Heat preservation rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and foam, applied in the field of polyurethane, to meet the needs of diversified foaming, high compressive strength, and small cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

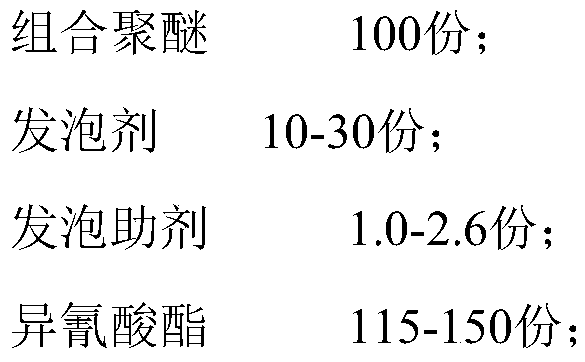

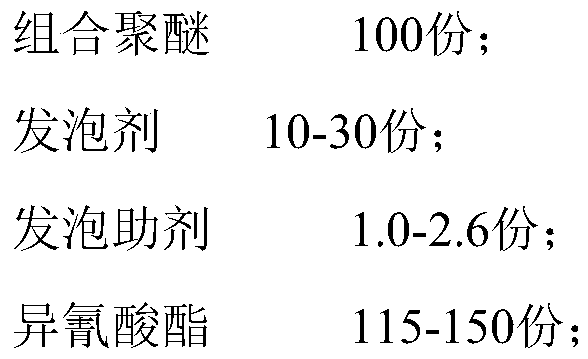

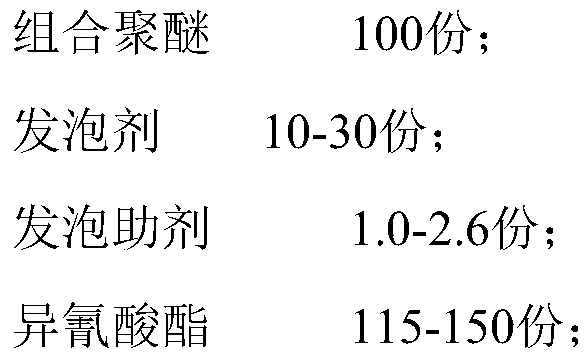

Method used

Image

Examples

Embodiment 1

[0033] Combine 100kg polyether (functional group degree is 4, viscosity at 25°C is 4000mPa·s), 15kg foaming agent cyclopentane CP, 2.6kg foaming aid (which contains 2.34kg perfluoro-E-(4- Methylpent-2-ene) and 0.26kg perfluoro-Z-(4-methylpent-2-ene)) into the static mixer; the above-mentioned materials after static mixing enter the premix tank, N 2 0.5 atmospheric pressure in the atmosphere, emulsified for 30 minutes under 1500 rev / min rotating speed to obtain the emulsified white material; the above emulsified white material and 150kg polymethylene polyphenyl isocyanate (the average functional group degree is 2.7-2.8, the viscosity at 25 ° C 400-420mPa·s) are mixed by a high-pressure foaming machine to obtain a foaming system, which is quickly injected into a foaming mold.

[0034] The milky time of the foam system is 3s, the drawing time is 46s, the non-sticky time is 180s, and the free foaming density is 23kg / m 3 , the liquidity index is 2.9497.

[0035] The mold temperat...

Embodiment 2

[0037] Combine 100kg polyether (functional group degree is 8, viscosity at 25°C is 6000mPa·s), 30kg foaming agent HFC-245fa, 2.6kg foaming aid (which contains 1.6kg perfluoro-E-(4-methyl pent-2-ene) and 1kg1,1,1,2,3,4,4,5,5,5-decafluoro-3-methoxy-2-trifluoromethylpentane) into static mixing In the device; the above-mentioned materials after static mixing enter the premix tank, N 2 1 atmospheric pressure in the atmosphere, emulsified for 10 minutes at a speed of 4000 rpm to obtain an emulsified white material; the above-mentioned emulsified white material and 140kg polymethylene polyphenyl isocyanate (average functional group degree is 3.0-3.2, viscosity at 25°C 780-800mPa·s) are mixed by a high-pressure foaming machine to obtain a foaming system, which is quickly injected into a foaming mold.

[0038]The milky time of the foaming system is 3s, the drawing time is 40s, the non-sticky time is 100s, and the free foaming density is 28kg / m 3 , the liquidity index was 2.9431.

[...

Embodiment 3

[0041] Combine 100kg polyether (functional group degree is 6, viscosity at 25°C is 5100mPa·s), 30kg foaming agent HCFC-141b and 2.6kg foaming aid (which contains 2.1kg perfluoro-E-(4-methanol) pent-2-ene), 0.3kg perfluoro-Z-(4-methylpent-2-ene) and 0.2kg1,1,1,2,2,3,3,4,4,4-nonafluoro -4-ethoxybutane) into the static mixer; the above-mentioned materials after static mixing enter the premix tank, N 2 At 3 atmospheric pressures in the atmosphere, emulsify for 120 minutes at 1000 rpm to obtain emulsified white material; mix the above emulsified white material with 150kg polymethylene polyphenyl isocyanate (the average functional group degree is 3.0-3.1, the viscosity at 25°C 580-610mPa·s) are mixed by a high-pressure foaming machine to obtain a foaming system, which is quickly injected into a foaming mold.

[0042] The milky time of the foaming system is 10s, the drawing time is 90s, the non-sticky time is 200s, and the free foaming density is 20kg / m 3 , the liquidity index was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com