Epoxy asphalt and crushed stone drainage foundation

A technology of epoxy asphalt and crushed stone, applied in roads, on-site coagulation pavement, roads, etc., can solve the problems of poor fatigue durability, poor corrosion resistance, and high cost, and achieve good fatigue durability and excellent resistance. Alkaline, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

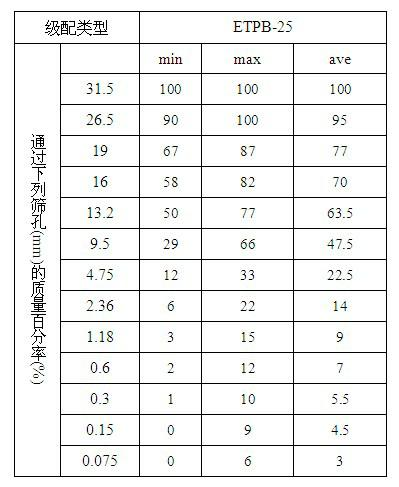

[0026] Example 1 : A large-porosity epoxy asphalt macadam drainage base with drainage function is a mixture formed by uniform mixing at 110°C with epoxy asphalt as the binder and open-graded crushed stone as the aggregate. The mass ratio of epoxy asphalt to gravel is 3.0:100, and the design gradation of the aggregate is as follows:

[0027]

[0028] The laying process of the epoxy asphalt gravel drainage base as mentioned above is as follows: firstly, clean the surface of the subbase; secondly, evenly spray the epoxy asphalt waterproof bonding layer, according to 0.4Kg / m 2 thirdly, lay epoxy asphalt macadam drainage base, rolling and forming, pavement thickness is 6cm, and wait for the end of the age to construct the surface layer.

Embodiment 2

[0029] Example 2: The difference from Example 1 is that the mass ratio of epoxy asphalt to gravel is 4.0:100, and the epoxy asphalt waterproof bonding layer is laid according to 0.6Kg / m 2 The amount of spraying is controlled and the paving thickness is 10cm.

Embodiment 3

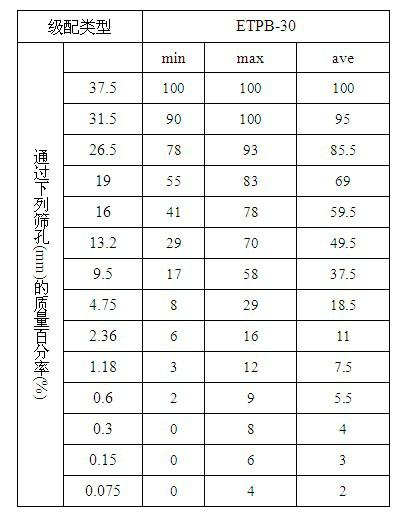

[0030] Example 3: A large-porosity epoxy asphalt macadam drainage base with drainage function is a mixture formed by uniform stirring at 110°C with epoxy asphalt as the binder and open-graded gravel as the aggregate material, wherein the mass ratio of epoxy asphalt to crushed stone is 3.0:100, and the design gradation of the aggregate is as follows:

[0031]

[0032] The laying process of the epoxy asphalt gravel drainage base is as follows: firstly, clean the surface of the subbase; secondly, spray the epoxy asphalt waterproof adhesive layer evenly, according to 0.4Kg / m 2 thirdly, lay epoxy asphalt macadam drainage base, rolling and forming, pavement thickness is 8cm, and wait for the end of the age to construct the surface layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com