Environment-friendly medium-high temperature heat pump working medium containing dimethyl ether and iodotrifluoromethane

A technology of trifluoroiodomethane and high temperature heat pump, which is applied in the field of working fluid, can solve the problems of decreasing circulation efficiency and increasing unsafe factors, and achieves the effects of small greenhouse effect, reduced greenhouse effect and good thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

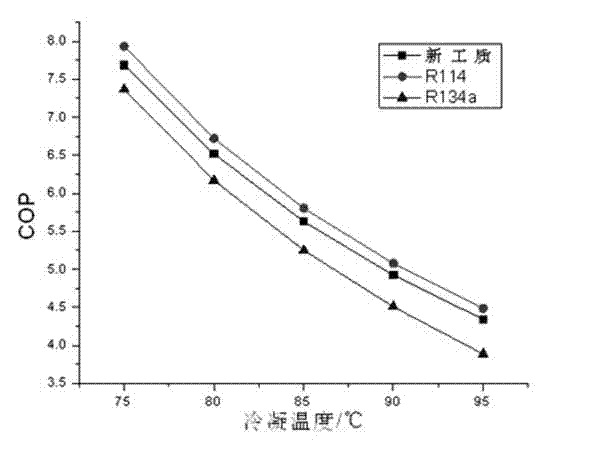

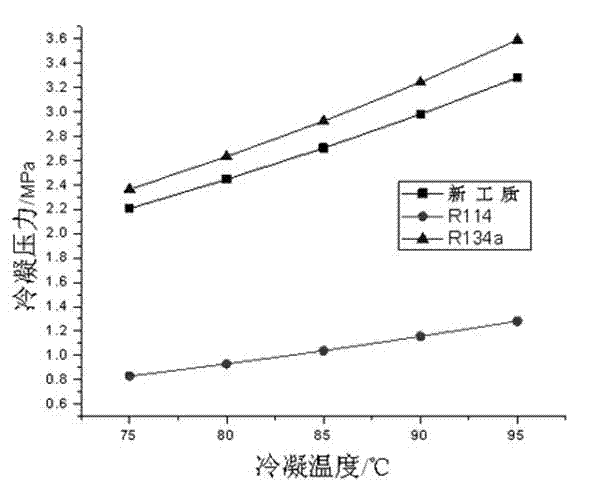

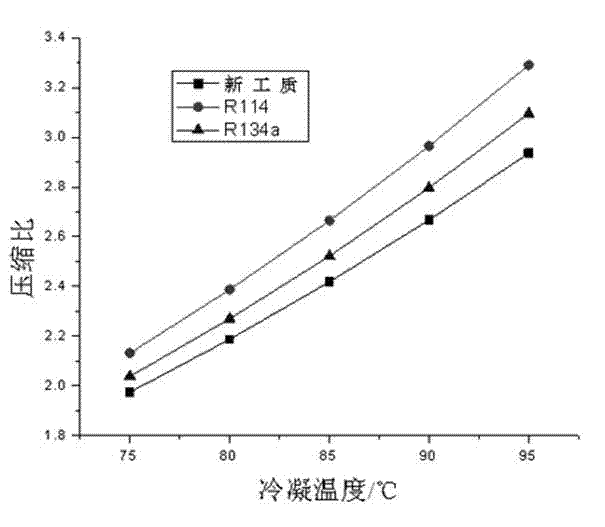

[0029] Take 70% DME, 15% R13I1, and 15% R152a, and mix them physically at room temperature as the refrigerant for the heat pump system.

[0030] The design conditions of the heat pump system are: the average evaporation temperature is 40°C, the average condensation temperature is 80°C, and the degree of superheat and subcooling are respectively 5°C. The isentropic efficiency of the compression process is taken as 0.75.

Embodiment 2

[0032] Take 47% DME, 27% R13I1, and 26% R152a, and mix them physically at room temperature as the refrigerant for the heat pump system.

[0033] The design working conditions of the heat pump system are taken as follows: the average evaporation temperature is 45°C, the average condensation temperature is 80°C, and the degree of superheat and subcooling are respectively 5°C. The isentropic efficiency of the compression process is taken as 0.75.

Embodiment 3

[0035] Take 41% DME, 29% R13I1, and 30% R152a, and mix them physically at room temperature as the refrigerant for the heat pump system.

[0036] The design conditions of the heat pump system are taken as follows: the average evaporation temperature is 50°C, the average condensation temperature is 90°C, and the degree of superheat and subcooling are respectively 5°C. The isentropic efficiency of the compression process is taken as 0.75.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com