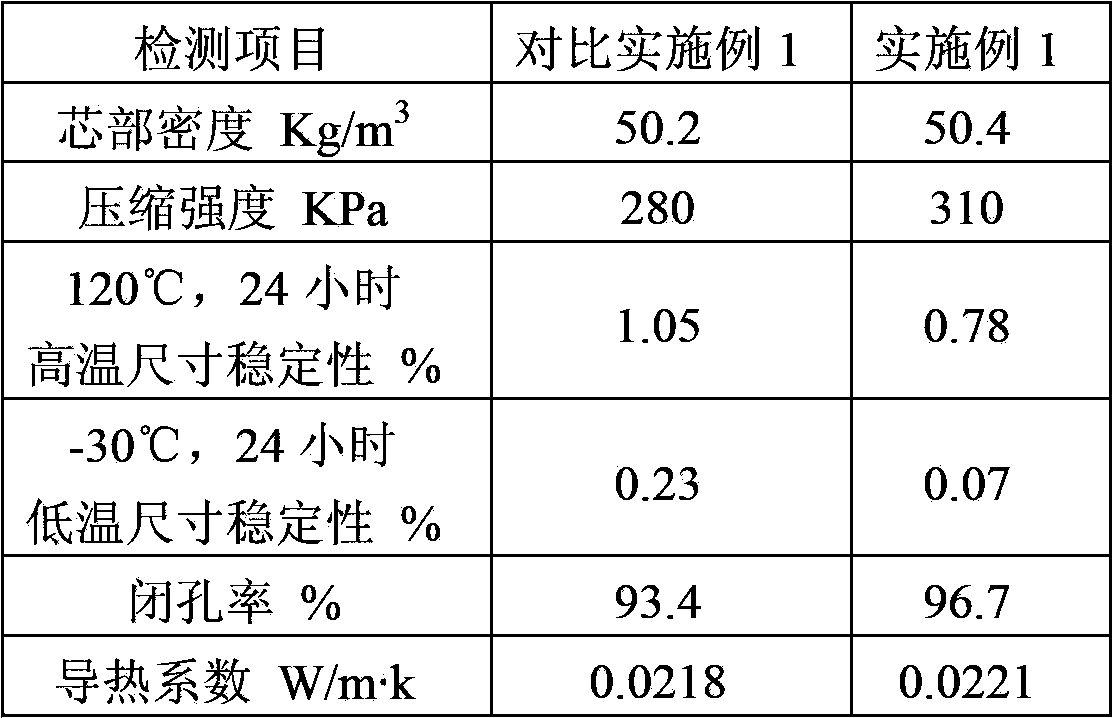

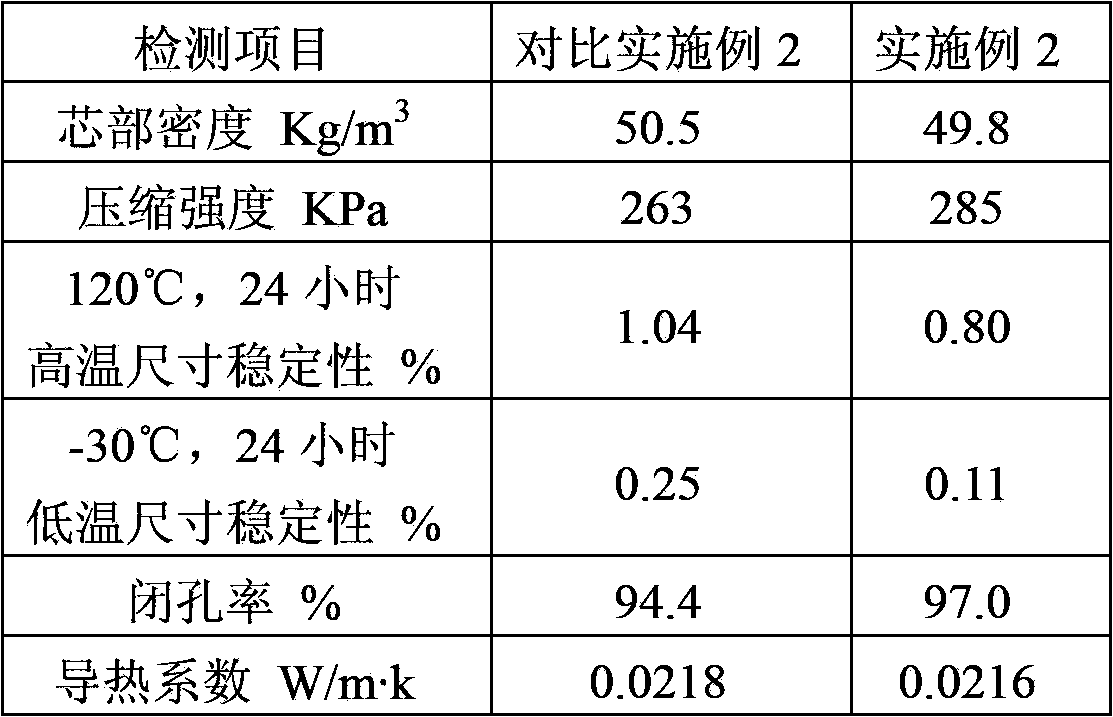

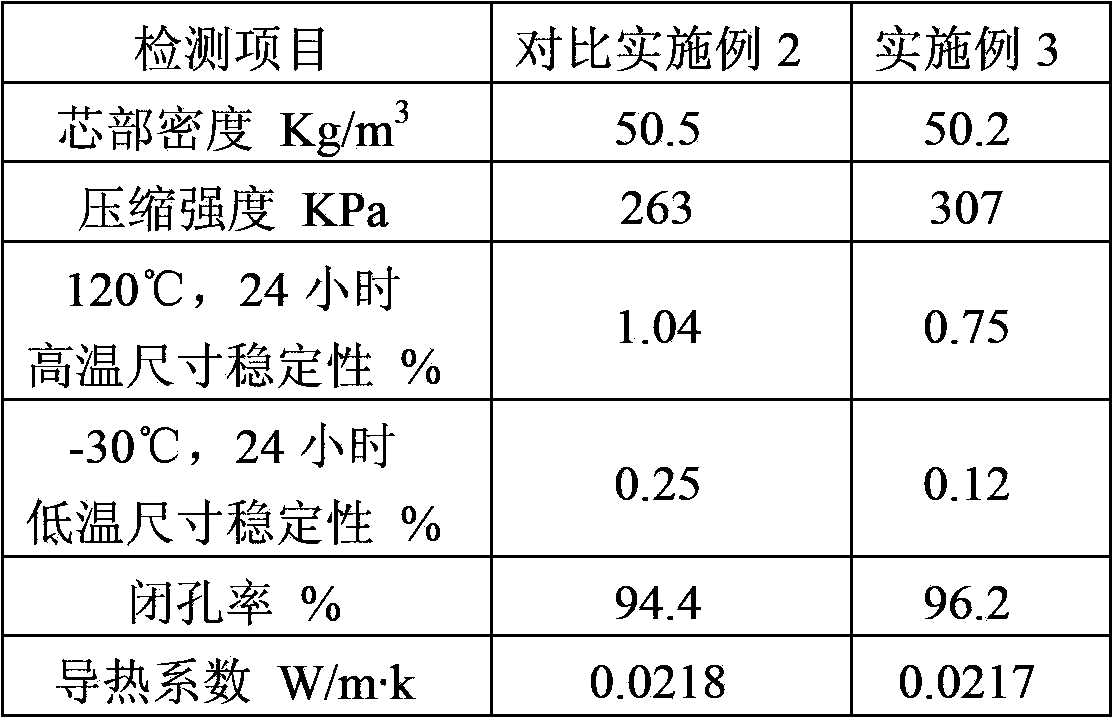

The invention relates to a heat preservation rigid polyurethane foam and a preparation method thereof. The heat preservation rigid polyurethane foam is prepared from the following raw materials by weight: 100 parts of combined polyether; 10-30 parts of a foaming agent; 1-2.6 parts of a foaming assistant; and 115-150 parts of isocyanate. Specifically, the foaming agent is one of 1, 1-dichloro-1-fluoroethane, 1-chloro-3, 3, 3-trifluoropropene, 1, 1, 1, 3, 3,-pentafluoropropane, 1, 1, 1, 4, 4, 4-hexafluoropropylene or cyclopentane; the foaming assistant is one of or a mixture of perfluoroolefineand hydrofluoroether, and the perfluoroolefine and hydrofluoroether are in a weight ratio of 100:0-100; the combined polyether is high functionality polyether; and the isocyanate is polymethylene polyphenyl isocyanate. The heat preservation rigid polyurethane foam has the characteristics of high compression strength, small cell size and low thermal conductivity, and can generate obvious energy saving and consumption reduction effects.

Owner:海斯福(深圳)科技有限公司

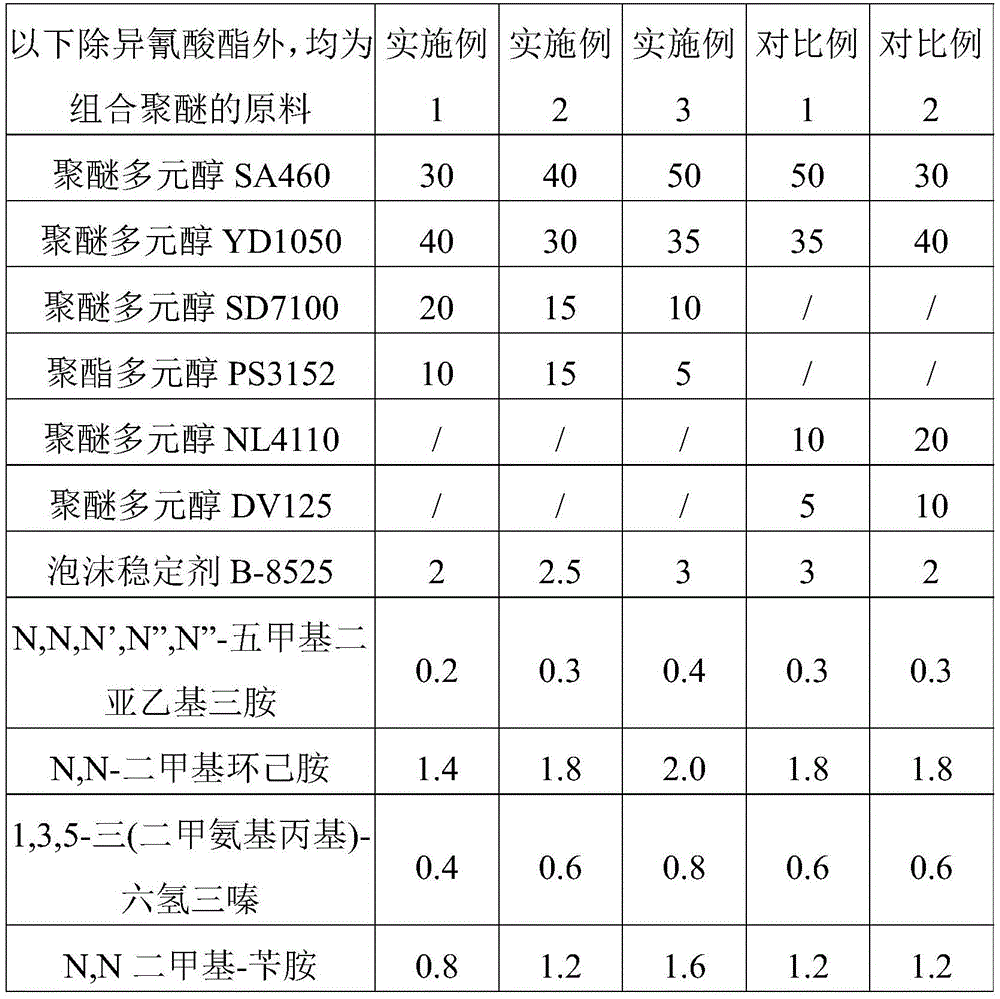

Combined polyether, raw material composition and polyurethane foam as well as preparation method and application of combined polyether, raw material composition and polyurethane foam

ActiveCN103665295ALow ODPComply with the environmental requirements of replacing HCFC-141BChemistryRaw material

The invention discloses combined polyether, a raw material composition and rigid polyurethane foam as well as a preparation method and application of the combined polyether, the raw material composition and the polyurethane foam. The combined polyether comprises the following components in parts by weight: 3-5 parts of polyether polyol SU-450L, 2-4 parts of polyether polyol SA380, 3-5 parts of polyether polyol NL2010, 0.2-0.3 part of foam stabilizer, 0.1-0.3 part of catalyst, 0.7-0.9 part of alkane foaming agent and 0.18-0.22 part of water. The alkane foaming agent adopted by the combined polyether has the advantages of zero ODP (Ozone Depletion Potential) value and low GWP (Global Warming Potential) value. The rigid polyurethane foam disclosed by the invention is excellent in various aspects including size stability, compressive strength and heat conductivity coefficient and is suitable for being used as a heat preservation material for applications in industries such as steam, oil pipelines and the like.

Owner:SHANGHAI DONGDA POLYURETHANE

Mixed refrigerant containing trifluoroiodomethane

ActiveCN102766438AReduce flammabilityWon't breakHeat-exchange elementsCombustionOzone depletion potential

The invention relates to a mixed refrigerant containing trifluoroiodomethane, which is formed by physically mixing a component 1, a component 2 and a component 3, wherein the component 1 is trifluoroiodomethane having the function of inhibiting combustion and explosion, the component 2 is 1,1,2,2,-tetrafluoroethane, and the component 3 is propylene; and in the mixed refrigerant, the content of the component 1 is 1-10 wt%, the content of the component 2 is 20-40 wt%, and the content of the component 3 is 50-75 wt%. The ODP (ozone depletion potential) value of the mixed refrigerant is zero, the GWP (global warming potential) value is much smaller than that of a conventional HFC (hydrofluorocarbon) working medium, and the mixed refrigerant has favorable lubricating oil intersolubility; and thus, the mixed refrigerant can directly substitute an R22 working medium without great changes in the refrigeration system. Since the mixed refrigerant has the combustion inhibiting component, the refrigerant has greatly lower flammability and is even non-flammable, so that the safety of the refrigeration system is greatly enhanced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

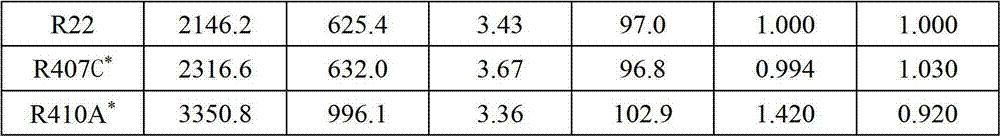

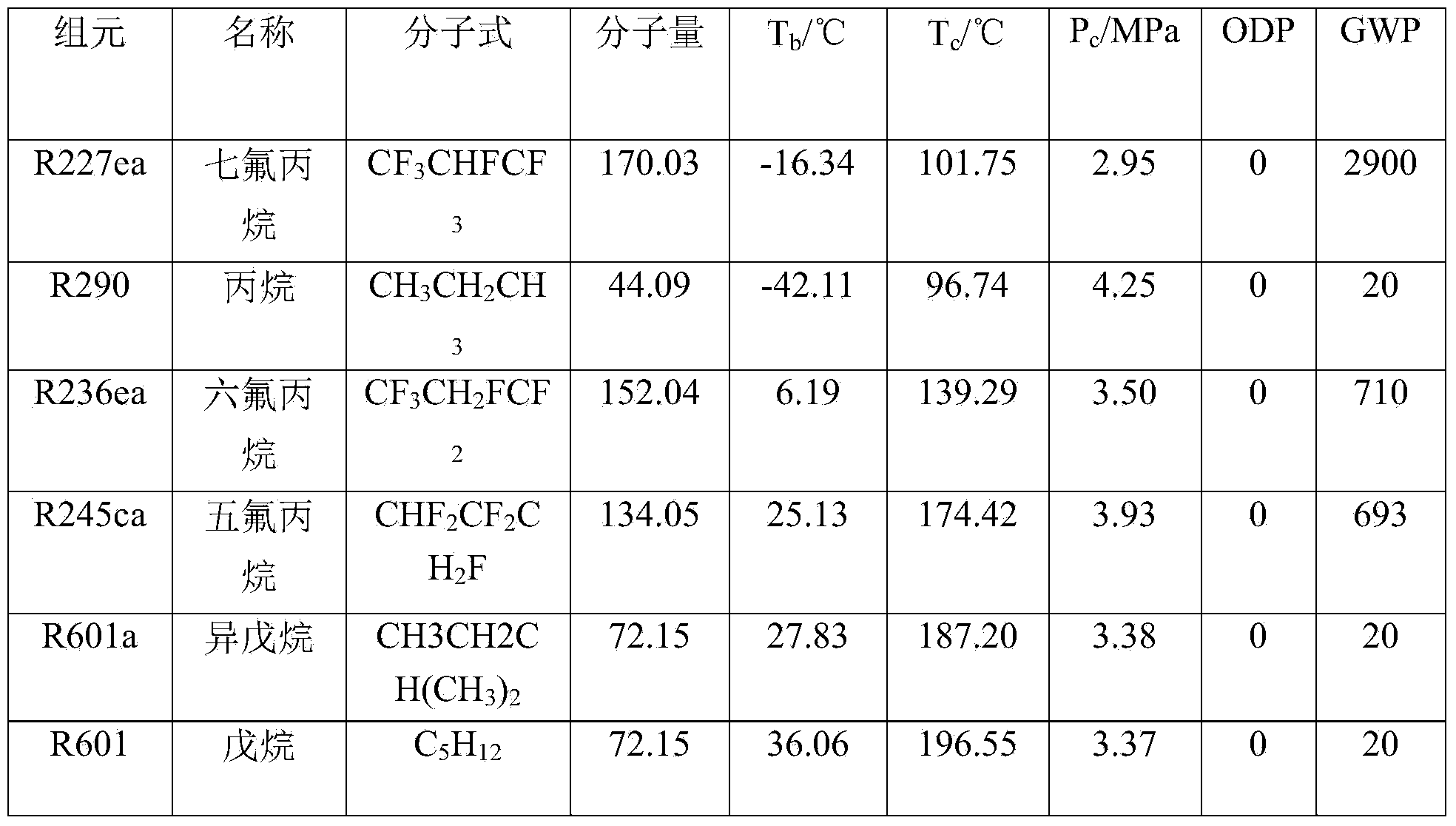

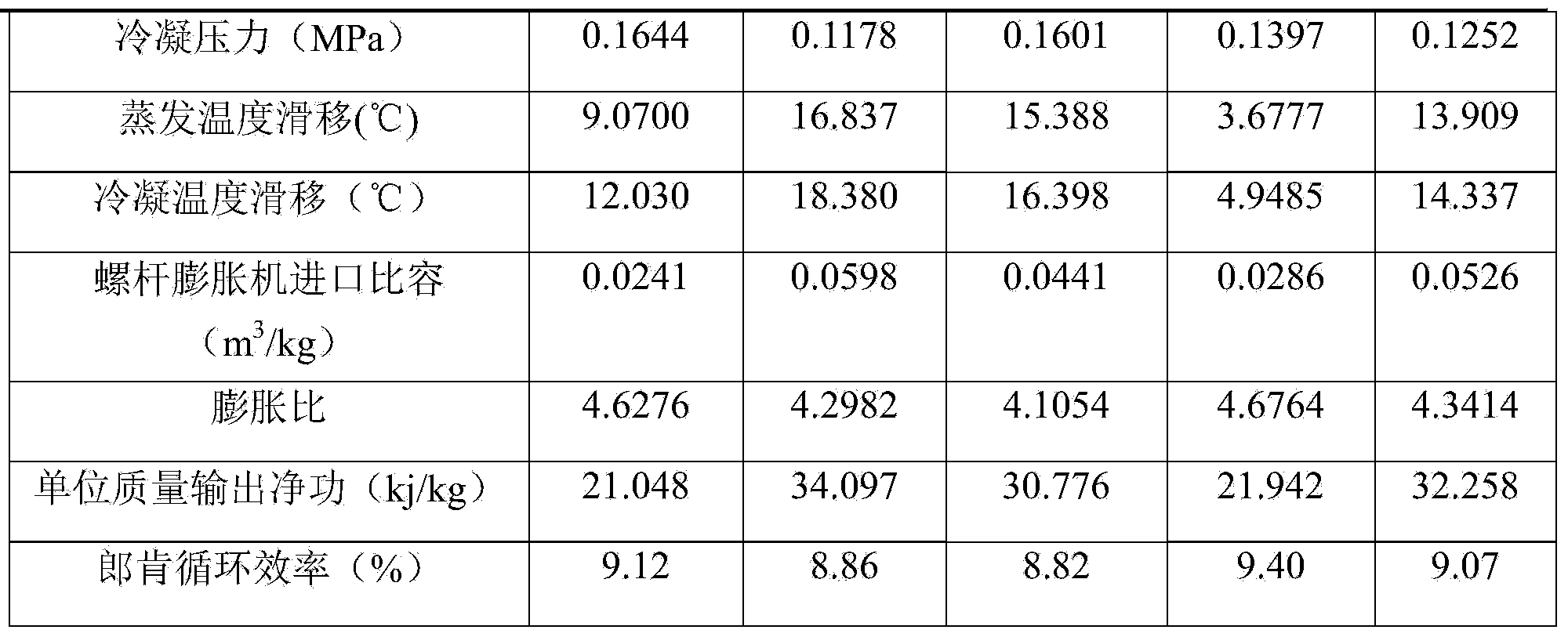

HFC-227ea-containing low-temperature organic mixed working medium for Rankine cycle system

InactiveCN102816555AImprove securityImprove flame retardant performanceHeat-exchange elementsRankine cycleEngineering

The invention relates to an HFC-227ea-containing low-temperature organic mixed working medium for a Rankine cycle system, which comprises the following six components: HFC-227ea, R290, HFC-236ea, HFC-245ca, R601 and R601a. The mixed working medium specifically comprises the following components in percentage by mass: R227ea / R245ca (5-95 / 95-5%); R227ea / R601 (5-95 / 95-5%); R227ea / R601a (5-95 / 95-5%); R227ea / R236ea / R245ca (5-95 / 2-80 / 3-93%); R227ea / R236ea / R601 (5-90 / 5-80 / 5-90%); R227ea / R236ea / R601a (5-90 / 3-80 / 5-92%%); R227ea / R245ca / R601 (5-90 / 5-90 / 5-80%); and R227ea / R290 / R601a (5-95 / 0-90 / 5-90%). The invention can enhance the safety of the mixture, and has the advantages of proper heat engineering parameters and favorable cycle performance.

Owner:TIANJIN UNIV

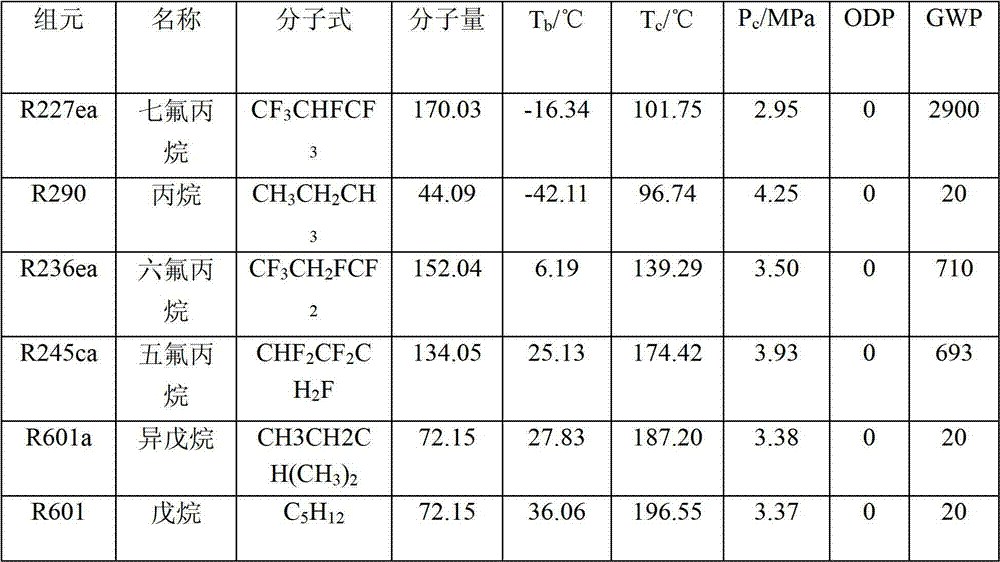

Organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of internal combustion engine

InactiveCN105062426AGood environmental characteristicsComply with protectionHeat-exchange elementsEnvironmental resistanceOrganic Rankine cycle

The invention discloses a group of organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of an internal combustion engine. The organic Rankine cycle mixed working media comprise components in percentage by mass as follows: 20%-32% / 68%-80% of n-butane / CO2, 20%-32% / 68%-80% of iso-butane / CO2 and 15%-27% / 73%-85% of n-pentane / CO2. The mixed working media are physically mixed at the normal temperature and then subjected to systematical filling. The mixed working media belong to natural working media, the ODP (ozone depletion potential) value is zero, the GWP (global warming potential) value is very small, and the organic Rankine cycle mixed working media have good environment protection performance; besides, the organic Rankine cycle mixed working media can meet the ISO 817-2010 standard and the A2-class safety working medium standard of the ASHRAE 34-2010 standard and have higher safety. The critical pressure and the critical temperature of the mixed working media are appropriate, the heat efficiency under the working condition of organic Rankine cycle design is higher than 14%, and the thermal performance is excellent.

Owner:TIANJIN UNIV

Mixed refrigerant containing iodotrifluoromethane

ActiveCN102925109AReduce flammabilityImprove securityHeat-exchange elementsChemistryTrifluoroiodomethane

The invention relates to a mixed refrigerant containing iodotrifluoromethane. The mixed refrigerant is composed of a component 1, a component 2 and a component 3 which are physically mixed, wherein the component 1 is the iodotrifluoromethane with the function of fire and explosion suppression; the component 2 is 1,1,1,2-tetrafluoroethane; and the component 3 is propane; in the mixed refrigerant, the content of the component 1 is 1-10wt%, the content of the component 2 is 20-40wt%, and the content of the component 3 is 50-75wt%. The mixed refrigerant disclosed by the invention has the advantages that the ODP (Ozone Depletion Potential) value is zero, the GWP (Global Warming Potential) value is far lower than that of the conventional HFCs (Hydrofluorocarbon) working media, the lubricating oil intersolubility is favorable, and the mixed refrigerant can directly replace the R22 working medium without doing big changes for the refrigerating system; the because the components comprise the fire suppression component, the flammability of the mixed refrigerant is greatly lowered and is even lowered to be zero, and the safety of a refrigerating system is greatly enhanced.

Owner:青岛中科未来健康研究院有限公司

Medium-high-temperature heat pump set working medium

InactiveCN1978581AMeet environmental protection requirementsLow ODPHeat-exchange elementsMature technologyWork function

This invention relates to new type medium high temperature heat pump engine working medium, it is matched of various component in mass percentage such as HCFC124, HFC245fa, HC600a, HCFC22, HFC134a and so on, its component reach the requirement of the environmental protection, heat work function is fine, hindering burning commixture working medium, and may use the compression engine directly which adopts the mature technology and whose former working medium is HCFC22.

Owner:河南绿源制冷有限公司

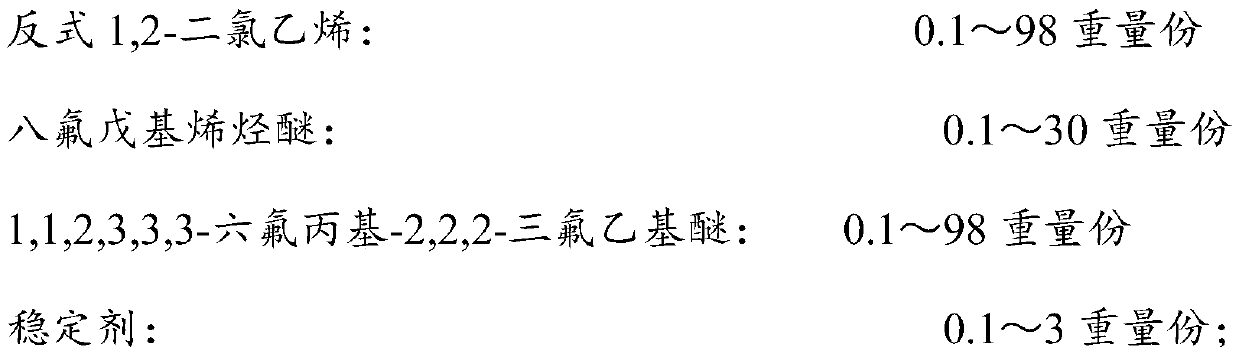

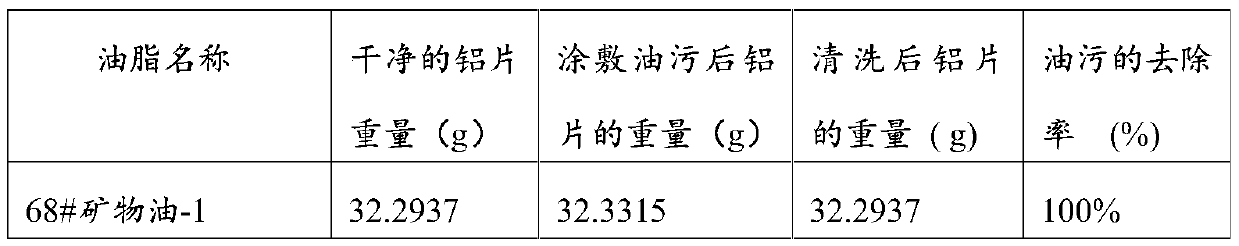

Halogenated hydrocarbon combined solvent containing octafluoropentyl olefin ether and application of halogenated hydrocarbon combined solvent

ActiveCN109706008AStrong cleaning, dissolving and degreasing abilityHigh solvencyOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsChemistryEther

The invention discloses a halogenated hydrocarbon combined solvent containing octafluoropentyl olefin ether. The halogenated hydrocarbon combined solvent is characterized by being prepared from trans-1,2-dichloroethylene, octafluoropentyl olefin ether, 1,1,2,3,3,3-hexafluoropropyl 2,2,2-trifluoroethyl ether and a stabilizer according to the weight ratio of (0.1-98):(0.1-30):(0.1-98):(0.1-3). The combined solvent is mixed with an alcohol according to a volume ratio of 1:(0.001-0.05) to be used as a cleaning agent of electronic components and scaling powder, or is mixed with a propellant according to a volume ratio of 1:(0.1-0.3) in a spraying tank to be used as a cleaning agent for precise machining parts. Compared with the prior art, the combined solvent has relatively high cleaning and dissolving capacity and degreasing and decontaminating capability, and especially meets the surface decontamination and cleaning requirements of electronic components and machine processing parts. The raw materials are non-toxic, harmless and non-corrosive, the preparation process is simple, the environment is not polluted, production cost is low, and therefore the combined solvent is a high-efficiency cleaning agent with a high industrial application value.

Owner:SHANGHAI RICHEM ENVIROTEC CO LTD

HFC-227ea-containing mixed refrigerant for organic Rankine cycle system

InactiveCN104031611AExcellent flame retardancyImprove securityHeat-exchange elementsOrganic Rankine cycleRefrigerant

A HFC-227ea-containing mixed refrigerant for an organic Rankine cycle system comprises six compositions, and the six compositions are HFC-227ea, R290, HFC-236ea, HFC-245ca, R601 and R601a, and the mixed refrigerant specifically comprises the following combinations according to corresponding mass ratio: R227ea / R245ca (5-95 / 95-5%); R227ea / R236ea / R245ca (5-95 / 2-80 / 3-93%); and R227ea / R245ca / R601 (5-90 / 5-90 / 5-80%). The mixed refrigerant is capable of improving the safety of a mixture added with the mixed refrigerant, and is appropriate in thermal engineering parameters and excellent in cycle performance.

Owner:TIANJIN UNIV

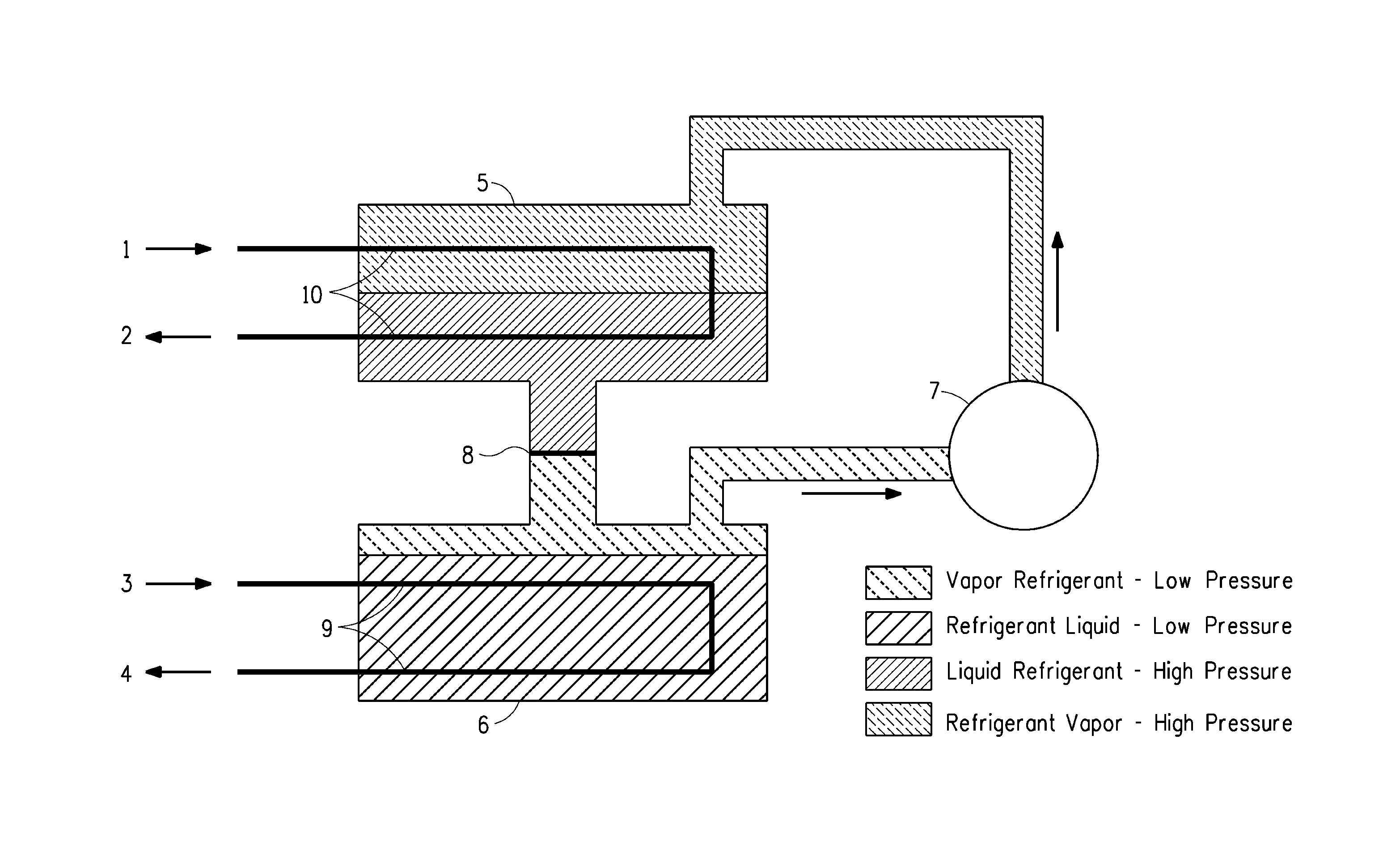

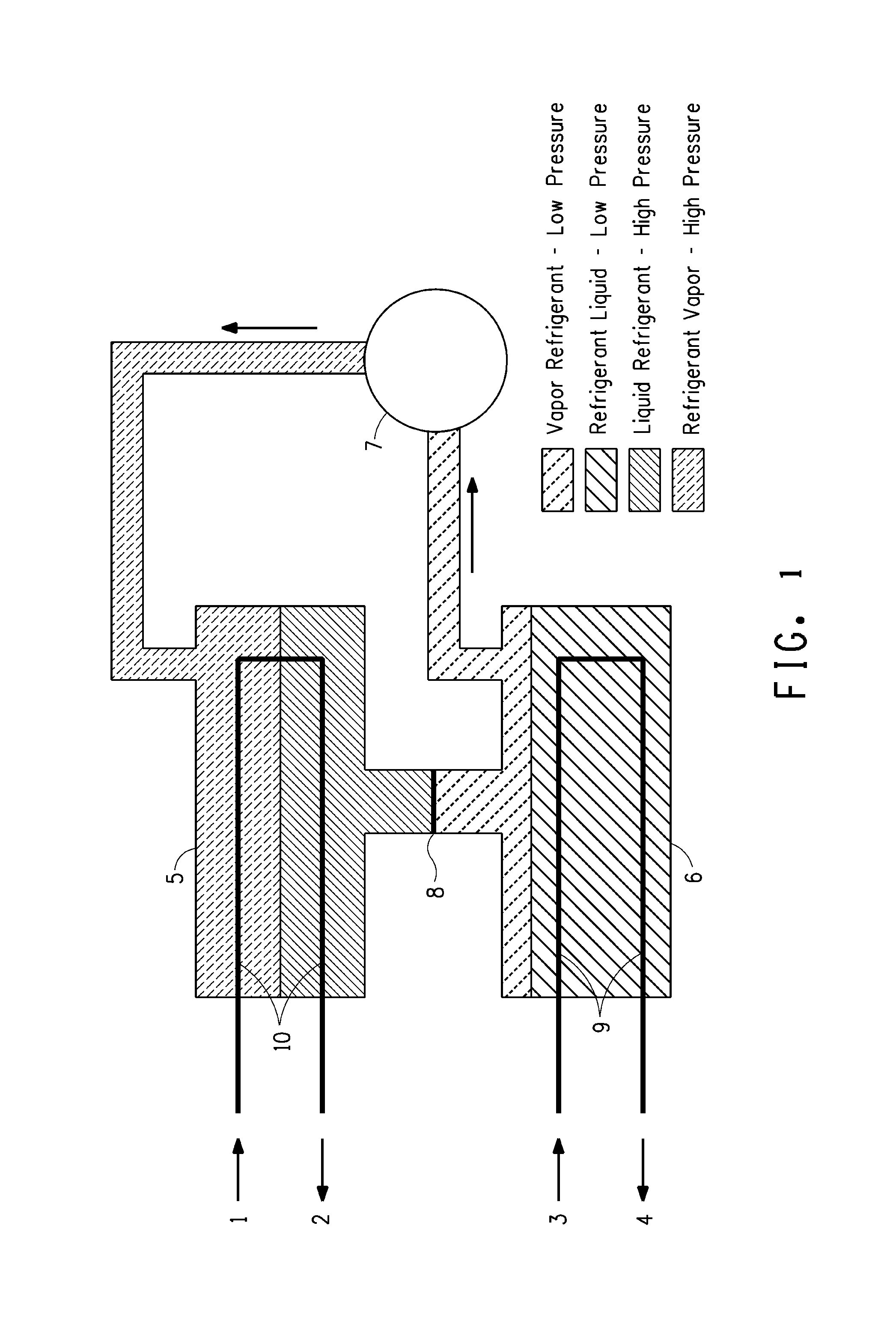

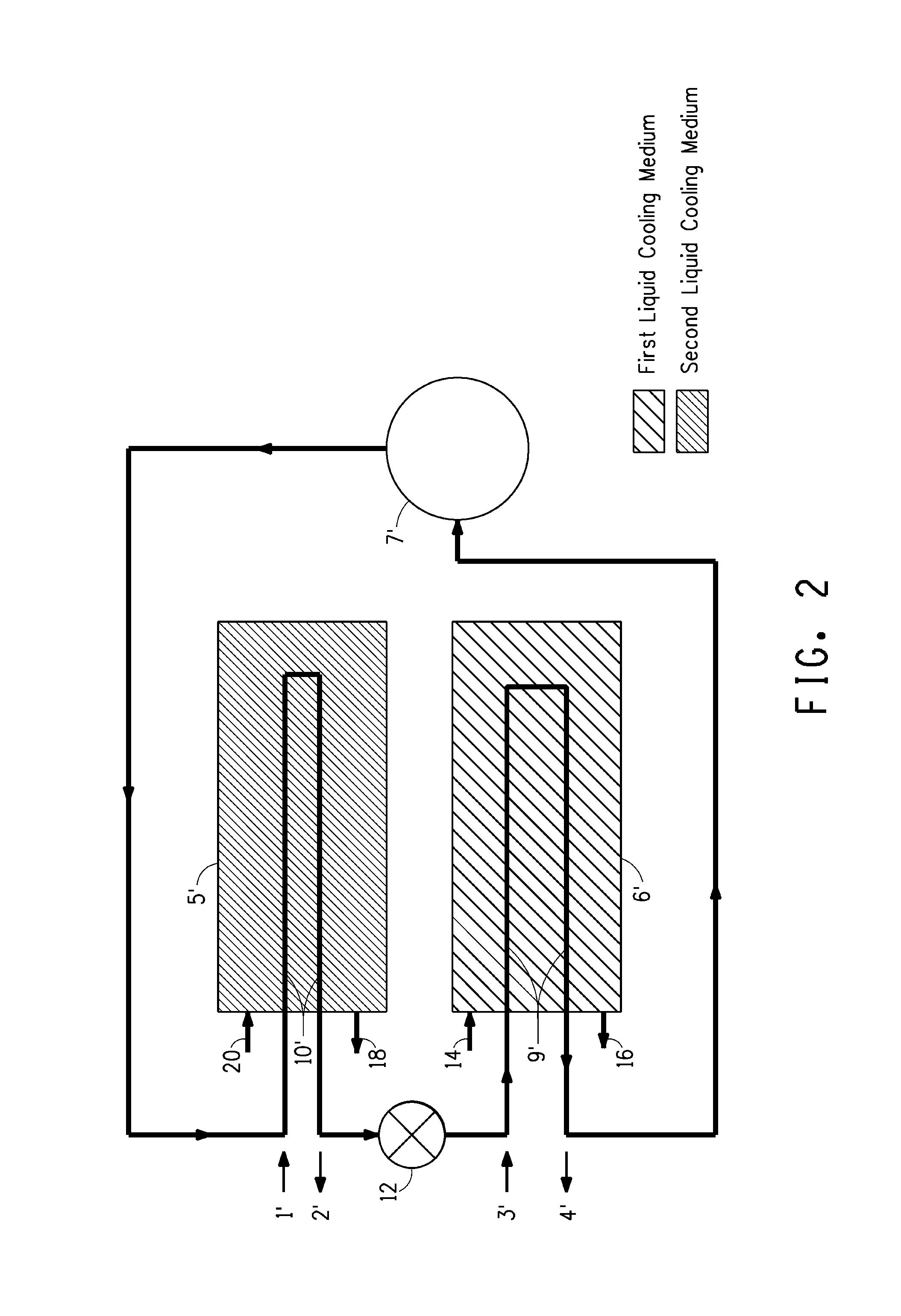

Composition comprising cis-1,1,1,4,4,4-hexafluoro-2-butene and trans-1,2-dichloroethylene, apparatus containing same and methods of producing cooling therein

ActiveUS9150770B2Increase capacityImprove efficiencyDomestic cooling apparatusCompression machines with non-reversible cycleButene2-Butene

Owner:THE CHEMOURS CO FC LLC

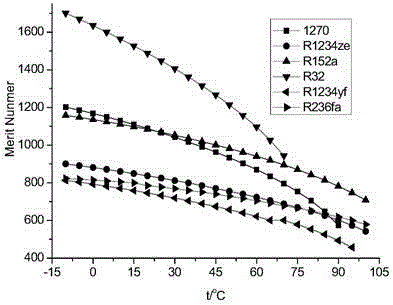

Gravity assisted heat pipe mixing working medium

ActiveCN106032462AMeet environmental protection requirementsLow ODPHeat-exchange elementsWorking temperatureGravity assist

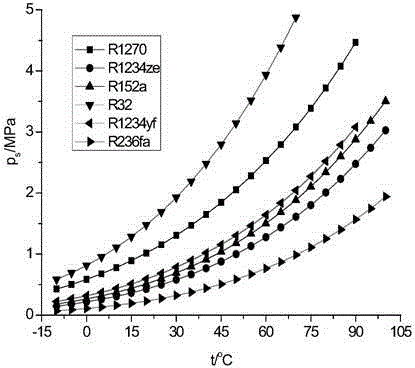

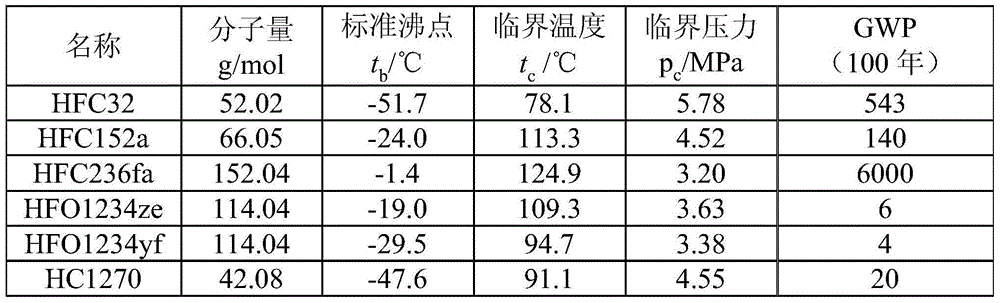

The invention provides a gravity assisted heat pipe mixing working medium. The mixing working medium contains HC1270 and HFC236fa, as well as HFC32, HFC152a, HFO1234ze or HFO1234yf. The working medium has good thermal stability, safety and no toxicity, and meets the requirement of environmental protection, wherein ODP is 0, and GWP is low. The mixing working medium has moderate saturated vapor pressure, proper heat transfer performance, high M' criteria number for reflecting thermal physics and heat transfer comprehensive performance at the working temperature of 0 DEG C to 100 DEG C, and has good heat transfer properties and transport properties.

Owner:CHINA PETROCHEMICAL CORP +1

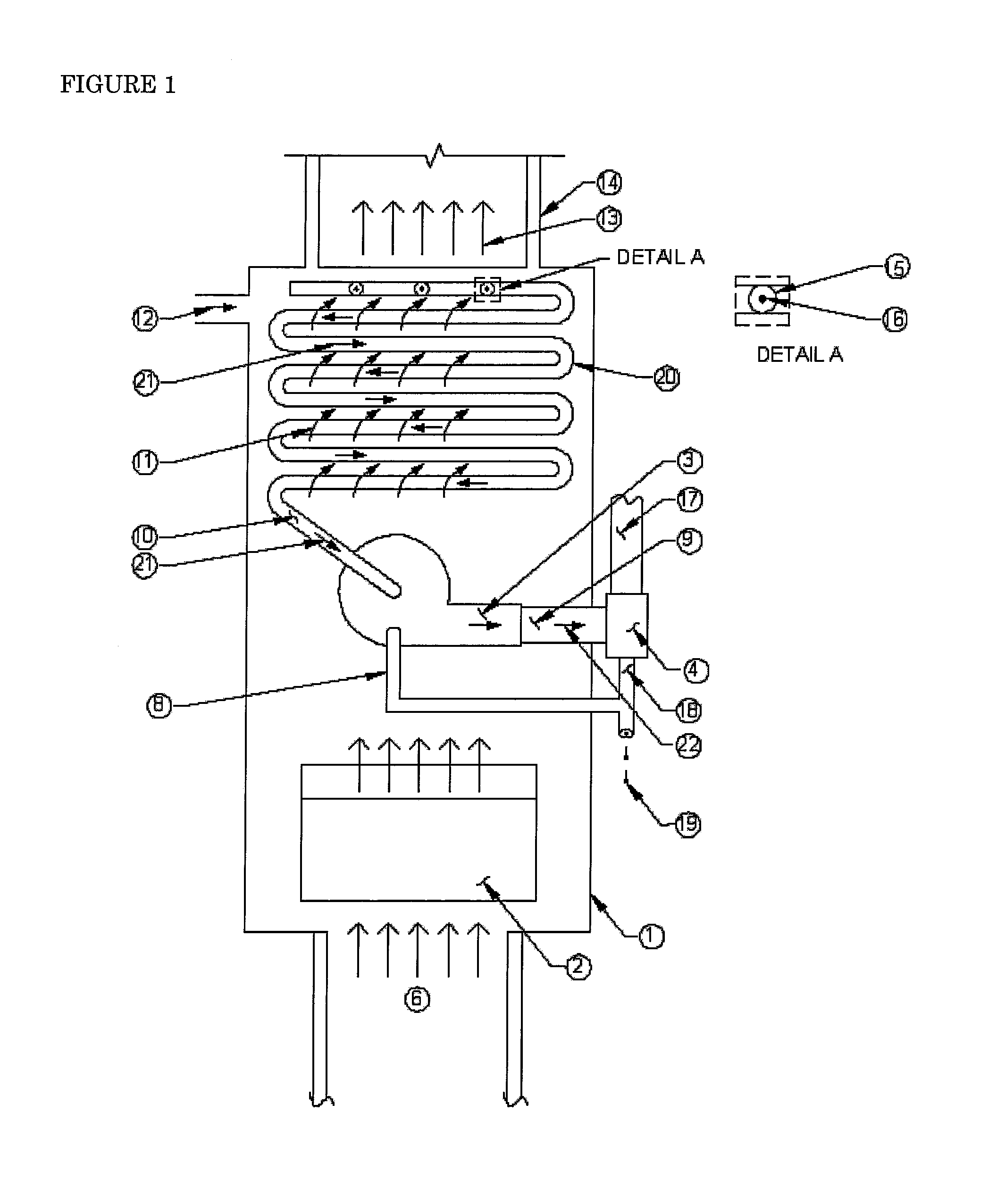

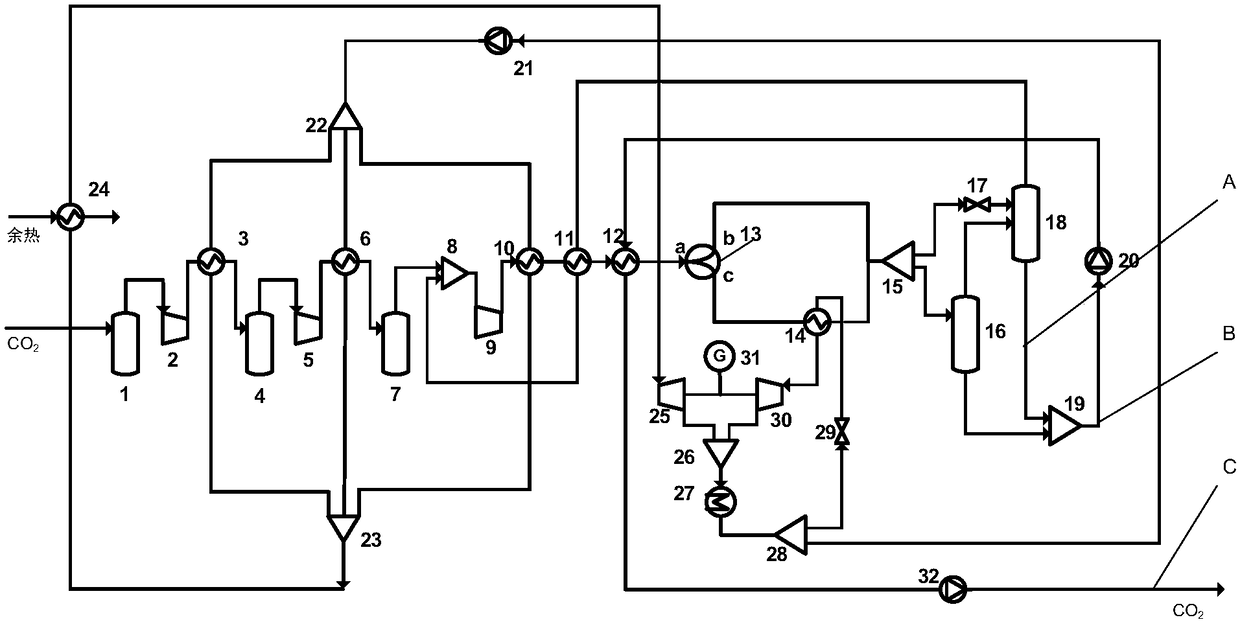

CO2 compressive liquidation adjustable compound system based on recovery of internal energy of power plant

The invention discloses a CO2 compressive liquidation adjustable compound system based on recovery of internal energy of a power plant, and belongs to the technical field of energy and environments. The system comprises a three-way valve, liquid separating tanks, diverters, an expander, heat exchangers, compressor interstage heat exchangers, multiple stages of CO2 compressors, compressors, a condenser, mixers, a cold side evaporator, throttle valves, a generator set and CO2 booster pumps. The system comprises an adjustable CO2 compressive liquidation unit and an internal energy integrated system. Waste heat in multiple varieties and at multiple temperature levels is integrally used section by section at multiple stages, the CO2 flow is dynamically adjusted, a good effect is achieved for extracting at different temperature levels and coping with the generating capacity fluctuation, the system is highly integrated, nonreversible losses generated in the heat exchange process are reduced,the energy consumption of the system is obviously reduced, the energy utilization rate is remarkably increased, and the system can be widely applied to the field of carbon trapping and compressing.

Owner:DALIAN UNIV OF TECH

High-temperature heat pump mixed working medium

InactiveCN101735773AReduce exhaust temperaturePromote circulationHeat-exchange elementsCondensation temperatureEngineering

The invention relates to a high-temperature heat pump mixed working medium. In a first scheme, the mixed working medium comprises the composition in the percentage by weight: 50-90% of HCFC-124 (chloride-1,2,2,2-tetrafluoroethane) and 10-50% of HCFC-142b (chloride-1,1-difluoroethane). The high-temperature heat pump mixed working medium of the invention is friendly to environment, has favourable thermal performance, can satisfy the using requirements of medium-high temperature heat pump systems of which the condensing temperature is 70-105 DEG C.

Owner:周小平 +1

Preparation method of 2, 3, 3, 3-tetrafloropropylene

ActiveCN103833511AReduce the probability of side effectsAvoid the production of highly toxic substance perfluoroisobutyleneHalogenated hydrocarbon preparationChemistryPyrolysis

The invention provides a preparation method of 2, 3, 3, 3-tetrafloropropylene. The method comprises the following steps: with monochlorodifluoromethane and monochloro methane which are in a molar ratio of (0.5-4):1 as reaction raw materials, preheating the reaction raw materials, then mixing with superheated steam, wherein the volume ratio of the superheated steam to the reaction raw materials is (1-20):1, the temperature of the superheated steam is 900-1100 DEG C, the temperature in the reaction section is 600-1100 DEG C, and the stay time of reactants in the reaction section is 0.01-1s; and quenching, deacidifying, drying and rectifying and separating the product mixed flow to obtain 2, 3, 3, 3-tetrafloropropylene. The method provided by the invention overcomes the deficiency that a hollow tube is prone to carbonization in pyrolysis and side reactions are complex, the equipment maintenance rate is reduced, and meanwhile, the reaction period is prolonged, and the utilization ratio of the device is improved. The method provided by the invention has the characteristics of use of easily available raw materials, simple reaction process and the like. The obtained 2, 3, 3, 3-tetrafloropropylene has the advantages of zero ODP (Ozone Depletion Potential) and low GWP (Global Warming Potential), and is used as a substituent of automotive air conditionor refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

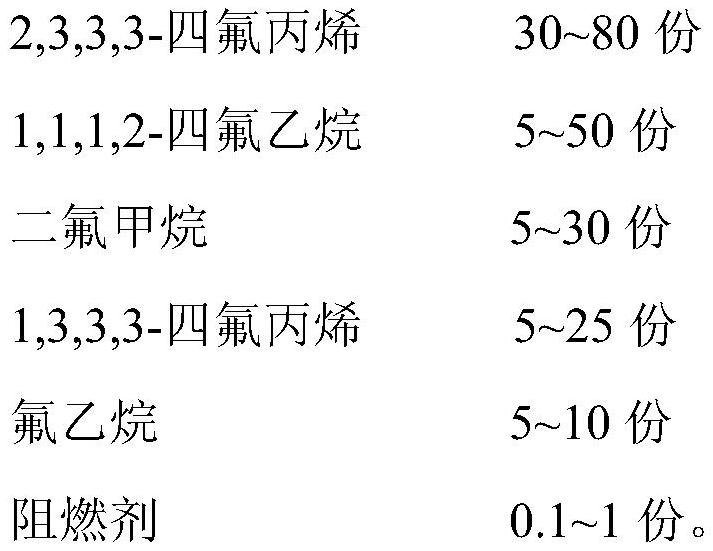

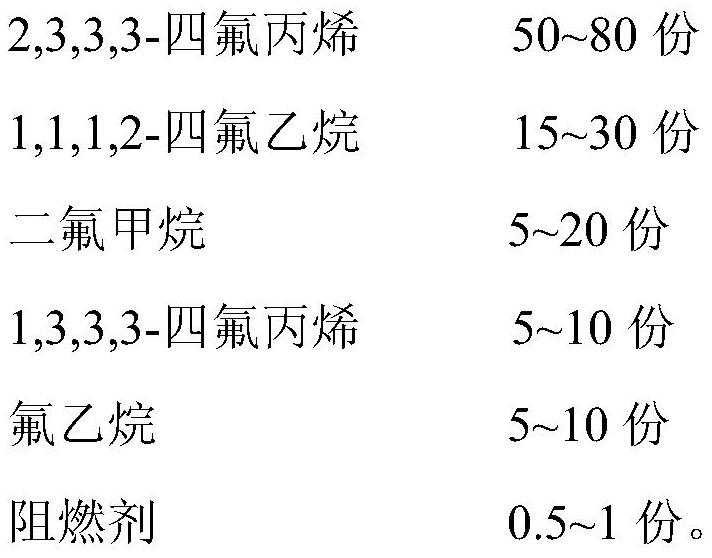

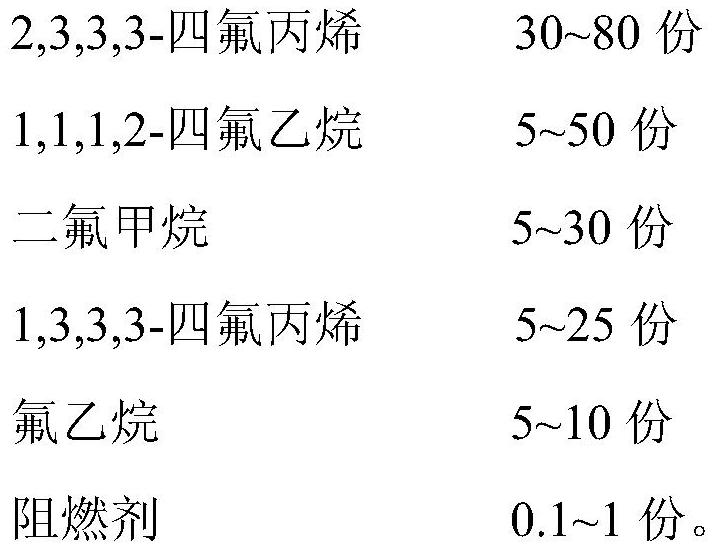

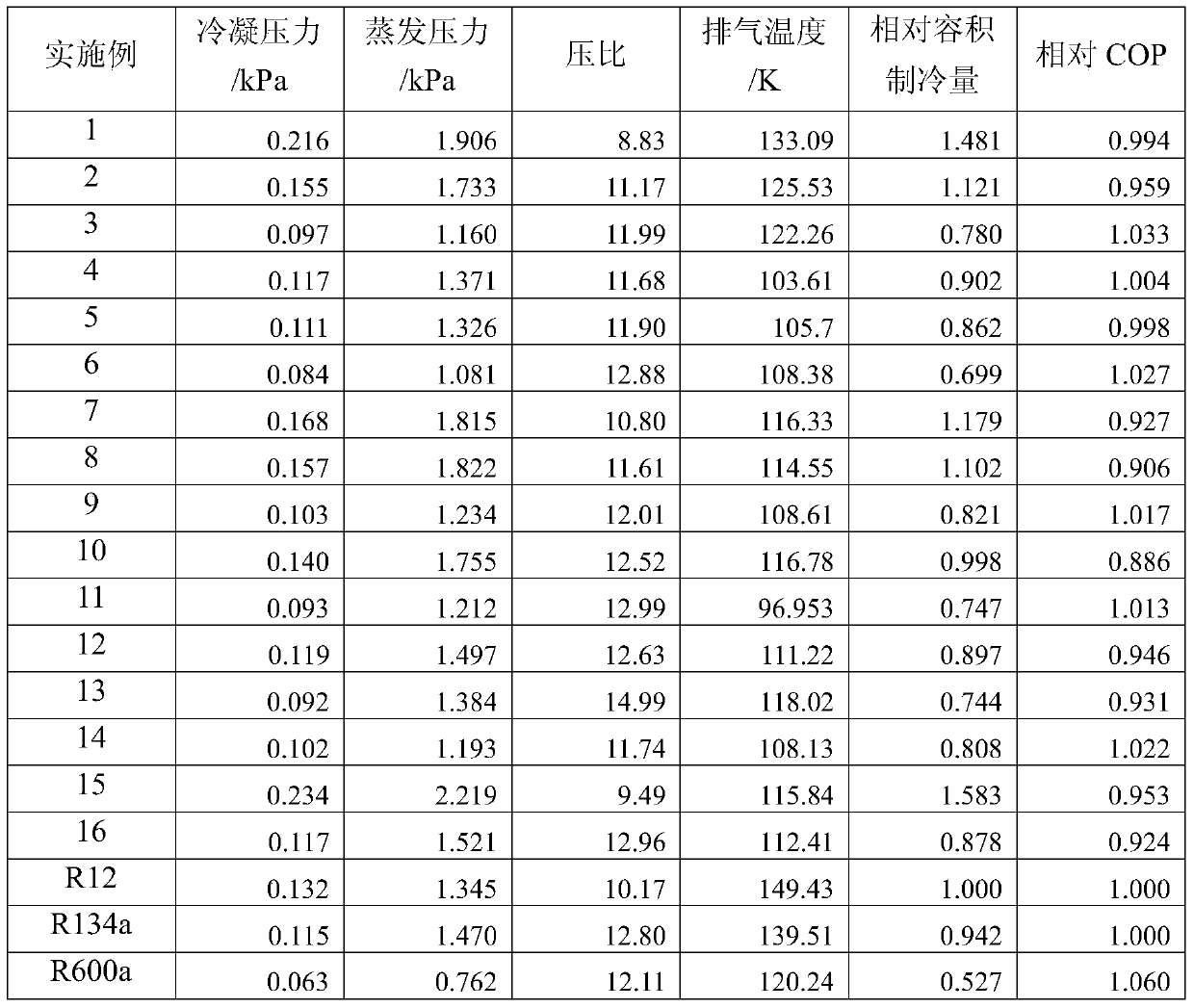

Fluorohydrocarbon-containing composition and preparation method thereof

The invention discloses a fluorohydrocarbon-containing composition which comprises the following components in parts by weight: 30-80 parts of 2,3,3,3-tetrafluoropropene, 5-50 parts of 1,1,1,2-tetrafluoroethane, 5-30 parts of difluoromethane, 5-25 parts of 1,3,3,3-tetrafluoropropene, 5-10 parts of fluoroethane and 0.1-1 part of a flame retardant. The compositions are useful as refrigerants, propellants and blowing agents for heating and cooling. The invention also discloses a preparation method of the fluorohydrocarbon-containing composition. The composition has the advantages of being low inGWP, environmentally friendly, good in refrigeration effect and good in lubricant compatibility.

Owner:ZHEJIANG QUHUA FLUOR CHEM

A kind of mixed refrigerant containing tetrafluoropropene

ActiveCN104531079BGood miscibilityReduce flammabilityChemical industryHeat-exchange elementsTrifluoroiodomethaneButane

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Trifluoroiodomethane-containing mixed refrigerant

InactiveCN101824305BReduce flammabilityWon't breakHeat-exchange elementsTrifluoroiodomethaneComponents of crude oil

The invention relates to a trifluoroiodomethane-containing mixed refrigerant. The trifluoroiodomethane-containing mixed refrigerant is prepared by mixing component 1, a component 2 and a component 3, wherein the component 1 is trifluoroiodomethane with the combustion and explosion inhibiting effect; the component 2 comprises 1,1,1,2-tetrafluoroethane, 1,1,2,2-tetrafluoroethane or mixture of the 1,1,1,2-tetrafluoroethane and 1,1,2,2-tetrafluoroethane; the component 3 comprises propane, propylene or mixture of the propane and propylene; in the mixed refrigerant, the content of the component 1 is between 1 and 10 weight percent; the content of the component 2 is between 20 and 40 weight percent; the content of the component 3 is between 50 and 75 weight percent; the ODP value of the mixed refrigerant is zero; the GWP value is far less than that of a routine HFCs work substance; and the trifluoroiodomethane-containing mixed refrigerant has good lube intersolubility, can directly substitute an R22 working substance without making large alteration on a refrigeration system; and as the mixed refrigerant has the combustion inhibiting component, the combustibility of the refrigerant is greatly reduced or even the refrigerant is completely incombustible so that the safety of the refrigeration system is greatly improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com