Patents

Literature

34results about How to "To achieve the purpose of drag reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

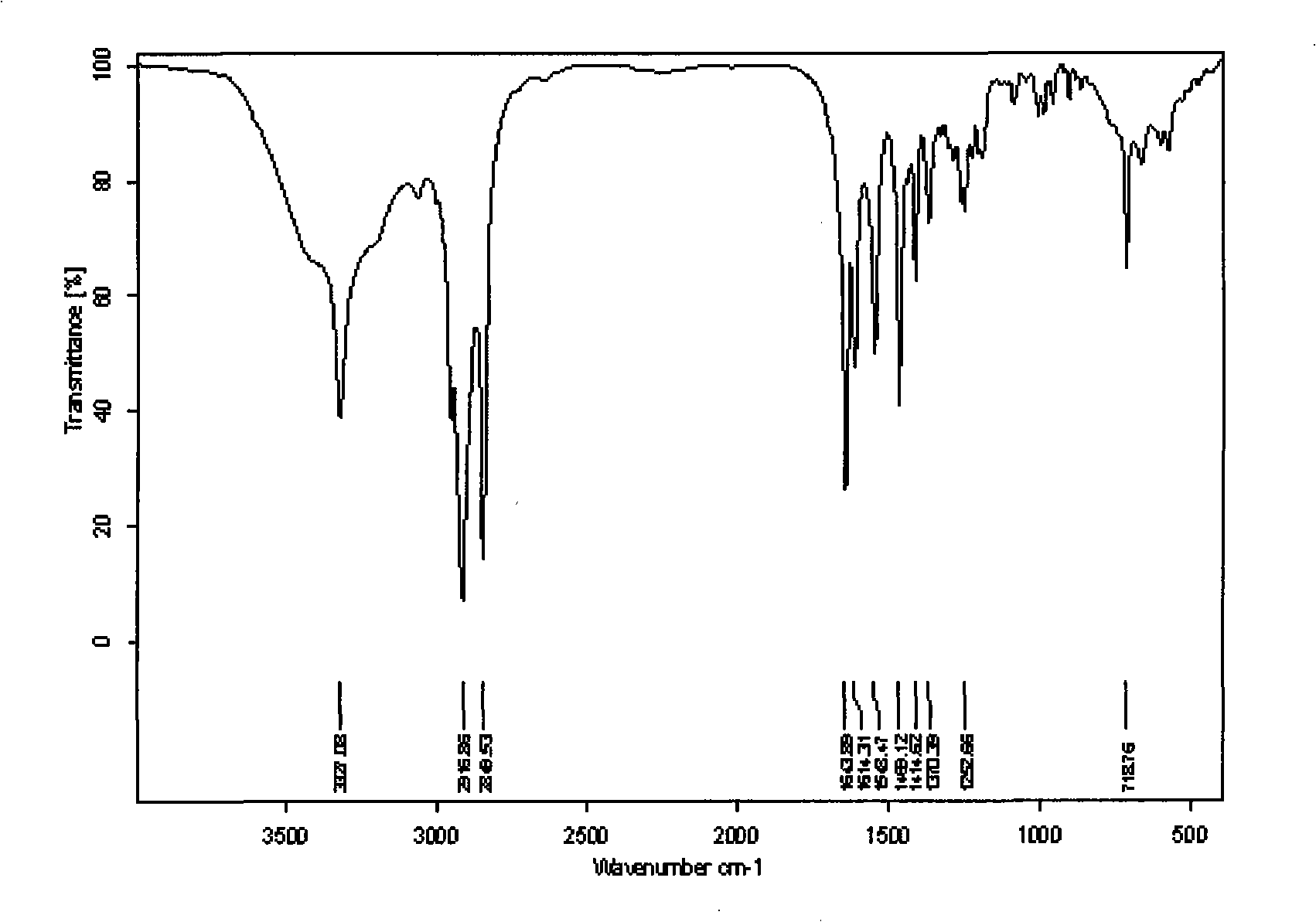

Gas pipeline drag reducer and preparation thereof

The invention relates to a gas pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas pipeline drag reducer is characterized in that: the drag reducer is synthesized by long-chain acid and enamine according to a molar ratio of between 1:1 and 2.2:1. The preparation method comprises the following steps that: the long chain acid in proportional quantity is added in a reaction container; a heater is started so as to carry out heating while stirring; when temperature reaches to 100 DEG C, the long chain acid is melted, and the enamine in proportional quantity is added at the same time; nitrogen is fed in to carry out protection, and the mixture is preheated to between 120 and 140 DEG C; after preheating is finished, programmed heating is carried out till temperature is increased to between 210 and 220 DEG C; a stirrer is removed and a vacuum pump is connected to carry out evacuation for 2 to 4 hours; when reaction is finished, brown solid crude product can be obtained after cooling down. The gas pipeline drag reducer has obvious drag reduction effect on gas pipelines, direct source of raw materials, simple operation, moderate reaction conditions, relatively simple process and low requirements on equipment, and is easy to realize large-scale industrialized production.

Owner:PETROCHINA CO LTD

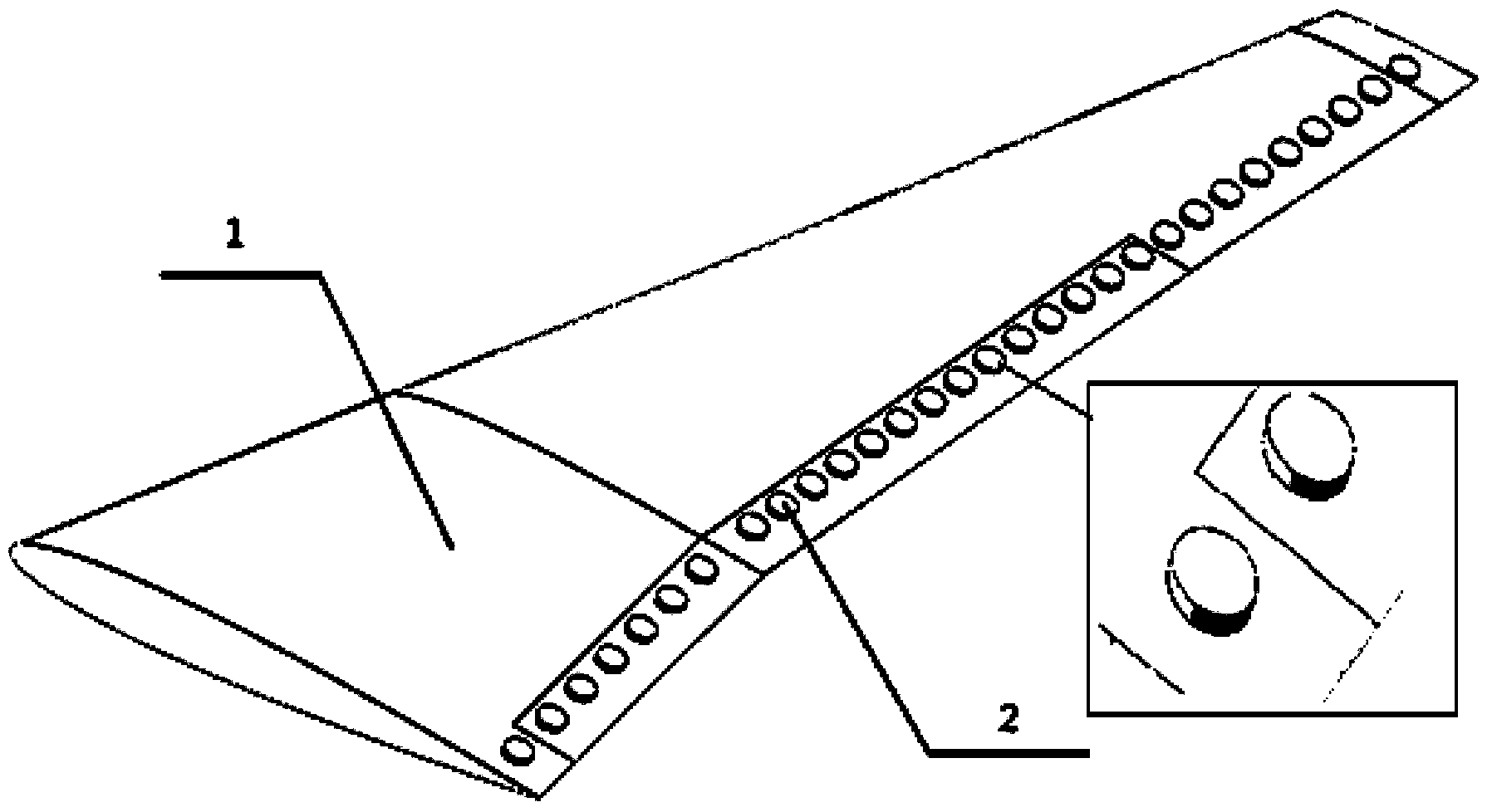

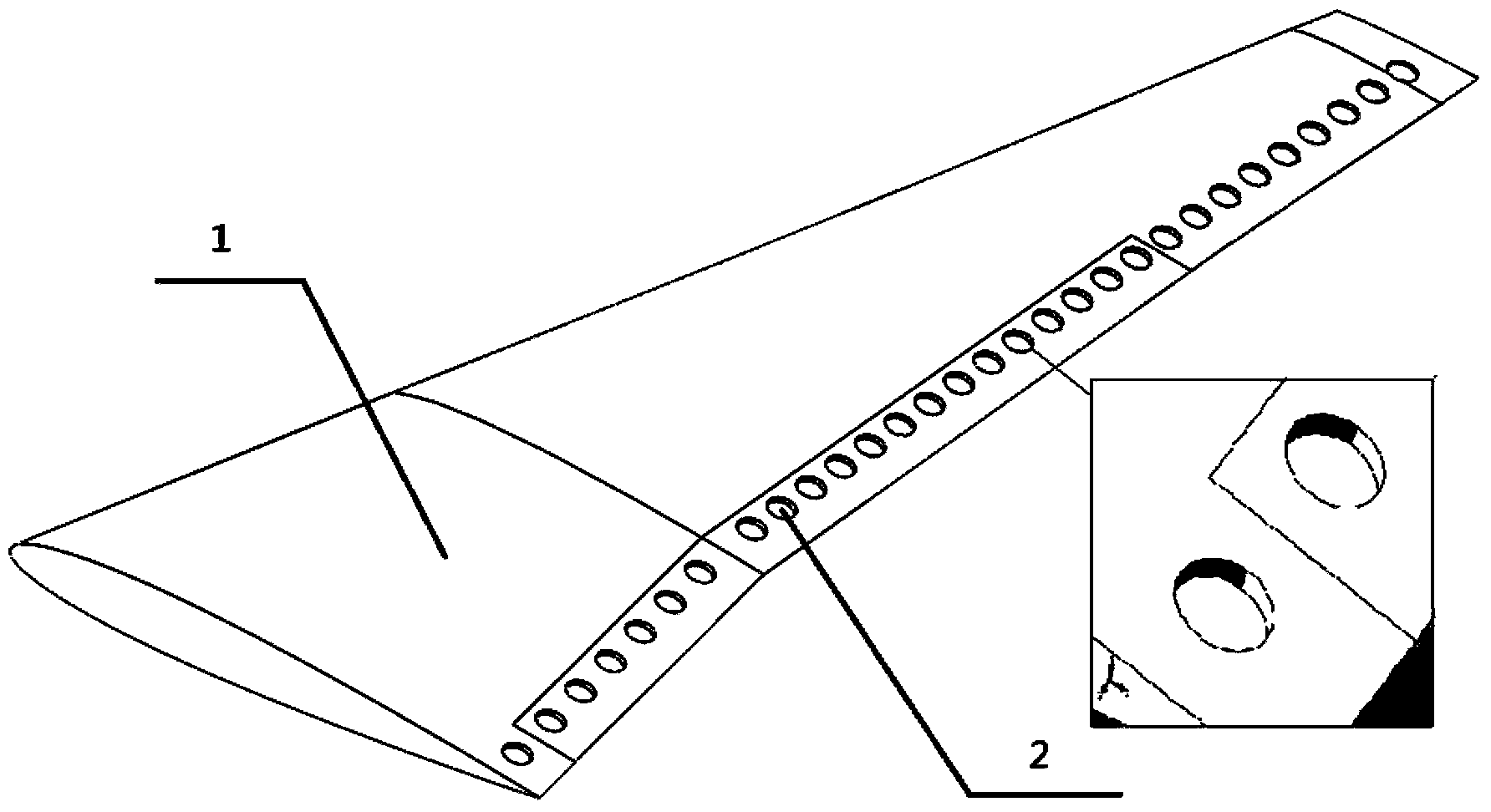

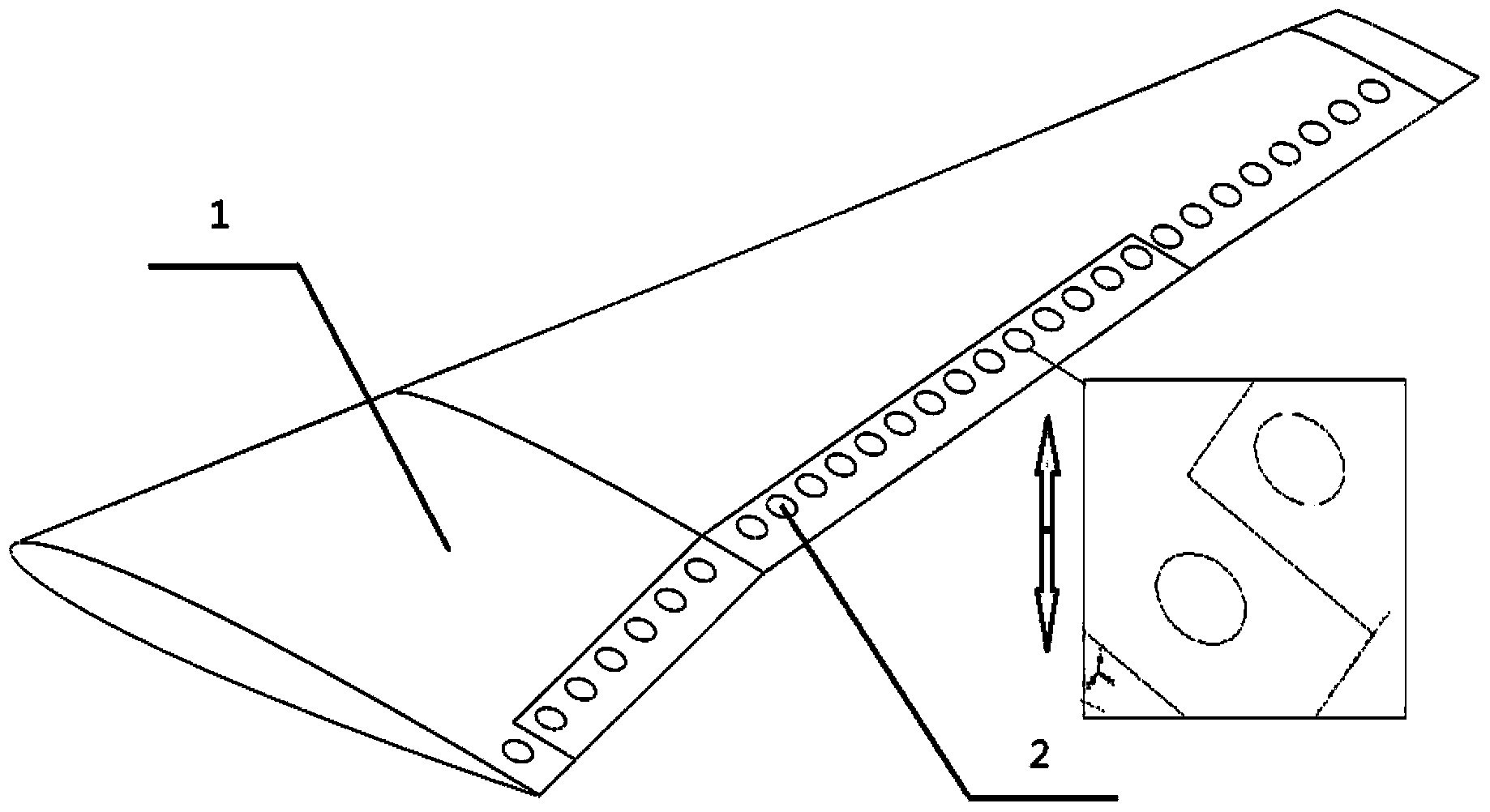

Active control method and device for aerofoil drag reduction

InactiveCN103482055AImprove flow qualityPostponed separationInfluencers by generating vorticesDrag reductionControl flowElectricity

The invention relates to the technical field of aerospace, and discloses an active control method and device for aerofoil drag reduction. A plurality of piezoelectric devices are uniformly arranged at the trailing edge of an aerofoil in advance, and when an aircraft takes off or flies at a low speed, the piezoelectric devices are controlled to dent so as to enable concave pits to be formed in the corresponding position of the aerofoil, so that the separation of the boundary layer is postponed and the pressure drag is reduced; when the aircraft flies at a high speed, the piezoelectric devices are controlled to be bulged so as to enable bumps to be formed in the corresponding position, so that the drag is reduced; or the piezoelectric devices are controlled to be in the periodic oscillation operating mode, so that the wake zone of the aerofoil is enabled to form a periodic vortex structure so as to control flow separation. The active control method and device for aerofoil drag reduction have the advantages that the aircraft is enabled to actively switch the corresponding drag reduction mode in different flight regimes, and the flight efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

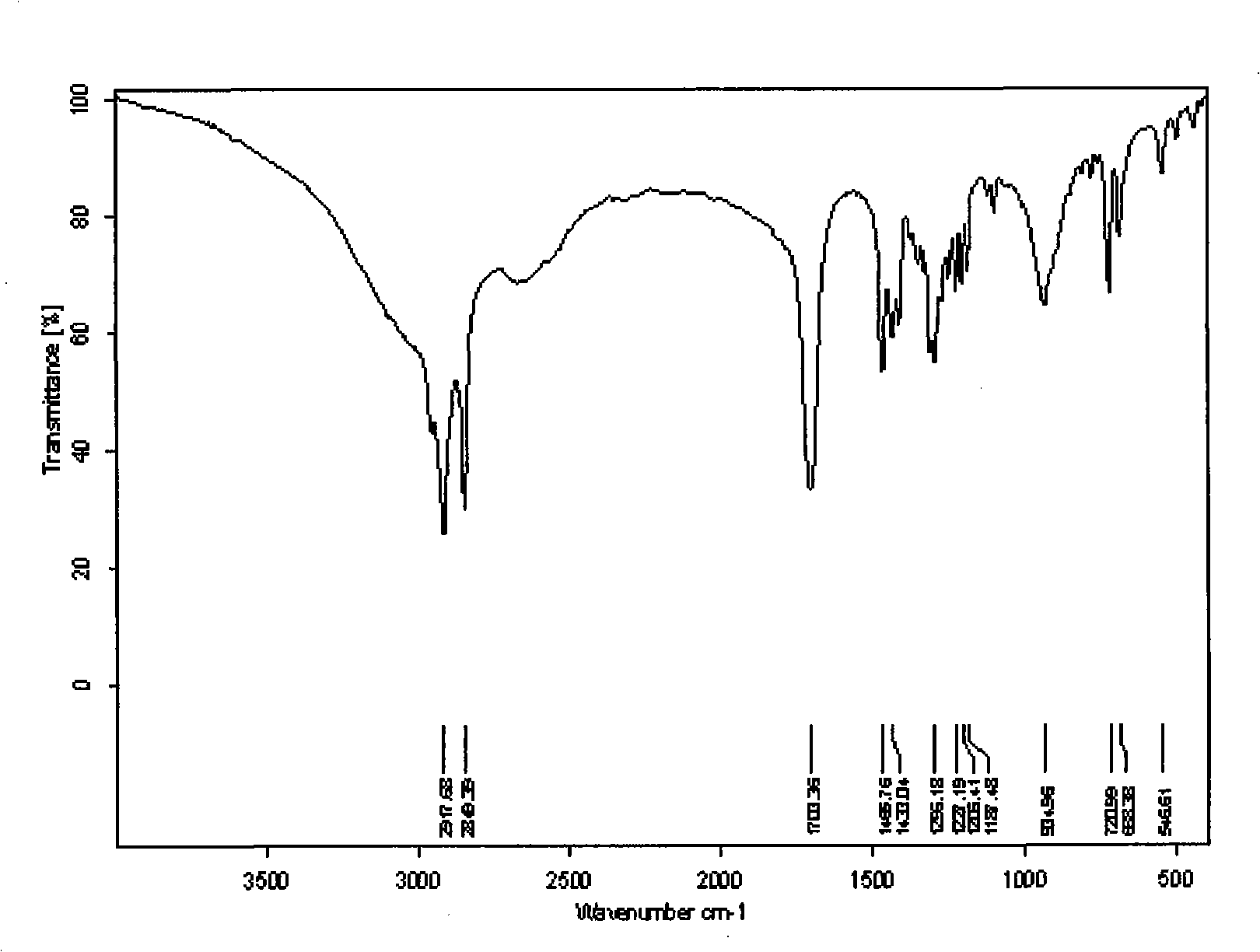

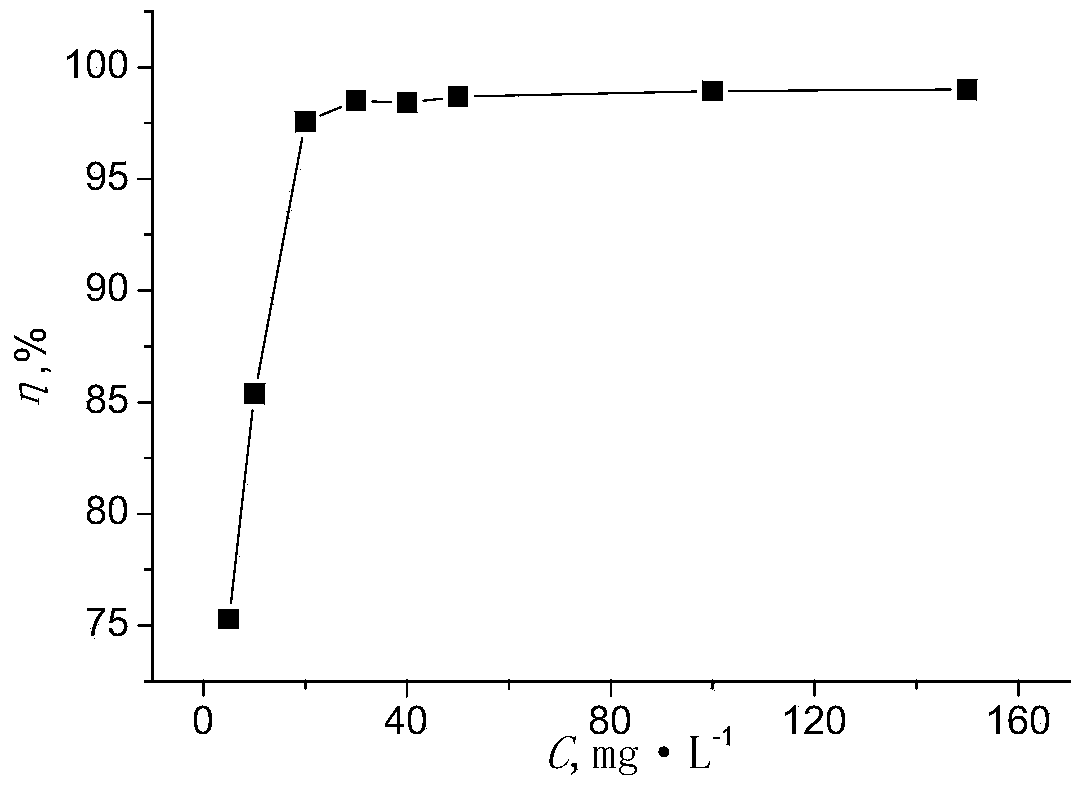

Composite gas drag reducer and preparation method thereof

ActiveCN103450471AGood energy saving effectRaw materials are cheap and easy to getPipeline systemsDibasic acidCarbon chain

The invention claims a composite gas drag reducer and a preparation method thereof. The method comprises the following step of: reacting organic dibasic acid or organic binary acid anhydride, organic amine and monocarboxylic acid with a long carbon chain, thereby obtaining the composite gas drag reducer, wherein the specific steps the reaction are as follows: (1) reacting the organic dibasic acid or organic binary acid anhydride and the organic amine in an inert atmosphere, (2) adding the monocarboxylic acid with the long carbon chain to the reaction system of the finished reaction in the step (1), thereby obtaining the composite gas drag reducer via reaction. The composite gas drag reducer is obvious in drag reduction of the pipeline gas and energy conservation, and has the advantages of cheap and easily available raw material, simplicity in operation, mild reaction conditions, simple processes, low equipment requirements and easiness for industrial production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Gas pipeline anti-drag composition and preparation thereof

ActiveCN101328443AGood drag reduction effectSource directlyPipeline systemsBase-materialsEnamineNitrogen gas

The invention relates to a gas pipeline drag reduction composition used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The composition is characterized in that: the composition consists of a long-chain acid mixture and enamine according to a molar ratio of between 1:1 and 1.5:1. The preparation method comprises the following steps that: after the long chain acid is added in a reactor and is heated to melting, the enamine is added and nitrogen is fed in to carry out protection and preheating; then, reflux and liquid separation are carried out; a method combining a programmed heating-up method, a vacuum method and an azeotropic agent is adopted to carry out reaction; and finally, when the reaction is finished, a product can be obtained after cooling down. The gas pipeline drag reduction composition has obvious drag reduction effect on gas pipelines, direct source of raw materials, simple operation, moderate reaction conditions, relatively simple process and low requirements on equipment, and is easy to realize large-scale industrialized production.

Owner:PIPECHINA SOUTH CHINA CO

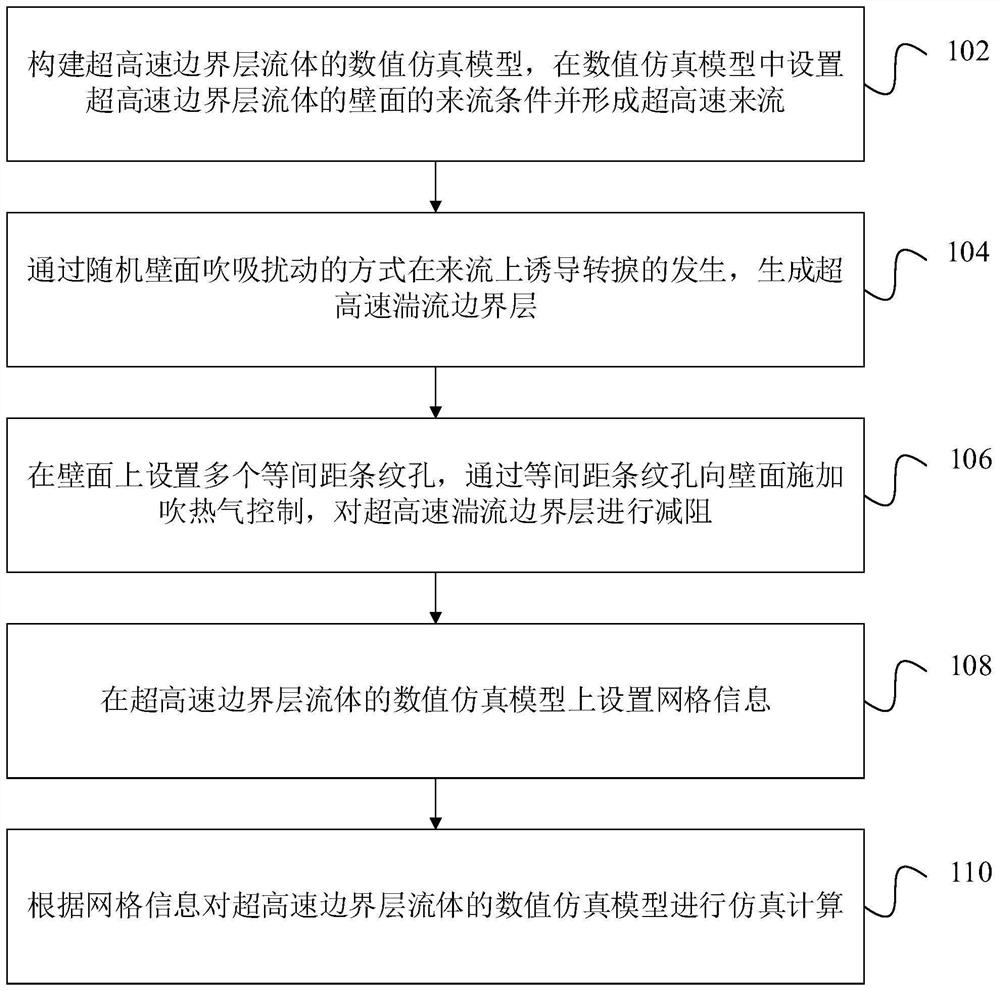

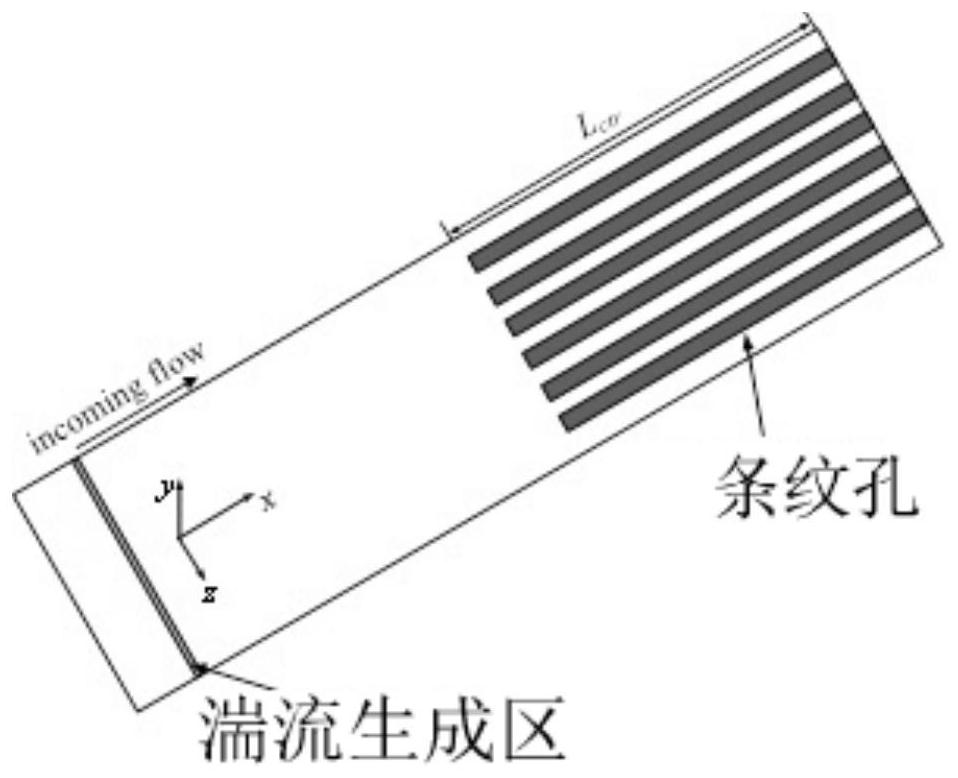

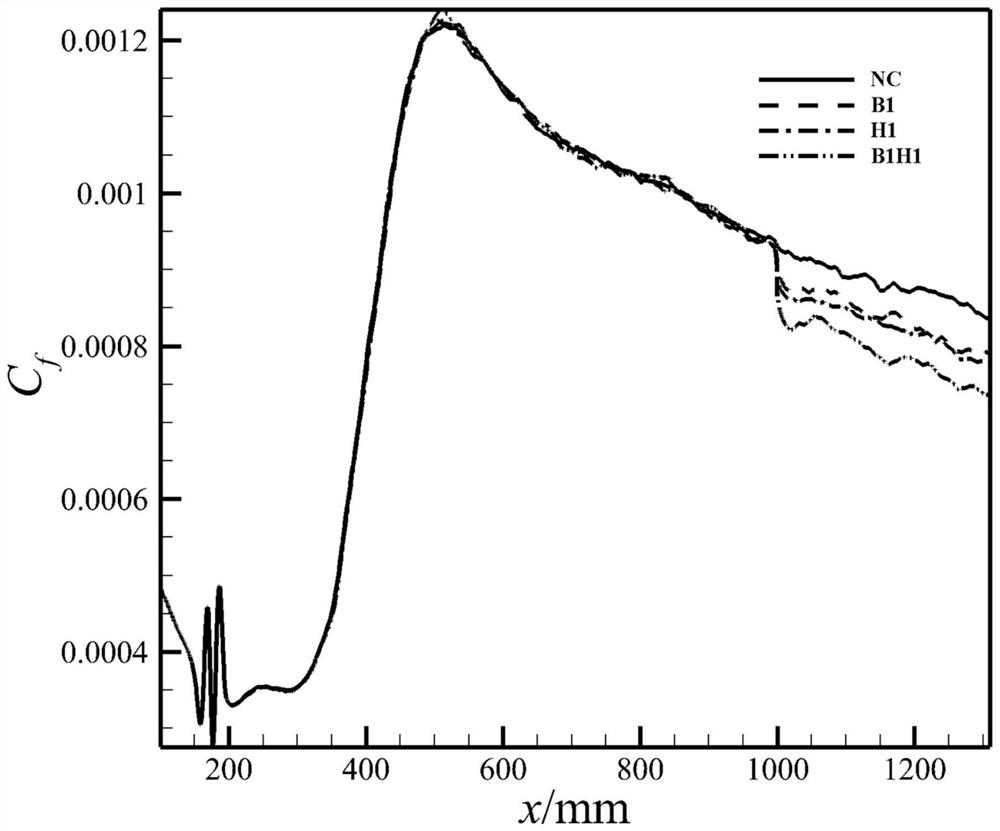

Ultra-high-speed turbulence boundary layer drag reduction control method

ActiveCN112395694AChange flow stateInhibit up-spray/down-sweep activityGeometric CADSustainable transportationUltra high speedFlight vehicle

The invention relates to an ultra-high-speed turbulence boundary layer drag reduction control method, a simulation method, a simulation device, computer equipment and a storage medium. The ultra-high-speed turbulence boundary layer drag reduction control method comprises the steps that array type stripe holes are formed in the local wall face, forming a turbulence boundary layer, of an ultra-high-speed aircraft in the flow direction, and when the aircraft flies at an ultra-high speed, hot air is blown to the wall face from the stripe holes through a wall face hot air blowing device arranged onthe surface of the ultra-high-speed aircraft; and drag reduction control is performed on the turbulence boundary layer of the ultra-high-speed aircraft. The simulation method comprises the steps thata numerical simulation model of superspeed boundary layer fluid is constructed, incoming flow conditions are set, transition is induced, and a superspeed turbulence boundary layer is generated; hot air blowing control is applied to the wall surface through the equidistant stripe holes; simulation calculation is carried out on the numerical simulation model according to the set grid information, and the effectiveness and superiority of the ultrahigh-speed turbulence boundary layer drag reduction control method based on speed and temperature coupling are analyzed.

Owner:NAT UNIV OF DEFENSE TECH

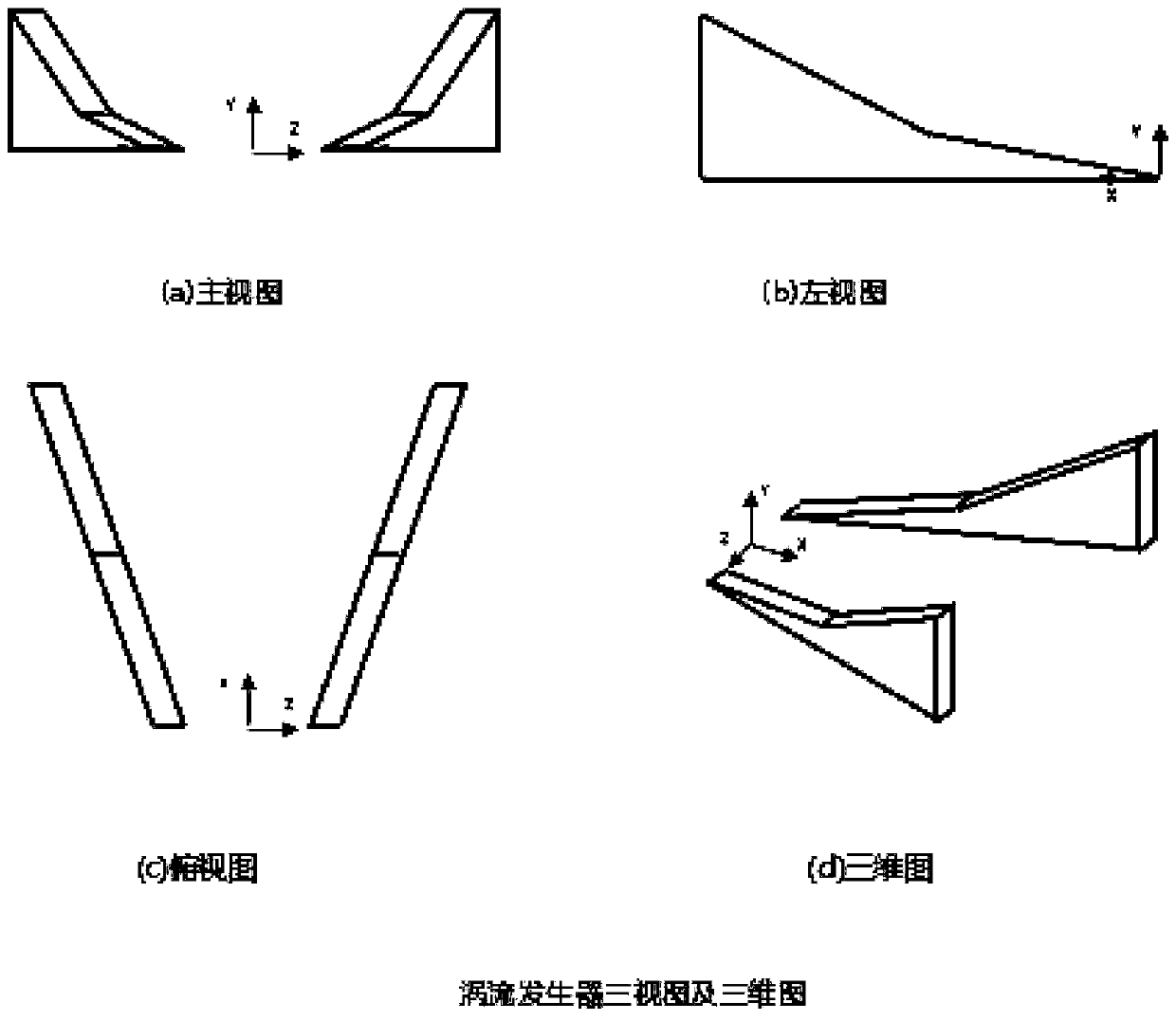

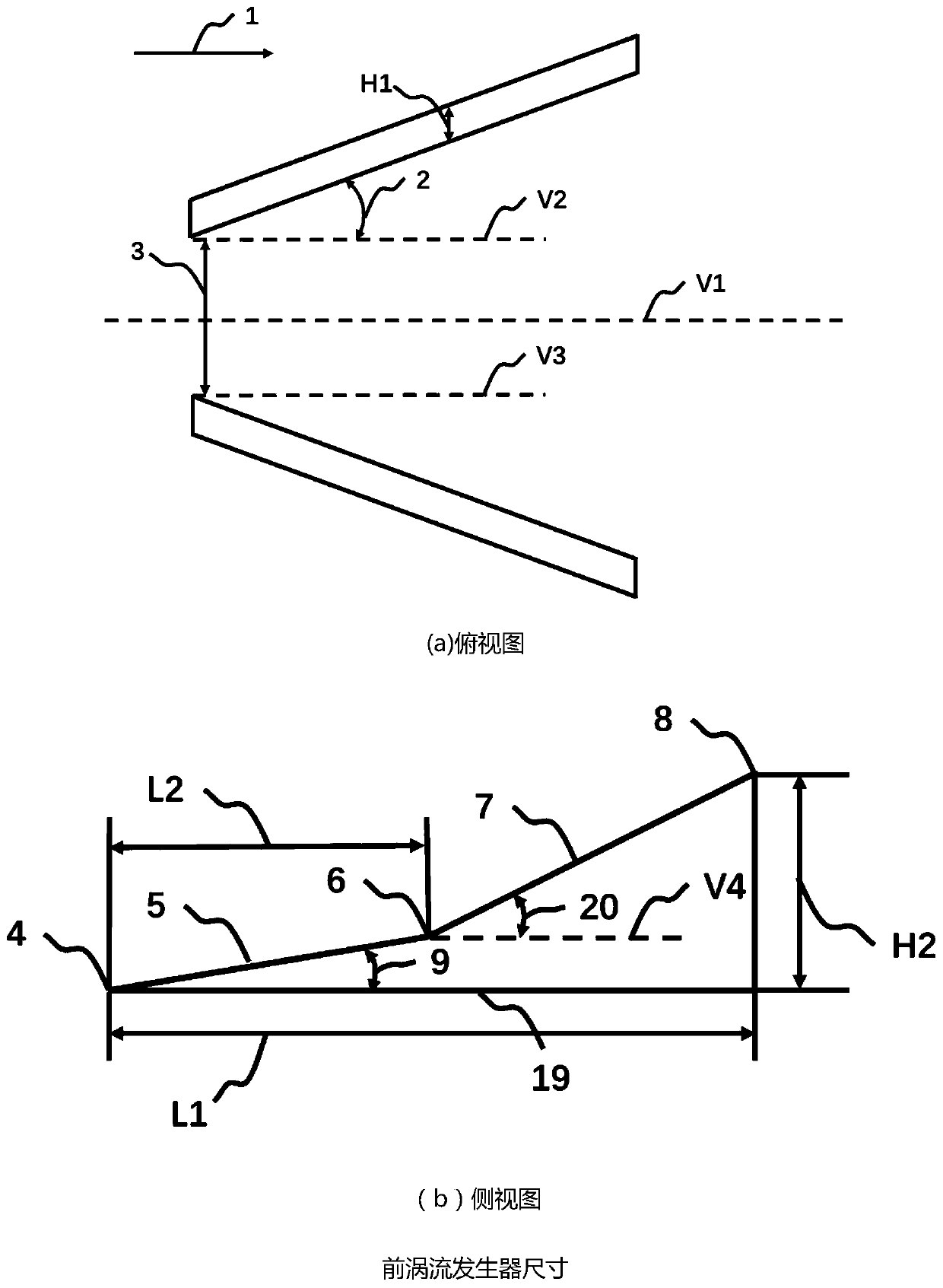

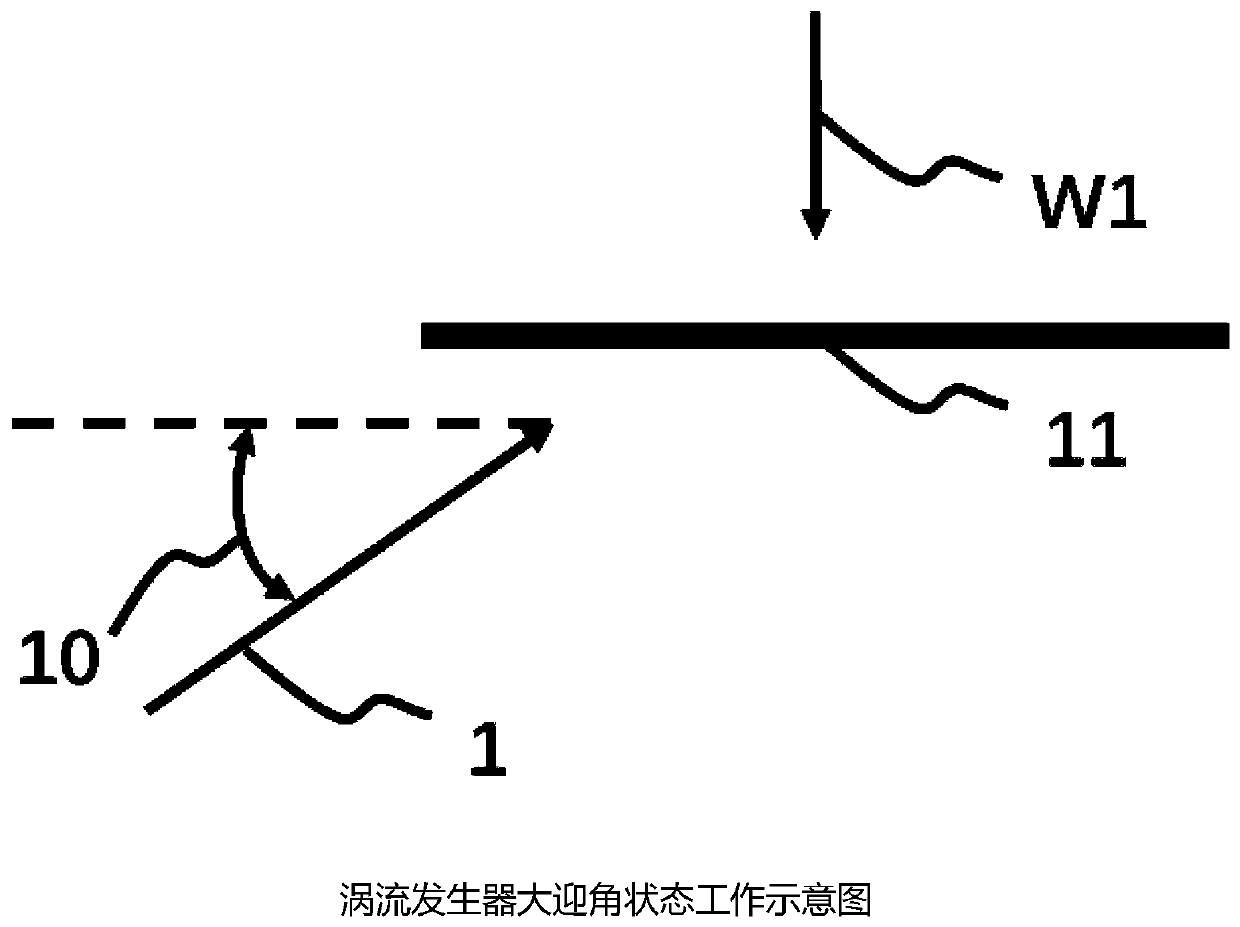

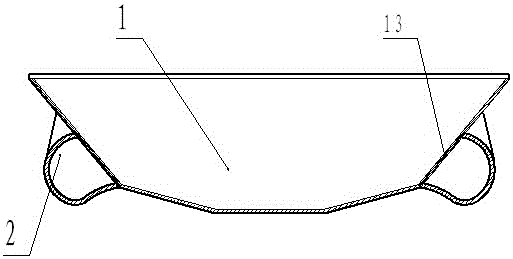

Vortex generator for reducing resistance of fuselage and delaying airflow separation

PendingCN110450942ATo achieve the purpose of drag reductionEasy to separateInfluencers by generating vorticesBoundary layer controlsFailure rateSingle chip

The embodiment of the invention discloses a vortex generator for reducing resistance of a fuselage and delaying airflow separation, and relate to the technical field of rotor aircraft manufacturing. According to the vortex generator, the passive control for the flowing of a flow field near the fuselage can be realized when a rotor aircraft encounters strong cross-wind or carries out side flight, so that the resistance of the rotor aircraft is reduced, and meanwhile, the implementation cost and the failure rate are reduced. The vortex generator provided by the invention comprises an installation angle (2) of the vortex generator, a first corner (9) of a single-chip vortex generator and a second corner (20) of the single-chip vortex generator, wherein a value of the installation angle (2) ofthe vortex generator is larger than or equal to 10 degrees and less than or equal to 45 degrees; the second corner (20) of the single-chip vortex generator is an included angle between an upper surface (7) of the second section and a connecting section (19) of the vortex generator and the object surface; a value of the first corner (9) of the single-chip vortex generator is less than 30 degrees;and a value of the second corner (20) is larger than or equal to 40 degrees and less than or equal to 60 degrees. The vortex generator is suitable for the passive control for the flow of the flow field near the fuselage when the rotor aircraft encounters the strong cross-wind or carries out side flight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

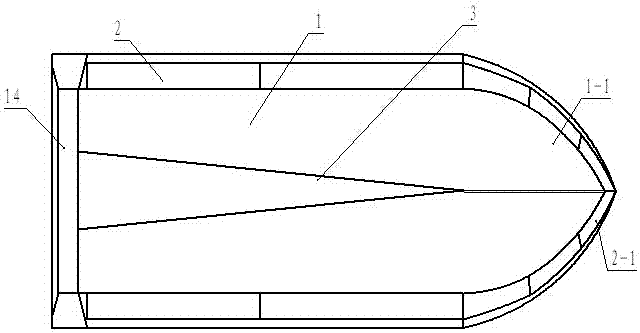

Novel energy-saving three-body ship form

InactiveCN106494564AIncrease inertiaIncrease dampingHydrodynamic/hydrostatic featuresKeelMarine engineering

The invention discloses a novel energy-saving three-body ship form. The novel energy-saving three-body ship form comprises a main ship body, two side bodies and connecting bridges, wherein the two side bodies are symmetrical relative to the central longitudinal profile of the main ship body; keel lines of the side bodies are parallel to a keel line of the main ship body; side body outer plates are inwardly inclined from a deep V angle line below a design waterline, and are integrally designed with an upper structure; side body inner plates are outwardly inclined from the deep V angle line below the design waterline; the stem part of the main ship body is of a clipper type, and a stem column is forwardly inclined; the stem parts of the side bodies are inwardly inclined in a wave piercing way, and stem columns are backwardly inclined; the stern parts of the main ship body and the side bodies are square and are flush with one another. Compared with the conventional three-body ship form, the novel energy-saving three-body ship form provided by the invention has the advantages and beneficial effects as follows: the novel energy-saving three-body ship reduces the radar wave radiating cross section area and the ship resistance, improves the invisibility and the fastness of radar wave, and is energy-saving and high in efficiency.

Owner:CHINA SHIP DEV & DESIGN CENT

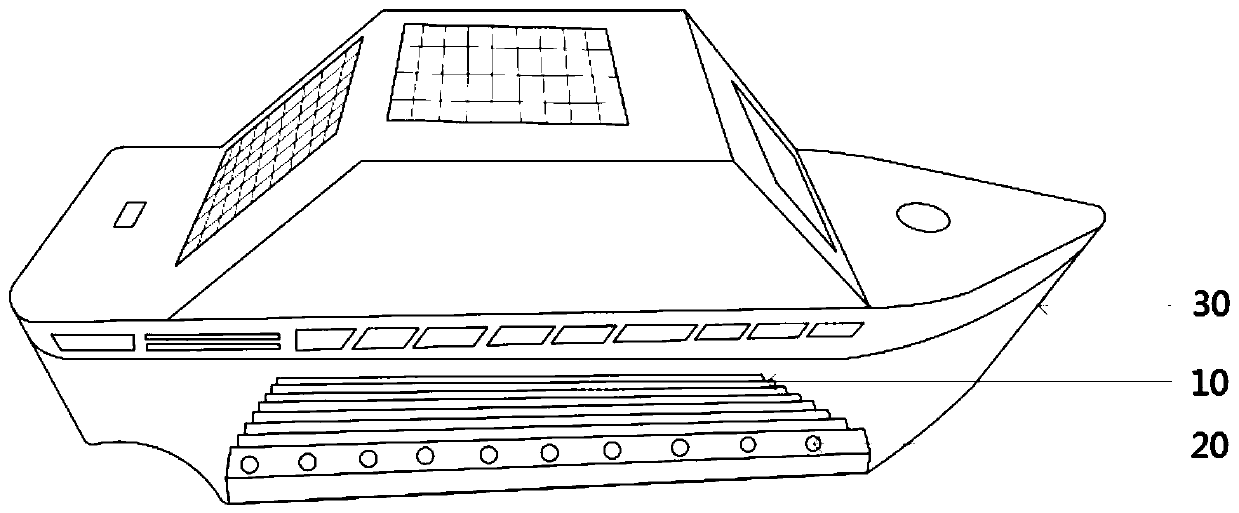

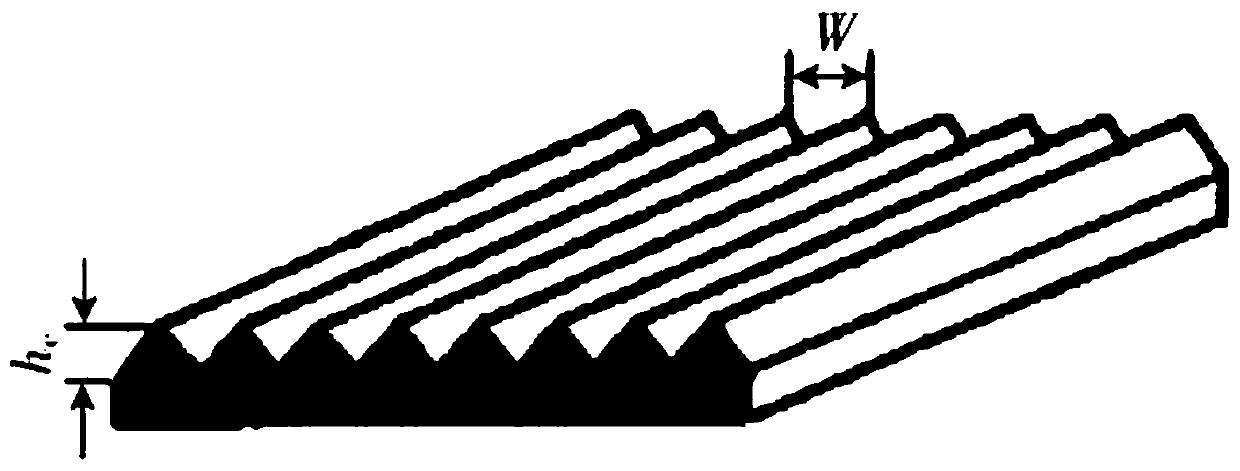

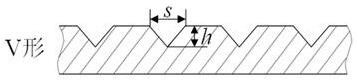

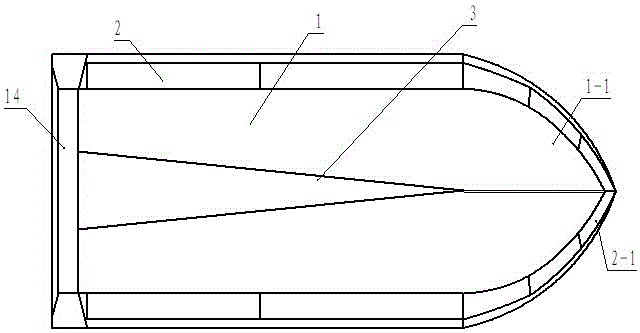

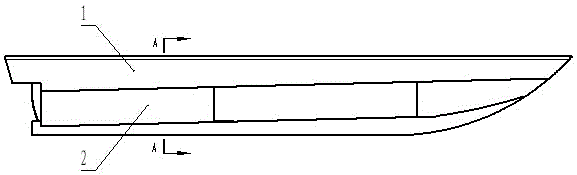

High-speed sailing vehicle combing micro-bubble drag reduction technology and groove surface turbulence drag reduction technology

InactiveCN110203323AReduce resistanceImprove drag reduction efficiencyWatercraft hull designHydrodynamic/hydrostatic featuresMicro bubbleNacelle

The invention relates to a high-speed sailing vehicle combining a micro-bubble drag reduction technology and a groove surface turbulence drag reduction technology. The high-speed sailing vehicle is characterized in that a plurality of parallel grooves which are parallel to each other are formed in the bottom surface of a ship body in the length direction of the ship body, the cross sections of thegrooves are square, U-shaped or V-shaped, the groove height hc of the grooves is equal to the width W of the grooves, the high-speed sailing vehicle further comprises a micro-bubble generation devicearranged inside a cabin, the micro-bubble generation device generates air bubbles and conveys the air bubbles to the bottom of the ship body through air pipes, the air pipes are laid inside the grooves, and exhaust holes are uniformly formed in the length direction of the grooves. According to the high-speed sailing vehicle, the grooves are designed at the bottom of the ship body, and the purposeof reducing the resistance is achieved by changing the flowing structure of the bottom layer of the boundary layer; and meanwhile, the exhaust holes are formed in the grooves, and the bubbles are discharged out of the surfaces of the grooves to generate a dispersed fine air curtain so that the resistance can be further reduced, the combined drag reduction effect can be achieved through the effective combination of the two drag reduction technologies, the drag reduction efficiency is improved, and then the rapidity of the sailing vehicle is improved.

Owner:WUHAN UNIV OF TECH

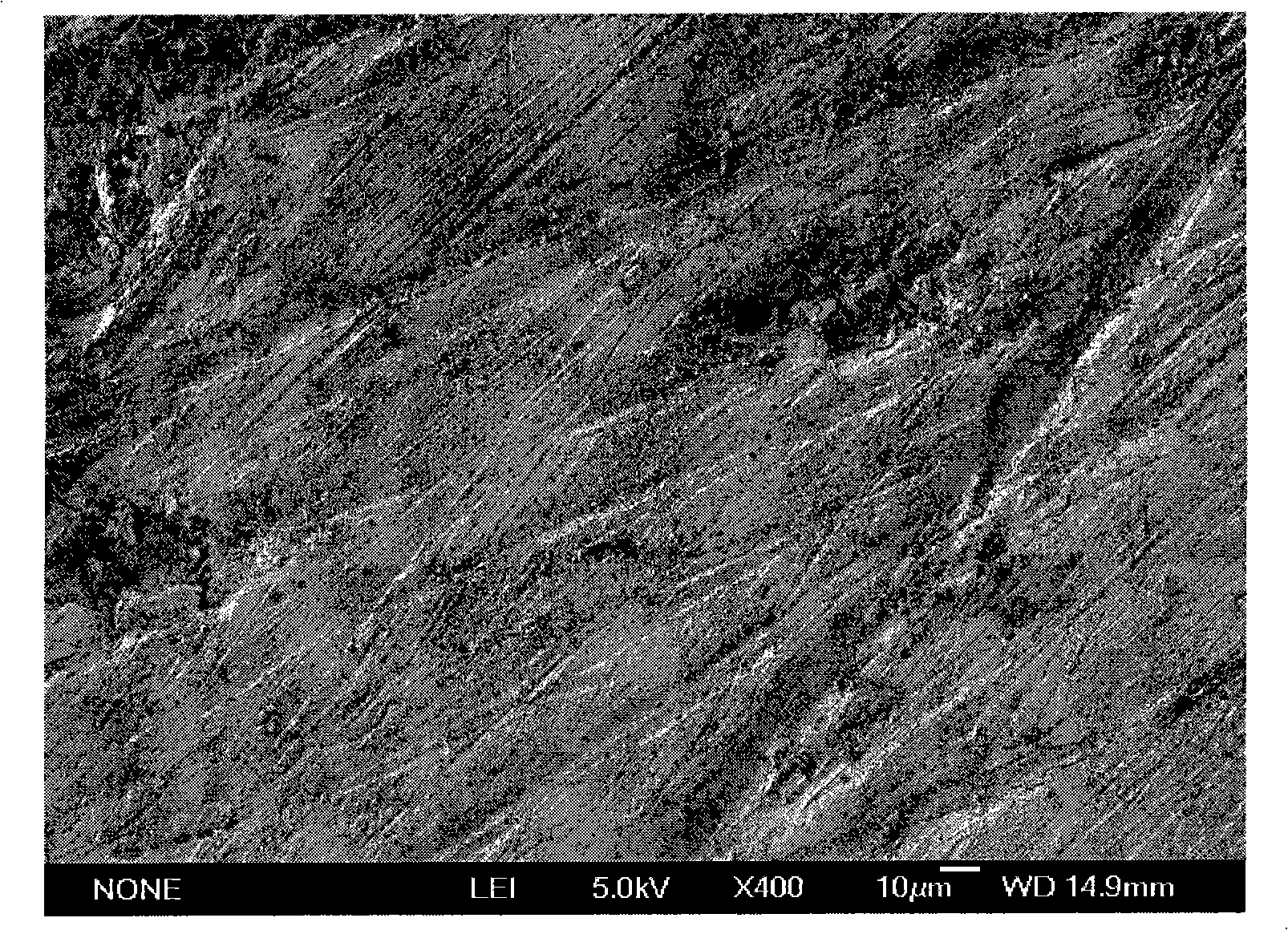

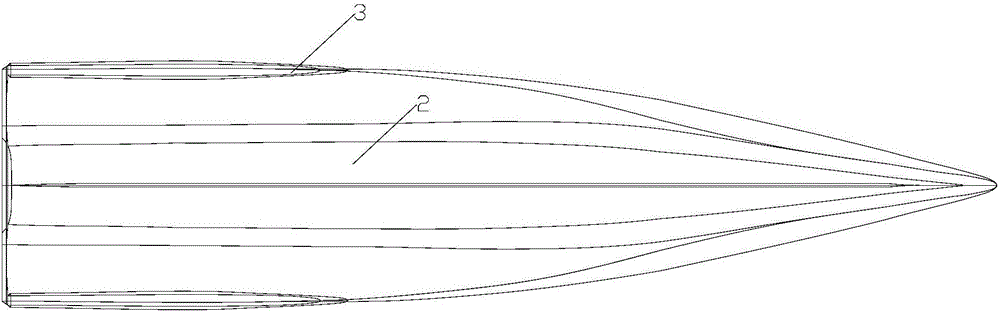

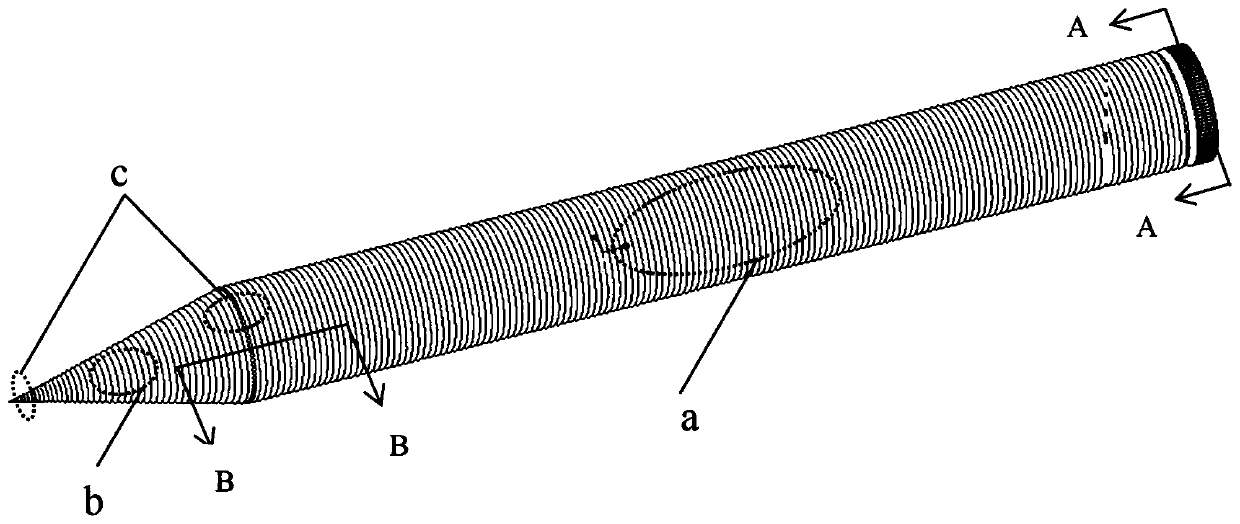

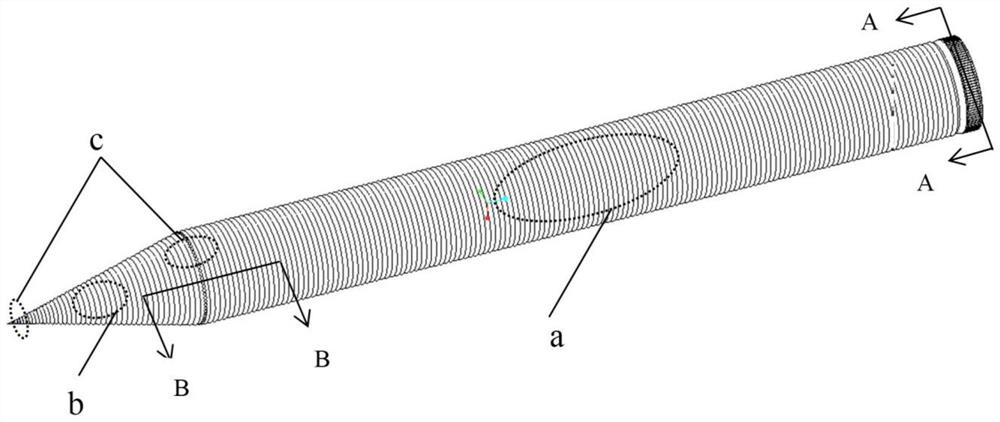

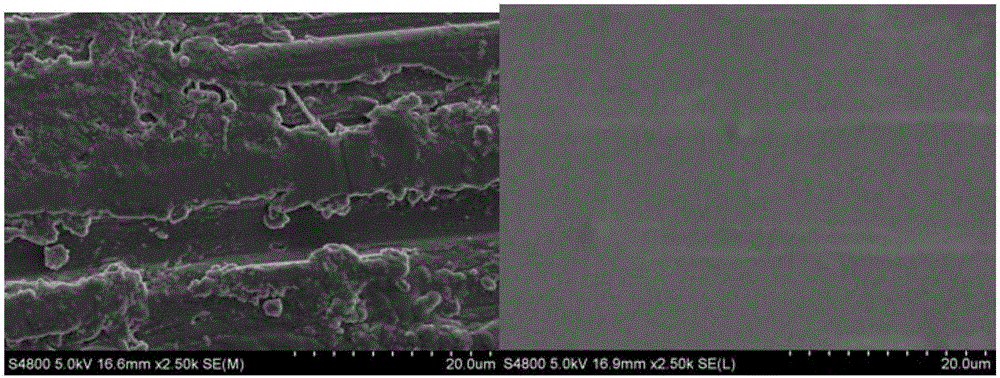

Underwater drag reduction bionic micro-nano structure

The invention discloses an underwater drag reduction bionic micro-nano structure which comprises U-shaped structures of bionic dolphin spine skin and sawtooth structures of bionic mosquito stylets. Aswimming bladder comprises a conical body structure at the front end and a cylindrical body structure at the rear end, the sawtooth structures are distributed on the surface of the conical body structure, and the U-shaped structures are distributed on the surface of the cylindrical body structure. According to the invention, the micro structures of bionic dolphin spine skin and the micro structures of bionic mosquito stylets are adopted, and the novel micro-nano combined structure is formed by combining the two micro-structures and is applied to the swimming bladder, and a good drag reductioneffect is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

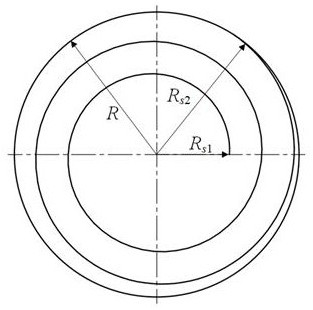

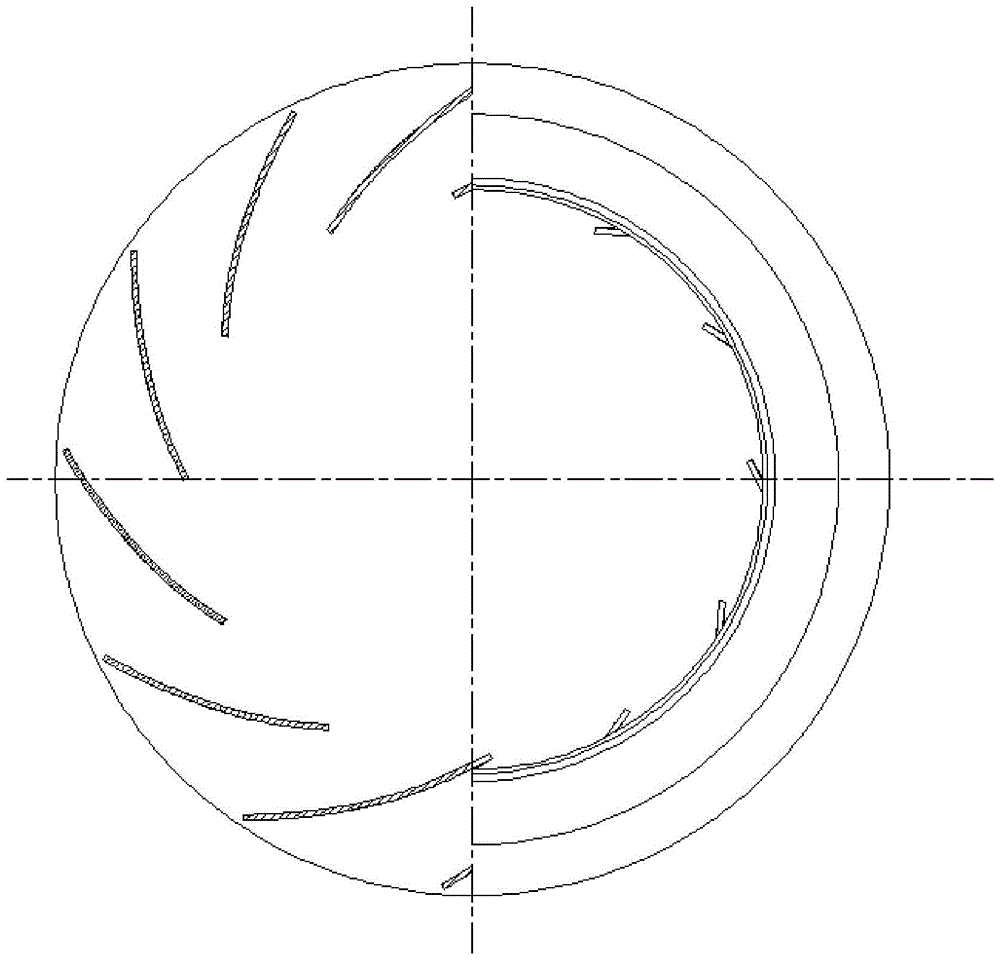

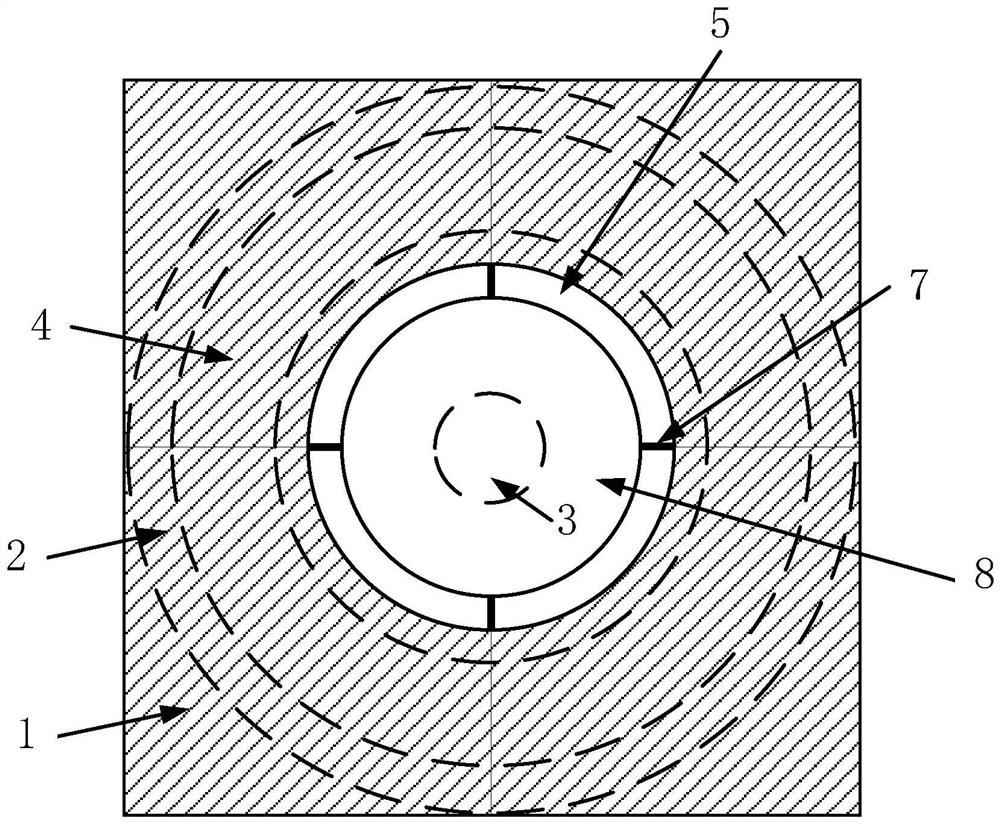

Dynamic and static cavity flow micro-groove drag reduction design method

PendingCN111723447ATo achieve the purpose of drag reductionGeometric CADDesign optimisation/simulationEngineeringMechanical engineering

The invention relates to a dynamic and static cavity flow micro-groove drag reduction design method. A space molded line equation set of the micro groove is established by considering circumferentialand radial flow of a near-wall area of the movable disc. Firstly, working parameters of a dynamic cavity and a static cavity are given, the equation set is solved through a numerical method, and the space molded line of the micro-groove is obtained. Then, the shape of the cross section of the micro-groove is selected, the height and arc length of the cross section of the micro-groove are designed,and the number of the micro-grooves is selected; and finally, micro-grooves are machined in the movable disc in combination with the space molded lines of the micro-grooves and the geometrical parameters and number of the cross sections of the micro-grooves. According to the invention, the purpose of reducing resistance is achieved by processing the micro-grooves on the movable disc.

Owner:YANGZHOU UNIV

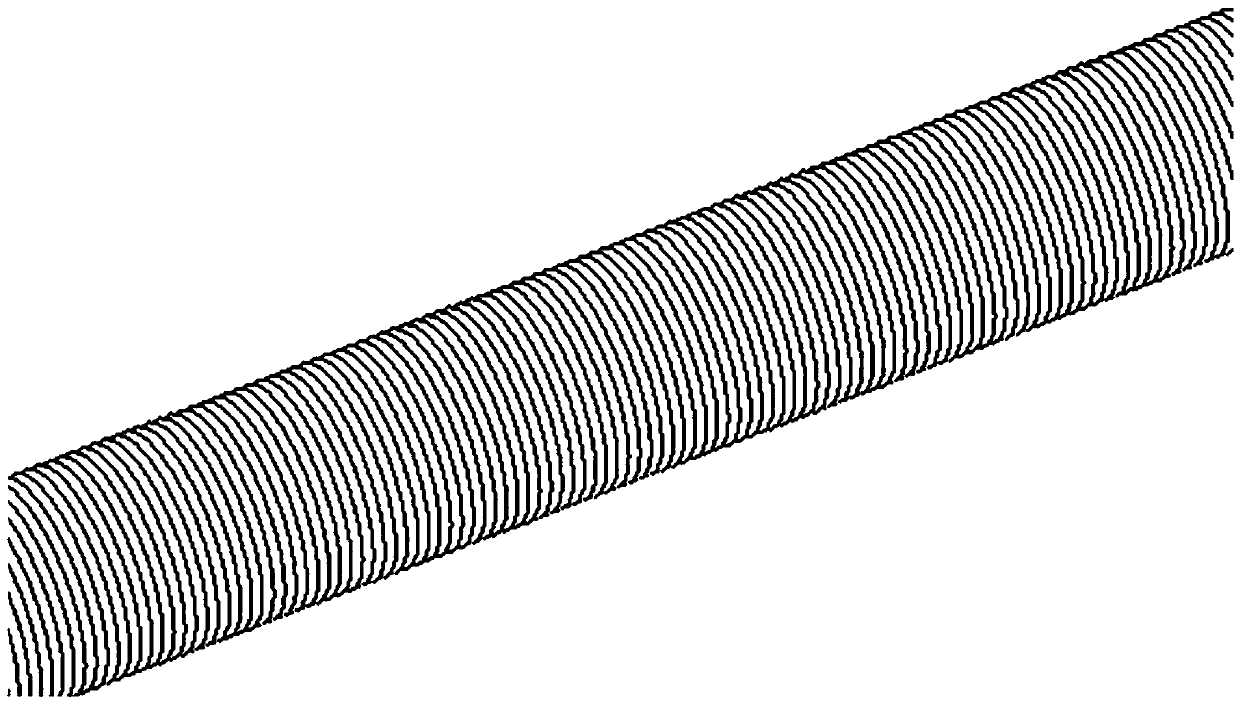

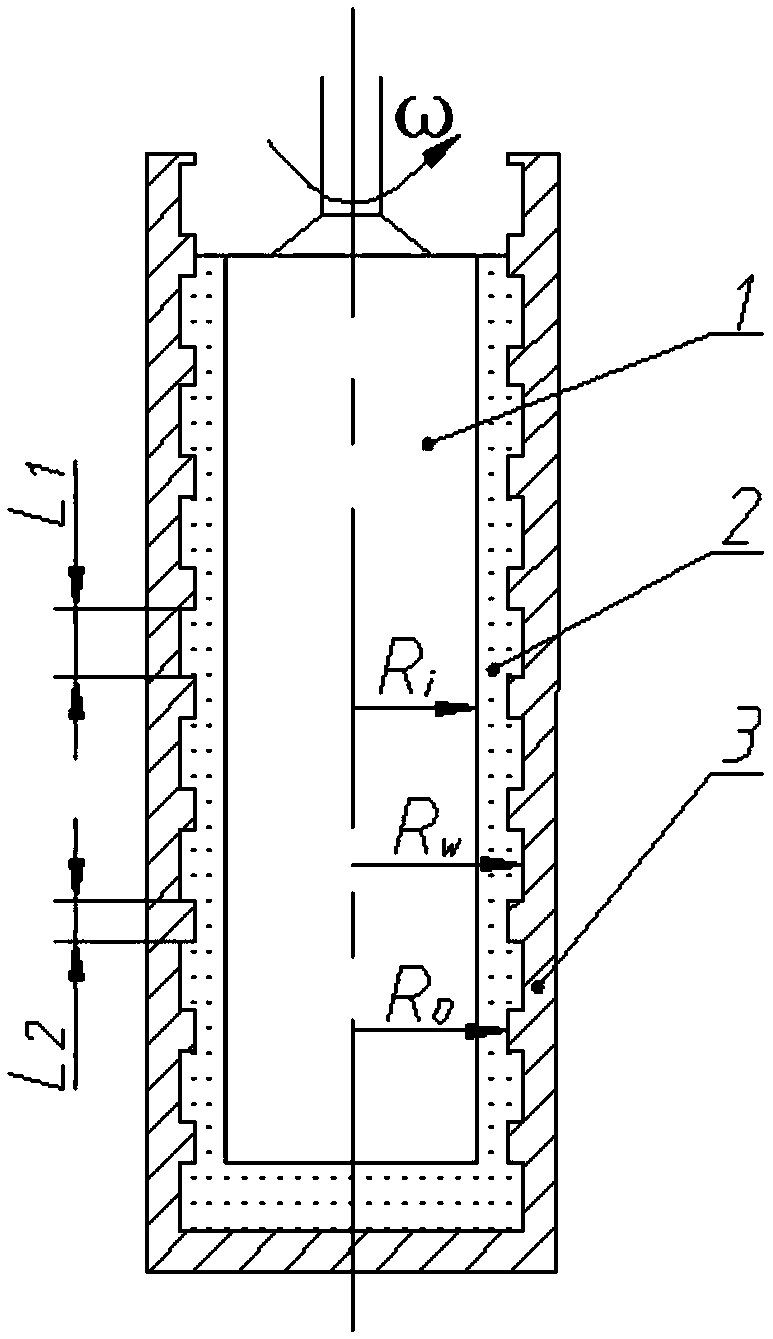

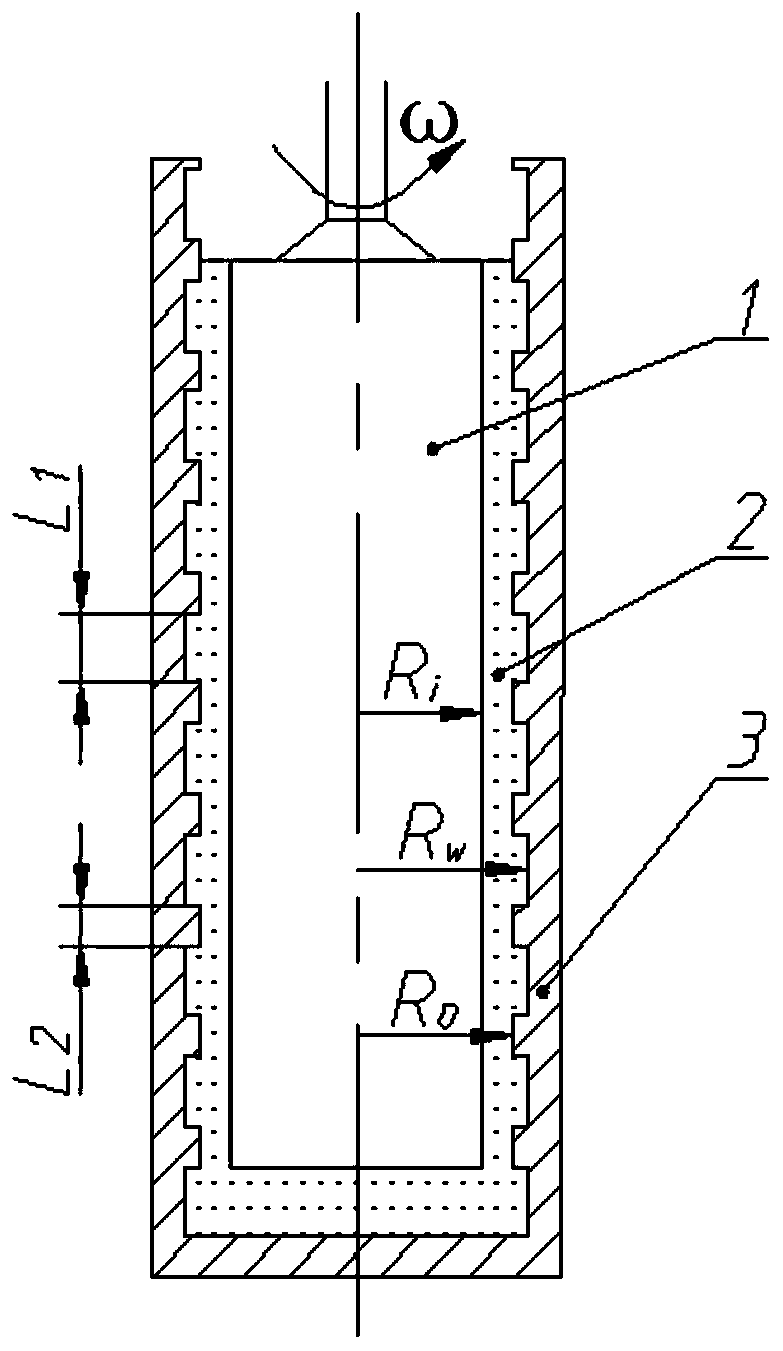

Damping device and damping method based on periodical step cylindrical surface

The invention discloses a damping device and a damping method based on the periodical step cylindrical surface. According to the damping device and the damping method, through the periodicity of reverse rotating Taylor vortices under the Taylor-Couette flow conditions, the size of the Taylor vortices is changed, and the number of the big-size Taylor vortices is reduced. By arranging periodical cylindrical surfaces with different radii on the inner wall of a shaft sleeve in the axial direction and controlling the height of the liquid level in the gap between a rotary shaft and the shaft sleeveduring Taylor-Couette flow, the rotating speed of the rotary shaft and the injection speed of working fluid are controlled to achieve the hysteresis effect of the Taylor vortices under different injection speeds. By slowly increasing the liquid level height of the working fluid between the rotary shaft and the shaft sleeve, the size and number of the Taylor vortices are changed, so that the size of the Taylor vortices is changed, and the number of the big-size Taylor vortices is reduced. Accordingly, resistance of the rotary shaft is reduced. The damping device has the characteristics that thedamping device is fast and convenient to manufacture and low in cost, and the damping method is remarkable in damping effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

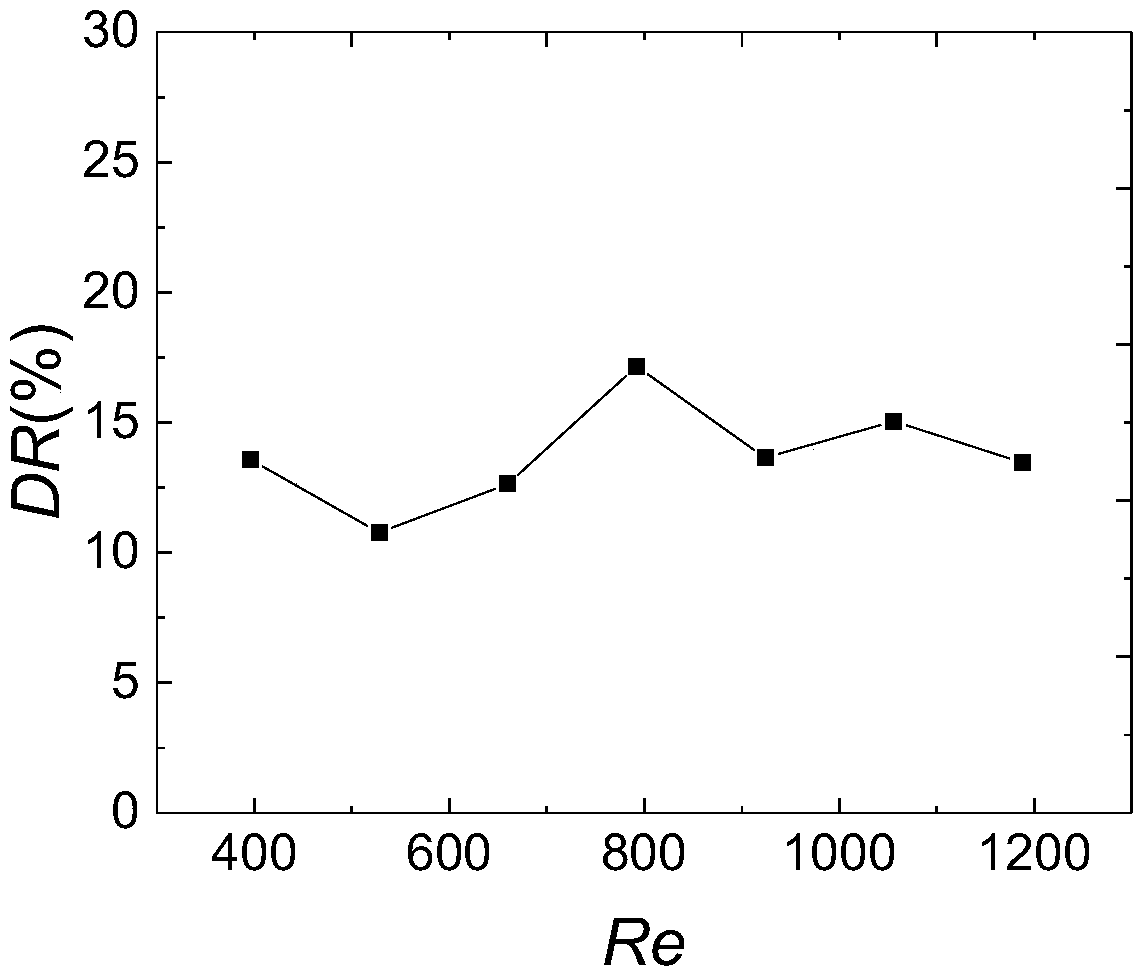

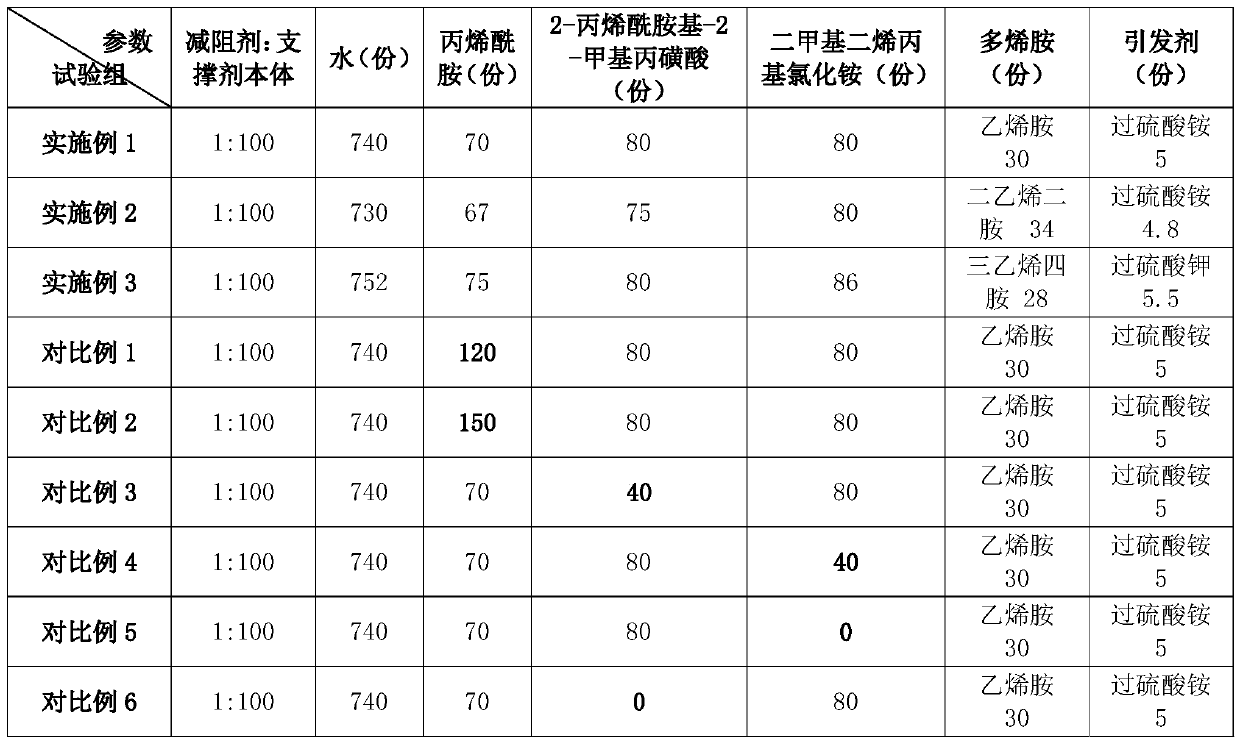

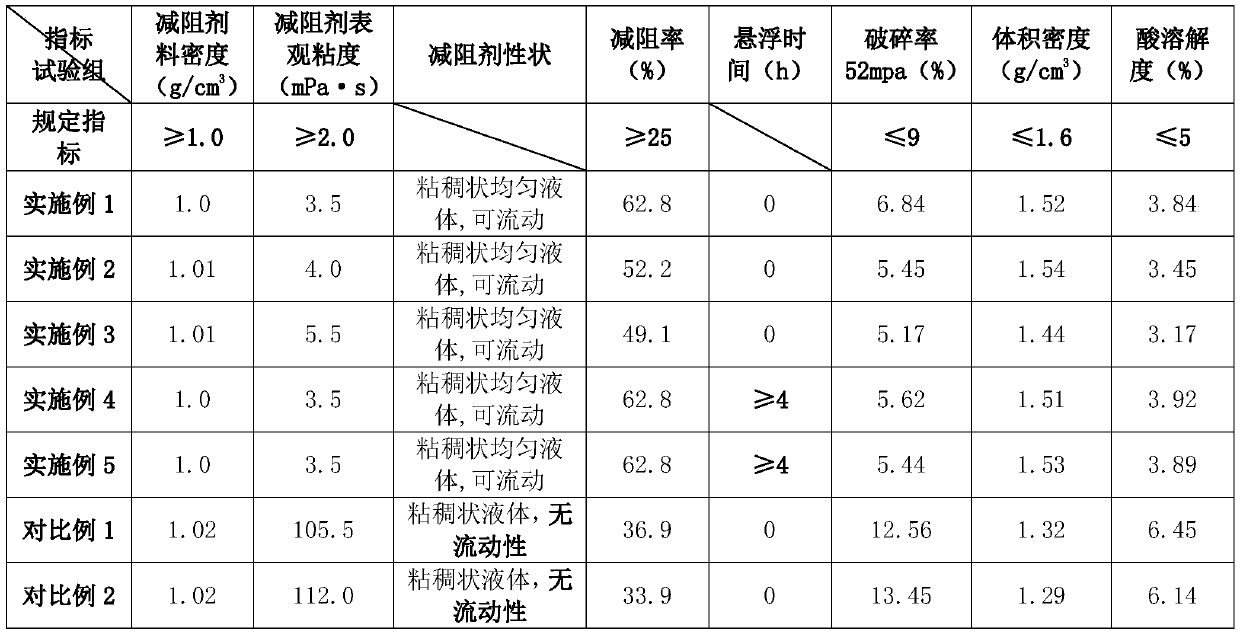

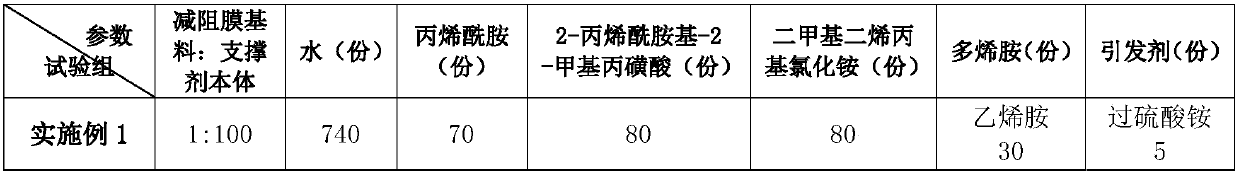

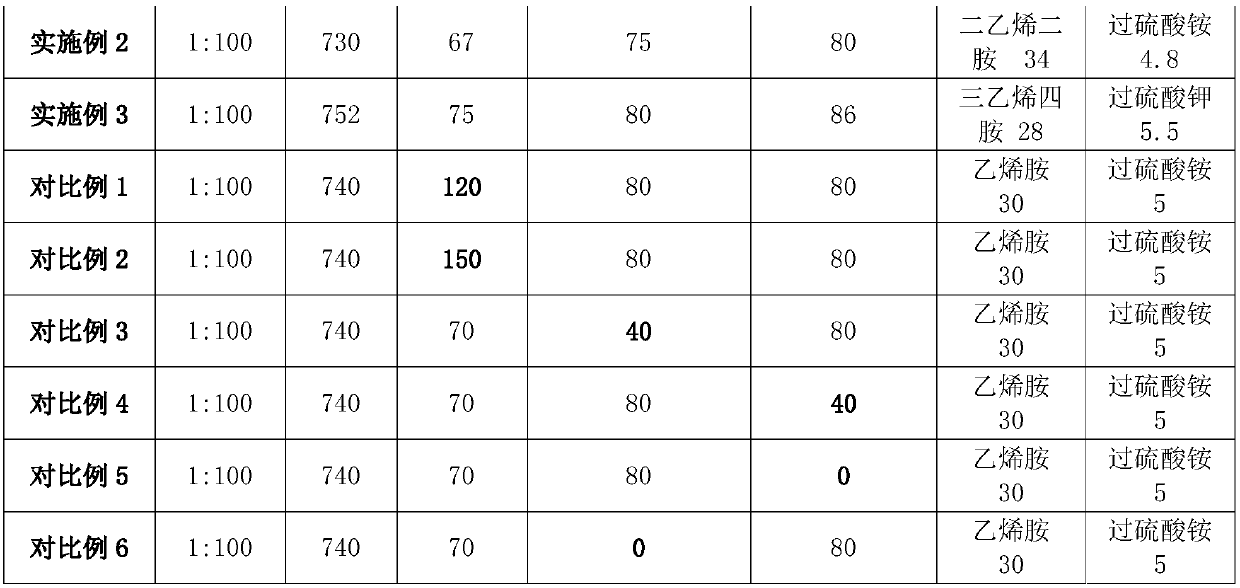

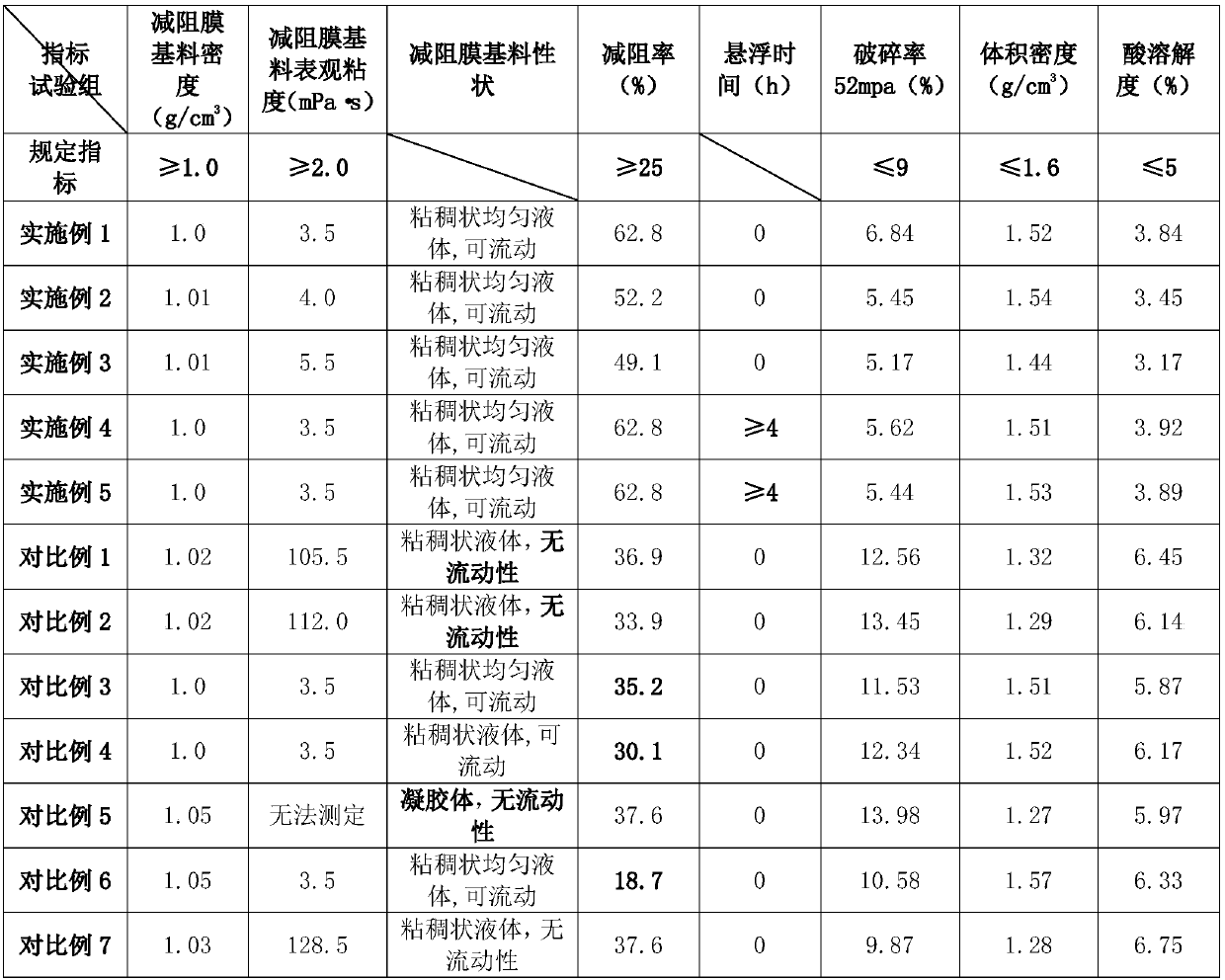

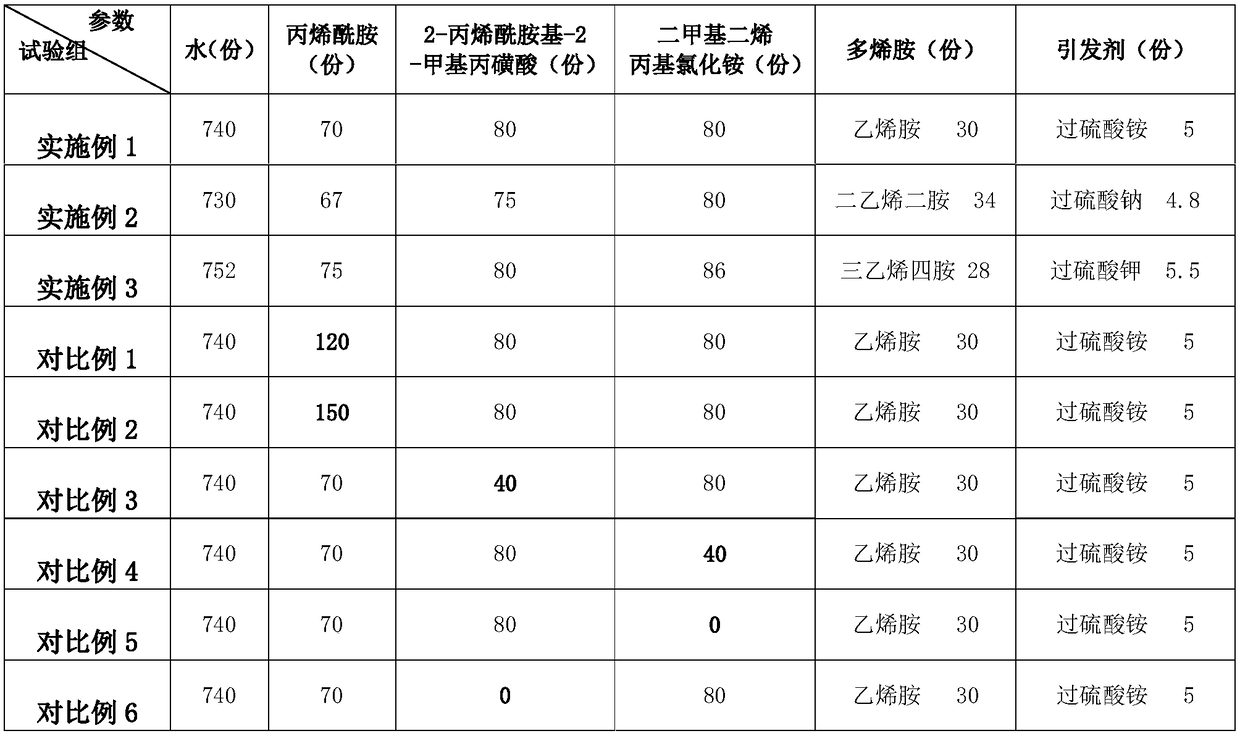

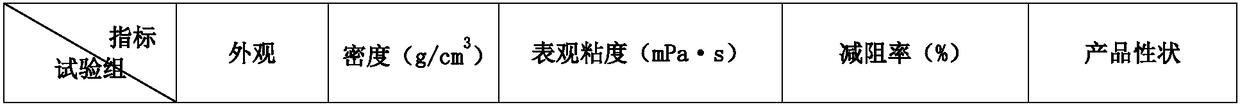

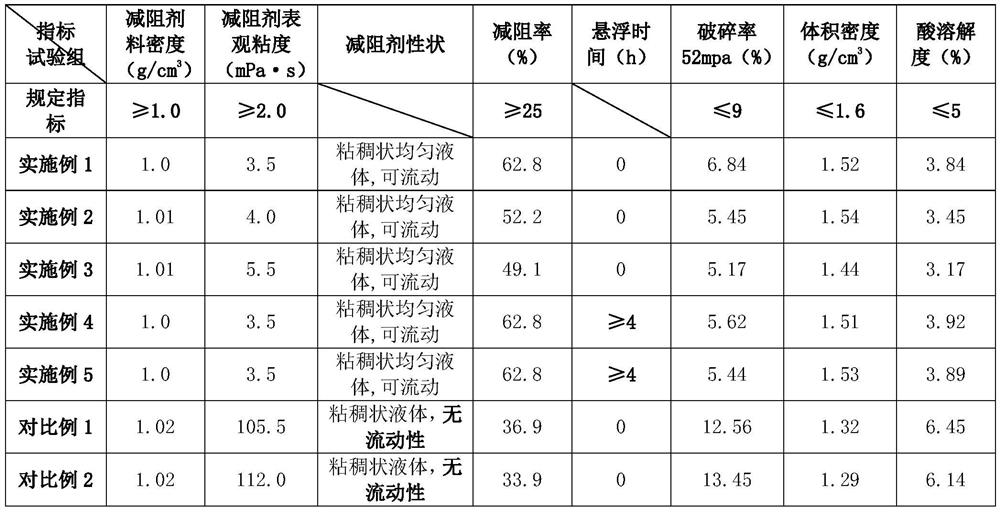

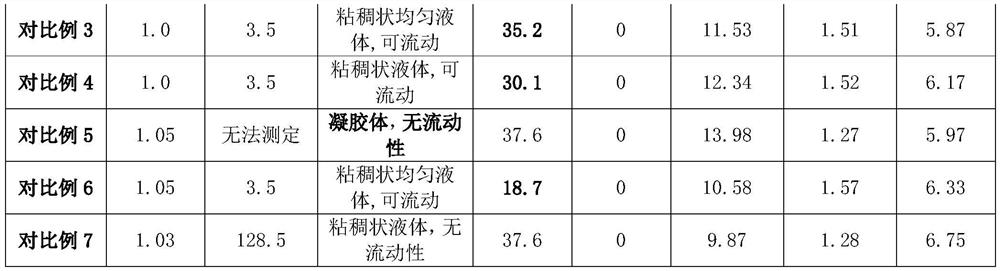

Preparation method of film covered supporting agent for fracturing

The invention belongs to the technical field of compositions for improving breaking effects, and specifically discloses a preparation method of a film covered supporting agent for fracturing. The method comprises the following steps: (1) preparing raw materials; (2) adding water to a reaction kettle, and increasing the temperature; (3) stirring; adding acrylamide, 2-acryloylamino-2-methallyl sulfonate, polyene amine and dimethyl diallyl ammonium chloride; and continuously stirring after adding the raw materials; (4) stirring when the temperature of the materials is maintained at 65-75 DEG C; adding an initiator; and continuously stirring for 4-7min; (5) reacting for 3.5-4.5h to obtain a drag reducer; and discharging when the drag reducing rate of the drag reducer is more than 25%; otherwise, adding a sodium hydroxide solution for adjusting; and (6) mixing the drag reducer and a supporting agent body on the basis of the mass ratio of 0.8-1.5 to 100; and covering the drag reducer on thesurface of the supporting agent body to obtain the film covered supporting agent for fracturing.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Floating bearing of turbocharger

InactiveCN106545577AFlow through effectivelyReduce shear resistanceShaftsBearing componentsTurbochargerLubrication

The invention discloses a floating bearing of a turbocharger. The floating bearing comprises a floating bearing body, namely a floating sleeve, wherein a plurality of annular oil grooves are formed in inner and outer surfaces of the floating sleeve; the cross section of each annular oil groove is isosceles triangle-shaped; a ridge structure is arranged between every two adjacent annular oil grooves; through oil holes which penetrate through a wall of the floating sleeve are uniformly formed in the floating sleeve along a circumferential direction and an axial direction; and penetration positions of the oil holes are located on the ridge structures. The floating bearing has the beneficial effects that the annular oil grooves on the inner and outer surfaces of the floating sleeve form an unsmooth surface, and shearing resistance formed when lubrication oil flows by the unsmooth surface provided with the longitudinal annular oil grooves is smaller than that formed when the lubrication oil flows by a smooth surface, so that the lubrication oil can effectively flow by the surface, and an aim of drag-reduction is reached. Furthermore, the through oil holes are uniformly formed in the floating sleeve, and on the condition that the lubrication oil is used for lubrication, the oil holes have high capability of lubrication oil storage and oil film forming.

Owner:BEIJING UNIV OF TECH

Large cascaded shear model box internally provided with electromagnetic damping devices, and use method thereof

ActiveCN105926691AAchieve weight lossEasy to meet the requirements of self-respectFoundation testingMagnetic polesElectrical polarity

The invention discloses a large cascaded shear model box internally provided with electromagnetic damping devices. The model box is formed by cascading rectangular frames formed by welding square steel tubes at an equal interval, wherein sheet magnets are bonded and fixed on the inner top surfaces of the square steel tubes along a vibration direction; a steel cross beam embedded with a plurality of iron cores contactlessly penetrates through each steel tube, and the polarities of magnetic poles of an upper working surface of each iron core and a lower surface of the corresponding sheet magnet are enabled to be the same; the two ends of each cross beam are connected with screws suspended on a cross beam of a counter-force frame respectively; and cross beams with iron cores are arranged on a plurality of frame layers to form a multilayer damping system. According to the model box disclosed by the invention, electromagnets generate an upward electromagnetic repulsion force with the sheet magnets, and generate an attraction force for the lower bottom surfaces of the steel tubes in the case of power-on, a part of the dead weight of the frame layer where the electromagnets are located is transferred to be born by the cross beam, and transferred to the counter-force frame outside a vibration table surface, thus an interlayer damping effect of the model box is realized. The model box disclosed by the invention is simple in structure and capable of being repeatedly used.

Owner:TAIYUAN UNIV OF TECH

Fracturing lamination propping agent

InactiveCN109575909AModerate viscosityImprove liquidityFluid removalDrilling compositionPolymer chemistryDimethyldiazene

The invention belongs to the technical field of compositions for enhancing rupturing, and particularly discloses a fracturing lamination propping agent which comprises a propping agent body and a dragreduction film covering the surface of the propping agent body. The drag reduction film is prepared from water, acrylic amide, 2-acrylamide-2-methyl propanesulfonic acid, polyenamine, dimethyl diallyl ammonium chloride and initiators. The fracturing lamination propping agent has good drag reduction performance and suspension property, can be directly placed into clear water to perform fracturingconstruction, and is convenient and reliable to use.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

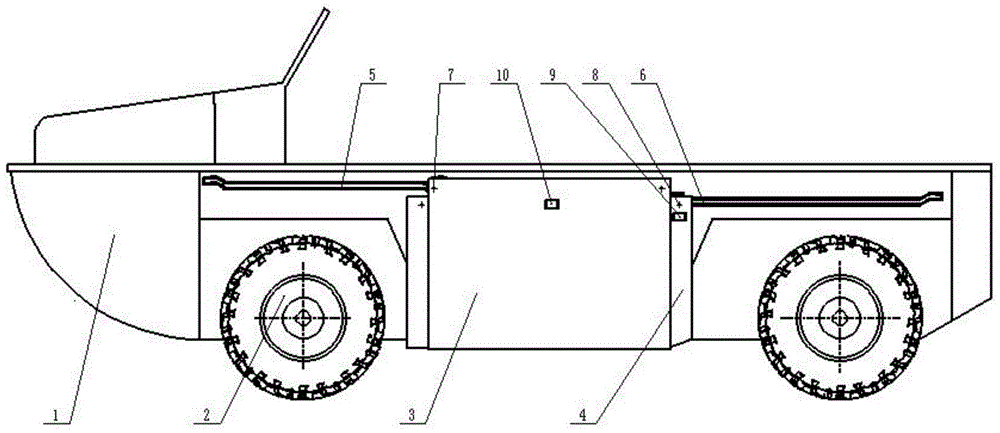

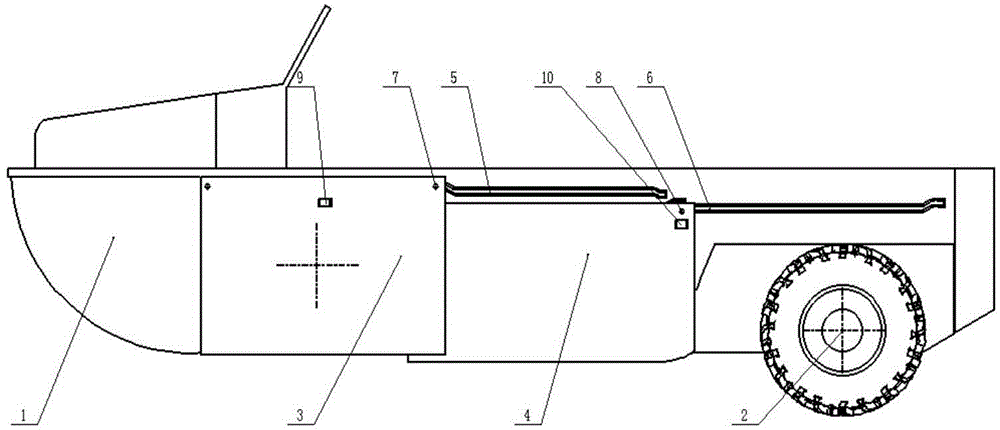

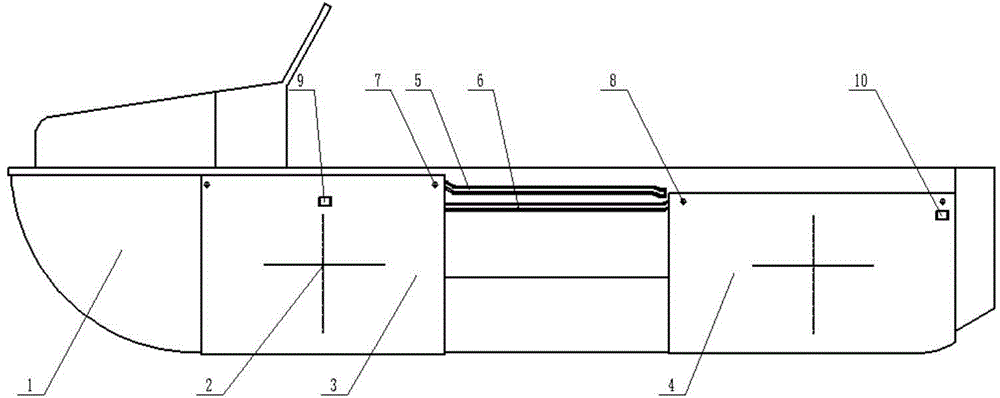

Drag reduction mechanism for wheel type multipurpose vehicle

InactiveCN104149564AThe principle of mechanism is simpleSimple structureConvertible vehiclesAutomotive engineering

A drag reduction mechanism for a wheel type multipurpose vehicle comprises a vehicle body, wheels, a front drag reduction baffle, a rear drag reduction baffle, a front slide rail, a rear slide rail, a front roller, a rear roller, a front baffle handle, a rear baffle handle and a rear baffle water inlet groove. The front slide rail and the rear slide rail are assembled on the two sides of the vehicle body, and the front drag reduction baffle and the rear drag reduction baffle are matched with the front slide rail and the rear slide rail to move in a back and forth mode through the front roller and the rear roller which are assembled on the inner sides of the upper portions of the two sides. The front drag reduction baffle and the rear drag reduction baffle reach the designated spot to wrap the wheels by means of the front roller and the rear roller after the wheels are put away, and drag reduction effect is achieved. The rear baffle water inlet groove is formed in the rear drag reduction baffle. Drag reduction devices similar to a sliding door type are additionally arranged at the two ends of the vehicle body of the multipurpose vehicle after the front wheels and the rear wheels are put away, so that the problem that the multipurpose vehicle cannot meet requirements of dynamic property and economical efficiency at the same time in design and use due to overlarge resistance when the multipurpose vehicle drives in water is solved.

Owner:BEIHANG UNIV

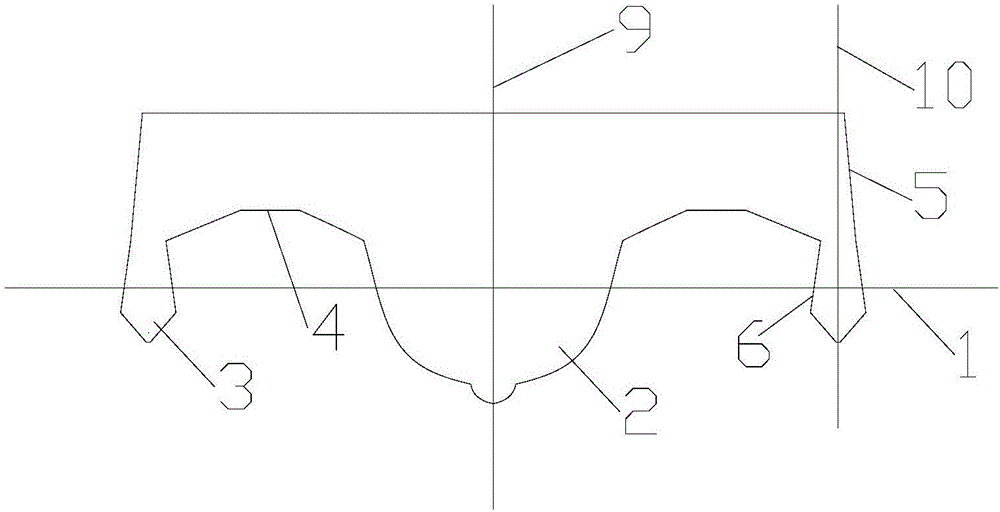

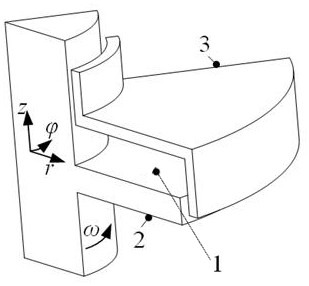

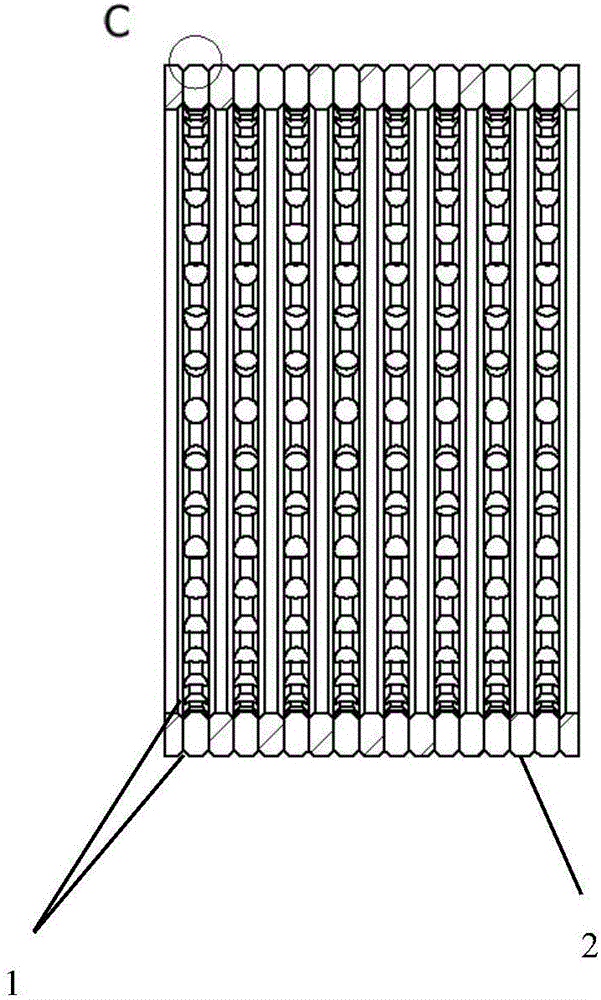

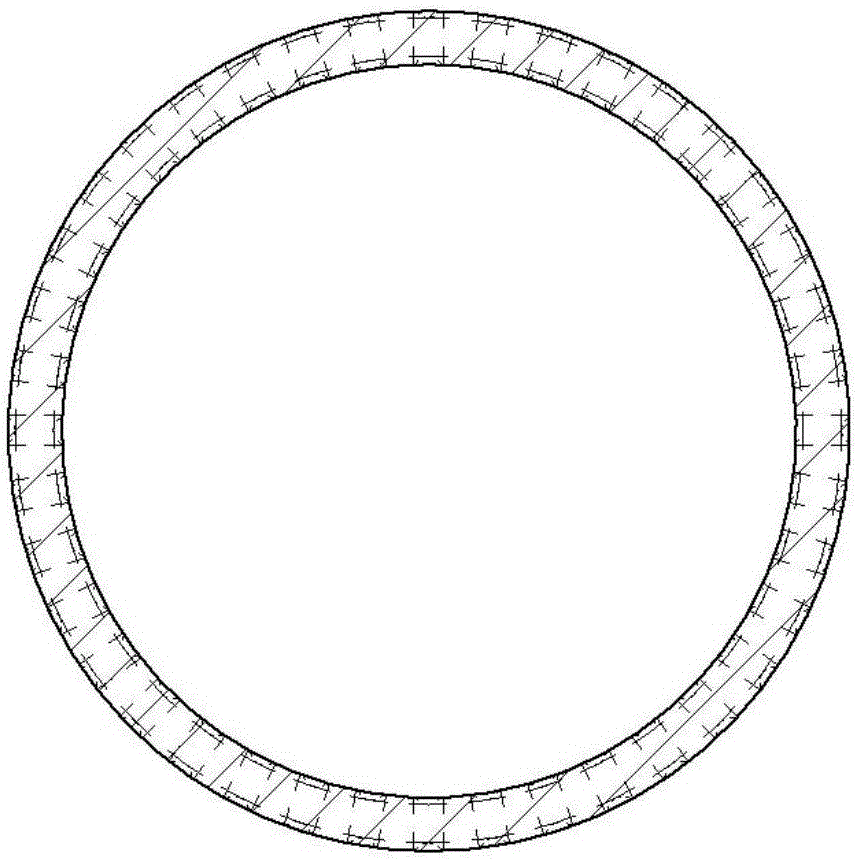

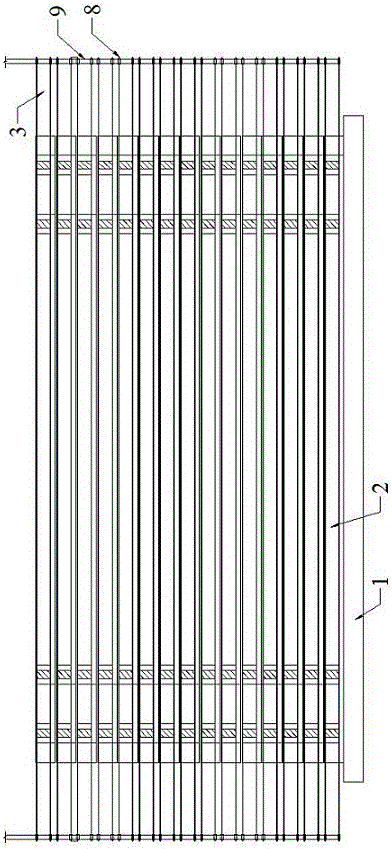

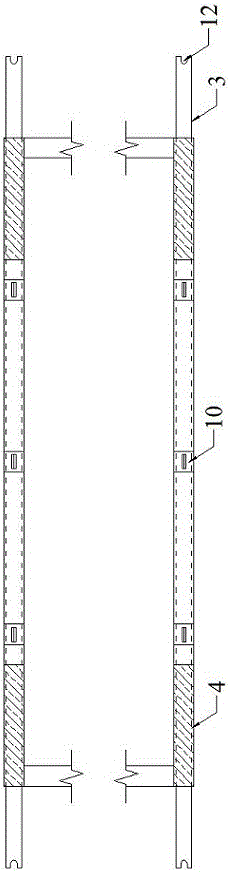

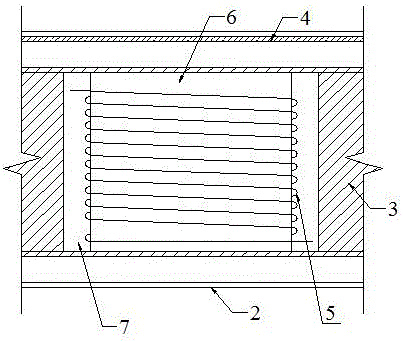

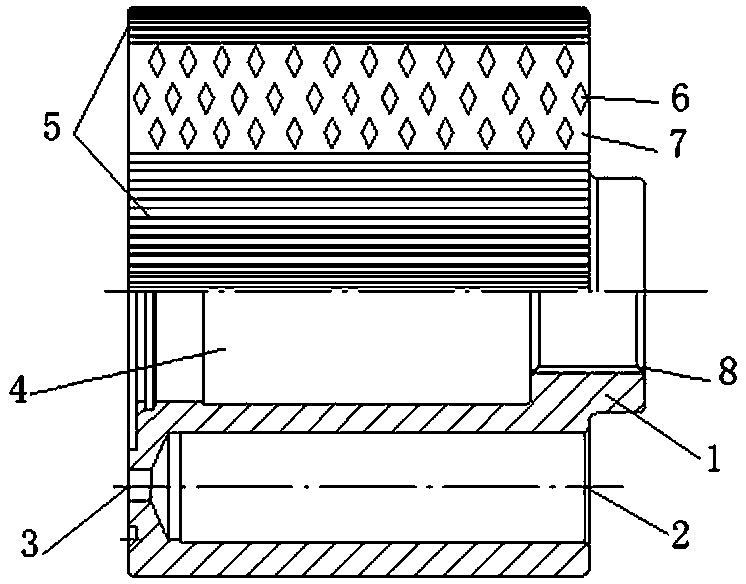

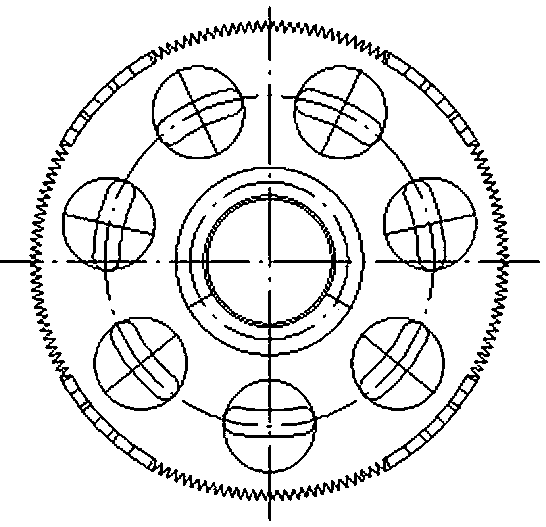

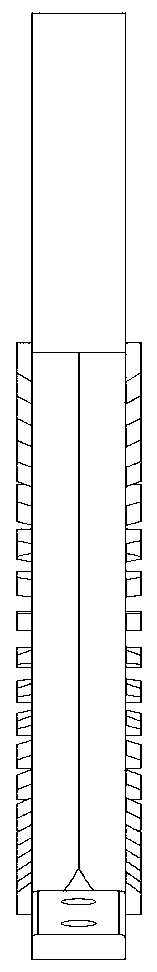

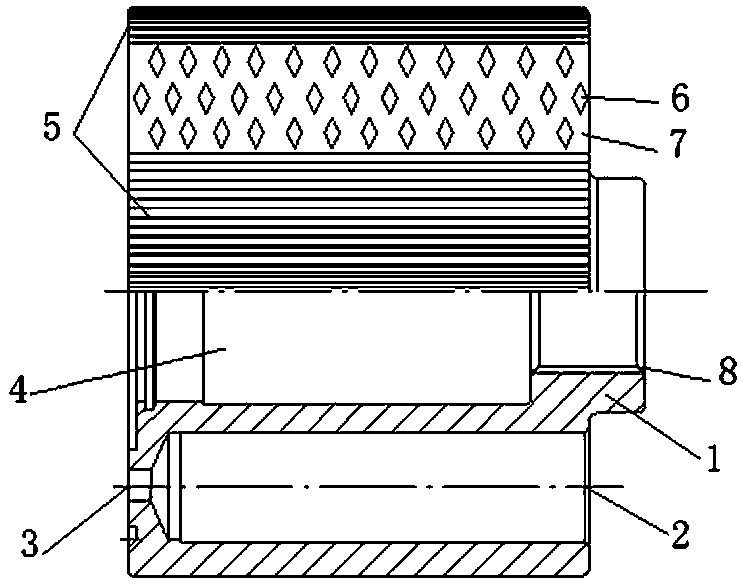

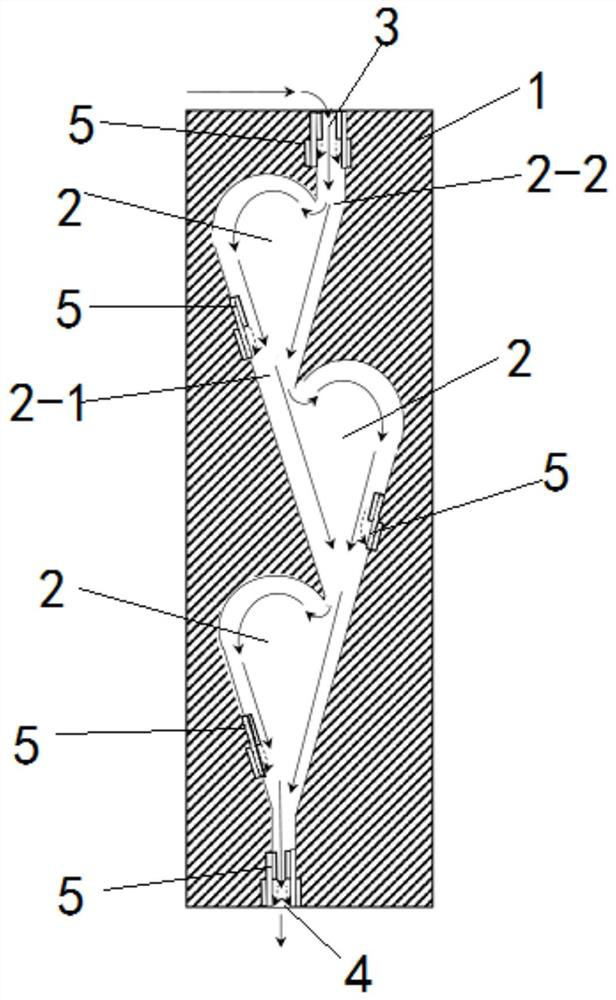

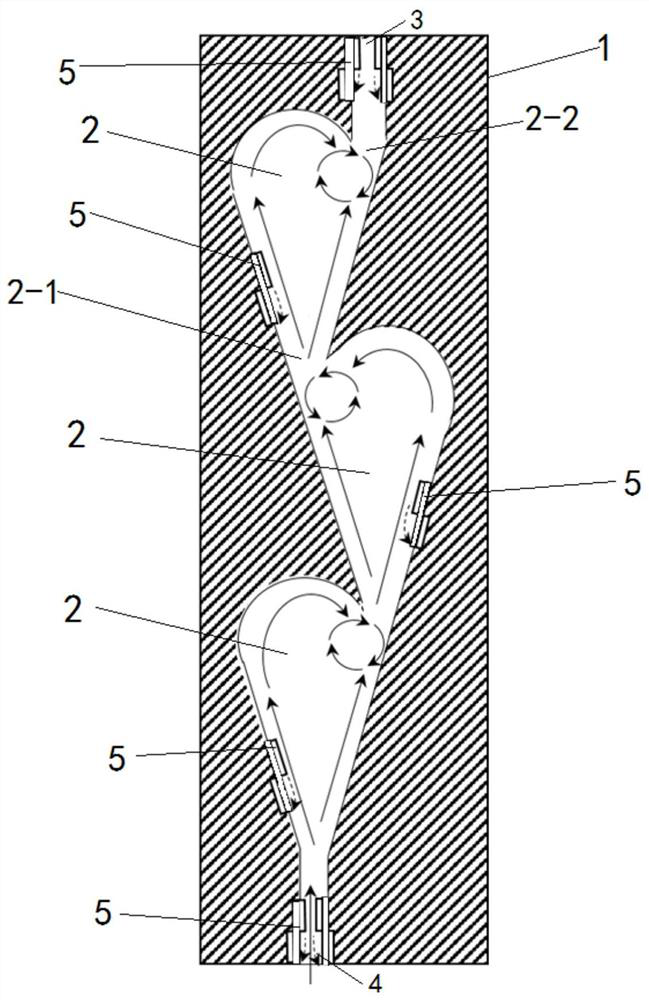

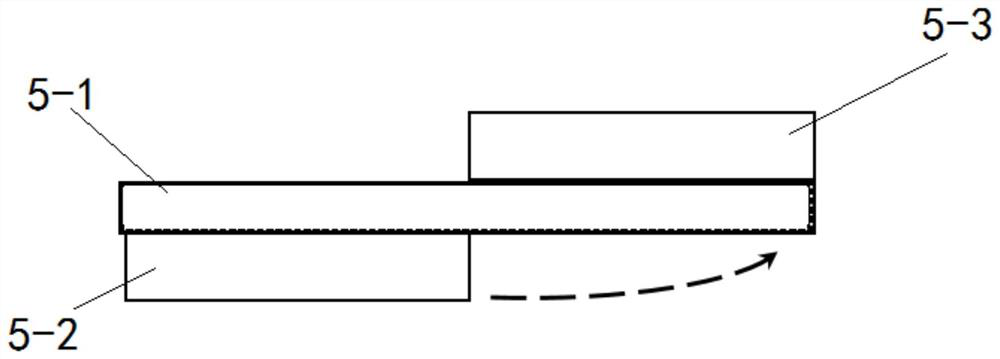

Surface resistance reducing type hydraulic plunger pump/motor cylinder block

ActiveCN108799096AReduce friction lossReduce churning lossPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpCylinder block

The invention relates to a surface resistance reducing type hydraulic plunger pump / motor cylinder block which aims to reduce stirring losses generated by the cylinder body in the plunger pump / motor running process and improve the efficiency of the hydraulic plunger pump / motor. The cylinder block comprises a main cylinder block (1), plunger holes (2), oil through holes (3), a shaft hole (4) and a spline (8), and a resistance reducing groove (5), a protrusion (6) and an oleophobic coating (7) are arranged on the surface of the outer circle of the main cylinder block (1); the shaft hole (4) is formed in the center of the main cylinder block (1), the plunger holes (2) are evenly distributed around the shaft hole (4) of the main cylinder block (1) and communicates with the oil through holes (3)in the bottom of the main cylinder block (1), and the spline (8) is arranged at the head of the shaft hole (4). The resistance reducing groove is formed in the outer circle of the cylinder block, a secondary vortex is formed in the resistance reducing groove when the cylinder body rotates, it like the condition that a row of rolling columns are clamped between the wall face and coming flow, the effect like that of a roller bearing is achieved, sliding friction of the liquid flow and the wall face becomes rolling friction, and the aim of resistance reducing is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Drag-reduction film composition

InactiveCN109504361AImprove liquidityHigh affinityFluid removalDrilling compositionPolymer chemistryPolyene

The invention belongs to the technical field of drag-reduction film composition for oil field production increase, and particularly discloses drag-reduction film composition. The drag-reduction film composition is prepared from raw materials as follows: water, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, polyene amine, dimethyl diallyl ammonium chloride and an initiator. The drag-reduction film composition in the scheme has excellent drag-reduction performance, a propping agent is coated with a drag-reduction film by the prepared drag-reduction film composition, and after the propping agent is added to clear water, the drag-reduction film can be rapidly dissolved in the clear water and performs drag-reduction on the clear water.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Gas delivery pipeline drag reducer and preparation thereof

The invention relates to a gas conveying pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecularcompound composition and the pipeline system technical field. The gas conveying pipeline drag reducer is characterized in that: the drag reducer consists of pyridine, secondary amine, formaldehyde oracetaldehyde, aromatic acid and deionized water; base on a 100-percent total weight, the compositions in percentage by weight include: 10 to 20 percent of the pyridine, 20.4 to 28.4 percent of the secondary amine, 7.6 to 8.4 percent of the formaldehyde or the acetaldehyde, 37 to 38.4 percent of the aromatic acid and 13 to 15 percent of the deionized water. The preparation method comprises the following steps that: the pyridine and the secondary amine in proportional quantities are added in a container and are mixed evenly; the formaldehyde or the acetaldehyde in proportional quantity is dripped to carry out reaction; the aromatic acid in proportional quantity is added, and the deionized water in proportional quantity is dripped so as to carry out reaction continuously; and finally, redundant water is removed, and a target product is obtained after purification. The gas conveying pipeline drag reducer has direct source of raw materials; moreover, the preparation method has simple process, convenient operation and moderate reaction conditions, and a product prepared by the method has excellent drag reduction effect.

Owner:PIPECHINA SOUTH CHINA CO

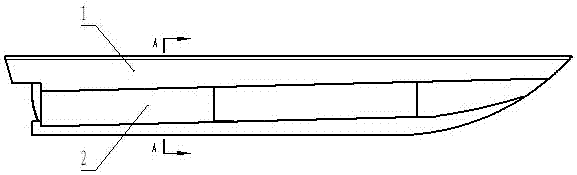

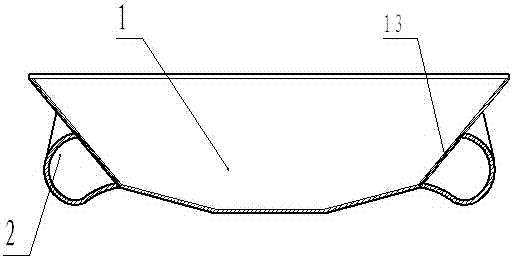

Speedboat and manufacturing method thereof

InactiveCN105775066BImprove lateral stabilityReduce resistanceWatercraft hull designVessel partsMarine engineeringUltimate tensile strength

The invention discloses a speed boat and a manufacturing method thereof and relates to the field of water surface boats. The speed boat comprises a hull. Floating barrels are symmetrically arranged on the two sides of the hull along knuckle lines of the hull. The floating barrels are closed long tank bodies with cavities formed inside. The bottoms of the outer side faces of the long tank bodies are bent downwards. The manufacturing method of the speed boat includes the steps that a metal plate is cut and developed into the hull with the floating barrels, side floating barrels communicating with the floating barrels of the hull are welded to the two sides of a bow, the side faces of the bow are welded to the side walls of the hull, and finally, a metal plate is pressed into a tail seal to be welded to the tail of the hull. Compared with the prior art, due to the fact that the closed floating barrels with the cavities formed inside are symmetrically arranged at the positions of the knuckle lines of the hull on the two sides of the hull, in the static floating process, part of the floating barrels are submerged in water, the reserved buoyancy of the floating barrels is greatly improved, the draught of the hull is greatly reduced, and the transverse stability performance is improved; when the speed is increased, the floating barrels gradually jump out of the water surface, resistance is reduced, and a rapid sailing target is achieved; and a rigid whole is composed of the floating barrels and the hull, and the structural strength is enhanced.

Owner:刘石全

A kind of preparation method of film-coated proppant for fracturing

The invention belongs to the technical field of compositions for strengthening fracturing, and specifically discloses a method for preparing a film-coated proppant for fracturing, comprising the following steps: (1) preparing raw materials; (2) adding water into a reaction kettle, Heat up; (3) stir, then add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, polyenamine, dimethyl diallyl ammonium chloride, after the raw material is added, continue to stir; (4 ) When the temperature of the material is stable at 65-75°C, stir, add the initiator, and continue to stir for 4-7min; (5) After reacting for 3.5-4.5h, the drag reducing agent is obtained, and the drag reducing rate of the drag reducing agent reaches more than 25%. Discharging; if it does not meet the requirements, add sodium hydroxide solution to adjust; (6) mix the drag reducer and the proppant body according to the mass fraction ratio of the drag reducer and the proppant body is 0.8-1.5:100, The drag reducer is covered on the surface of the proppant body to obtain the film-coated proppant for fracturing. The film-coated proppant for fracturing prepared by this scheme has good drag reduction and suspension properties.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

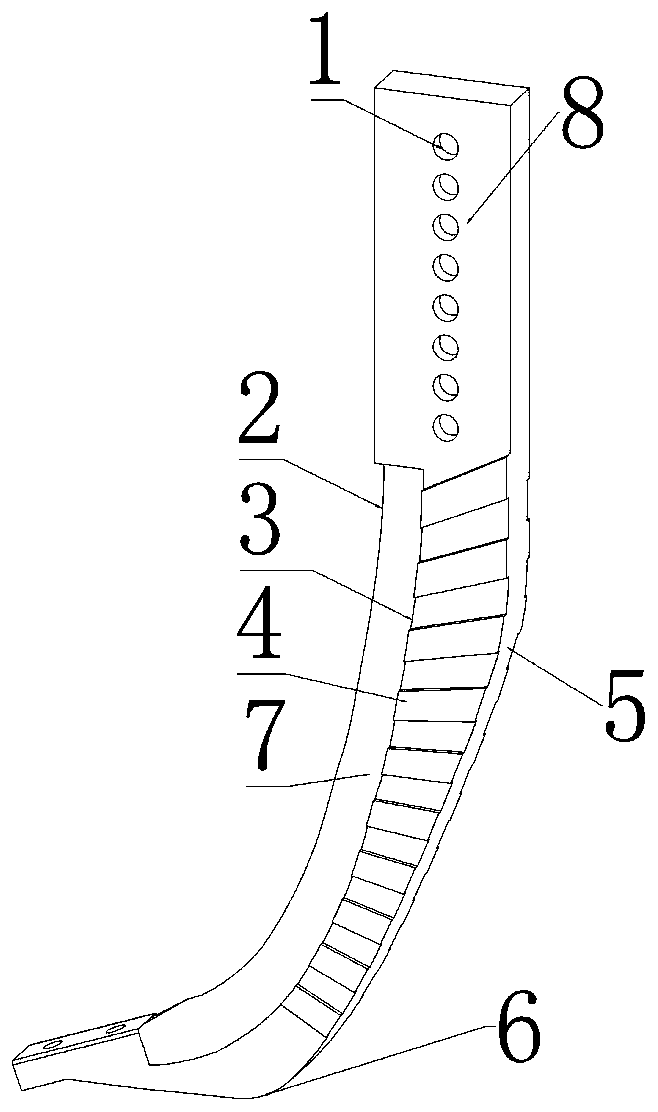

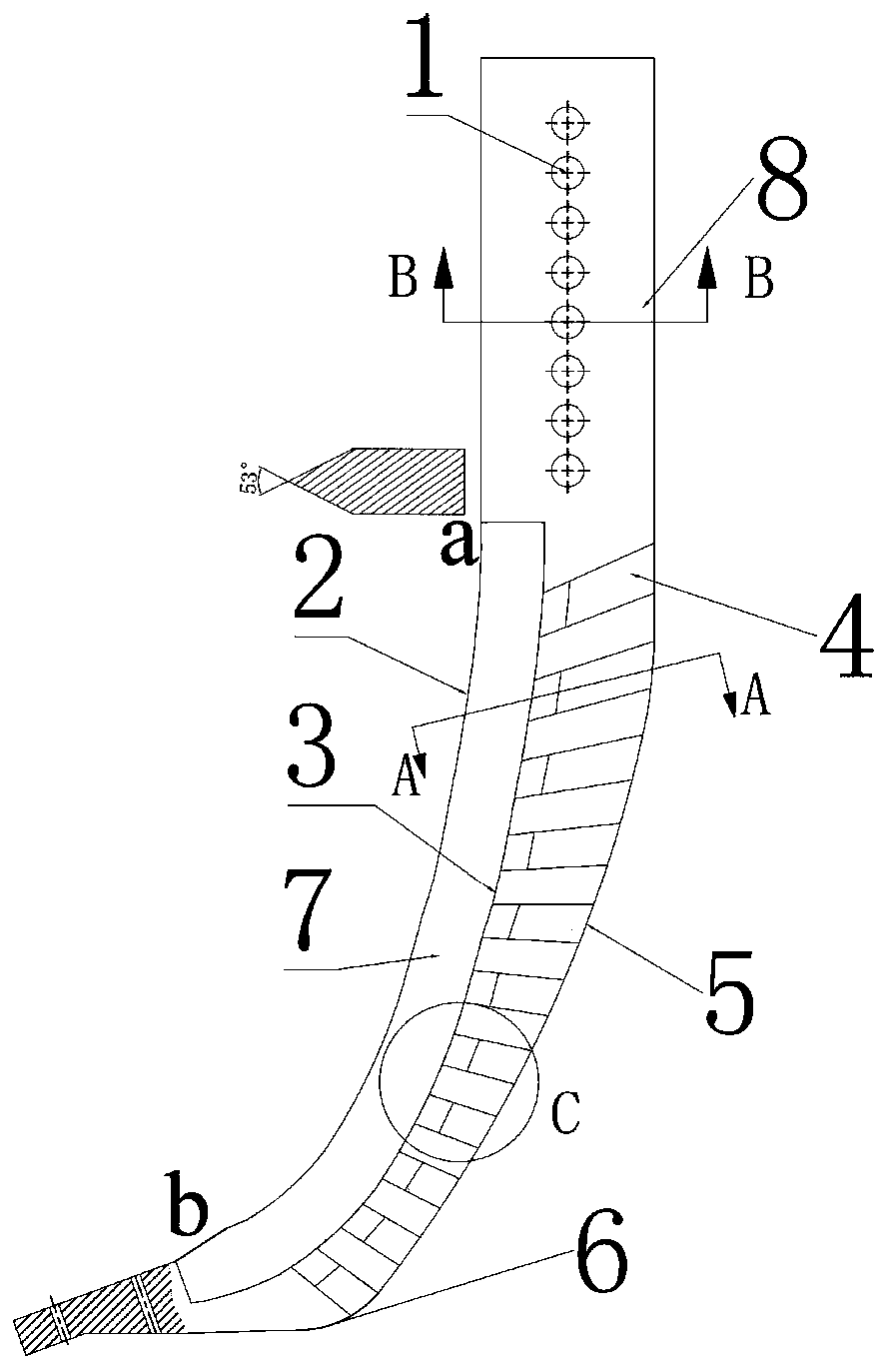

Bionic sub-soiling shovel with drag-reduction bionic surface

The invention provides a bionic sub-soiling shovel with a drag-reduction bionic surface. The bionic sub-soiling shovel comprises blind holes, a cutting edge front outline line, an inner standard line,bionic convex edge strip structures, a first arc line, a second arc line, a cutting edge curved surface and a shovel body, wherein eight blind holes are distributed on the central line at the upper side of the shovel body; the blind holes are fixed on a rack through two bolts and are used for fixing the shovel body; the shovel body is provided with the cutting edge front outline line and the inner standard line; the cutting edge curved surface is formed by a curved surface between the cutting edge front outline line and the inner standard line; the cutting edge front outline line and the inner standard line are front cutting edge curves; the front cutting edge curves are bionic curves; the bionic convex edge strip structures with different heights are distributed on the surface of the shovel body; one side, close to the inner standard line, of each bionic convex edge strip structure is an inclined plane; the bionic convex edge strip structures are symmetrically distributed at two sides of the shovel body; a rear outline line is formed by the first arc line and the second arc line; the two arc lines are tangent. Compared with an international circular-arc-shaped sub-soiling shovel,the bionic sub-soiling shovel provided by the invention has the advantages that the working resistance can be reduced by about 17 percent, the disturbance quantity of soil is reduced, the energy consumption is reduced and the whole quality of the soil is improved.

Owner:JILIN UNIV

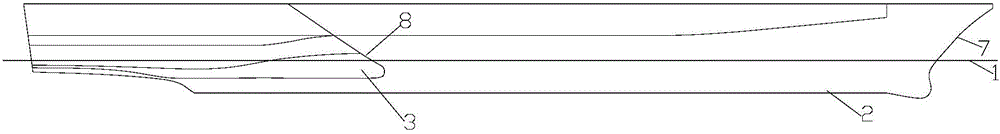

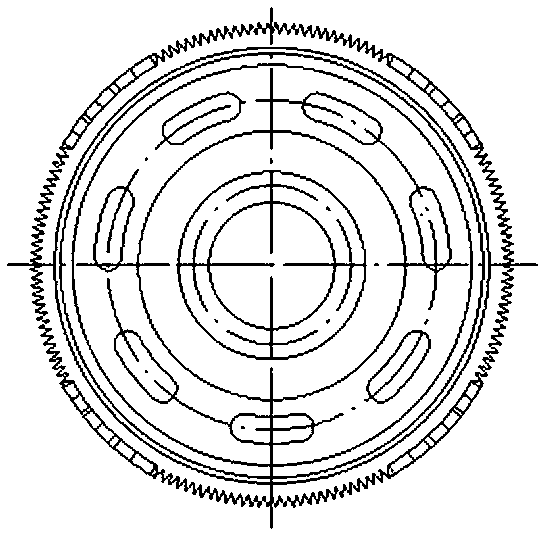

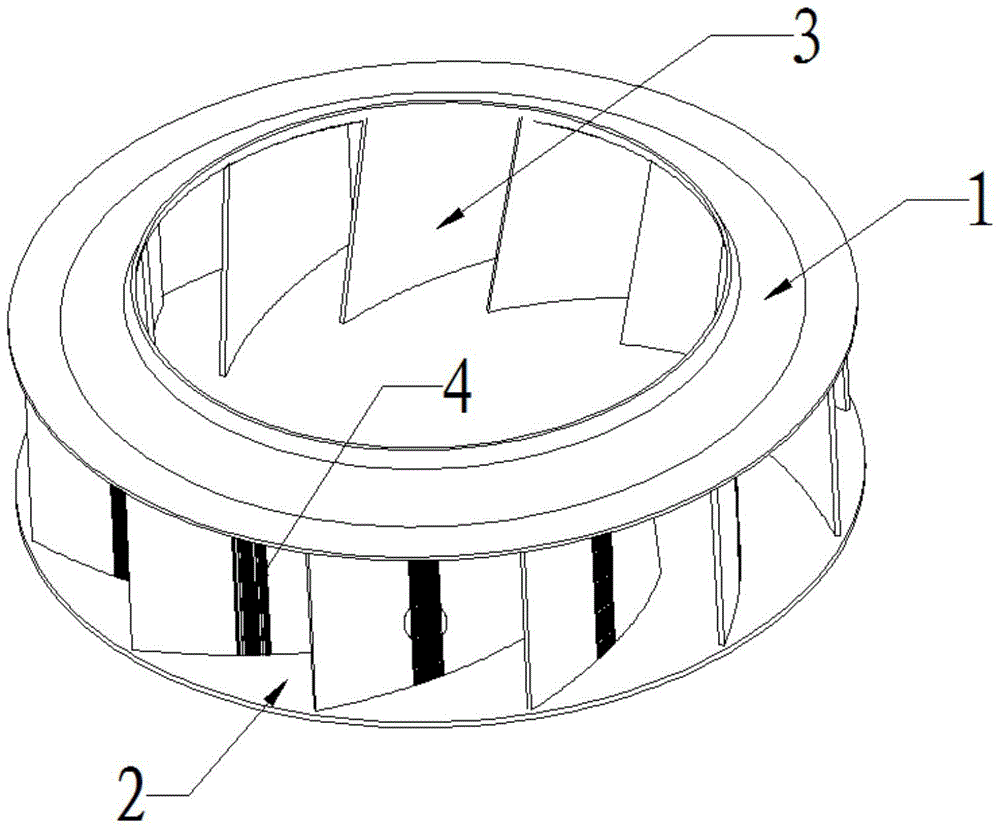

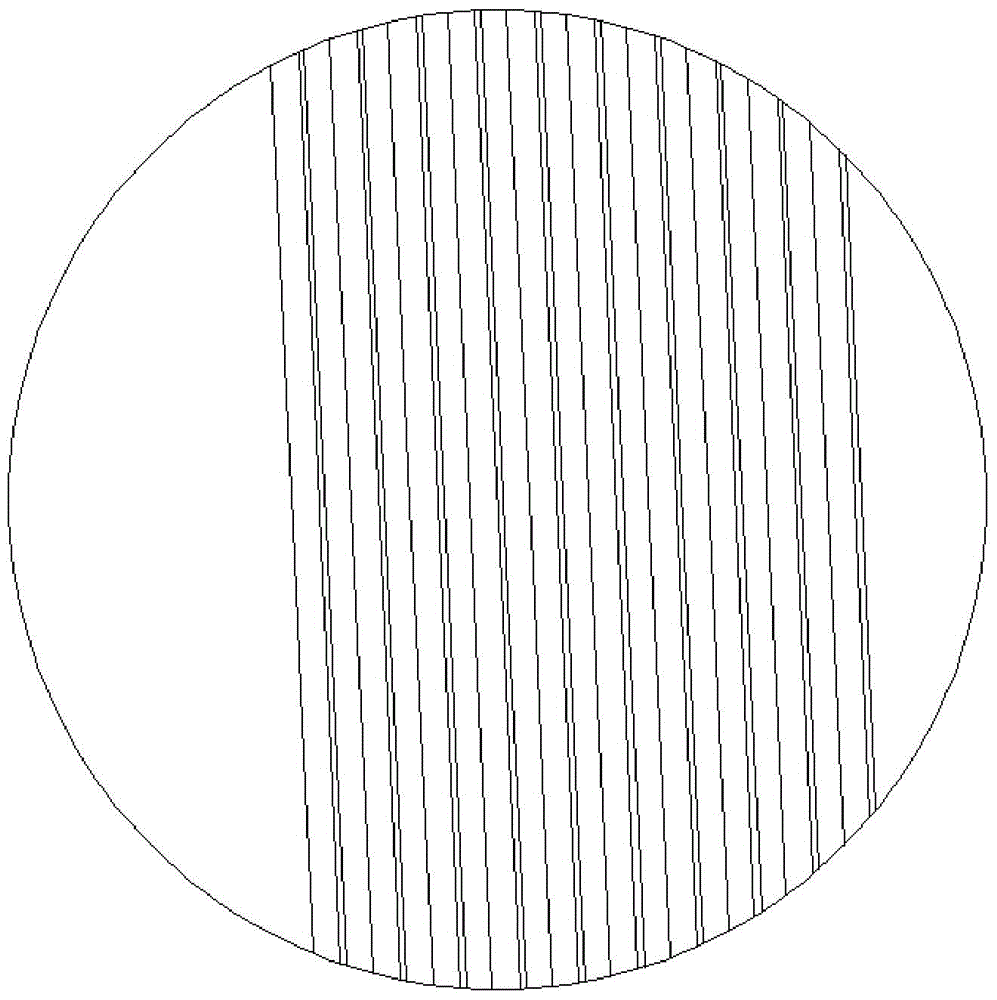

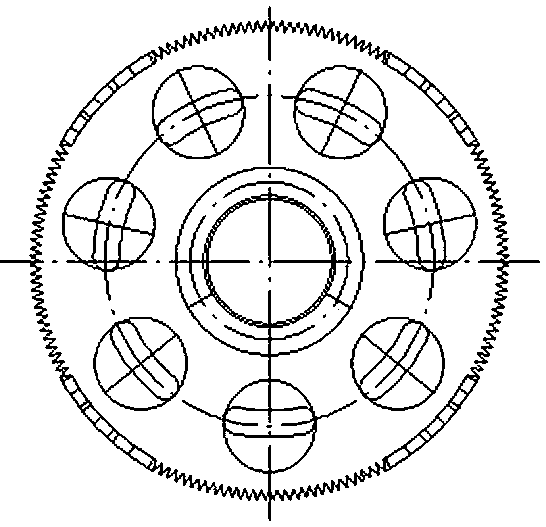

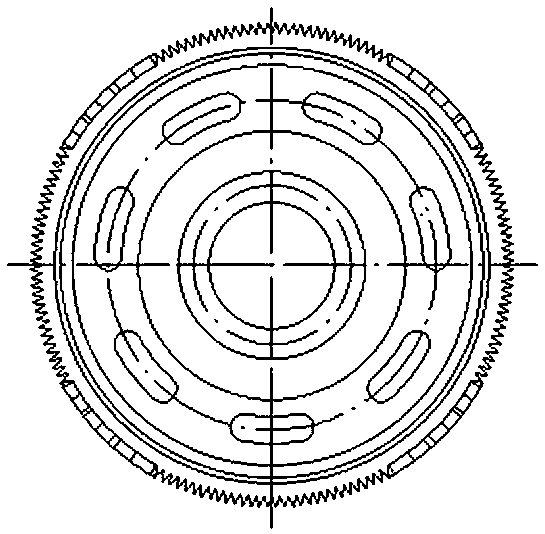

A non-volute centrifugal fan with drag-reducing groove

InactiveCN104564802BIncrease power consumptionImprove efficiencyPump componentsPumpsCircular discMotor shaft

The invention discloses a novel volute-less centrifugal ventilator with resistance reduction grooves. The novel volute-less centrifugal ventilator with the resistance reduction grooves comprises a wheel disc, a wheel cover, blades and the resistance reduction grooves; the blades are welded between the wheel cover and wheel disc, the blades are uniformly distributed around the axial line of the wheel cover, the resistance reduction grooves are milled after processing the blades, the wheel disc is disc-shaped, and a flange structure is arranged at the middle for mounting a motor shaft; the sections of the blades are the same curves, the parts in contact with the wheel cover conform to the molded line of the wheel cover, the resistance reduction grooves are rectangular, from 50% part of the molded line of each blade, the resistance reduction grooves are uniformly distributed on the pressure surfaces of the blades from the blade inlet to the outlet, there are 12 resistance reduction grooves, the gap between the resistance reduction grooves is 0.21 delta, each resistance reduction groove is 0.125 delta in depth and 0.25 delta in width, delta is the blade thickness, and the length direction of each resistance reduction groove runs through the whole blade. The novel volute-less centrifugal ventilator with the resistance reduction grooves reduces turbulent dissipation so as to reduce resistance, and the novel volute-less centrifugal ventilator with the resistance reduction grooves is capable of reducing the power consumption and improving the efficiency of the volute-less centrifugal ventilator.

Owner:ZHEJIANG SCI-TECH UNIV

A Surface Drag Reducing Hydraulic Piston Pump/Motor Cylinder

InactiveCN108799096BReduce frictionReduce friction lossPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpCylinder block

The invention relates to a surface resistance reducing type hydraulic plunger pump / motor cylinder block which aims to reduce stirring losses generated by the cylinder body in the plunger pump / motor running process and improve the efficiency of the hydraulic plunger pump / motor. The cylinder block comprises a main cylinder block (1), plunger holes (2), oil through holes (3), a shaft hole (4) and a spline (8), and a resistance reducing groove (5), a protrusion (6) and an oleophobic coating (7) are arranged on the surface of the outer circle of the main cylinder block (1); the shaft hole (4) is formed in the center of the main cylinder block (1), the plunger holes (2) are evenly distributed around the shaft hole (4) of the main cylinder block (1) and communicates with the oil through holes (3)in the bottom of the main cylinder block (1), and the spline (8) is arranged at the head of the shaft hole (4). The resistance reducing groove is formed in the outer circle of the cylinder block, a secondary vortex is formed in the resistance reducing groove when the cylinder body rotates, it like the condition that a row of rolling columns are clamped between the wall face and coming flow, the effect like that of a roller bearing is achieved, sliding friction of the liquid flow and the wall face becomes rolling friction, and the aim of resistance reducing is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

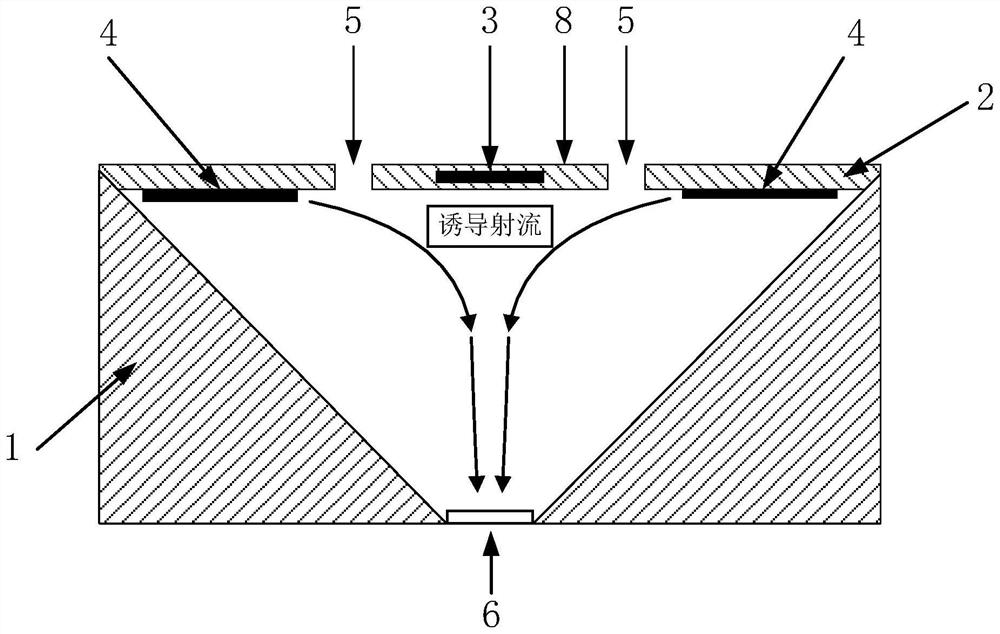

A Plasma Suction Device for Wing Drag Reduction

ActiveCN111688912BStrong shock waveStrong control abilityHeat reducing structuresInfluencers by shock wavesCircular discExhaust valve

The invention discloses a plasma suction device that can be used for drag reduction of airfoils. It includes an insulating shell, and a funnel-shaped cavity is provided at the center of the insulating shell. The wide mouth of the funnel-shaped cavity in the insulating shell is The end is provided with an annular first insulating medium layer, the center of the first insulating medium layer is provided with a disc-shaped second insulating medium layer, and there is an annular gap between the second insulating medium layer and the first insulating medium layer , the annular gap forms a suction hole, the first insulating medium layer is connected to the second insulating medium layer through several connecting rods; the narrow end of the funnel-shaped cavity in the insulating shell is provided with a one-way exhaust valve; the first insulating medium layer The lower surface of the medium layer is radiated with a lower electrode, and an upper electrode is buried inside the second insulating medium layer; the upper electrode is grounded, and the lower electrode is connected with a negative DC pulse high voltage. The plasma suction device of the invention can reduce the frictional resistance on the surface of the wing.

Owner:XIAN UNIV OF TECH

A drag reduction device and drag reduction method based on periodic stepped cylinder

The invention discloses a damping device and a damping method based on the periodical step cylindrical surface. According to the damping device and the damping method, through the periodicity of reverse rotating Taylor vortices under the Taylor-Couette flow conditions, the size of the Taylor vortices is changed, and the number of the big-size Taylor vortices is reduced. By arranging periodical cylindrical surfaces with different radii on the inner wall of a shaft sleeve in the axial direction and controlling the height of the liquid level in the gap between a rotary shaft and the shaft sleeveduring Taylor-Couette flow, the rotating speed of the rotary shaft and the injection speed of working fluid are controlled to achieve the hysteresis effect of the Taylor vortices under different injection speeds. By slowly increasing the liquid level height of the working fluid between the rotary shaft and the shaft sleeve, the size and number of the Taylor vortices are changed, so that the size of the Taylor vortices is changed, and the number of the big-size Taylor vortices is reduced. Accordingly, resistance of the rotary shaft is reduced. The damping device has the characteristics that thedamping device is fast and convenient to manufacture and low in cost, and the damping method is remarkable in damping effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A bionic micro-nano structure for underwater drag reduction

ActiveCN109699600BReduce frictional resistanceReduce lossFishingMarine engineeringStructural engineering

The invention discloses an underwater drag reduction bionic micro-nano structure which comprises U-shaped structures of bionic dolphin spine skin and sawtooth structures of bionic mosquito stylets. Aswimming bladder comprises a conical body structure at the front end and a cylindrical body structure at the rear end, the sawtooth structures are distributed on the surface of the conical body structure, and the U-shaped structures are distributed on the surface of the cylindrical body structure. According to the invention, the micro structures of bionic dolphin spine skin and the micro structures of bionic mosquito stylets are adopted, and the novel micro-nano combined structure is formed by combining the two micro-structures and is applied to the swimming bladder, and a good drag reductioneffect is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

A one-way conduction plasma suction device that can be used for drag reduction of wings

ActiveCN113316301BStrong shock waveStrong control abilityHeat reducing structuresPlasma techniqueEngineeringInhalation Devices

The invention discloses a one-way conduction plasma suction device that can be used for wing drag reduction. The air port and the exhaust port of the device are respectively connected with the internal cavity of the insulating shell, and the external gas can enter the internal cavity of the insulating shell through the air inlet of the device and then flow out from the exhaust port of the device; the internal cavity of the insulating shell It consists of a number of first cavities connected in sequence in a linear arrangement. An ion plasma exciter is arranged on the inner wall of each first cavity, and two ion plasma exciters are arranged on the inner wall of the air inlet of the device. Two plasma exciters are arranged on the inner wall of the exhaust port. The device can reduce the frictional resistance of the wing surface.

Owner:XIAN UNIV OF TECH

A kind of composite natural gas drag reducer and preparation method thereof

The invention claims a composite gas drag reducer and a preparation method thereof. The method comprises the following step of: reacting organic dibasic acid or organic binary acid anhydride, organic amine and monocarboxylic acid with a long carbon chain, thereby obtaining the composite gas drag reducer, wherein the specific steps the reaction are as follows: (1) reacting the organic dibasic acid or organic binary acid anhydride and the organic amine in an inert atmosphere, (2) adding the monocarboxylic acid with the long carbon chain to the reaction system of the finished reaction in the step (1), thereby obtaining the composite gas drag reducer via reaction. The composite gas drag reducer is obvious in drag reduction of the pipeline gas and energy conservation, and has the advantages of cheap and easily available raw material, simplicity in operation, mild reaction conditions, simple processes, low equipment requirements and easiness for industrial production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Speed boat and manufacturing method thereof

InactiveCN105775066AImprove lateral stabilityReduce resistanceWatercraft hull designVessel partsMarine engineeringUltimate tensile strength

The invention discloses a speed boat and a manufacturing method thereof and relates to the field of water surface boats. The speed boat comprises a hull. Floating barrels are symmetrically arranged on the two sides of the hull along knuckle lines of the hull. The floating barrels are closed long tank bodies with cavities formed inside. The bottoms of the outer side faces of the long tank bodies are bent downwards. The manufacturing method of the speed boat includes the steps that a metal plate is cut and developed into the hull with the floating barrels, side floating barrels communicating with the floating barrels of the hull are welded to the two sides of a bow, the side faces of the bow are welded to the side walls of the hull, and finally, a metal plate is pressed into a tail seal to be welded to the tail of the hull. Compared with the prior art, due to the fact that the closed floating barrels with the cavities formed inside are symmetrically arranged at the positions of the knuckle lines of the hull on the two sides of the hull, in the static floating process, part of the floating barrels are submerged in water, the reserved buoyancy of the floating barrels is greatly improved, the draught of the hull is greatly reduced, and the transverse stability performance is improved; when the speed is increased, the floating barrels gradually jump out of the water surface, resistance is reduced, and a rapid sailing target is achieved; and a rigid whole is composed of the floating barrels and the hull, and the structural strength is enhanced.

Owner:刘石全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com