Gravity assisted heat pipe mixing working medium

A technology of mixed working fluid and gravity heat pipe, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of heat pipe cost increase, aggravate the greenhouse effect, and difficulty in large-scale promotion and application, and achieve good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

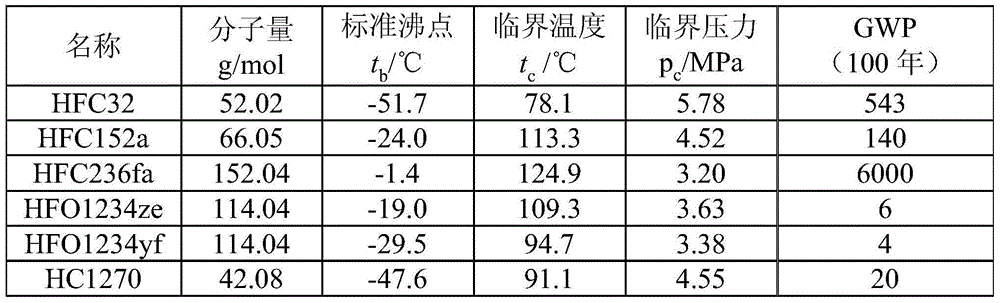

[0041] Take 25% HFC32, 16% HC1270, 69% HFC236fa, after physical mixing at normal temperature, it will be used as the working medium of the gravity heat pipe.

Embodiment 2

[0043] Take 70% HFC152a, 25% HC1270, 5% HFC236fa, after physical mixing at room temperature, it will be used as the working fluid of gravity heat pipe.

Embodiment 3

[0045] Take 10% HFO1234ze, 30% HFC32, 5% HC1270, 55% HFC236fa, and mix them physically at room temperature as the working fluid of the gravity heat pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com