Scroll compressor

A technology of scroll compressors and orbiting scrolls, applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of small reduction effect, difficulty in forming oil film, limitation, etc., to reduce bearing loss, Effect of reducing shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

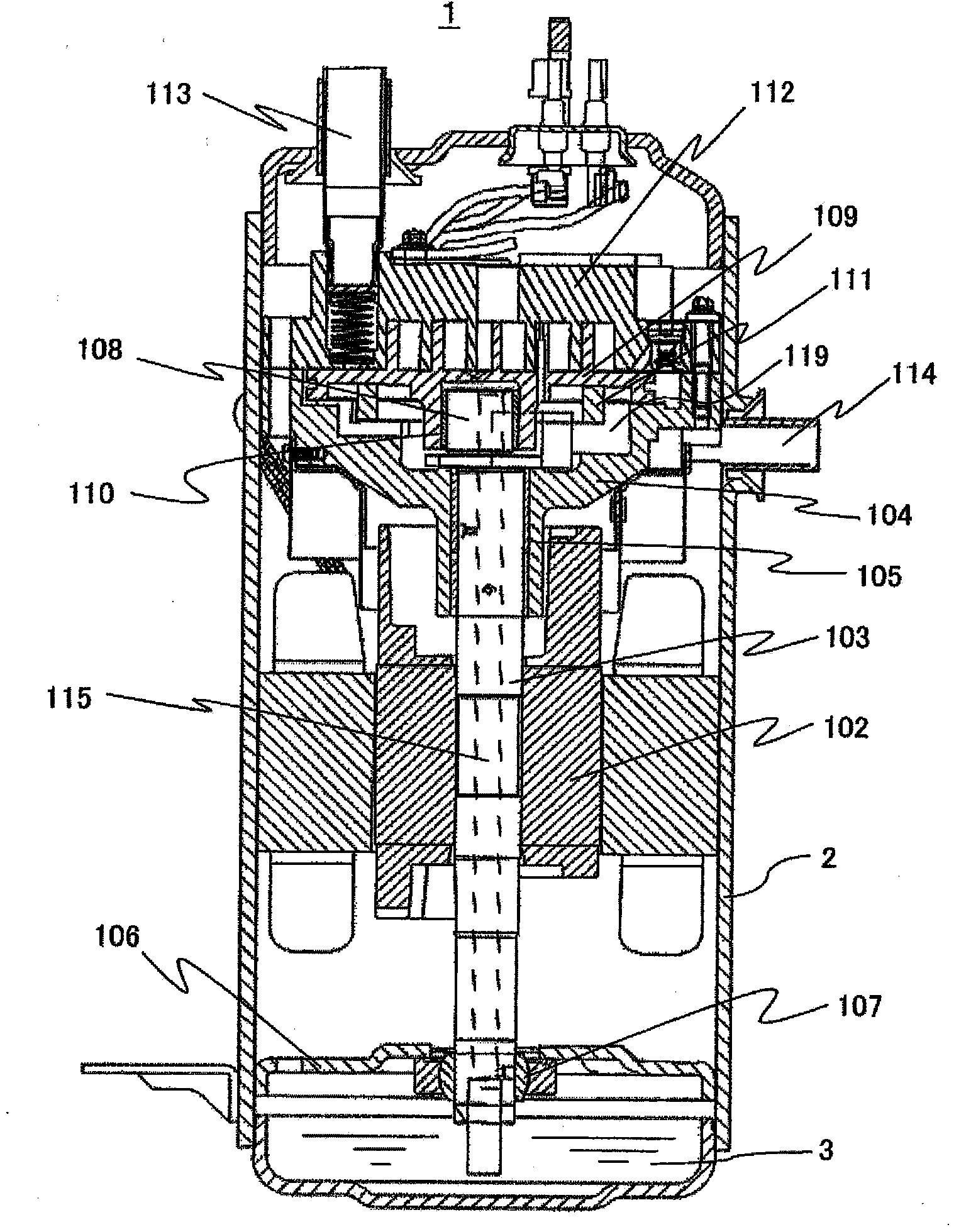

[0037] figure 1 It is a longitudinal sectional view showing Embodiment 1 of the scroll compressor of the present invention.

[0038] figure 1 The illustrated scroll compressor 1 is a hermetic scroll compressor used for refrigeration and air conditioning in air conditioners such as air conditioners and refrigerators. A fixed scroll 112 and an orbiting scroll 109 that engages with the fixed scroll 112 and orbits are provided in the upper part of the airtight container 2 . In addition, a motor 102 is provided in the airtight container 2, and a crankshaft 103 is connected to the motor 102. The crankshaft 103 consists of a main bearing 105 provided on a frame 104 fixedly installed in the airtight container 2, and a lower frame 106. The auxiliary bearing 107 is rotatably supported.

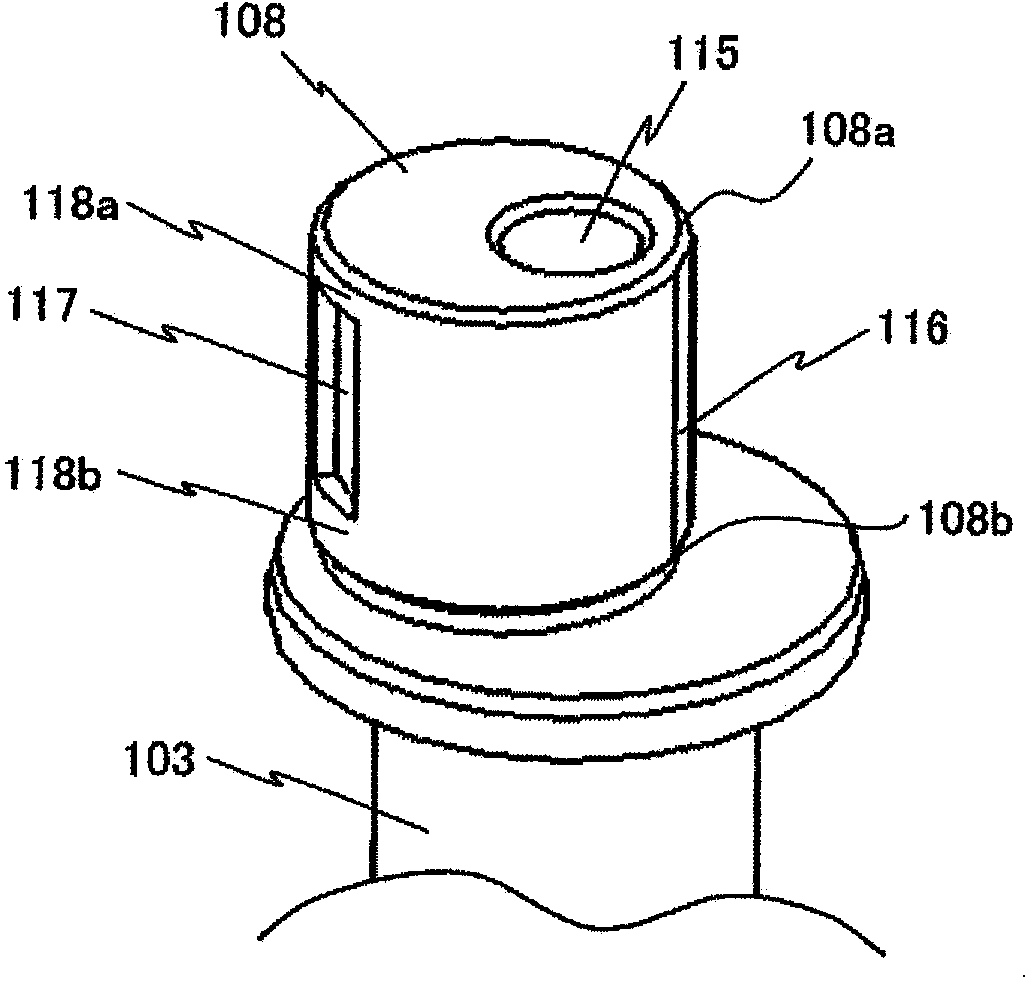

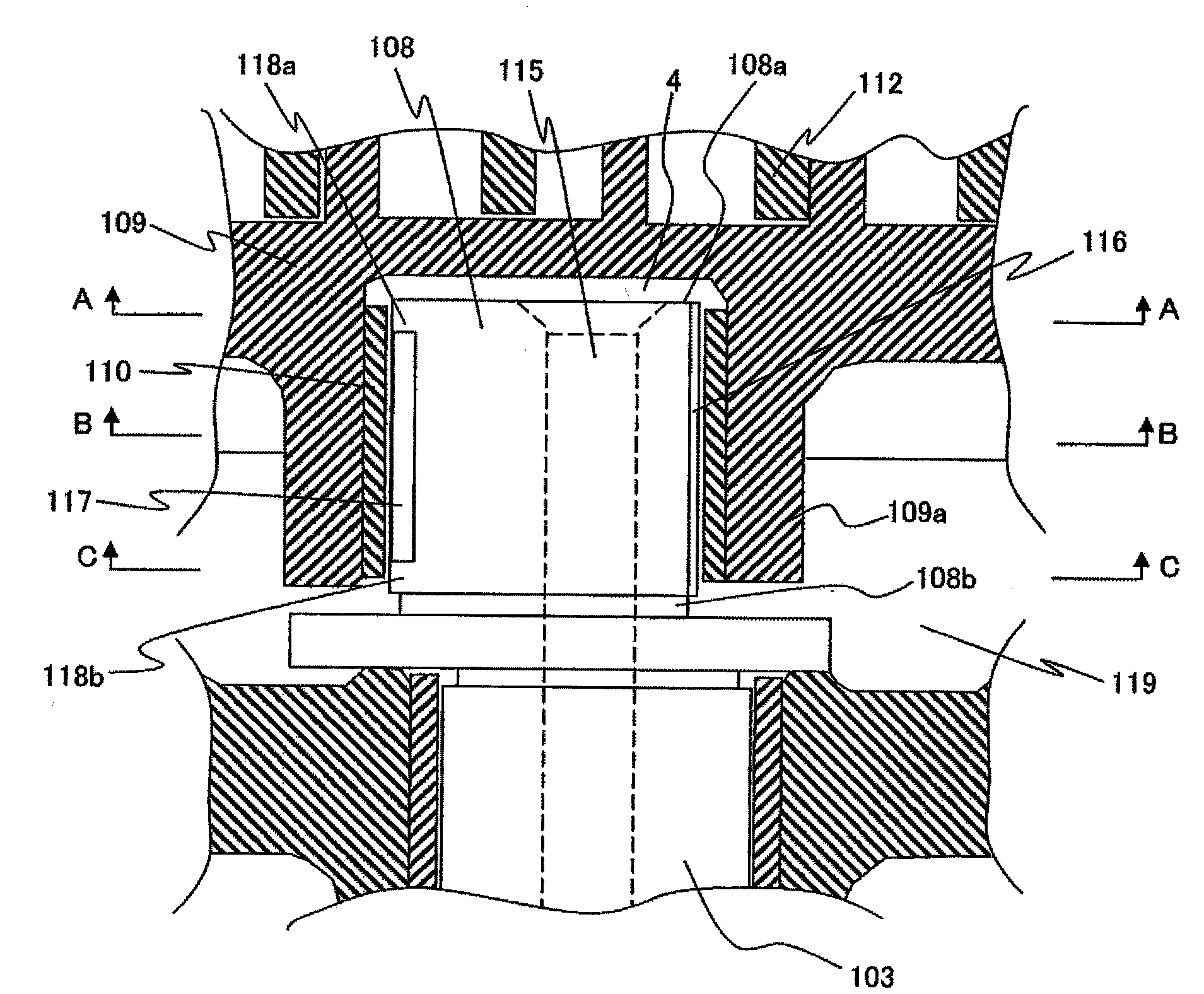

[0039] An eccentric portion 108 is provided on the upper portion of the crank shaft 103, and the eccentric portion 108 engages and slides with an orbiting sliding bearing 110 provided on the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com