Hard polyurethane foam

A technology of rigid polyurethane and foam, applied in the field of rigid polyurethane foam, can solve the problems of inability to achieve the expected thermal insulation effect and high thermal conductivity, and achieve the effects of high dimensional stability, low thermal conductivity and good mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

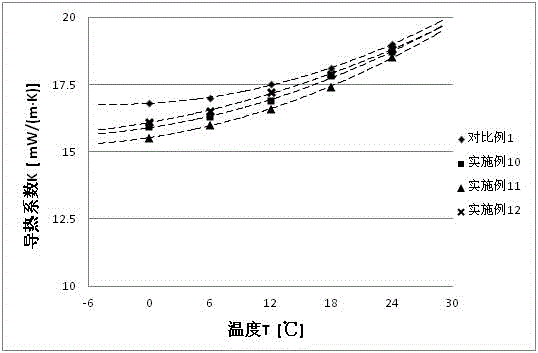

Image

Examples

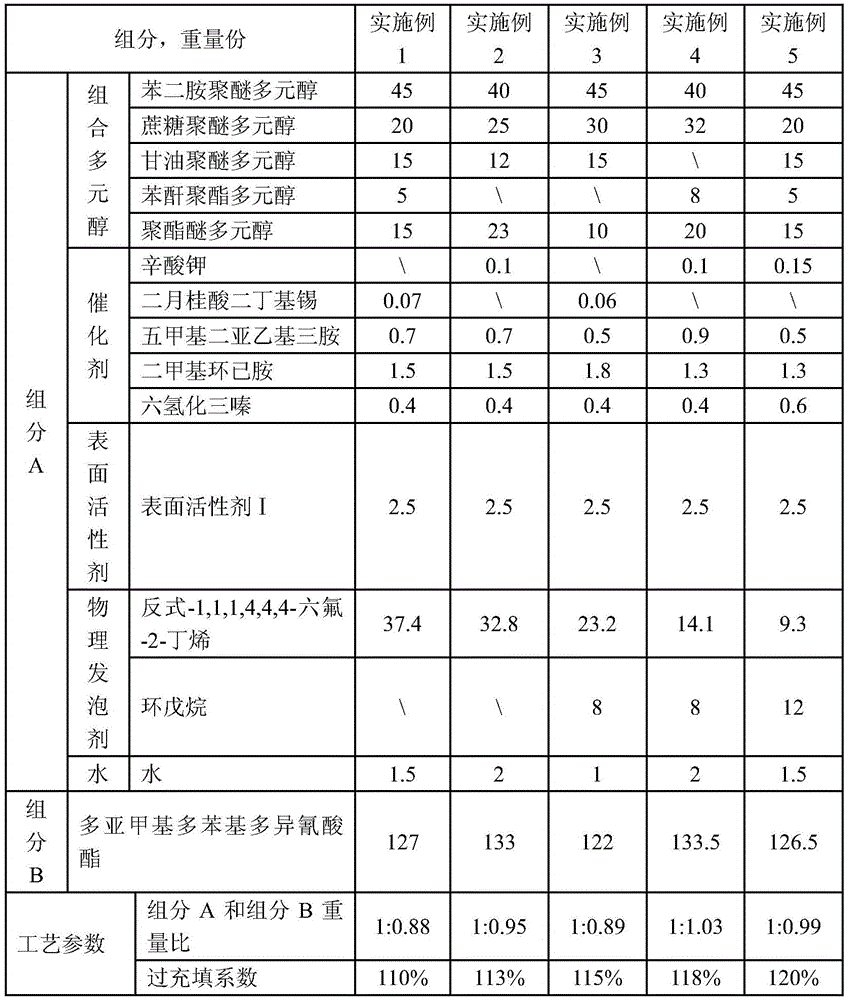

Embodiment 1-5

[0052] Table 1

[0053]

[0054] Add the catalyst, surfactant, and water into the combination polyol according to the ratio in the table, mix evenly, then add the physical foaming agent according to the ratio in the table, continue to mix evenly, and configure component A. Component A and component B are reacted by mixing the component A and component B according to the weight ratio in the formula through the head of a high-pressure machine gun, and injected into a closed mold (1200×400×70mm) to obtain a rigid polyurethane foam.

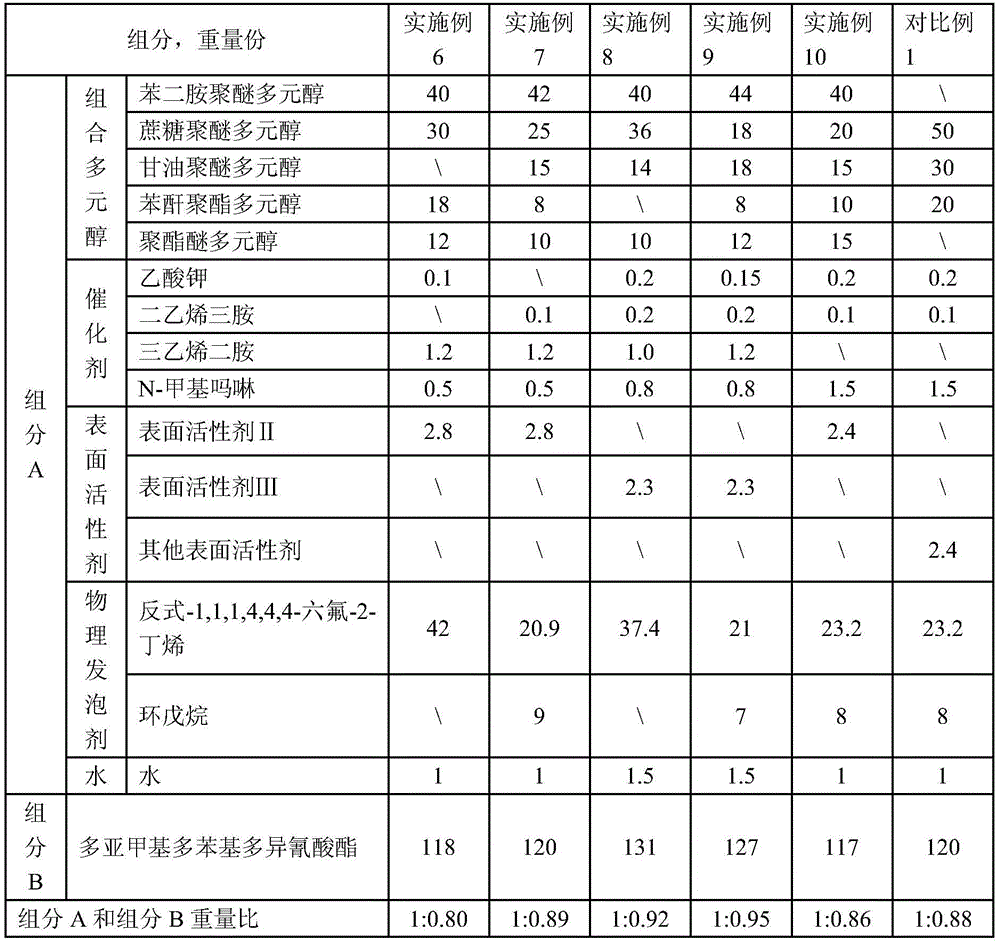

Embodiment 6-10 and comparative example 1

[0056] Table 2

[0057]

[0058] Add the catalyst, surfactant, and water into the combination polyol according to the ratio in the table, mix evenly, then add the physical foaming agent according to the ratio in the table, continue to mix evenly, and configure component A. Component A and component B were mixed and reacted by a high-pressure machine gun head according to the weight ratio in the table, and injected into a closed mold (1200×400×70mm) with an overfill coefficient of 112% to obtain a rigid polyurethane foam.

Embodiment 11-12 and comparative example 2-6

[0060] table 3

[0061]

[0062]Add the catalyst, surfactant and water to the combined polyol according to the proportion in the table, mix evenly, then add the physical foaming agent according to the proportion in the table, continue to mix evenly, and configure into component A. The above-mentioned component A and the above-mentioned component B are mixed and reacted by a high-pressure machine gun head according to the weight ratio in the formula, injected into a closed mold (1200×400×70mm), and the overfill coefficient is 112% to prepare rigid polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com