Sliding component

一种滑动部件、滑动面的技术,应用在发动机元件、发动机的密封、机械设备等方向,能够解决流体推回、泄漏量增多、泄漏等问题,达到增大负压产生起点、减小剪切阻力、实现低扭矩化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

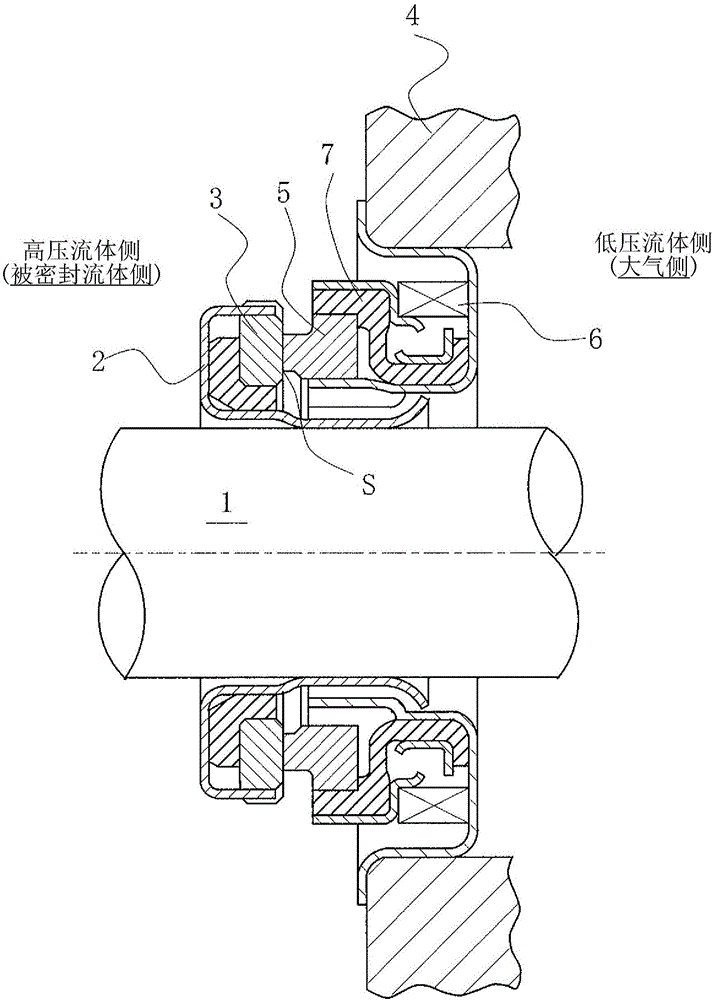

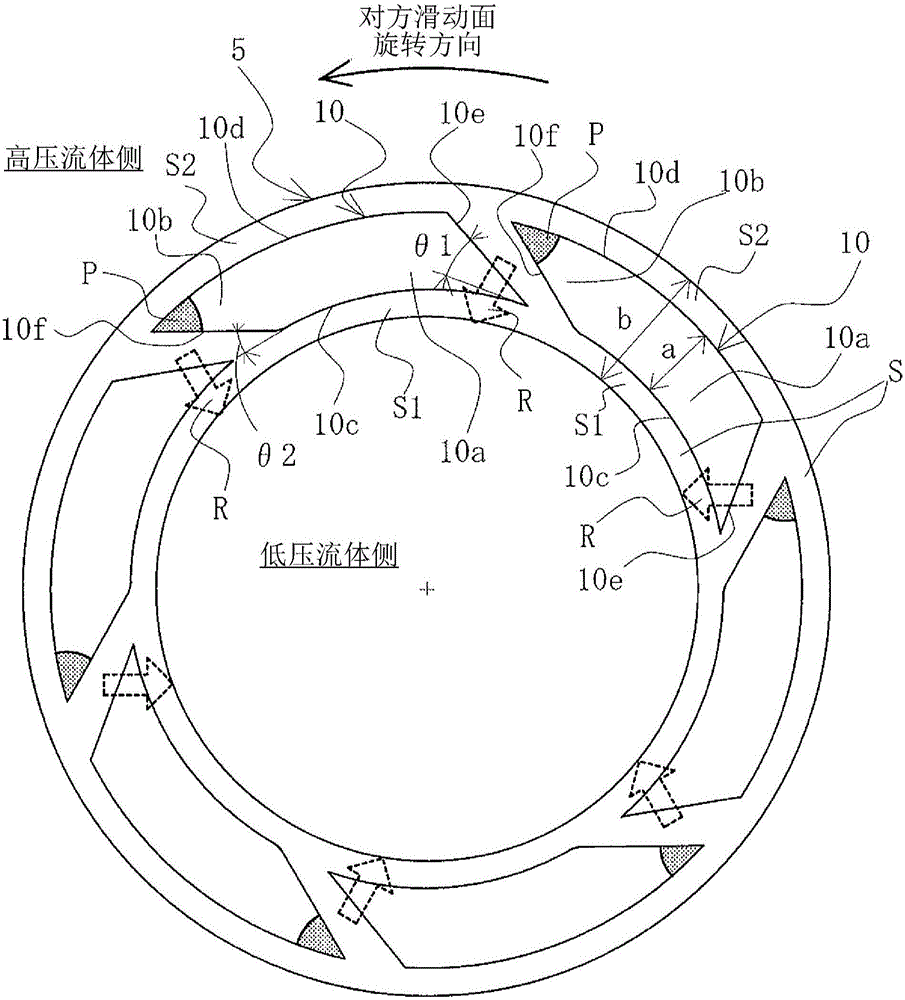

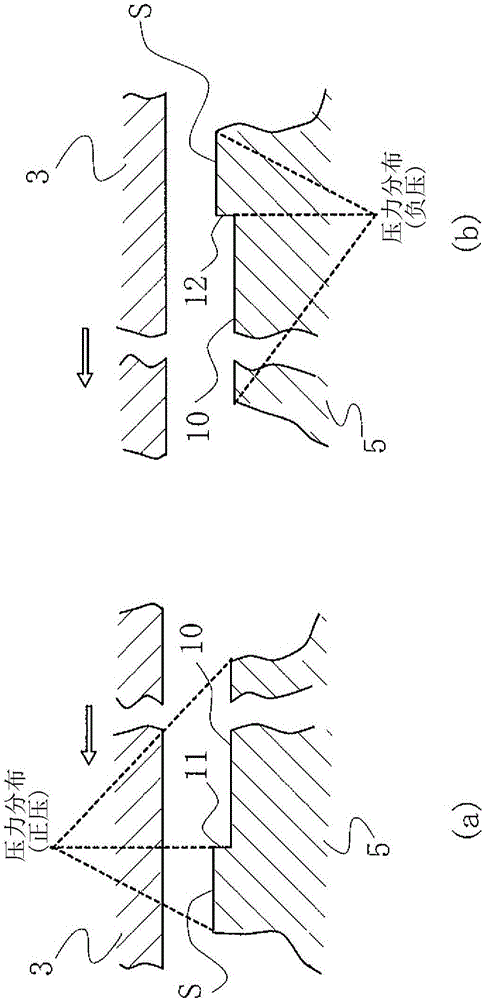

[0041] refer to Figure 1 to Figure 3 , the sliding member of Embodiment 1 of the present invention will be described.

[0042] In addition, in this embodiment, a case where the member constituting the mechanical seal is a sliding member will be described as an example.

[0043] figure 1 It is a vertical cross-sectional view showing an example of a mechanical seal, and is an inner type mechanical seal that seals the sealed fluid on the high-pressure fluid side that leaks from the outer circumference of the sliding surface toward the inner circumference, and is annular. The rotary ring 3 and the annular fixed ring 5 are pressed between the sliding surfaces S which are mirror-finished by grinding etc. The rotating ring 3 is provided on the side of the rotating shaft 1 that drives the pump impeller (not shown) on the side of the high-pressure fluid in a state capable of rotating integrally with the rotating shaft 1 via the sleeve 2. The fixed ring 5 It is provided in the casi...

Embodiment 2

[0071] Figure 4 It is a figure showing the sliding surface of the sliding member of Example 2 of the present invention, in order to figure 1 The case where a dent is formed on the sliding surface of the fixing ring 5 will be described as an example. Embodiment 2 is the same as figure 2 The shown embodiment 1 is different: a positive pressure generating mechanism composed of Rayleigh steps is arranged on the high-pressure fluid side of the sliding surface provided with dimples, but other aspects are basically the same as embodiment 1, and the same parts are marked the same , and omit repeated descriptions.

[0072] exist Figure 4 Among them, on the sliding surface S, dimples 10 are arranged on the low-pressure fluid side, and a positive pressure generating mechanism composed of Rayleigh steps 20 is arranged on the high-pressure fluid side.

[0073]The Rayleigh step 20 is composed of a narrowed step 21, a groove portion 22, and a radial groove 23 communicating with the h...

Embodiment 3

[0078] Figure 5 It is a figure showing the sliding surface of the sliding member of Example 3 of the present invention, in order to figure 1 The case where a dent is formed on the sliding surface of the fixing ring 5 will be described as an example. Embodiment 3 is the same as figure 2 The shown embodiment 1 is different: a positive pressure generating mechanism composed of Rayleigh steps is arranged on the high-pressure fluid side of the sliding surface provided with dimples, but other aspects are basically the same as embodiment 1, and the same parts are marked the same , and omit repeated descriptions.

[0079] exist Figure 5 Among them, on the sliding surface S, dimples 10 are arranged on the low-pressure fluid side, and a positive pressure generating mechanism composed of Rayleigh steps 30 is arranged on the high-pressure fluid side.

[0080] The Rayleigh step 30 is composed of a narrowed step 31, a groove portion 32, and a radial direction groove 33 communicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com