Mine cave stone mining method

A technology for mines and ore materials, which is applied in the field of mining and can solve problems such as tangential bending, unevenness, and difficulty in taking out ore materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The mine cave adopts stone method, including:

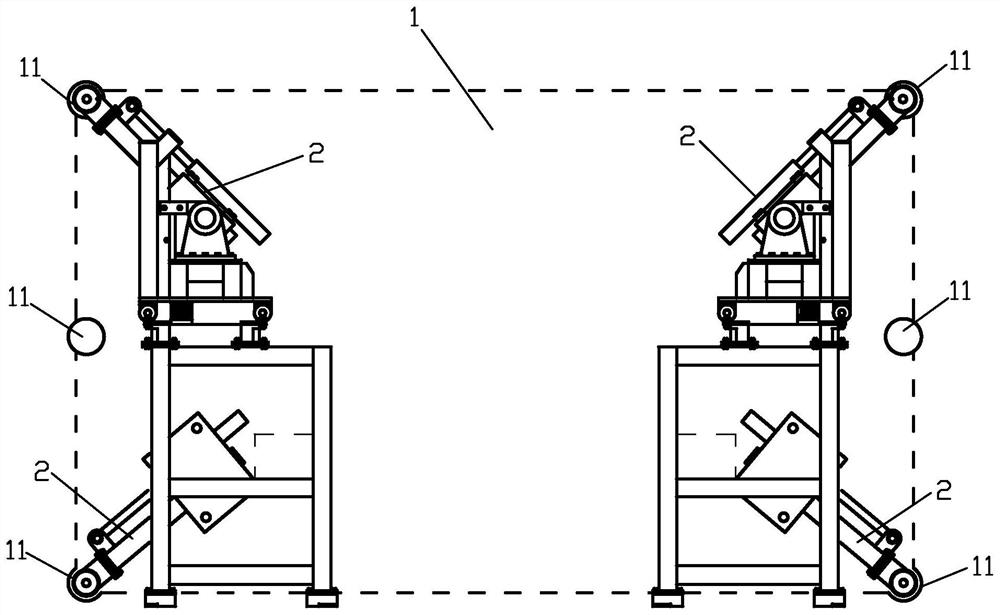

[0042] Step 1, please refer to figure 1 At least six guide holes 11 are drilled with a large-diameter drilling machine 2 on the working face 1 of the mine area. The six guide holes 11 are arranged in two rows on the left and right, and each row has three guide holes arranged at intervals up and down. The depth of the guide holes is as follows: More than 3 meters, if the distance between two rows of left and right is more than 6 meters;

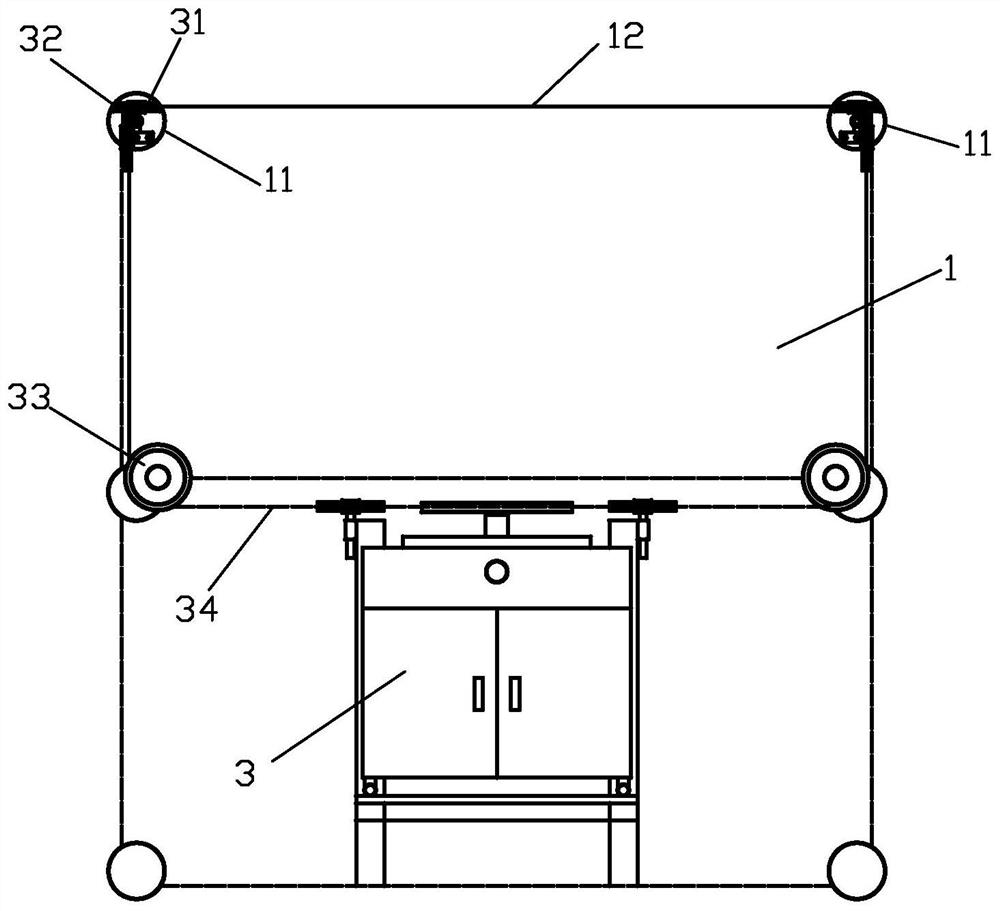

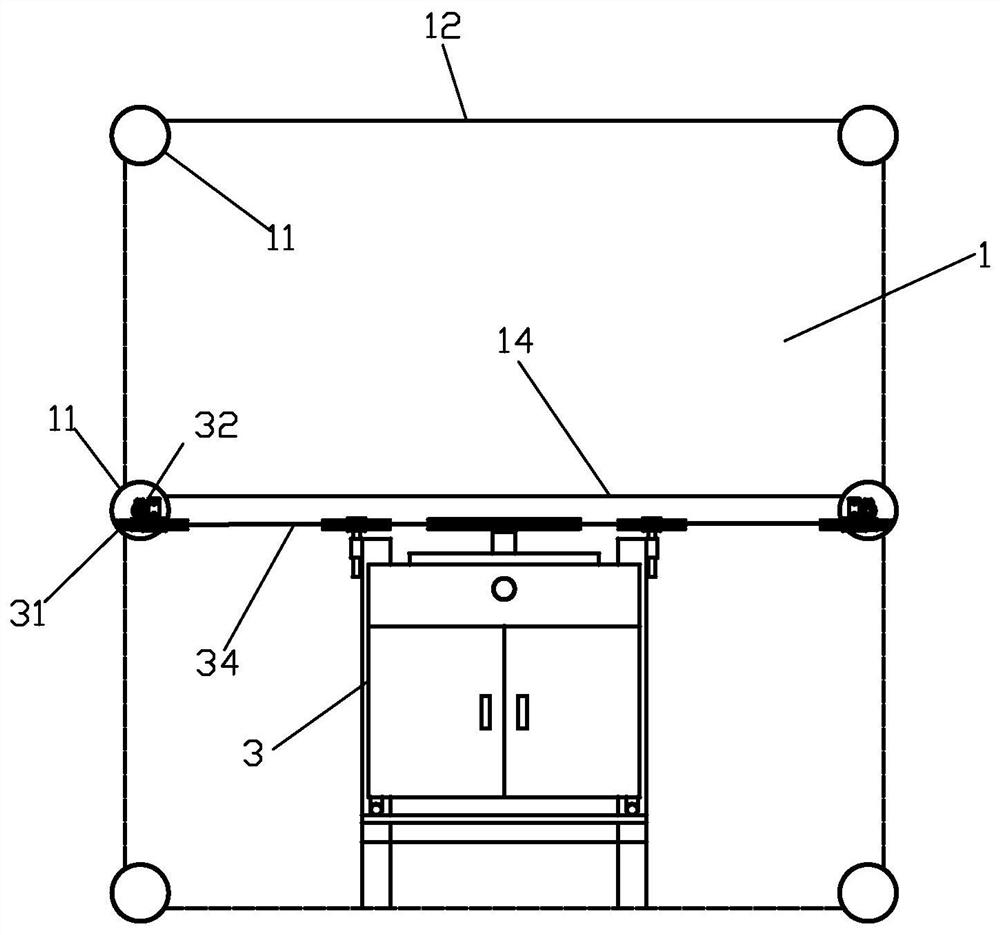

[0043] Step 2, please refer to Figure 2 to Figure 5 , exit the drilling machine 2, install the diamond wire saw machine 3 and the guide rod 32 with the first guide wheel 31, the guide rod 32 is inserted in the guide hole 11, and the diamond rope 34 is wound around the second guide wheel 33 and the first guide wheel 31 To cut out a top line 12, a bottom line 13 and two middle lines 14 on the working surface 1, and, two first vertical lines 15 and a second vertical line 16;

[0044] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com