Composite polyether, polyurethane foam and raw material composition and preparation method of polyurethane foam

A technology of polyurethane foam and raw material composition, which is applied in the field of combined polyether, polyurethane foam and its raw material composition and preparation, which can solve the problems of poor dimensional stability at low temperature, large amount of refrigerator filling, low compressive strength, etc., and achieve excellent size Stability and compressive strength, reduced production cost, effect of reduced molded density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

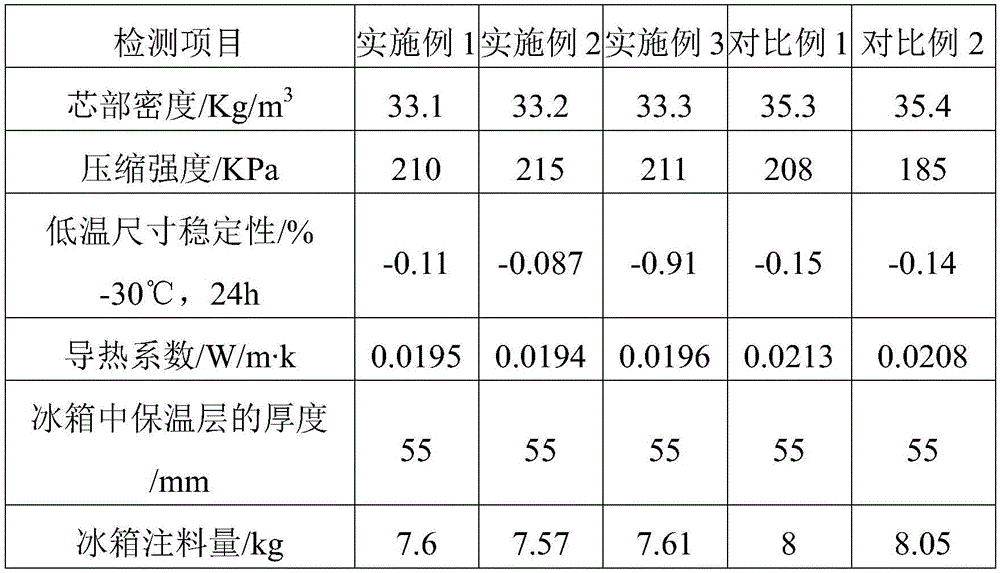

Examples

Embodiment 1-3

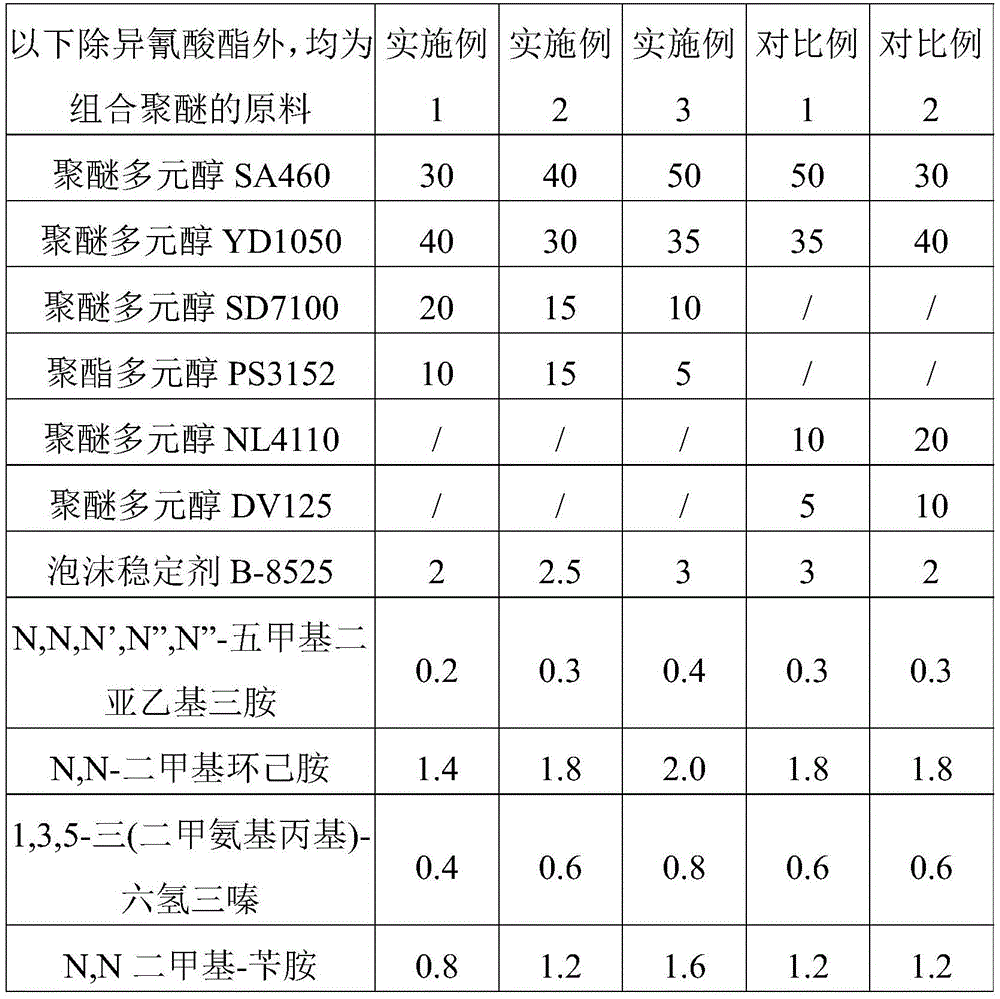

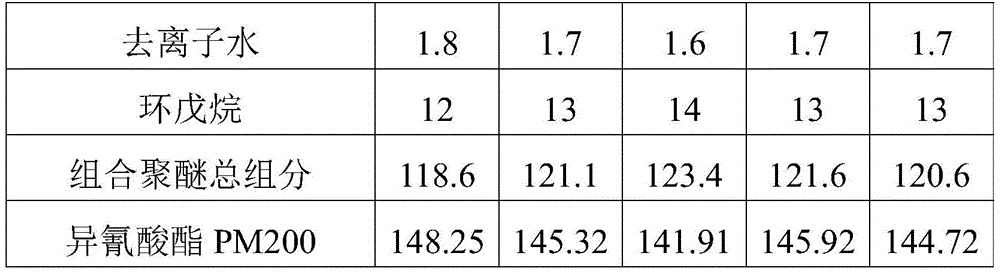

[0063] Table 1 shows the specific weight parts of the raw material composition of the polyether and the isocyanate component in Examples 1-3 and Comparative Examples 1-2. In Table 1, " / " means no addition.

[0064] Table 1

[0065]

[0066]

[0067] (1) Preparation of combined polyether

[0068] The other components except the isocyanate were uniformly mixed in the stainless steel mixing kettle for 45 minutes, and then stirred uniformly.

[0069] (2) Preparation of polyurethane foam

[0070] The combined polyether and isocyanate are reacted at 22° C. in proportion, and injected into a mold to prepare a rigid polyurethane foam insulation material for refrigerators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com