Floating bearing of turbocharger

A turbocharger and floating bearing technology, which is applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as insufficient lubrication and oil storage, weak drag reduction ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to understand the examples of the present invention more clearly, the present invention is further described below.

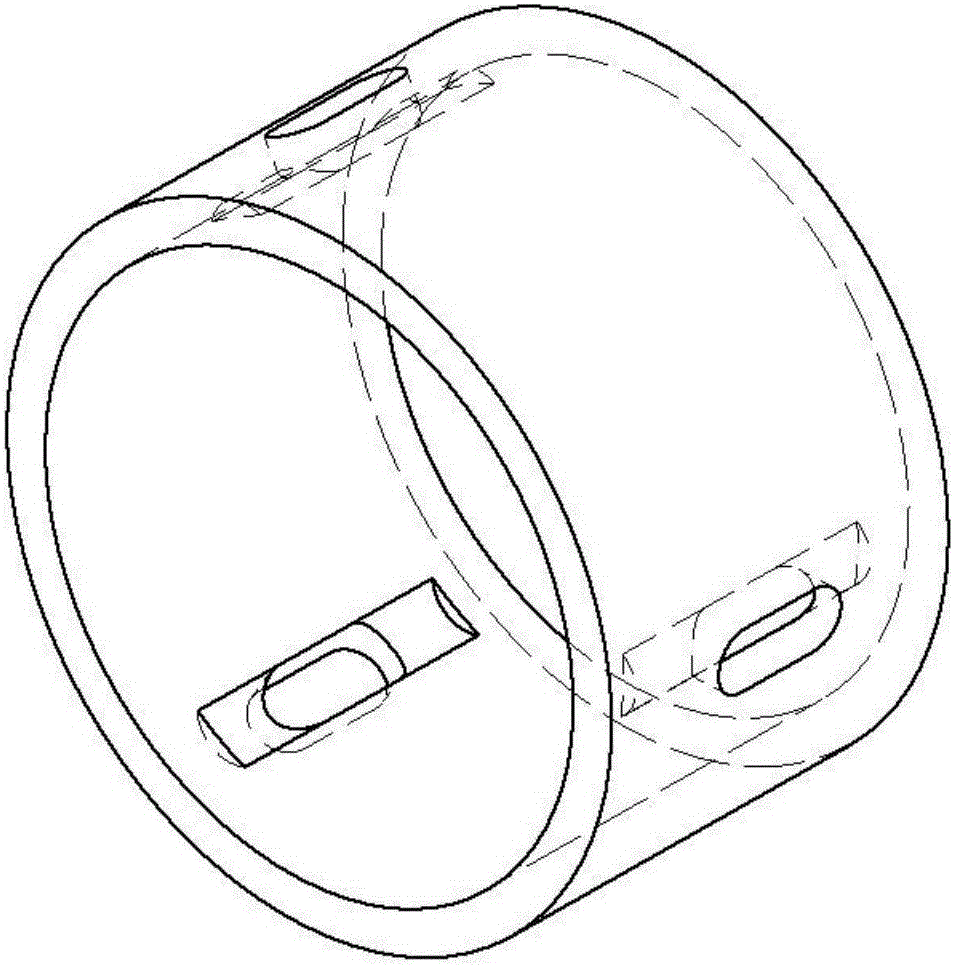

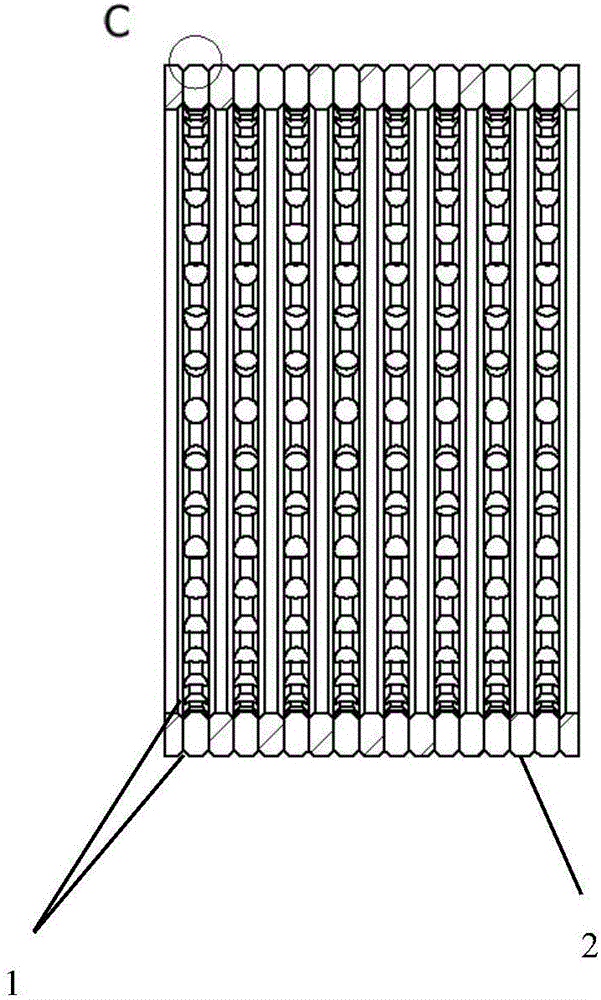

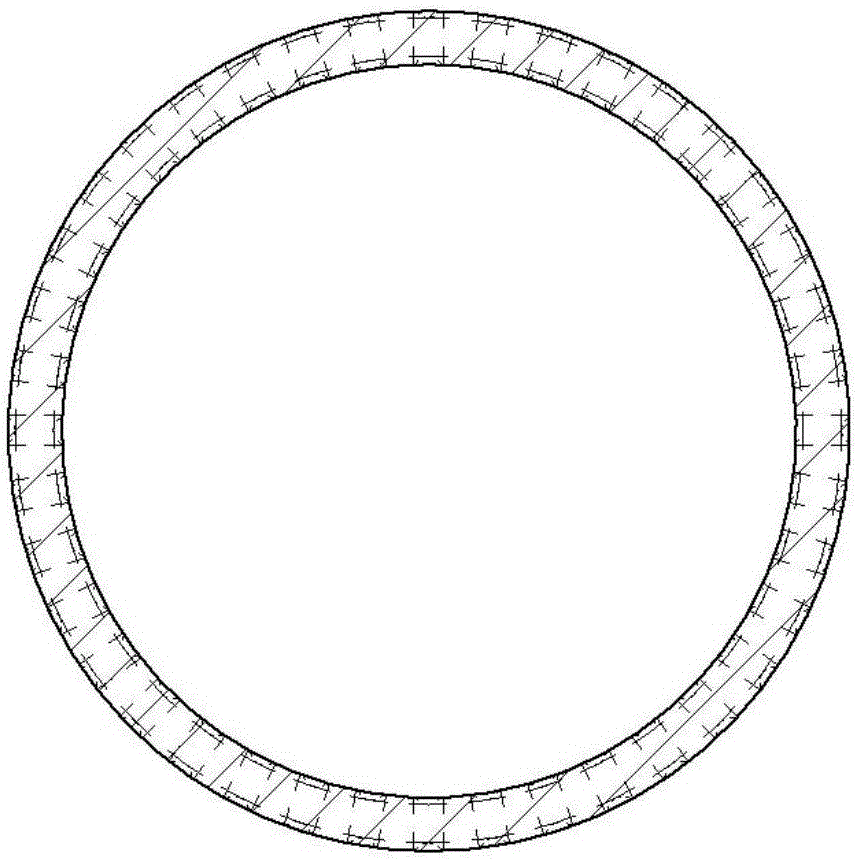

[0020] see figure 2 , 3 , 4, 5, a turbocharger floating bearing, including a floating bearing body, that is, a floating sleeve (3). The floating sleeve (3) is the main structure of the floating bearing. Several annular oil grooves (1) are uniformly arranged on the inner surface (4) of the floating sleeve and the outer surface (5) of the floating sleeve. The cross-sectional shape of the annular oil groove (1) is It is an isosceles triangle, and the annular oil grooves (1) are equidistantly arranged at intervals; there are ridge structures (2) between adjacent annular oil grooves (1), and the ridge structures (2) are the gaps between the annular oil grooves (1). Equally spaced raised portions. The annular oil groove (1) forms a non-smooth surface, and the shear resistance generated when the lubricating oil fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com