Organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of internal combustion engine

A technology of mixed working fluid and exhaust waste heat, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low critical temperature, harsh condensation conditions, and limited use conditions, so as to reduce the temperature difference and reduce the temperature of the greenhouse effect, the effect of high cycle heat utilization

Inactive Publication Date: 2015-11-18

TIANJIN UNIV

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, single use of CO 2 As a circulating working fluid, its critical temperature is very low, and the requirements for condensation conditions are very strict, which also limits its use conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

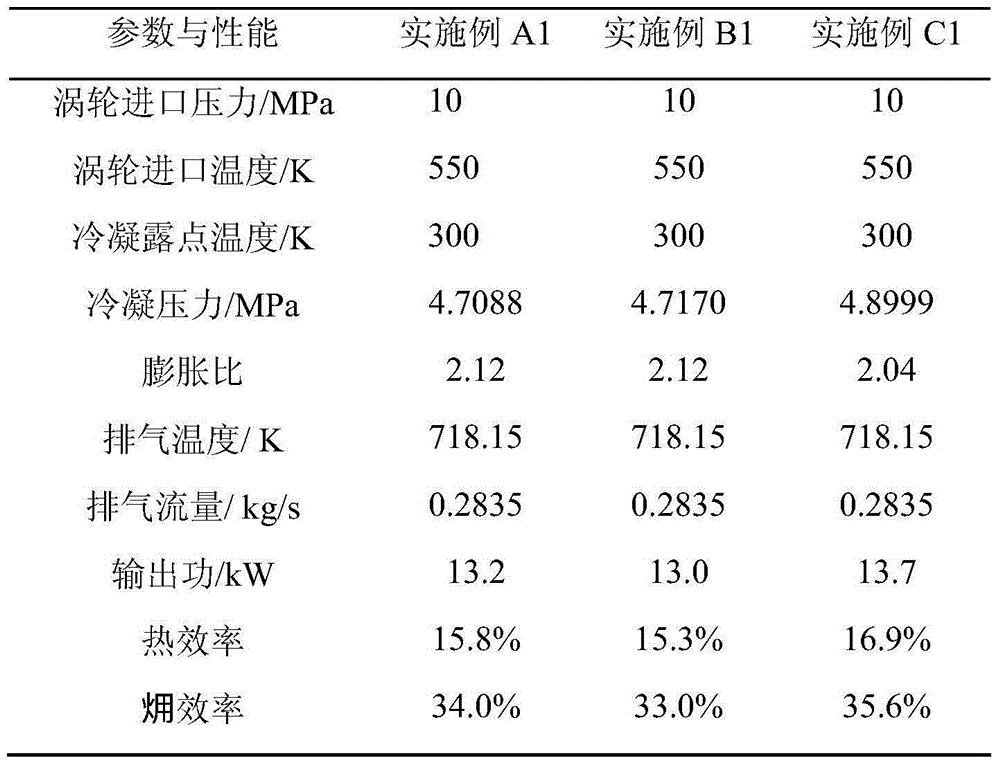

Embodiment A1

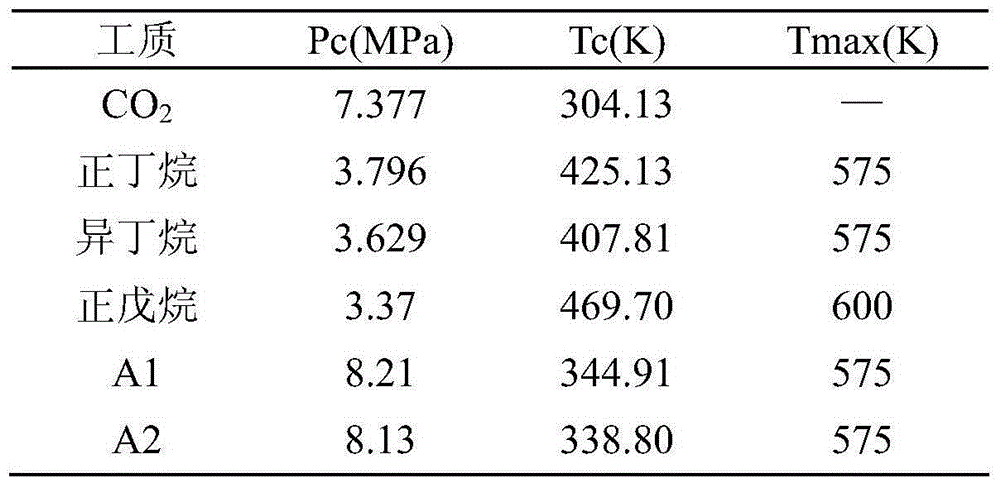

[0014] Embodiment A1: the n-butane / CO 2 According to 32:68, the system is filled after physical mixing at room temperature.

Embodiment A2

[0015] Example A2: the n-butane / CO 2 According to 28:72, the system is filled after physical mixing at room temperature.

Embodiment A3

[0016] Embodiment A3: the n-butane / CO 2 According to 24:76, the system is filled after physical mixing at room temperature.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Login to View More

Abstract

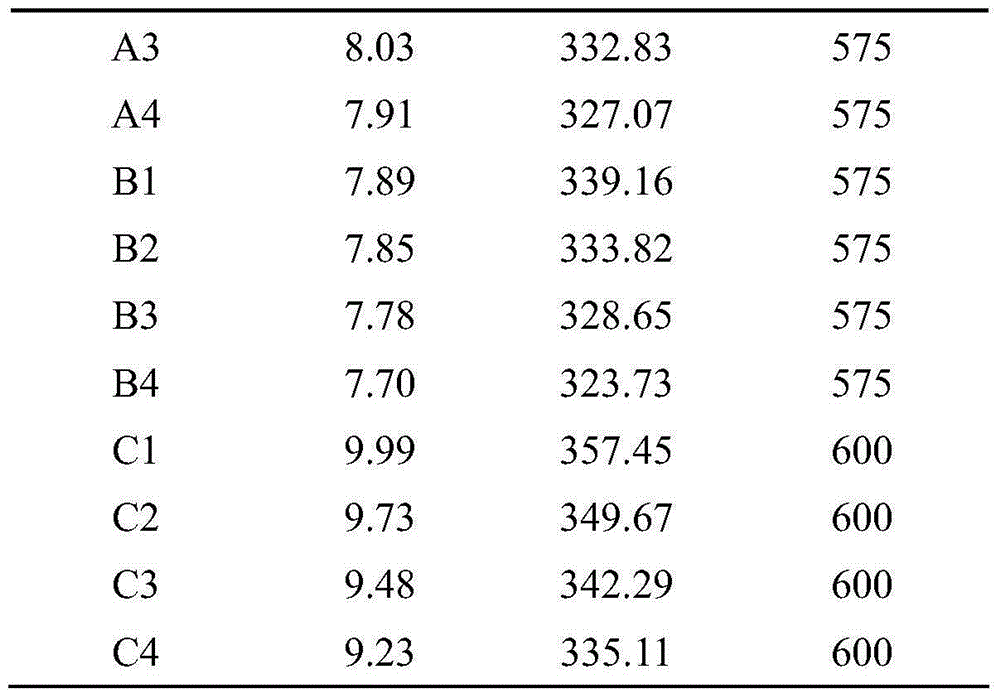

The invention discloses a group of organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of an internal combustion engine. The organic Rankine cycle mixed working media comprise components in percentage by mass as follows: 20%-32% / 68%-80% of n-butane / CO2, 20%-32% / 68%-80% of iso-butane / CO2 and 15%-27% / 73%-85% of n-pentane / CO2. The mixed working media are physically mixed at the normal temperature and then subjected to systematical filling. The mixed working media belong to natural working media, the ODP (ozone depletion potential) value is zero, the GWP (global warming potential) value is very small, and the organic Rankine cycle mixed working media have good environment protection performance; besides, the organic Rankine cycle mixed working media can meet the ISO 817-2010 standard and the A2-class safety working medium standard of the ASHRAE 34-2010 standard and have higher safety. The critical pressure and the critical temperature of the mixed working media are appropriate, the heat efficiency under the working condition of organic Rankine cycle design is higher than 14%, and the thermal performance is excellent.

Description

technical field [0001] The invention belongs to the organic working medium in the thermodynamic cycle, in particular to a group of alkane and CO 2 organic Rankine cycle working fluid. Background technique [0002] At present, the internal combustion engine using organic Rankine cycle for waste heat recovery has been paid more and more attention. The exhaust temperature of the engine is high and the temperature difference is large, so the choice of working fluid is very critical to the recovery effect of the waste heat of the internal combustion engine. The decomposition temperature of common refrigerants is low. If the temperature of the thermodynamic cycle exceeds its decomposition temperature, the thermophysical properties of the refrigerant will change, which in turn will affect the performance of the entire circulation system. Therefore, most of these working fluids are suitable for low-temperature organic Rankine cycle (ORC), such as geothermal, solar energy and other...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/04

CPCC09K5/04

Inventor 舒歌群龙彪田华石凌峰刘祎

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com