Combined polyether, raw material composition and polyurethane foam as well as preparation method and application of combined polyether, raw material composition and polyurethane foam

A raw material composition and technology of combining polyether, applied in the field of polyurethane, can solve problems such as high requirements for use conditions, poor operability, and environmental pollution, and achieve the effects of easy acquisition, low GWP value, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of pentane-type combined polyether for pipelines

[0043] 5 parts of polyether polyol SU450L, 2 parts of polyether polyol SA380, 3 parts of polyether polyol NL20103, 0.2 part of silicone foam stabilizer B8525, 0.10 part of N,N-dimethylcyclohexylamine, N,N- 0.10 part of dimethylbenzylamine, 0.05 part of 1,2,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, 0.9 part of cyclopentane and 0.18 part of deionized water.

[0044] According to the above formula, add each component into the stainless steel mixing kettle, stir at room temperature for 1 hour at a speed of 500 rpm, and then discharge the material.

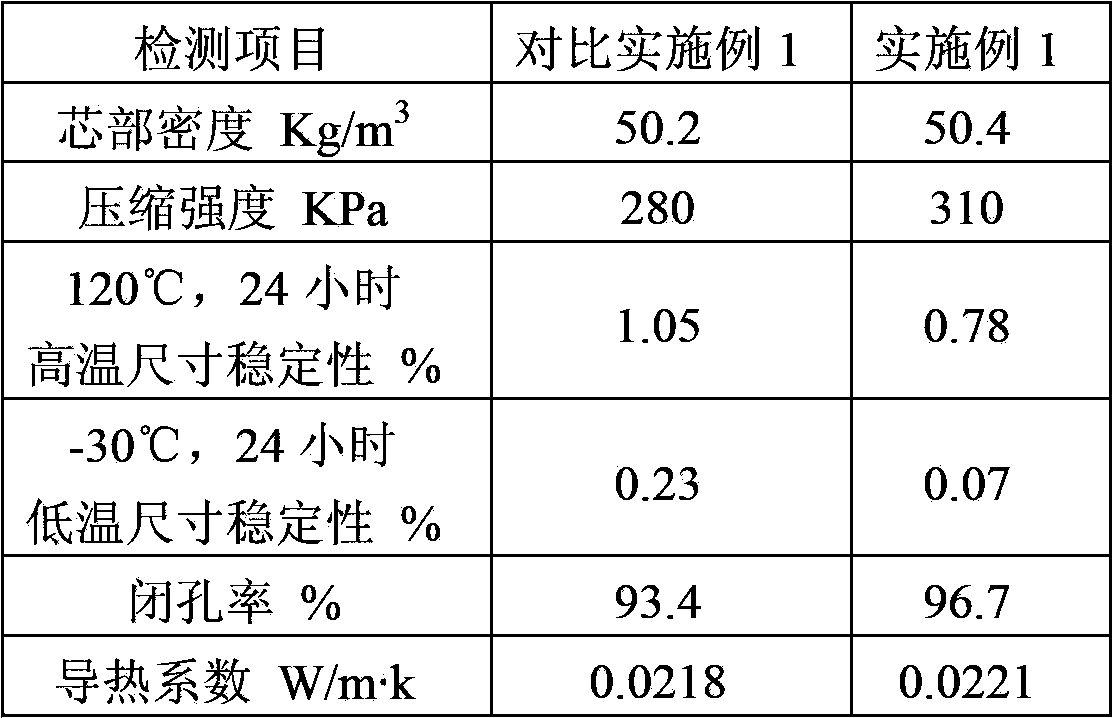

[0045] (2) Preparation of rigid polyurethane foam insulation material

[0046]The combined polyether and isocyanate of Example 1 were mixed in a mass ratio of 1:1.5 using a high-pressure foaming machine at a material temperature of 20°C, and injected into the pipe interlayer to obtain a core density of about 50Kg / m 3 The rigid polyurethane foam insulatio...

Embodiment 2

[0056] (1) Pentane type combined polyether for pipeline

[0057] 3 parts of polyether polyol SU450L, 3804 parts of polyether polyol SA, 3 parts of polyether polyol NL20103, 0.2 part of silicone foam stabilizer B8525, 0.10 part of N,N-dimethylcyclohexylamine, N,N-di 0.10 part of methylbenzylamine, 0.05 part of 1,2,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, 0.7 part of cyclopentane and 0.20 part of deionized water.

[0058] According to the above formula, add each component into the stainless steel mixing kettle, stir at room temperature for 1 hour at a speed of 500 rpm, and then discharge the material.

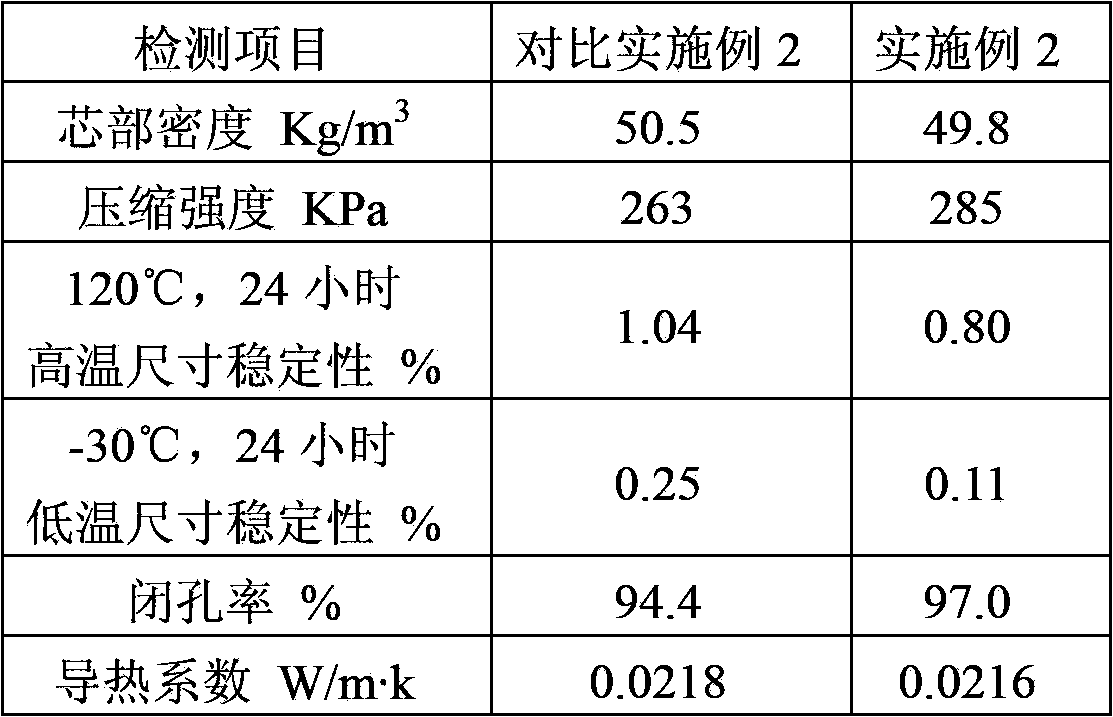

[0059] (2) Preparation of rigid polyurethane foam insulation material

[0060] The combined polyether and isocyanate of Example 2 were mixed in a mass ratio of 1:1.5 using a high-pressure foaming machine at a material temperature of 20°C, and injected into the pipe interlayer to obtain a core density of about 50Kg / m 3 Rigid polyurethane foam insulation material for pipe...

Embodiment 3

[0070] (1) Pentane type combined polyether for pipeline

[0071] 3 parts of polyether polyol SU450L, 2 parts of polyether polyol SA380, 5 parts of polyether polyol NL20105, 0.2 part of silicone foam stabilizer B8525, 0.06 part of N,N-dimethylcyclohexylamine, N,N- 0.10 part of dimethylbenzylamine, 0.05 part of 1,2,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, 0.8 part of cyclopentane and 0.19 part of deionized water.

[0072] According to the above formula, add each component into the stainless steel mixing kettle, stir at room temperature for 1 hour at a speed of 500 rpm, and then discharge the material.

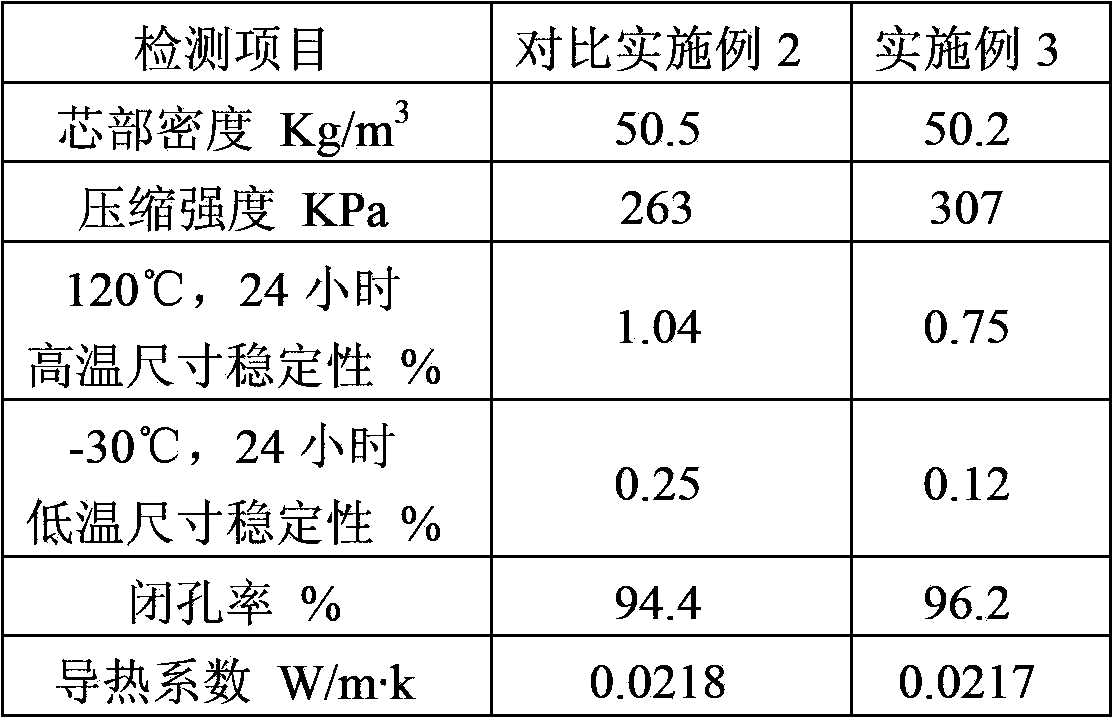

[0073] (2) Preparation of rigid polyurethane foam insulation material

[0074] The combined polyether and isocyanate of Example 3 were mixed in a mass ratio of 1:1.5 using a high-pressure foaming machine at a material temperature of 20°C, and injected into the pipe interlayer to obtain a core density of about 50Kg / m 3 The rigid polyurethane foam insulation material for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com