HFC-227ea-containing mixed refrigerant for organic Rankine cycle system

A technology of hfc-227ea and mixed working fluid, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of flammability, explosion, and high risk, and achieve enhanced safety, excellent flame retardancy, and cycle good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

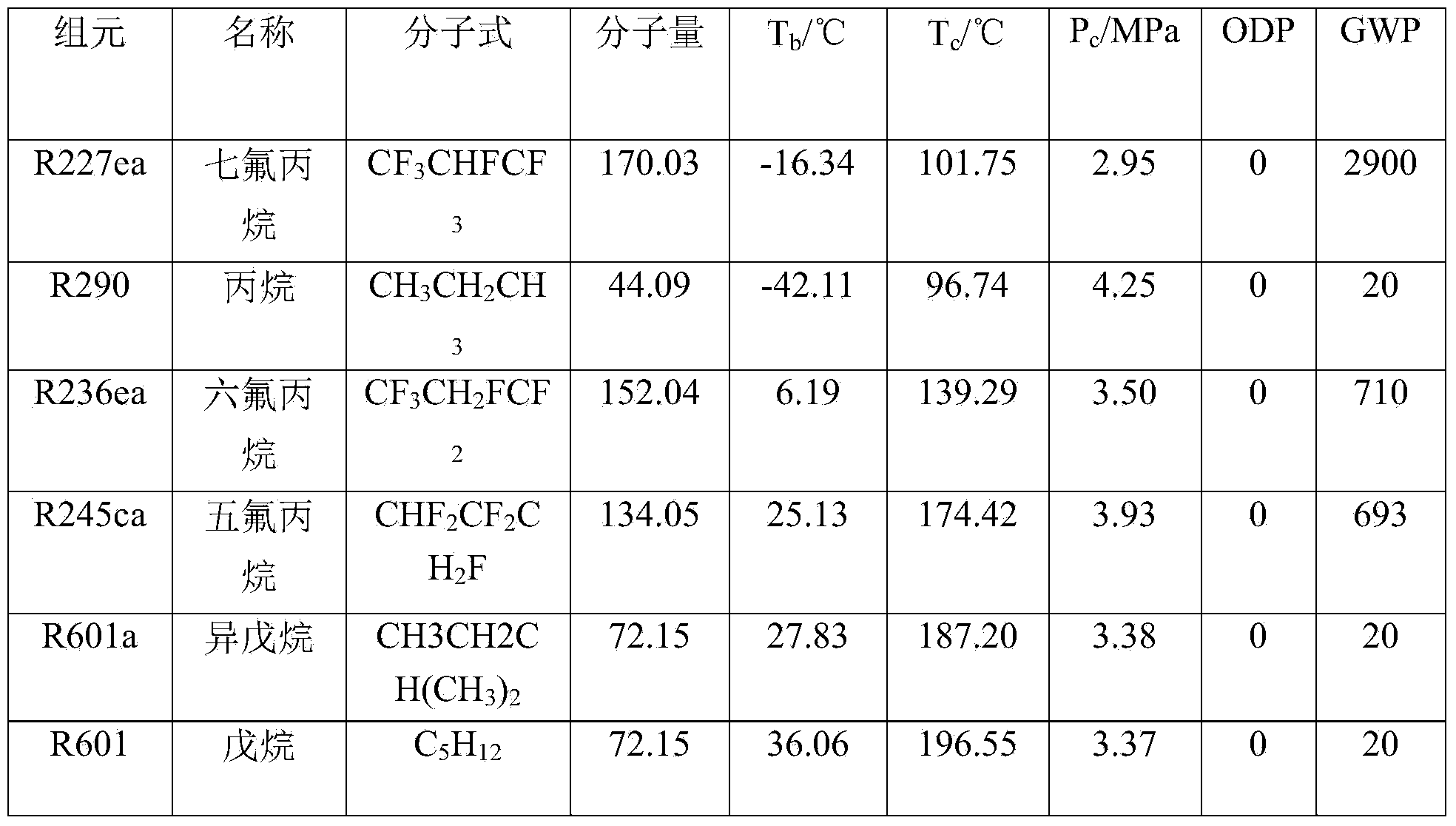

Method used

Image

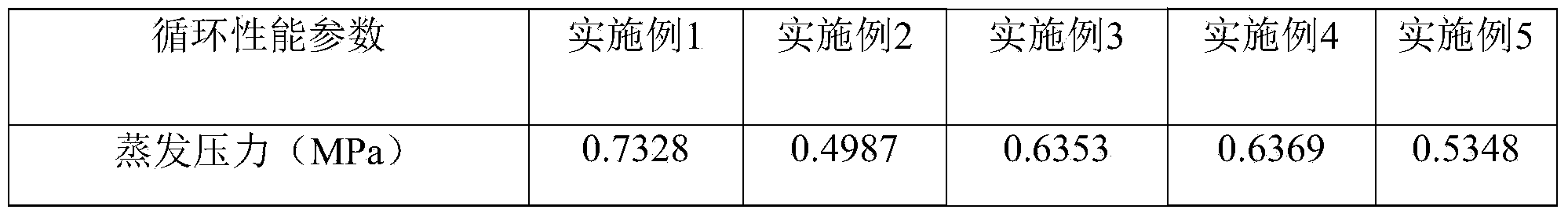

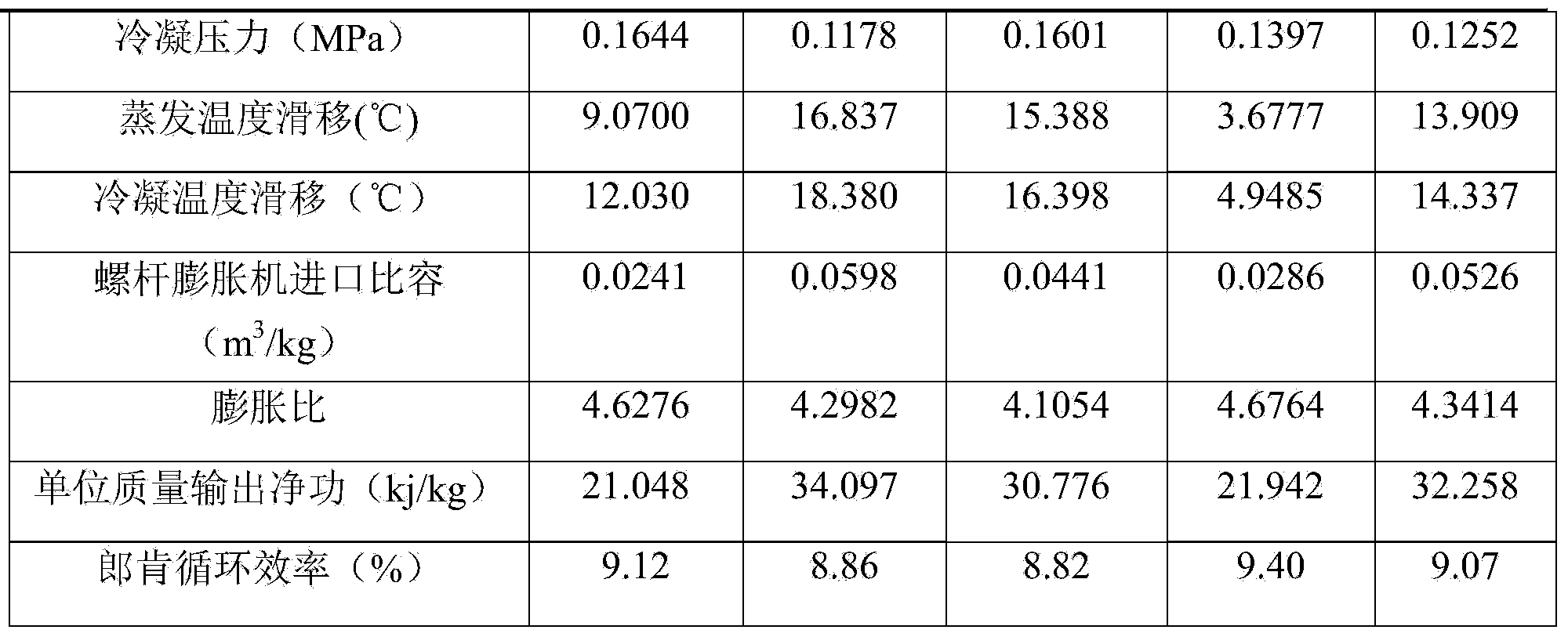

Examples

preparation example Construction

[0030] The preparation method of the mixed working medium of the present invention is to physically mix the above-mentioned component substances according to different mass ratios at normal temperature.

[0031] The following are specific examples:

Embodiment 1

[0033] Take 20% R227ea and 80% R245ca and mix them physically at room temperature as the circulating working fluid.

Embodiment 2

[0035] Take 30% R227ea and 70% R601 and mix them physically at room temperature as a circulating working fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com