Automobile front floor assembly

A technology for the front floor and front floor of a car, which is applied to the upper structure sub-assembly, vehicle parts, transportation and packaging, etc. It can solve the problem of not having enough space for motorcycles, achieve effective decomposition and transmission of collision force, and ensure safety performance , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

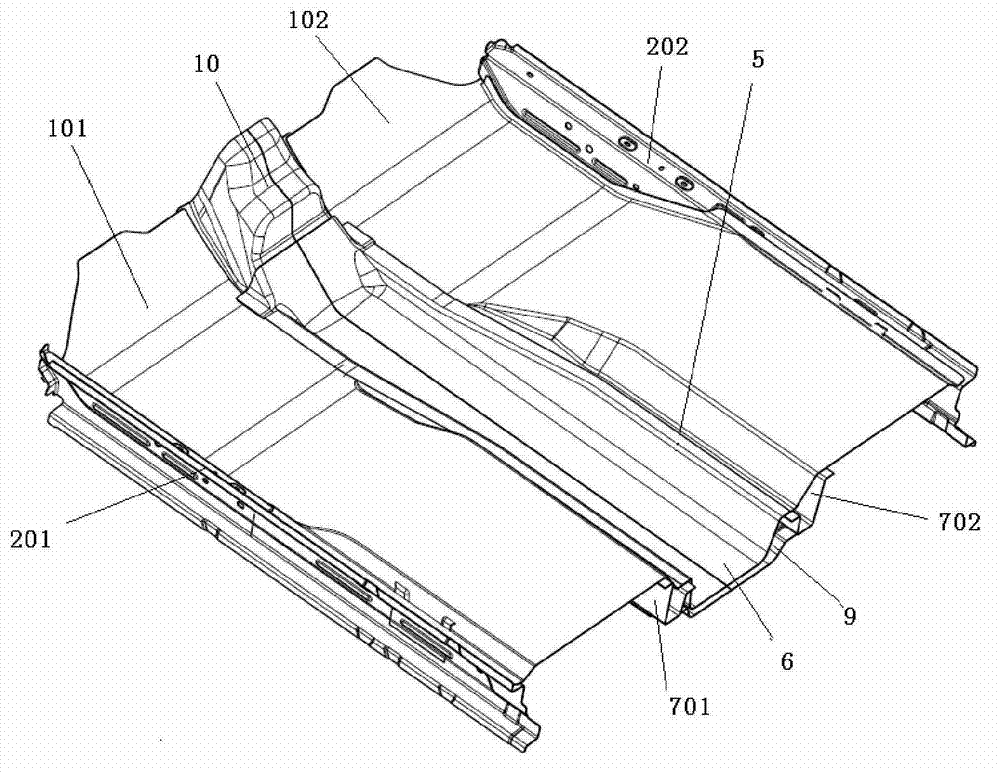

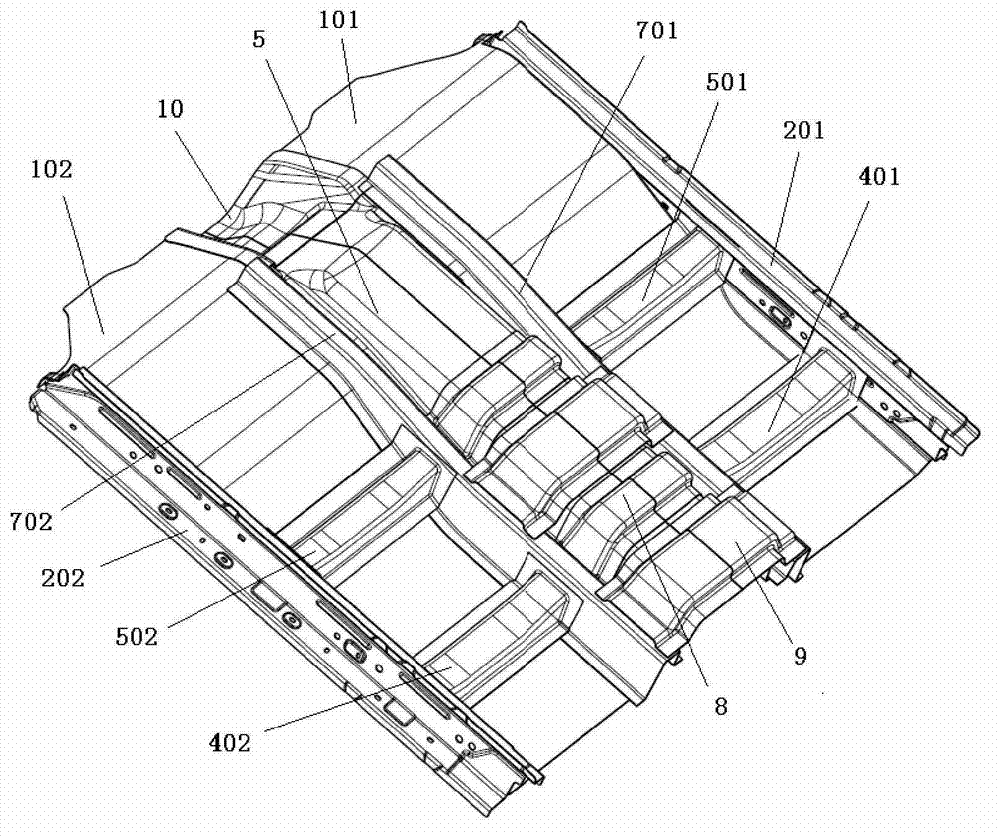

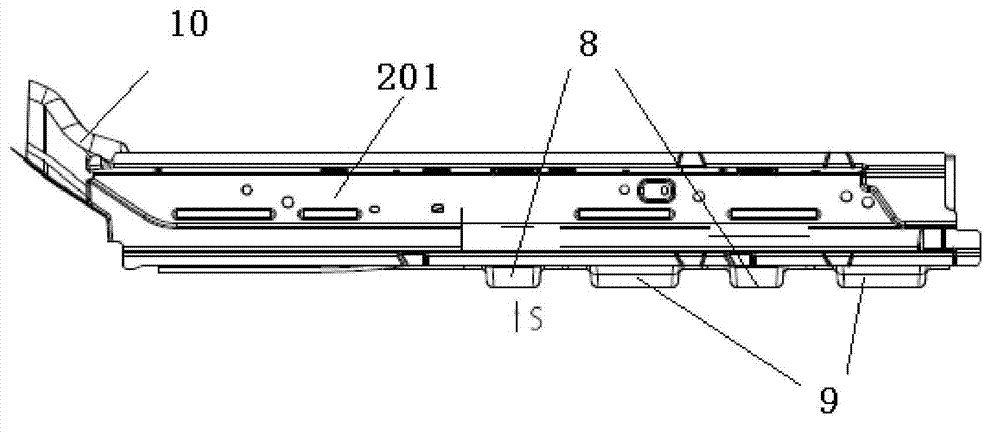

[0036] Such as Figure 1-6 As shown, the embodiment of the present invention provides a front floor assembly of an automobile, which is arranged between the cabin assembly and the rear floor assembly of the automobile. The front floor assembly structure may include a front floor body composed of a left front floor 101 , a right front floor 102 and a central tunnel panel 6 between them.

[0037] The front floor body may define a central tunnel 5 extending longitudinally of the vehicle with a central tunnel panel 6 therein. The central channel 5 can protrude outwards of the vehicle body, so that the cross-section of the front floor body is basically in the shape of an inverted "six", which is figure 1 , Figure 6 and Figure 7 It can be seen more cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com