Carbon electronic paste and preparation method thereof

A technology of electronic paste and carbon electronics, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Function deterioration and other problems, to achieve the effect of improving competitiveness, low cost and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

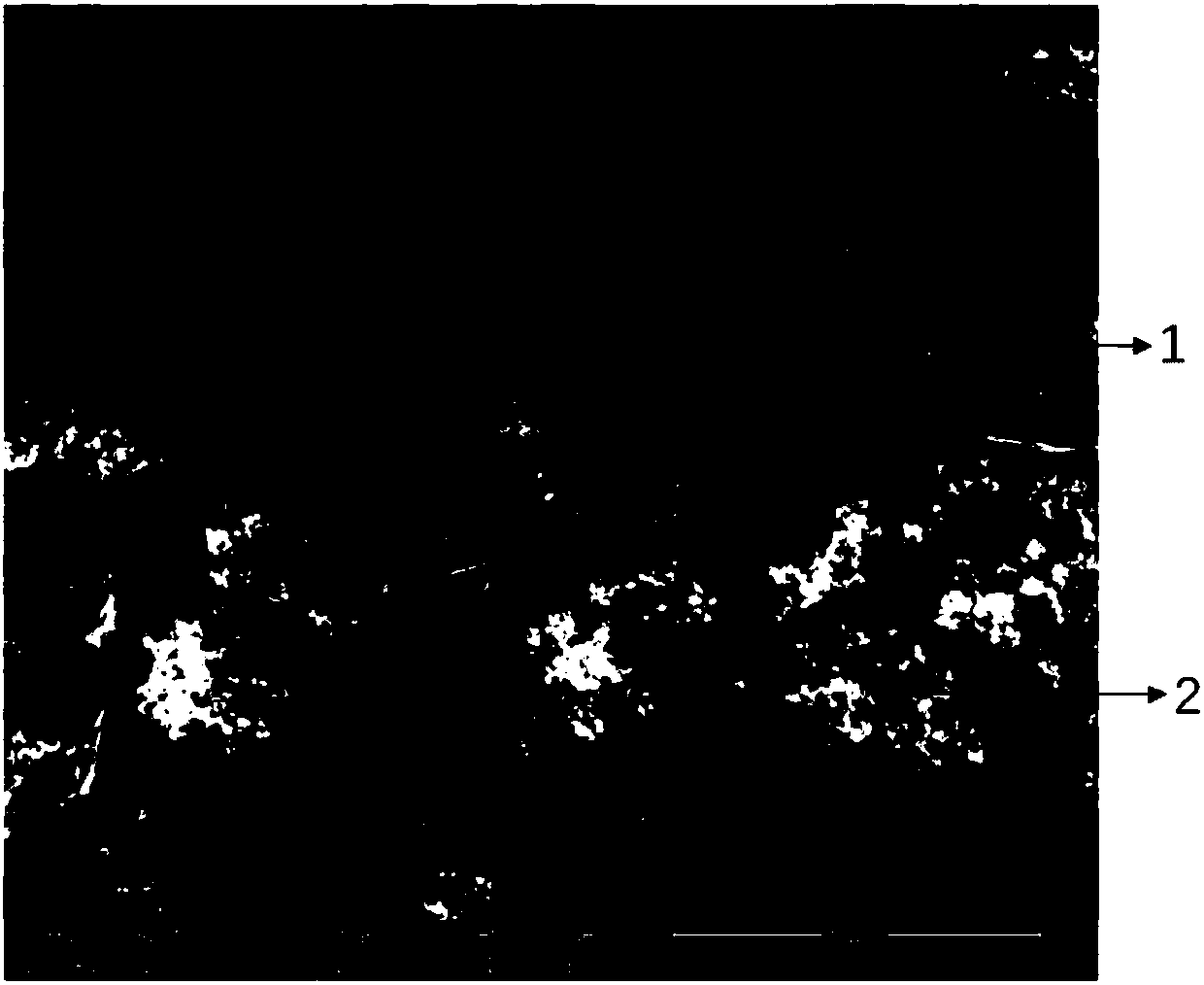

Image

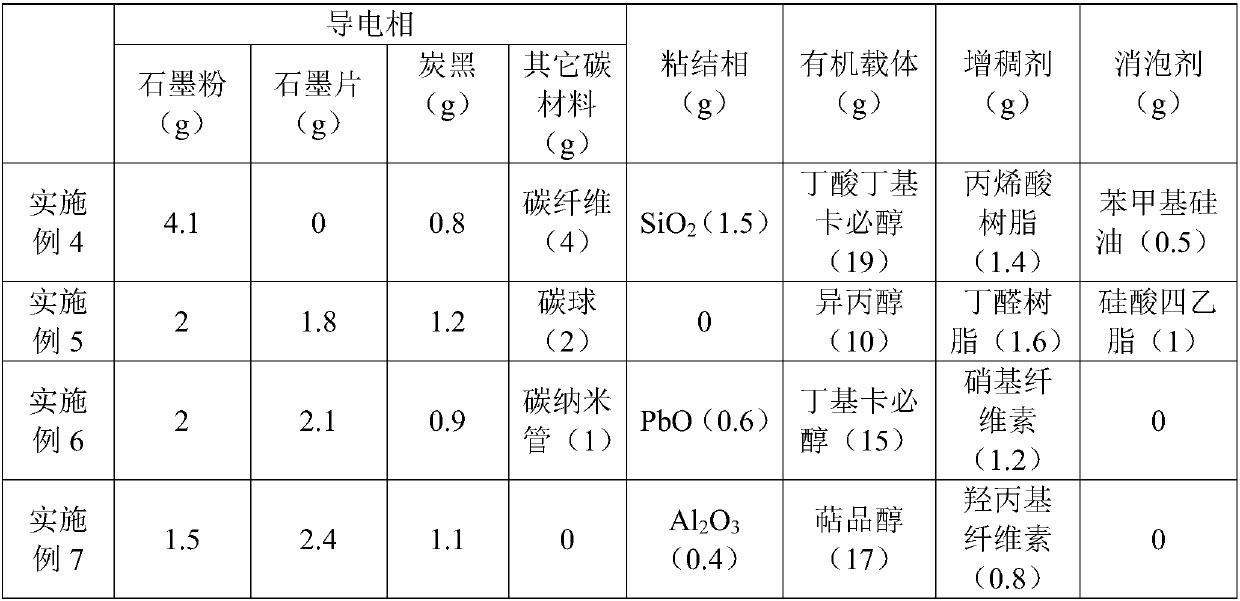

Examples

Embodiment 1

[0040] Weigh 2g graphite sheet, 2g graphite powder and 1g carbon black as conductive phase, 0.5g ZrO 2 As the binding phase, 16g of turpentine peroxide is used as an organic vehicle, and 1g of ethyl cellulose is used as a thickener.

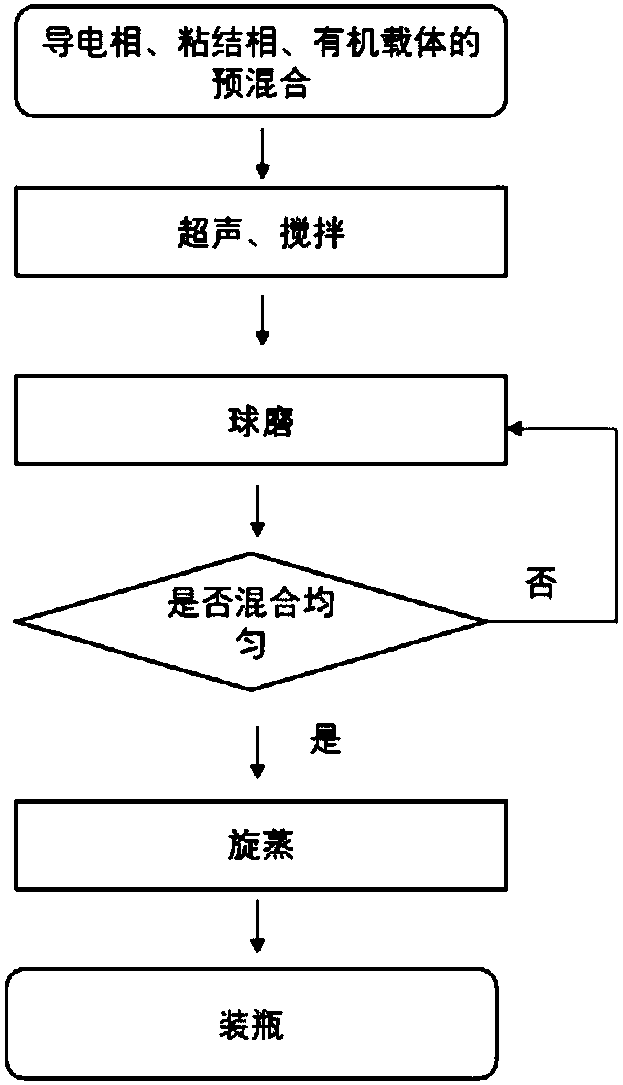

[0041] according to figure 2 The process of preparing carbon electronic paste, the specific steps are as follows:

[0042] 1) Pre-mixing: Add the conductive phase, binder phase and organic vehicle to absolute ethanol for pre-mixing, add a thickener during the pre-mixing process, then perform mechanical stirring for 10 minutes, and put it into a sonicator Perform ultrasonic crushing for 10 minutes, then repeat the above-mentioned mechanical stirring and ultrasonic crushing once;

[0043] 2) Ball mill mixing: transfer the pre-mixed slurry into the ball mill tank to 70% of the volume of the ball mill tank, then move the ball mill tank to the ball mill and perform ball milling at a speed of 275 rpm for 10 hours. Then continue ball milling, if not...

Embodiment 2

[0048] Take by weighing 1.3g graphite powder, 3g graphite sheet and 0.7g carbon black as conductive phase, 0.4g ZrO 2 As the binding phase, 13g of turpentine peroxide is used as an organic vehicle, and 1g of ethyl cellulose is used as a thickener.

[0049] according to figure 2 The process of preparing carbon electronic paste, the specific steps are as follows:

[0050] 1) Pre-mixing: Add the conductive phase, binder phase and organic vehicle to absolute ethanol for pre-mixing, add a thickener during the pre-mixing process, then perform mechanical stirring for 5 minutes, and put it into a sonicator Perform ultrasonic crushing for 5 minutes, then repeat the above-mentioned mechanical stirring and ultrasonic crushing twice;

[0051] 2) Ball mill mixing: transfer the pre-mixed slurry into a ball mill tank to 60% of the volume of the ball mill tank, then move the ball mill tank to a ball mill and perform ball milling at a speed of 375 rpm for 6 hours. Then continue ball milling,...

Embodiment 3

[0055] Take by weighing 3.7g graphite powder and 1.3g carbon black as conductive phase, 0.6g ZrO 2 As the binding phase, 19g of turpentine peroxide is used as an organic vehicle, 1g of ethyl cellulose is used as a thickener, and 0.5g of methyl silicate is used as a defoamer.

[0056] according to figure 2 The process of preparing carbon electronic paste, the specific steps are as follows:

[0057] 1) Pre-mixing: Add conductive phase, binder phase and organic vehicle to absolute ethanol for pre-mixing, add thickener and defoamer during pre-mixing, then perform mechanical stirring for 7 minutes, and place Ultrasonic crushing was carried out in the ultrasonic breaker for 8 minutes, and then the above-mentioned mechanical stirring and ultrasonic crushing were repeated three times;

[0058] 2) Ball mill mixing: transfer the pre-mixed slurry into a ball mill tank to 80% of the volume of the ball mill tank, then move the ball mill tank to a ball mill and perform ball milling at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com