Halogenated hydrocarbon combined solvent containing octafluoropentyl olefin ether and application of halogenated hydrocarbon combined solvent

A technology of octafluoropentyl olefin ether and halogenated hydrocarbon, which is applied in the field of halogenated hydrocarbon combination solvent, can solve the problems of inability to meet environmental protection requirements, high toxicity and GWP value, poor safety, etc., and achieves strong cleaning, dissolution, degreasing and decontamination. Ability, low production cost, high solvency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

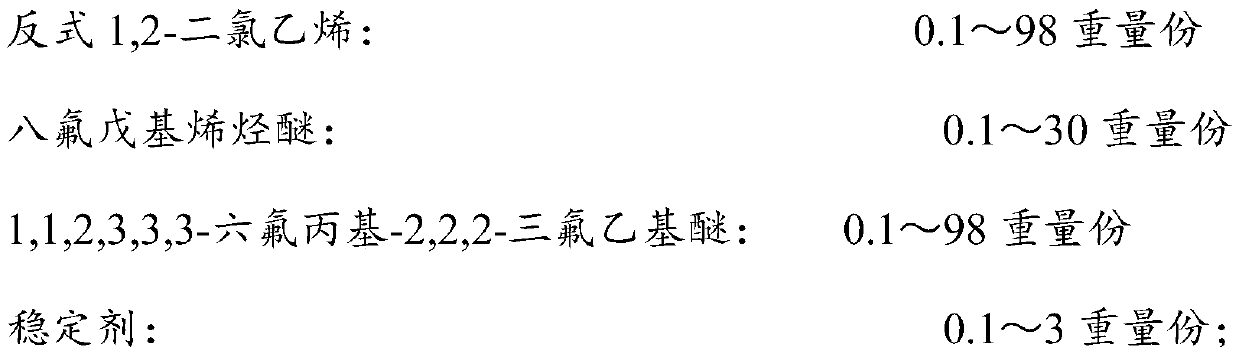

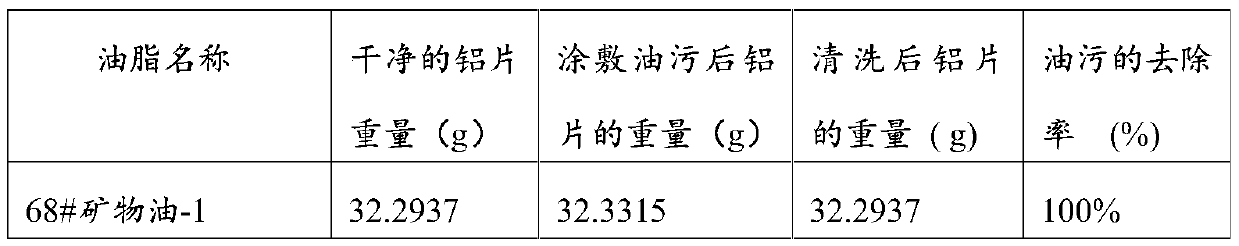

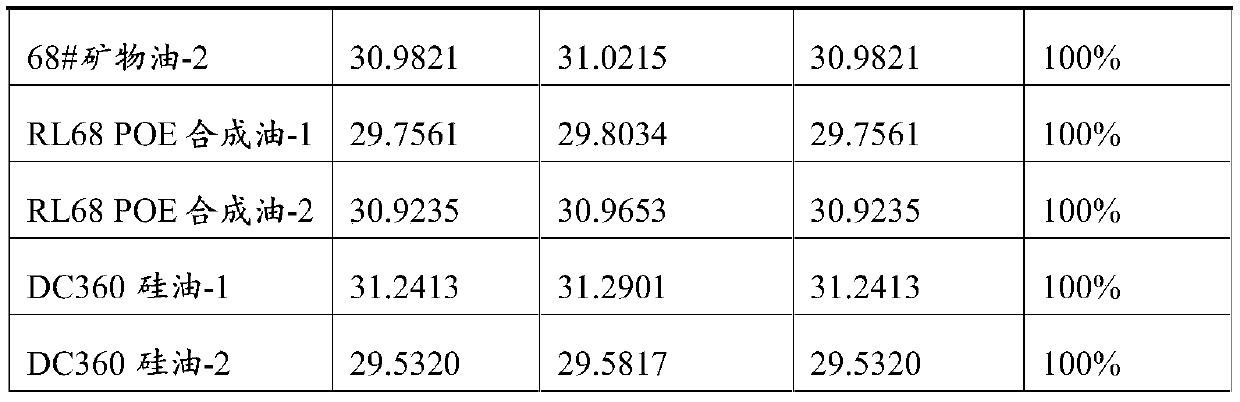

[0014] Weigh 80 grams of trans-1,2-dichloroethylene, 10 grams of octafluoropentyl olefin ether, 15 grams of 1,1,2,3,3,3-hexafluoropropyl-2,2,2-trifluoro Ethyl ether and 1 gram of fluoroalcohol, formulated as a halogenated hydrocarbon combination solvent used as an oil stain cleaning agent. The halogenated hydrocarbon combination solvent of above-mentioned preparation is carried out the experiment of parallel test to conventional mineral oil, POE synthetic oil and silicone oil according to the following steps:

[0015] a. Apply 68# mineral lubricating oil, RL68POE synthetic oil and DC360 silicone oil on the clean aluminum sheet, weigh it again, and record the weight of the clean aluminum sheet and the grease-coated aluminum sheet;

[0016] b. Submerge the aluminum sheet into a beaker filled with the above-mentioned halocarbon combination solvent prepared above, and soak for 3 minutes;

[0017] c. Place the aluminum sheet on top of the halogenated hydrocarbon combination solven...

Embodiment 2

[0025] Weigh 80 grams of trans-1,2-dichloroethylene, 10 grams of octafluoropentyl olefin ether, 20 grams of 1,1,2,3,3,3-hexafluoropropyl-2,2,2-trifluoro Ethyl ether, 1 g of fluoroalcohol, and 5 g of methanol were formulated as a halogenated hydrocarbon combination solvent for use as a flux remover. Use the halogenated hydrocarbon combination solvent prepared above to perform the rosin flux removal experiment on the PCBA connectors after reflow soldering according to the following steps, so as to meet the quality control requirements:

[0026] a. After reflow soldering, the PCBA is soaked in boiling solvent for 5 minutes, and then immersed in the second tank whose temperature is lower than the boiling point for a second cleaning for 5 minutes. It can be supplemented by ultrasonic, spraying or stirring to enhance the cleaning effect;

[0027] b. Take out the connector from the low-temperature tank, immerse in the steam area for steam bath washing for 2 minutes, and then condense...

Embodiment 3

[0030] The halogenated hydrocarbon combination solvent prepared in Example 1 or Example 2 is used to replace the HCFC-141B cleaning agent, and the experiment selects a PCB board with a very narrow pin line and an IC module, and completes it in the existing 141B ultrasonic vapor phase vapor phase equipment The effect test of two cleaning agents. Due to the difference in boiling point, the heating temperature needs to be adjusted to the boiling point of the halogenated hydrocarbon combined solvent prepared in Example 1 or Example 2 during the test. Experimental results show that the cleaning effect of the composition is better than that of 141B, and it can completely replace 141B. The 141B cleaning agent with a larger amount now belongs to hydrochlorofluorocarbons. According to the national plan, all cleaning purposes 141B will be eliminated in 2025, and the halogenated hydrocarbon combination solvent prepared in Example 1 or Example 2 and HCFC-141B cleaning It is suitable for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com